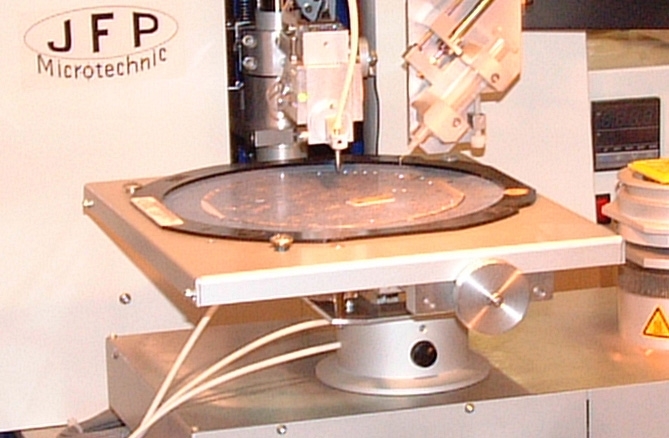

Used JFP MICROTECHNIC PP-1 #9212083 for sale

URL successfully copied!

Tap to zoom

ID: 9212083

Epoxy die bonder

With micro placer

Picking and placement:

Delicate IC devices

Laser diodes / Sensors

Micro-mechanical parts

Micrometer X & Y stage bases

Single head: Single / Dual camera

Dual head: Stamping / Dipensing

Stamping

Rotary dish

Adjustable blade

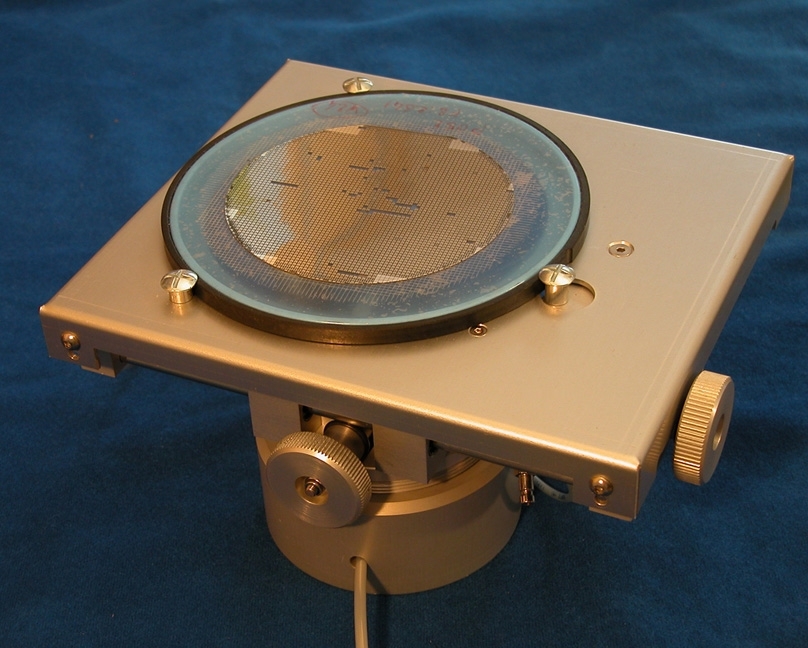

Eject system for wafer

Options

Mini-gripper pickup tool

Automatic place stepper

Motorized table kit

Inspection camera & zoom

System:

Table top machine / Stand alone

Motorized transfer arm & vertical Z

Vacuum tool holders: PP5 Series

Dummy cycle: 700 cph

Throughput: 300 p-400 p / hour

Die and substrate:

Minimum component size: 100*100 µm

Component size: 20 mm

Wafer sorter: 8"

Work holders:

Height adjustable

Working area: 200 x 300 (mm)

External timer controller

Manually handled

Gel pack / waffle pack

Vision:

Field of view: Adjustable

Optical resolution: 4µm/pixel / 1.5µm/pixel

Maximum field of view: 11 m / 4 mm

(2) CCD Color cameras high resolution

Digital cross hair

Adjustable digital video box generators

(2) TFT Monitors, 17"

Features

Low picking force: <7 g

Slow touch down speed for delicate device

Repeat ability: +/- 15 µm

Place force adjustable

Platforms for:

Compact laser bar stacker / Unstacker

Characterization / Test of lasers

High flexibility and controlled parameters

Interface / Guide menu on PC

Power: 100 / 230 VAC, 300 watt

Dry air: 5 bar

Vacuum: 70%.

JFP MICROTECHNIC PP-1 is an automated die attacher which can be used for simple low-cost automated die attachment. It works by pressing a small circular die to a printed circuit board (PCB). The equipment is easy to use, and is compatible with most of the popular PCB materials. The machine is designed to attach dies for different needs, including lead bond assembly, ceramic-to-ceramic die attachment and wire bonding. PP-1 comes equipped with a precise, spring-loaded die press, and the die press is adjustable, making it easy to get the correct pressure required for each die. It also has sensors which detect the correct contact point and make sure that the die is solidly pressed into position. This ensures that the die attachment is of high quality, and that the fibers in the material are not damaged. For safety JFP MICROTECHNIC PP-1 includes a two-handed safety system. It will only work if both hands are in the machine at the same time, preventing any potential accidents or injury. PP-1 is easy to set up, with an intuitive user interface, allowing the operator to quickly adjust settings and begin die attachment. The unit can also be used for multiple die attachment requirements without having to adjust or reprogram the entire machine. Overalla JFP MICROTECHNIC PP-1 is a reliable, low-cost, and easy to use die attacher. It can be used for many different die attachment requirements, and provides a safe and secure way of attaching dies to PCBs. The tool has a simple user interface which allows for easy setup and operation. PP-1 provides a cost-effective and reliable solution for those looking for automated die attachment.

There are no reviews yet