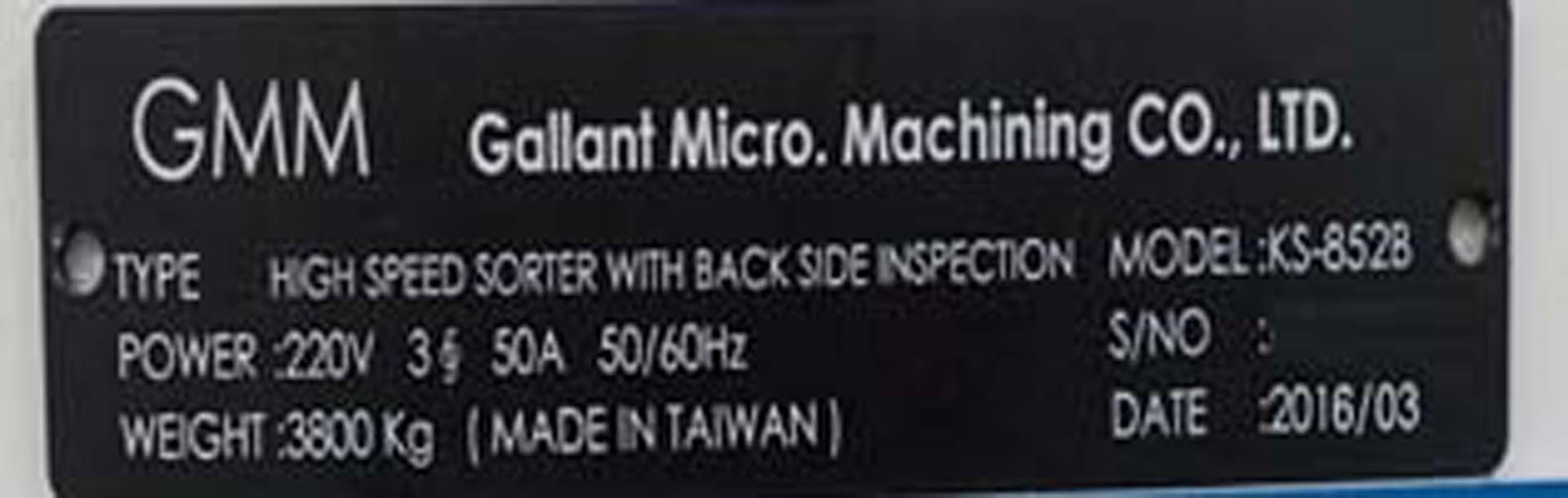

Used GMM KS852B #9237265 for sale

URL successfully copied!

Tap to zoom

ID: 9237265

Vintage: 2016

Die sorter

Air source: >0.5 MPa (200 Liters/min)

Air inlet tube:

Outer diameter: 12 mm

Inner diameter: 8 mm

Vacuum source: -70 kPa (100 Liters/min)

Vacuum inlet tube:

Outer diameter: 12 mm

Inner diameter: 8 mm

Air exhaust: Exhaust capacity 1800L/min

Die size: 0.5 x 1.4 ~ 10.0 x 30.0

Die thickness: 150~700

Die placement: ±50

Wafer diameter: 6" (6" Needs to be on 8" wafer frame) / 8"

Ejector height: 0 ~ 2500

Pick type: Tray pick

Wafer frame: FFC With blue tape

Pick up tooling: Collet / Rubber tip / Push-up needle

Automatic bar-code reader

ESD Table

Wafer handling: Automatic wafer changer

Tray handling, 2"-4"

Vision inspection function:

Top side inspection: 1.667 um/pixel CCD camera

Fixed zoom (FOV 11 x 7 mm)

Die back side inspection: 6.875 um/pixel CCD camera

Fixed zoom (FOV 14 x 14 mm)

Precisor inspection: 1.57 um/pixel CCD camera

Manual adjustable (FOV 1.3 x 6.8 mm)

Power supply: AC 380 V ±10 %, 50/60 Hz, 6.6 kVA, 3φ

2016 vintage.

GMM KS852B is a die attacher used in the production of small precision parts and components. It is suitable for a wide range of applications. KS852B utilizes a unique pneumatic equipment to accurately attach components of different sizes to each other and other surfaces. The pneumatic system uses compressed air to apply pressure to the component in order to secure and mount it in place. GMM KS852B features a highly accurate positioning unit that ensures precise and consistent positioning of the components during replacement and mounting operations. It includes a 400w pneumatic air motor that provides enough power to work with the heaviest metals, plastics and other materials. Additionally, KS852B also features adjustable pressure and pre-set limits as well as adjustable torque for accurate die attachment. GMM KS852B is made from heavy-duty steel and features four integrated pressure screws and two additional holders to provide maximum holding power. The die attach facility is equipped with an adjustable pressure range of between 0 and 10bar. This adjustable pressure range allows the operator to quickly and accurately apply the right amount of pressure for each application. The unit is further equipped with built-in safety sensors and pressure control settings to ensure optimal and safe operation. The control machine of KS852B includes a colour touch screen display and a user-friendly interface with intuitive icons. The interface allows the operator to quickly and easily make the necessary adjustments to the die attach parameters. GMM KS852B also includes a built-in data logger with memory card slot that enables detailed analysis of the production process. KS852B is highly efficient and helps to reduce production time and cost significantly. The device is easy to operate and maintain with minimal downtime required for regular maintenance. It is also lightweight and compact, making it an ideal choice for production-level operators.

There are no reviews yet