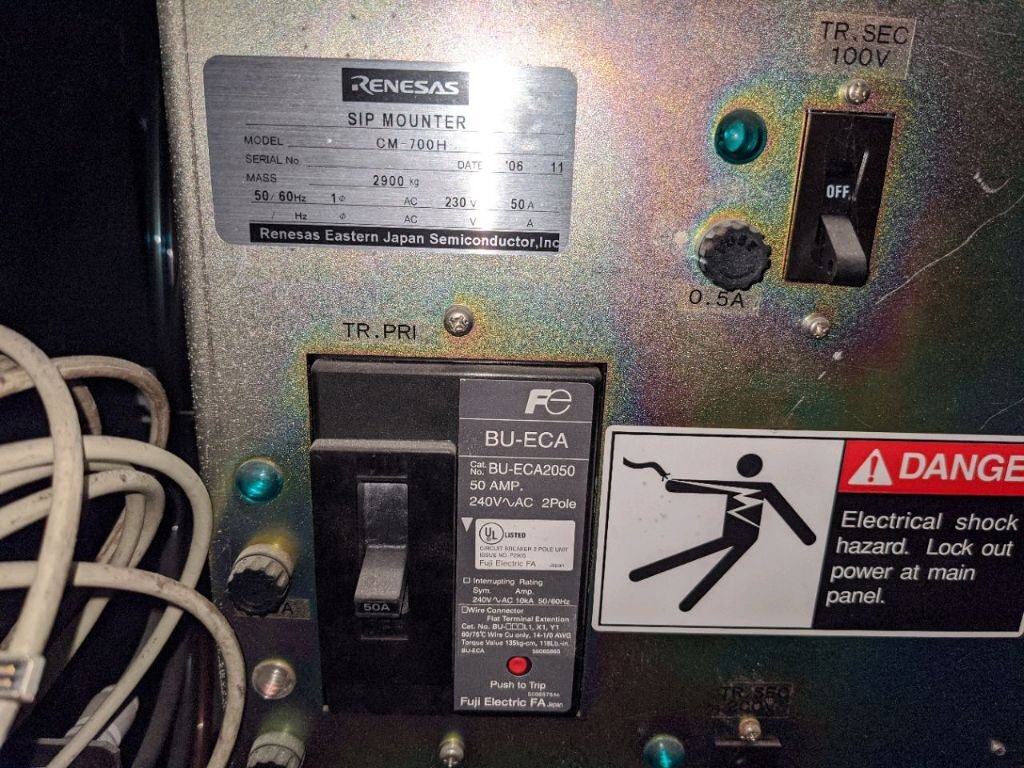

Used HITACHI / RENESAS CM 700H #9360231 for sale

URL successfully copied!

Tap to zoom

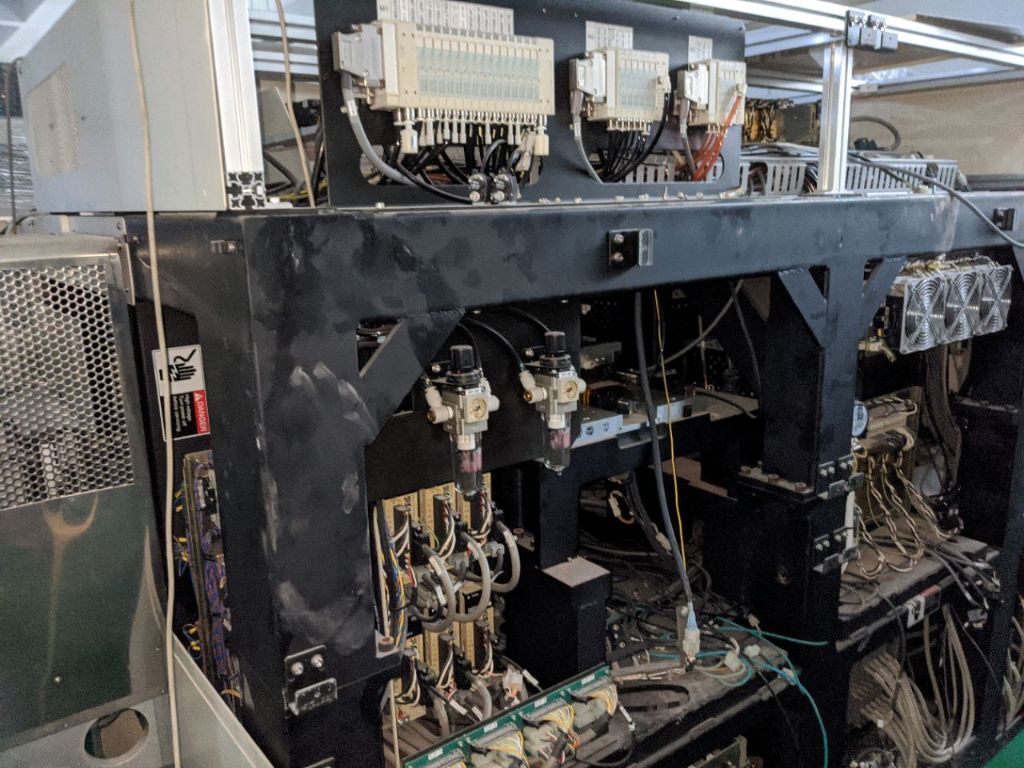

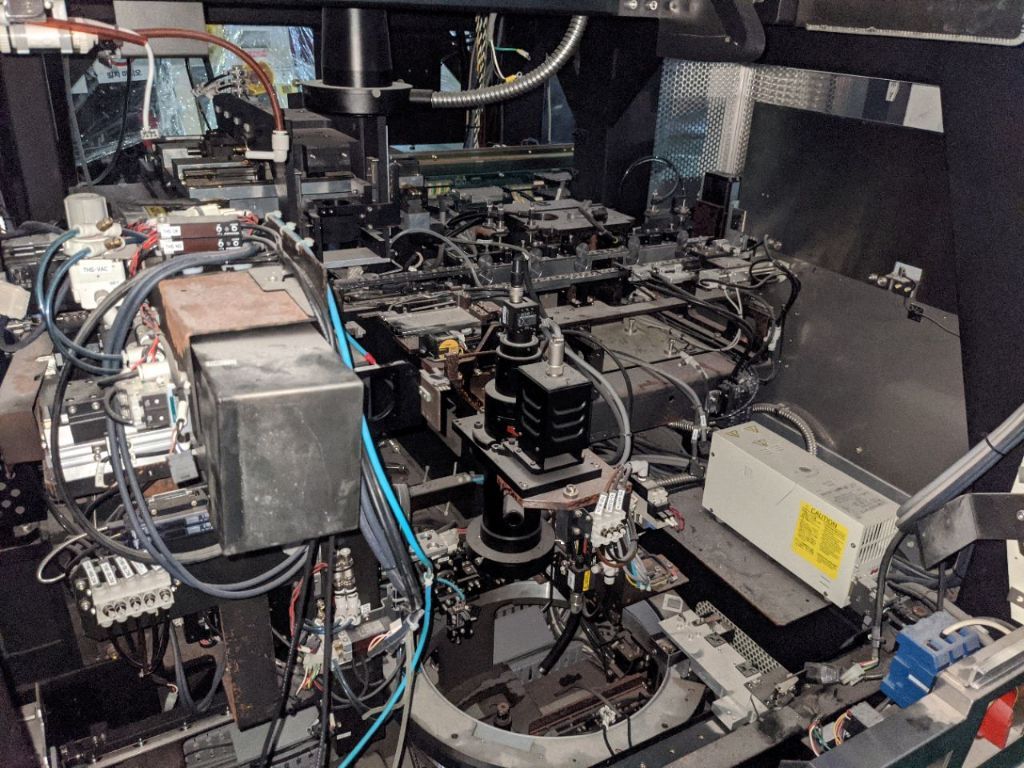

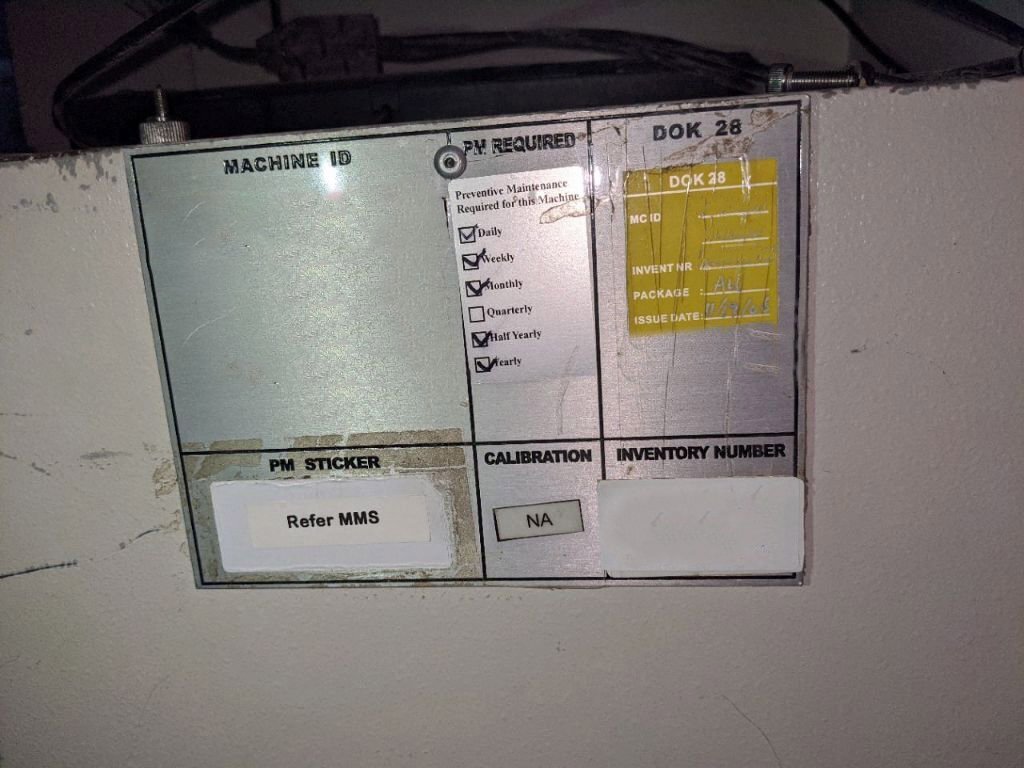

HITACHI / RENESAS CM 700H die attacher is a high-precision, automated equipment for attaching semiconductor die to a substrate or package. It uses the pick & place method; an operator selects the die to be placed, often from a separate wafer, and manipulates it in a magnetic head. The die is then accurately placed onto its predetermined location on the substrate. This machine is designed with a high degree of accuracy and is highly resilient even when exposed to extreme environmental conditions (humidity and shock). HITACHI CM 700H is equipped with an intuitive GUI, which facilitates programming, speeding up the operation process. RENESAS CM 700H has an XY pick & place equipment for die placement, which employs a two-step operation. In the first step, the die is manipulated with a magnetic head, held up by a vacuum, then accurately placed onto its predetermined location. In the second step, a pressure head is applied to join the die with the substrate. To ensure proper bonding between the die and the substrate, CM 700H offers a range of control functions. For instance, the precise controlling of two-step action is essential for accurate die attachment and is one of the features of this machine. Another is force control settings, which make it possible to adjust the amount of force applied during die attachment, allowing better bonding and ensuring a reliable joint. On top of that, the system also provides a fail-safe structure for proper die placement. Multiple sensors embedded in its operating mechanism detect any abnormalities and stop the operation immediately when something is out of range. HITACHI / RENESAS CM 700H is also equipped with a vision unit that confirms that normal placement has been carried out. This machine uses a CCD camera to take a high-resolution, real-time image of the die and its placement for analysis. For added convenience, HITACHI CM 700H also features a convenient user interface. This allows the operator to see the laser alignment for die placement, as well as a view of the CCD image, from the control panel. The display provides detailed information such as the die displacement rate and any problems that may occur during processing. In addition, the panels also allows easy programming for die placement and for setting parameters. RENESAS CM 700H is a reliable and precise die attacher. Its high accuracy and enhanced force adjustment procedures ensure strong and uniform bonding with the substrate and its fail-safe structure and vision tool avert any risks of error during the operation. Furthermore, its intuitive GUI is how to make use of this machine to unleash its full potential.

There are no reviews yet