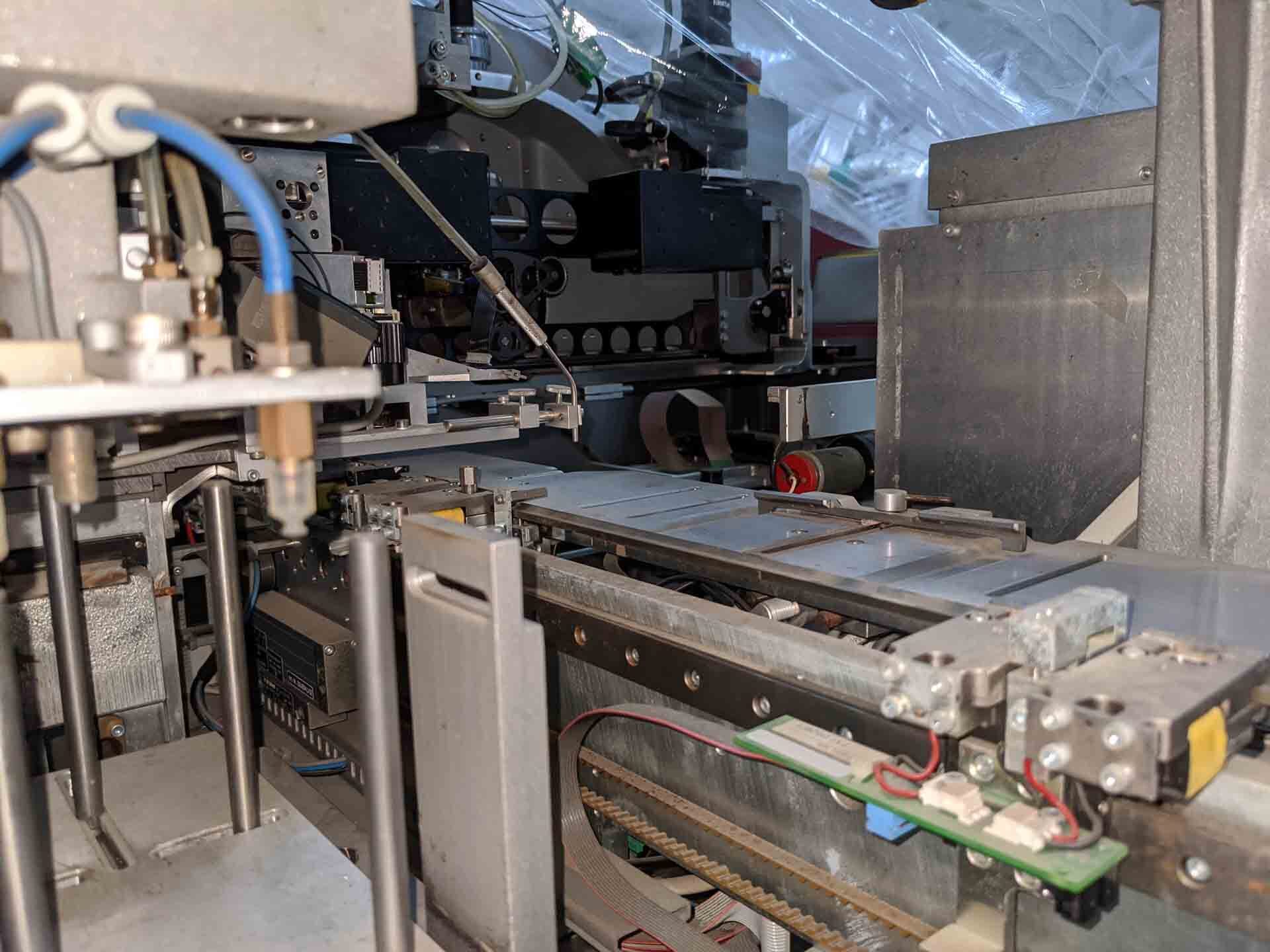

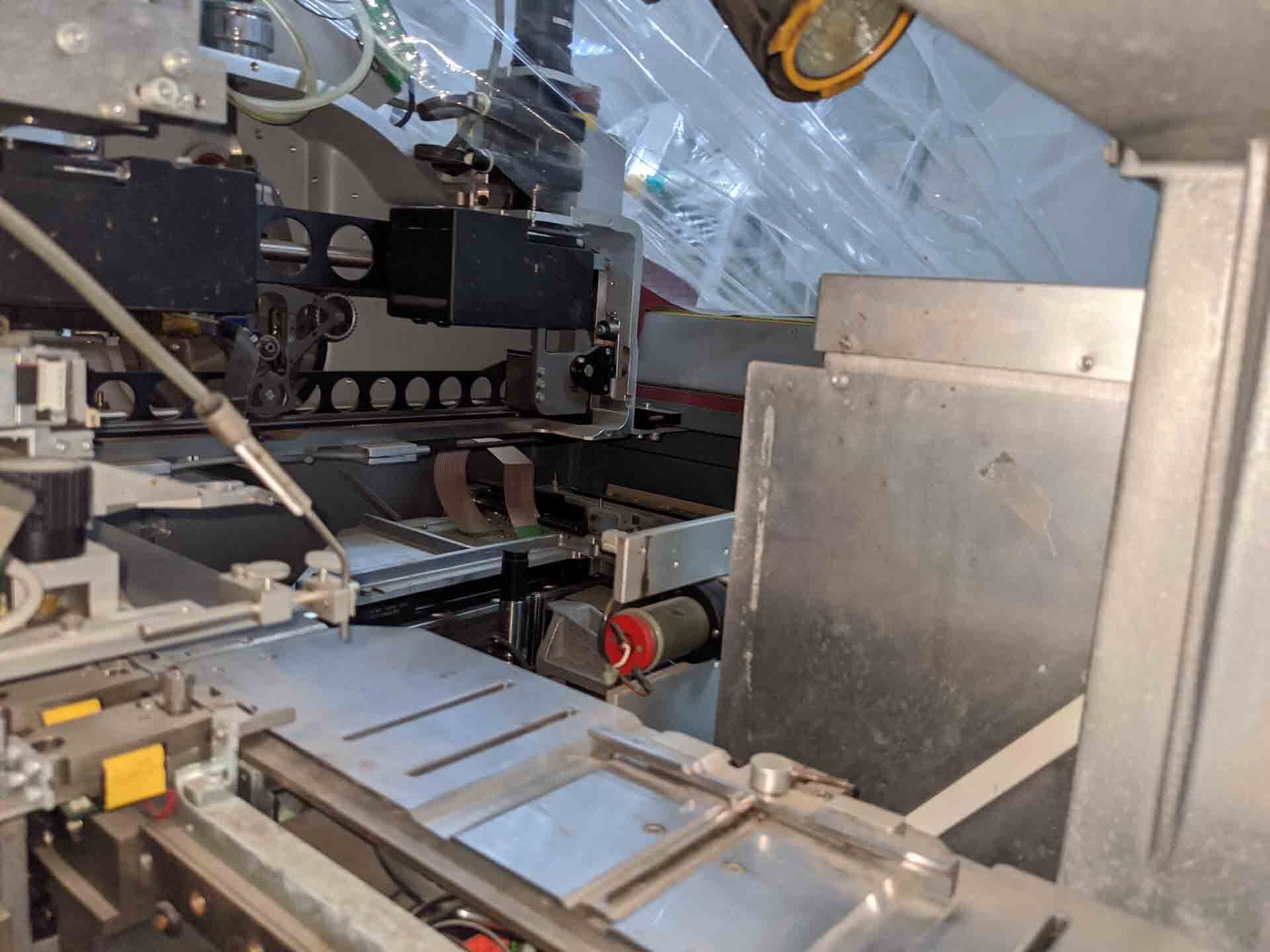

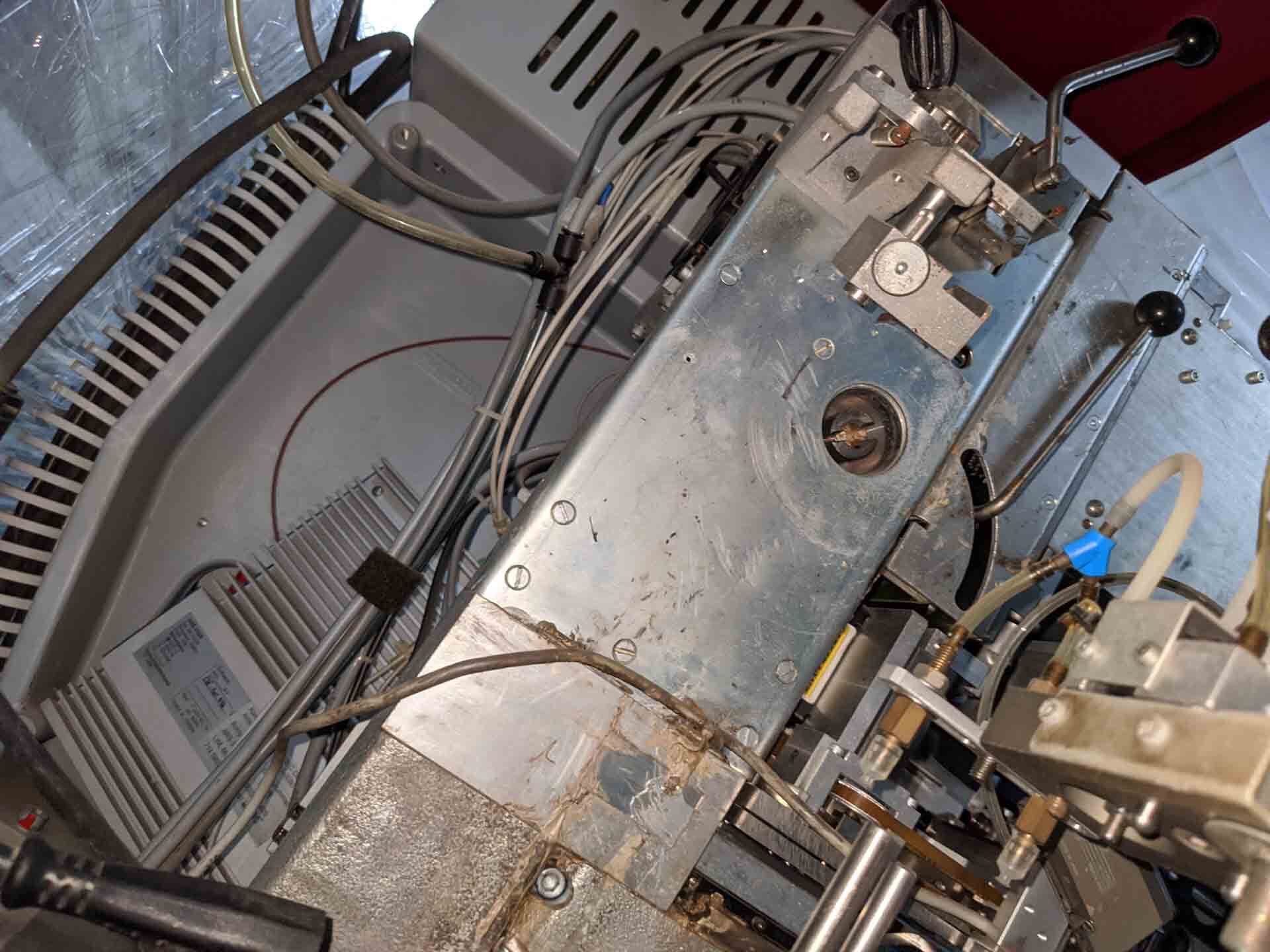

Used ESEC 2008 #9364745 for sale

URL successfully copied!

Tap to zoom

ESEC 2008 die attacher is a versatile machine capable of attaching steel pins of various characterizations to substrate materials. It is composed of 3 separate components: an attachment head, a bonder device, and a pressurisation equipment. The attachment head is a combination of piezo-ceramic actuators and servo motors that work together to provide precise control over the position of the die pins. Additionally, an automated measurement system is built-in for gauging the position of the pin as needed. It is also equipped with a nozzle for applying flux and a mechanism composed of clamping fingers to securely hold the die in place while bonding. The bonder device is used to provide the necessary heat for attachment. It is composed of a heating plate with a set of electrodes and heaters that allow a high degree of control over the heat delivered to the substrate and pins. A flux delivery unit is placed directly over the bonder to ensure that pins are properly coated with flux. It also has a pressure contact vise to secure the components in place while welding. The pressurisation machine is designed to generate a pressure of up to 300 psi for providing a tight seal between the pins and the substrate. It consists of a pressurised cylinder connected to a pressurisation manifold that is fitted with sensors to detect any leakage. The tool is designed to ensure that the pins are securely bonded and the substrate is not damaged during the process. Overall, 2008 die attacher is a reliable and efficient machine designed for attaching steel pins to any kind of substrate material. Its combination of various components makes it suitable for many different applications, including electrical, automotive, and aerospace industries. It is capable of providing superior and repeatable performance while ensuring a safe and secure attachment process.

There are no reviews yet