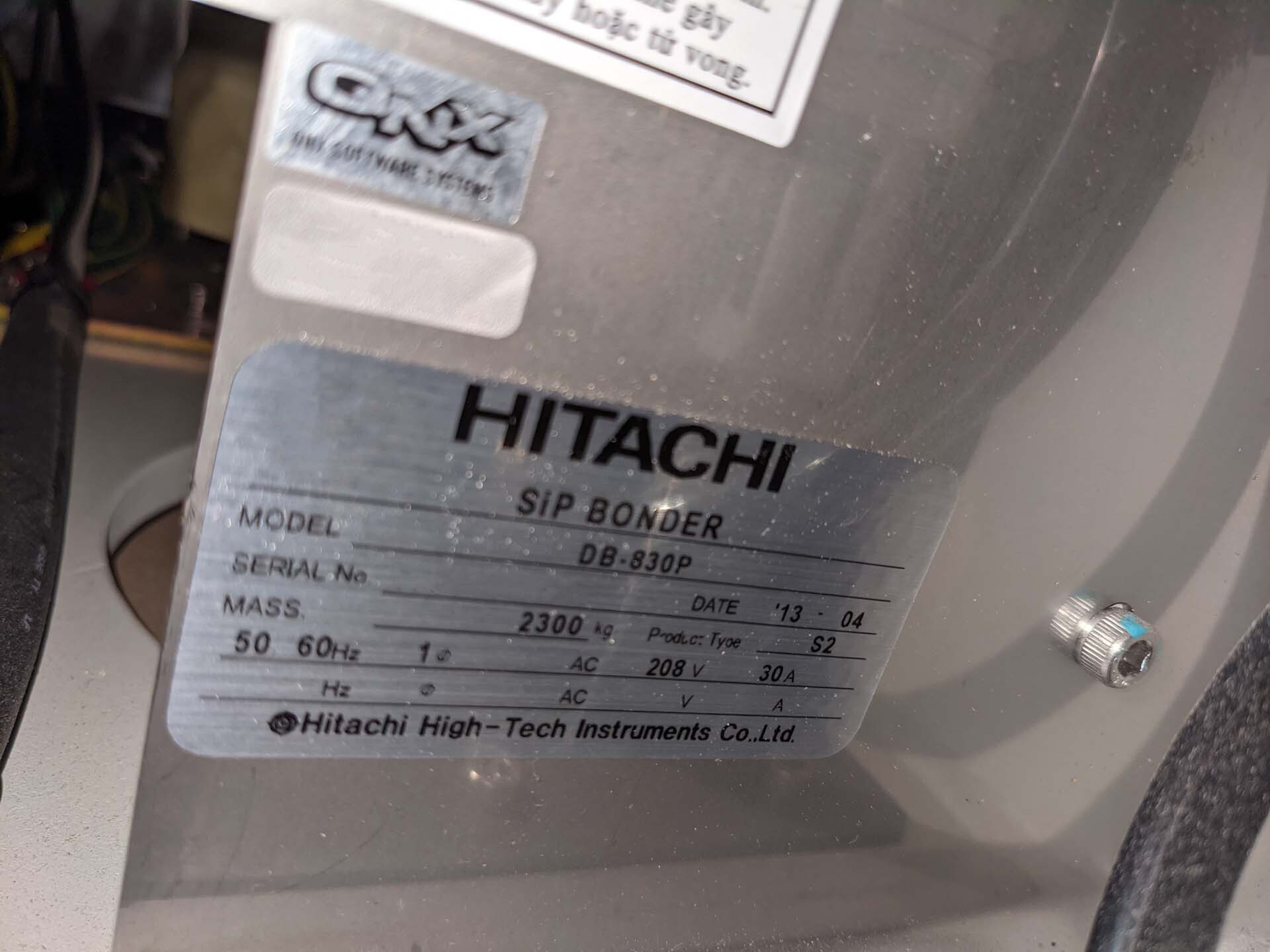

Used HITACHI / RENESAS DB 830P #293663160 for sale

URL successfully copied!

Tap to zoom

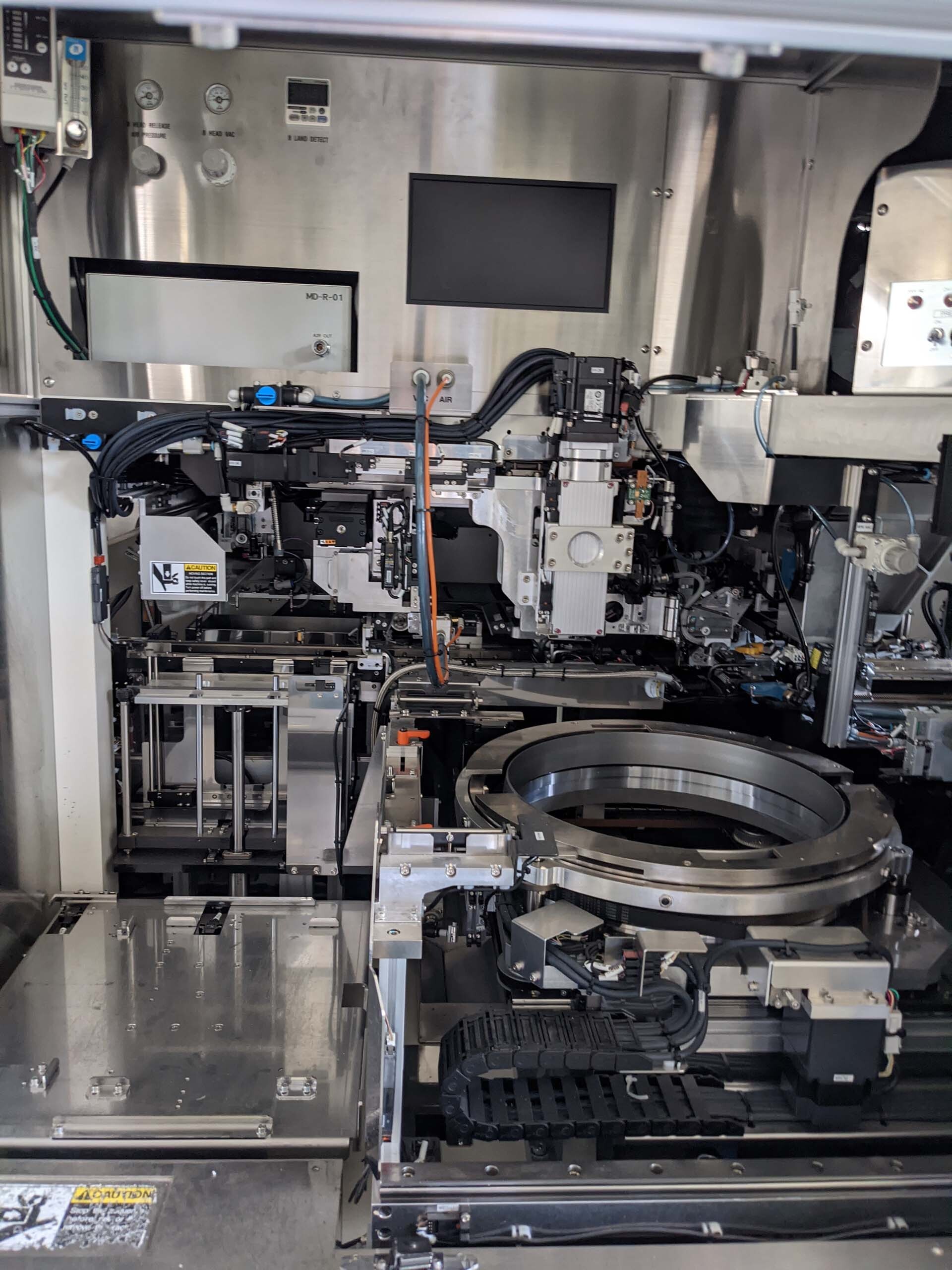

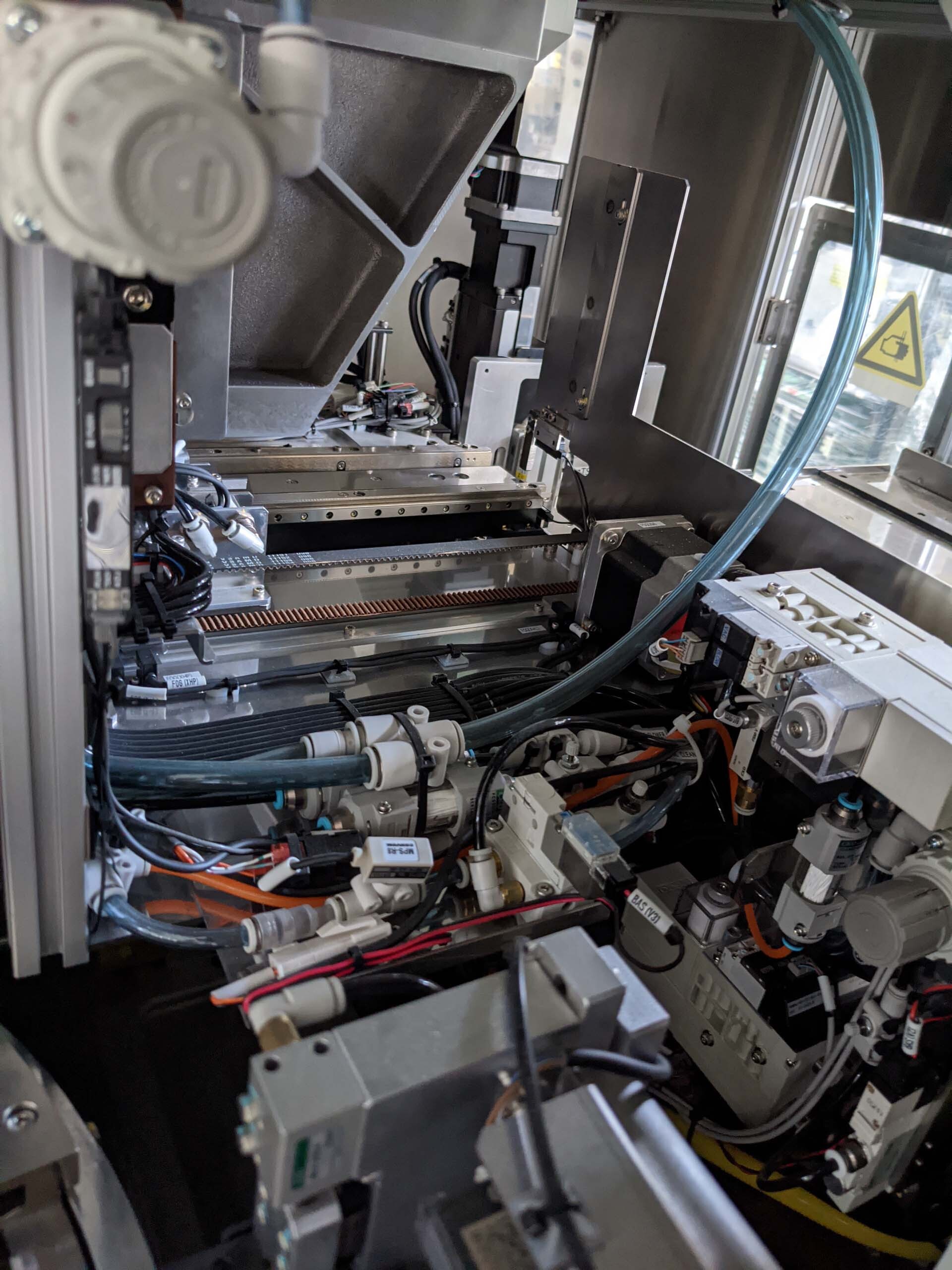

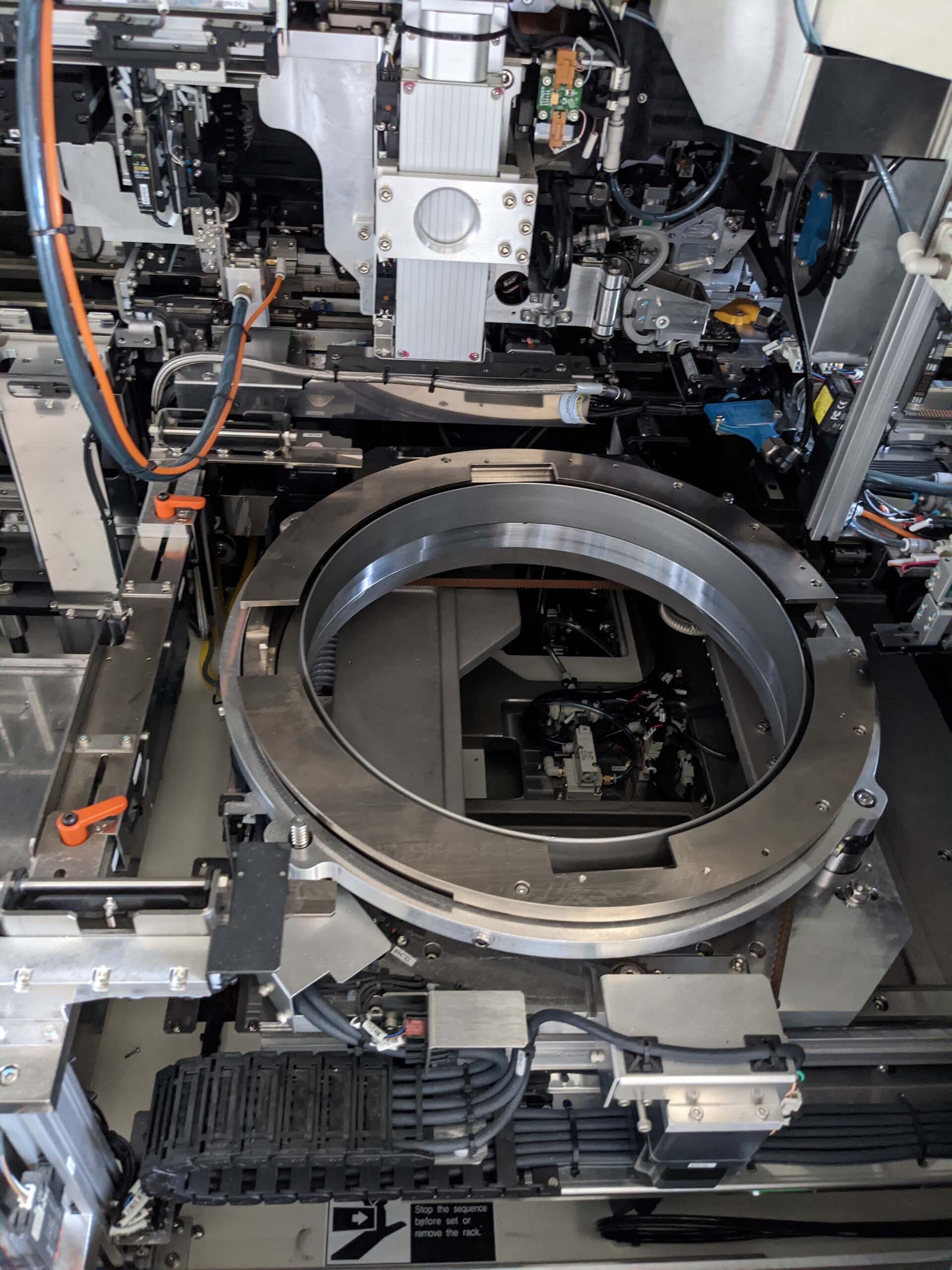

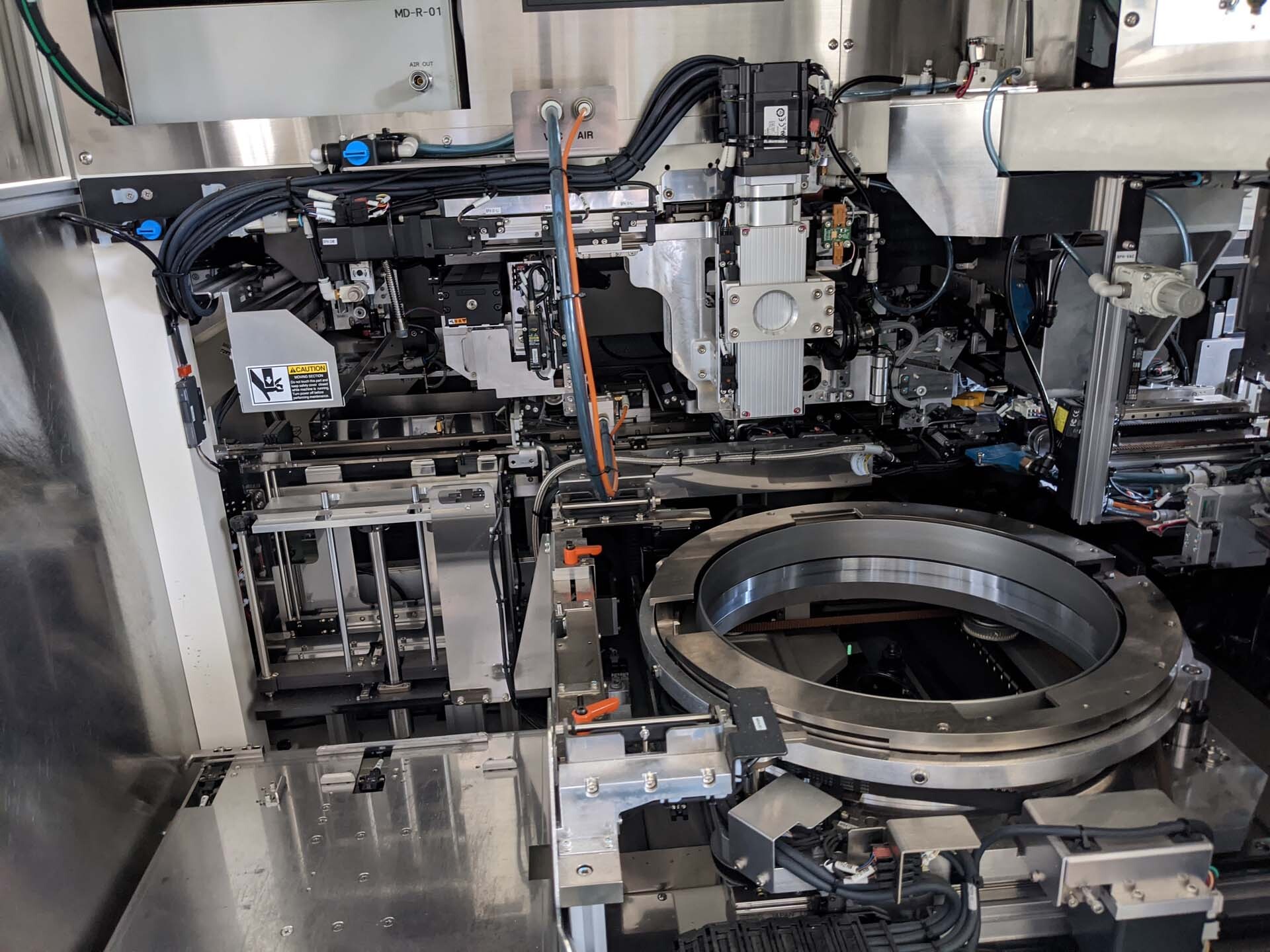

HITACHI / RENESAS DB 830P is an electronic assembly die attacher equipment designed for unloading, attaching, inspecting, and testing smaller auto assembly components. This machine is ideal for those who need a simple yet reliable process for attaching dies on their electronic components. With its intuitive controls and integrated design, HITACHI DB 830P can help streamline auto assembly processes and reduce scrap. RENESAS DB 830P has a unique design that allows it to work quickly and accurately to attach dies to components. The machine has two main zones: an unloading station and a die attach station. At the unloading station, components are placed in the magazine, where an unloader picks up the components one by one and photosensors detect their presence. The component is then transferred to the die attach station where a die attach arm positions the die and a special attachment method is used to mount the die to the contact pad. DB 830P is designed to handle up to four types of dies per component, with manual programming controls to adjust the die attach magnitude if needed. Programming can be done easily and quickly, enabling the user to configure parts quickly and accurately. HITACHI / RENESAS DB 830P also features a vision system that inspects and verifies the die position, orientation, and other information. This unit helps ensure quality assurance and reduce wasted materials. HITACHI DB 830P is a reliable and efficient way to attach dies to components for auto assembly applications. With its intuitive controls and robust design, it can help streamline operations and reduce scrap. Its simple design makes it easy to use and configure, with a vision machine for quality control. Whether it's for vehicle sensors or auto control systems, RENESAS DB 830P is a great choice for quick and accurate die attaching.

There are no reviews yet