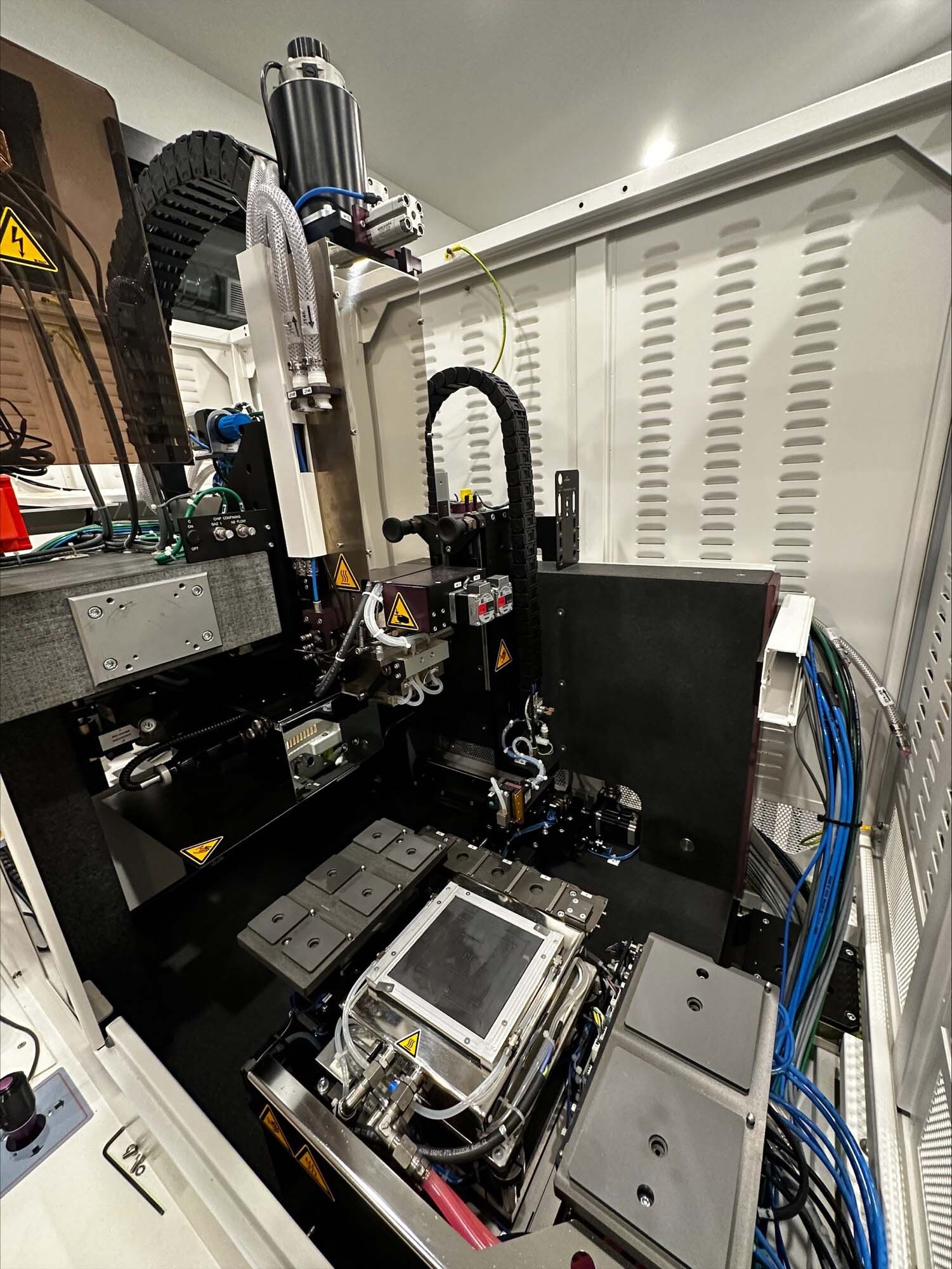

Used KARL SUSS / MICROTEC FC 150 #293637914 for sale

URL successfully copied!

Tap to zoom

KARL SUSS / MICROTEC FC 150 is an automated die-bonding equipment that processes dies quickly and reliably onto substrates in a production environment. It features a successful high precision die-attach process that ensures consistent results. MICROTEC FC 150 has a die-bonding accuracy that is less than ± 0.0006 inches (15 microns) while also providing very high short-term and long-term accuracy retention. The repeatability of the system is also excellent, +/- 0.0003 inches (8 microns) throughout the range of dispense parameters. KARL SUSS FC150 is also capable of achieving a dispense rate of up to 30 cycles per minute, or 1,800 chips per hour. FC 150 has the capability to attach dies to leadframes, flex circuits, substrates, flip chips, or other flexible substrates. It is mounted to the top of substrate handling and alignment unit and is designed to work with an automated mass pick and place machine that can provide support in the mounting and alignment of the die. KARL SUSS FC 150 utilizes a hot-melt epoxy die attach process that provides rapid die attachment, as well as precise and repeatable die bond locations with reduced setup and maintenance costs. The machine also has an adjustable dispensing speed, as well as an adjustable nozzle temperature. The tool also heat-pumps epoxy from the cartridge onto the substrate using a precise algorithm to ensure accurate die placement. KARL SUSS / MICROTEC FC150 operates in a nitrogen atmosphere and provides a temperature-controlled glue chamber, which ensures consistency and accuracy in bond locations. The hot-melt epoxy adheres to the die attach site immediately without additional curing time and allows for manual adjustments of the die attach location or delay after dispense, if desired. Furthermore, the asset also comes with a bubble-free seal that prevents moisture from entering the glue chamber and avoiding disturbances in the adhesive. MICROTEC FC150 also has several safety features to protect the operator and the bond. For example, it is equipped with a sensor to detect overpressure, thus making sure that air pressure is within the specified operating range. The model also comes with a double check-lock equipment that prevents accidental movement of the Z-axis during operation. Finally, the system also has built-in emergency shutdown in case of a malfunction. In summary, FC150 die-attach unit is a reliable, high-precision machine that offers excellent repeatability and accuracy retention. It provides rapid die attachment and is capable of processing up to 1,800 chips per hour. Additionally, KARL SUSS / MICROTEC FC 150 has several safety features and adjustable parameters to suit a wide range of applications.

There are no reviews yet