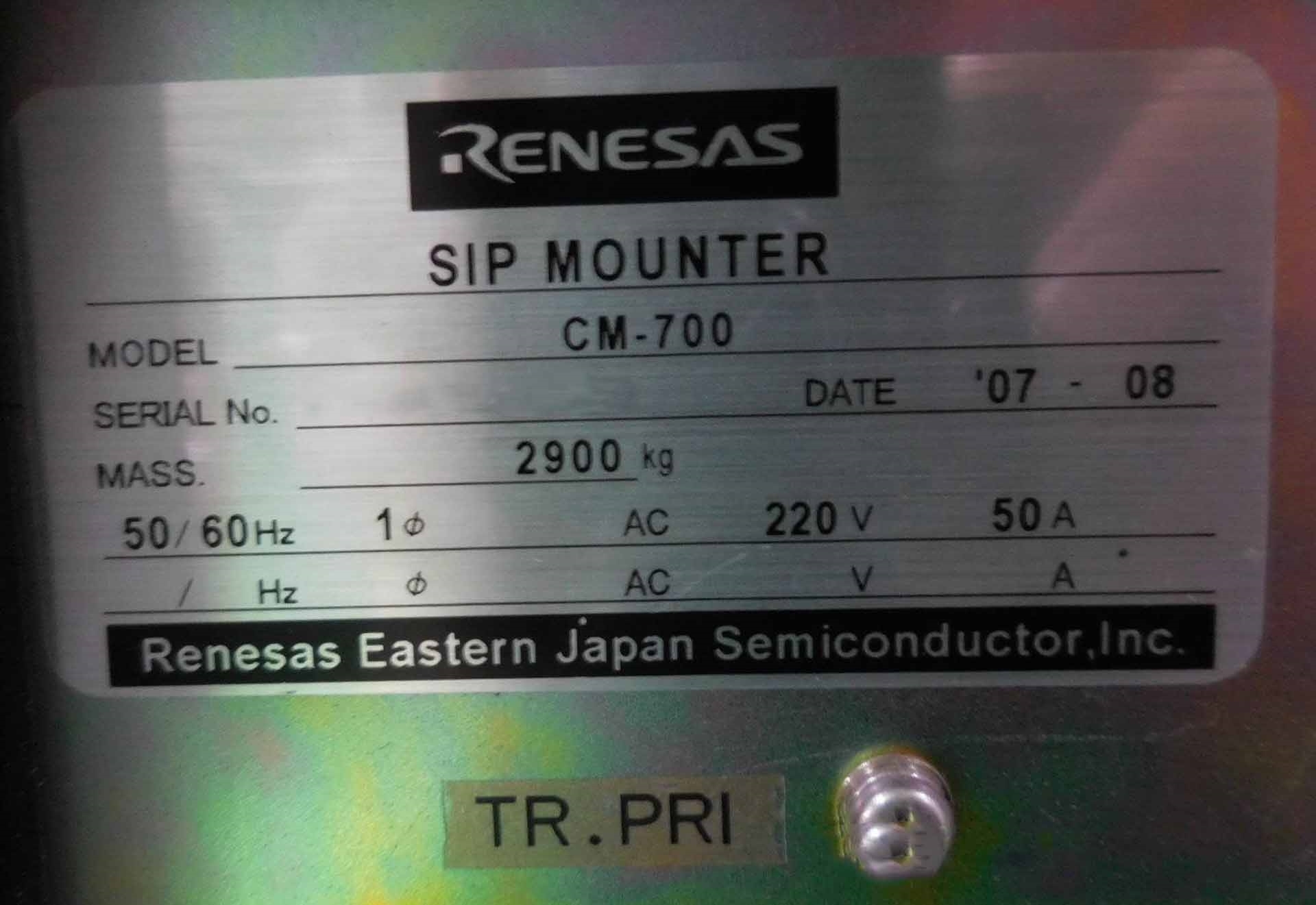

Used HITACHI / RENESAS CM 700 #9253784 for sale

URL successfully copied!

Tap to zoom

ID: 9253784

Vintage: 2007

SIP Mounter, 12"

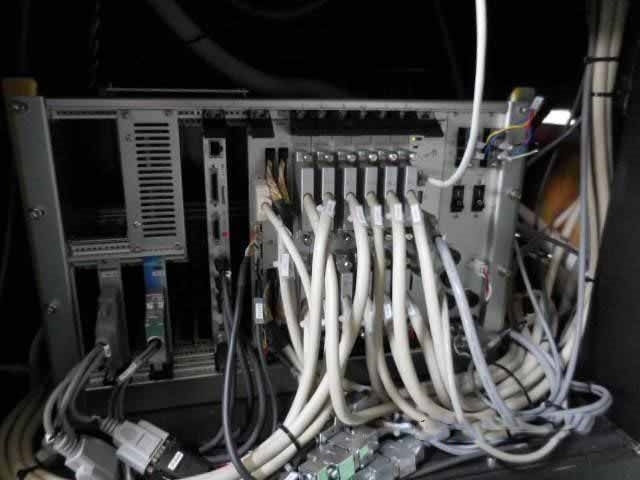

Configuration:

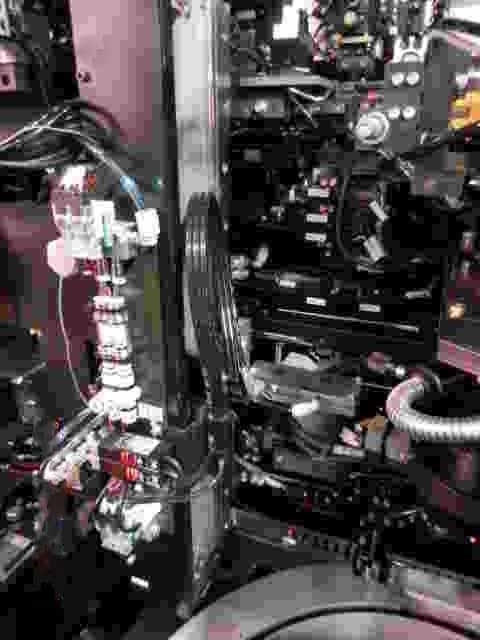

Input station:

Magazine handling system

Lead frame / Substrate stacker

Interposer loading system

Interposer handling system

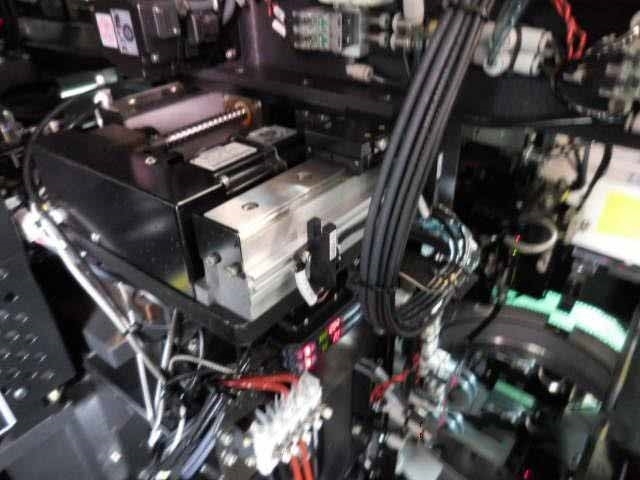

Pre bake unit: RT 300°C

Pre heat unit: RT 200°C

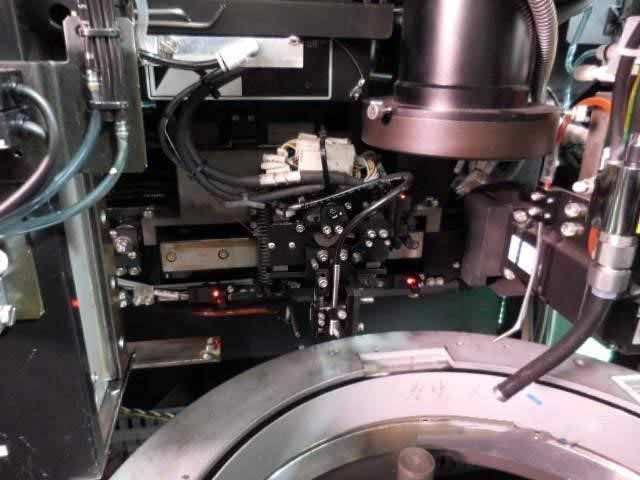

Die bonding system

Die lamination system

Output magazine handling system

Wafer handling system

Die pick and place system

Vision system

High speed bonding: 3600 UPH

Placement accuracy: XY < 38 μM (3σ)

Mount method: Face down heat compression

Bond tool:

Temperature: Up to 400°C

Force: 7.8 to 147 N

Lamination tool:

Temperature: Up to 400°C

Force: 19.6 to 490 N

2007 vintage.

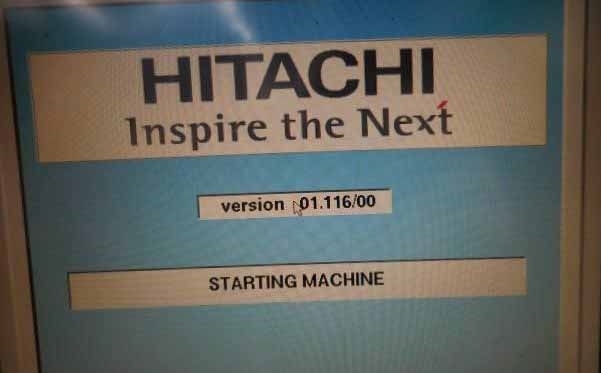

HITACHI / RENESAS CM 700 is a highly specular die attach machine designed to provide optimum performance in fast, accurate die bonding operations. It is capable of handling any number of dies, including the latest ultra-thin, ultra-fine packages. The machine is equipped with multiple mechanisms to assure accurate positioning, alignment, and placement of die onto the substrate. The die pick-up station is equipped with a high-speed, precision camera alignment equipment and a wafer process to ensure exact die orientation and placement. The machine operates in a sealed environment to prevent environmental effects and is equipped with a closed-loop three-axis servo system for precise control of the die attachment process. In order to provide fast cycle times and user-friendly operation, HITACHI CM 700 is equipped with a precise linear memory unit. This memory machine allows the setting of parameters for each individual die as well as the overall operation of the machine. The machine is designed to provide maximum throughput, which is achieved by a two-step bonding process. The first step is to apply a uniform film of adhesive to the substrate and to allow it to set for a predetermined period of time. The second step is to use the pick-up station to pick up one die at a time, then slowly bring it into contact with the substrate. During this step, the die is aligned and positioned with the help of an automated viewing tool. RENESAS CM-700 is also designed to allow for in-situ flux application. During the bonding operation, a flux dispenser is used to apply a small amount of flux to the pre-coated substrate. The flux application ensures that a strong bond is achieved and that no contaminants are introduced. The machine is also equipped with a low temperature solder joint option which is ideal for applications that require delicate handling. In conclusion, RENESAS CM 700 is a highly specular die attach machine designed for maximum throughput and precise placement accuracy. Its advanced mechanisms allow for exact die positioning and alignment, as well as in-situ flux application and low temperature solder joint option. This makes the machine idea for high-volume production of small dies and ultra-fine packages.

There are no reviews yet