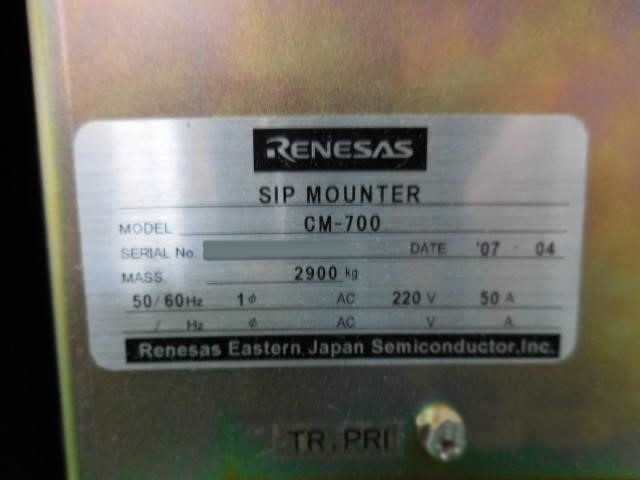

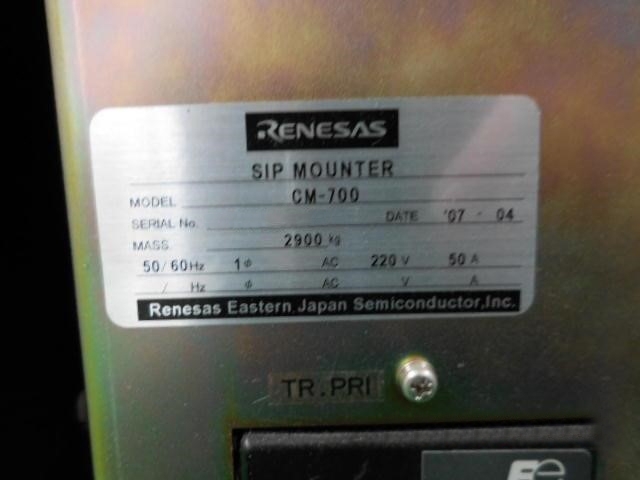

Used HITACHI / RENESAS CM 700 #9253797 for sale

URL successfully copied!

Tap to zoom

ID: 9253797

Wafer Size: 12"

Vintage: 2007

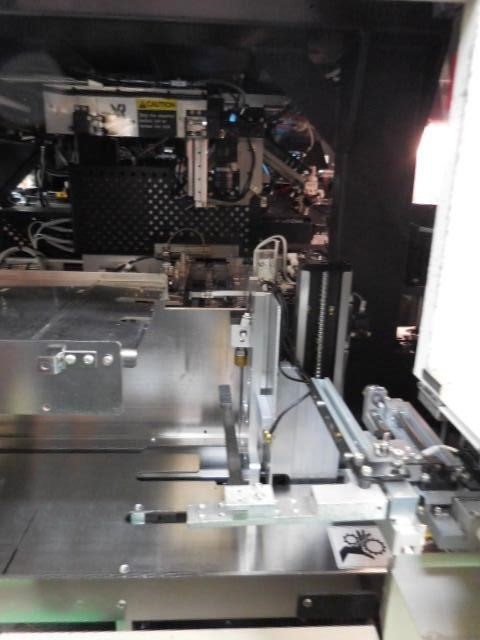

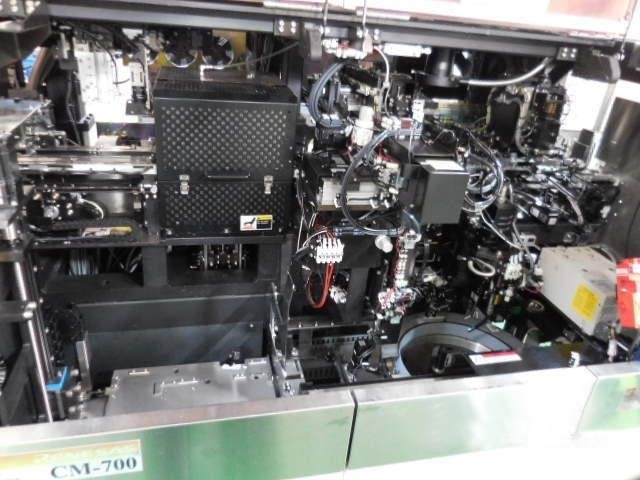

SIP Mounter, 12"

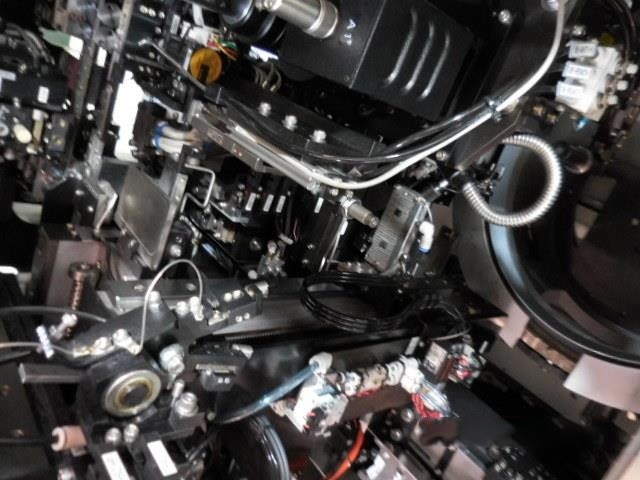

Input station:

Magazine handling system

Lead-frame / Substrate stacker

Interposer loading system

Interposer handling system

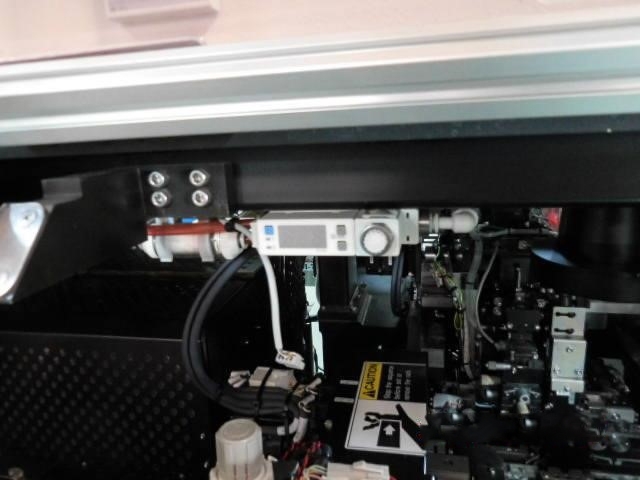

Pre-bake unit: RT~300°C

Pre-heat unit: RT~200°C

Die bonding system

Die lamination system

Output magazine handling system

Wafer handling system

Die pick and place system

Vision system

High speed bonding: Up to 3600 UPH

Placement accuracy: XY < 38 μM (3σ)

Mount method: Face down and heat compression

Bond tool:

Temperature: Up to 400°C

Force: 7.8 to 147 N

Lamination tool:

Temperature: Up to 400°C

Force: 19.6 to 490 N

2007 vintage.

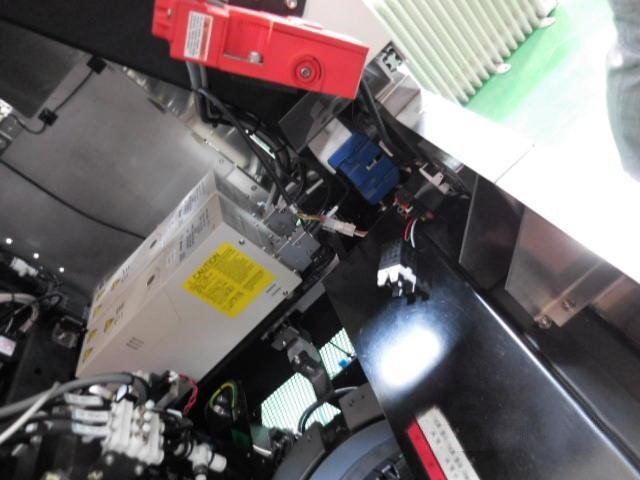

HITACHI / RENESAS CM 700 is a high-precision die-attach equipment designed for ultra-fine pitch applications. With a maximum speed of 200mm per second, superior accuracy control, and a wide range of die sizes from 0.537 to 1.7mm, HITACHI CM 700 is a popular choice for semiconductor packaging. RENESAS CM-700 features a wide range of die-attaching heads that can be mounted on an I/O port. These include a dual-sided head for simultaneous attachment of two dice, two-in-one heads for either two or three-in-one attachment, and a reverse head for L-shape or odd-shaped dice. Its height-adjustable head centering mechanism ensures precise die placements and consists of a camera-based system and a laser-based on-the-fly calibration. CM 700 also includes a die-pickup unit capable of handling 300 pieces at a time, minimizing operator downtime. The pick-and-place head is programmable to precisely locate die in its tray to ensure minimal vibration during transition. This is supplemented by a high-speed linear motor that can pick and place up to 200 chips per minute. In addition, a line-integrated dust blowing station allows loading chips without the risk of dust contamination. The unit's main body incorporates a jig, a die-mounting machine, and an operator console to precisely position the die and adjust its overall height and angle. High-performance CCD cameras are included to provide accurate real-time monitoring of die placements. HITACHI / RENESAS CM-700 also features a nozzle controller that uses a four-axis robot arm to precisely position the nozzle, and ensure optimal accuracy of die position and adherence. HITACHI CM-700 is equipped with options such as cycle time monitoring, alarms, an user interface, and traceability software. Moreover, it also includes safety features such as an emergency stop button and an operator console guard. RENESAS CM 700's high-end design and durability guarantee a long lifetime of excellent performance and superior accuracy, making it the ideal choice for high-precision die-attaching needs.

There are no reviews yet