Used KARL SUSS / MICROTEC FC 250 #88412 for sale

URL successfully copied!

Tap to zoom

ID: 88412

Vintage: 2000

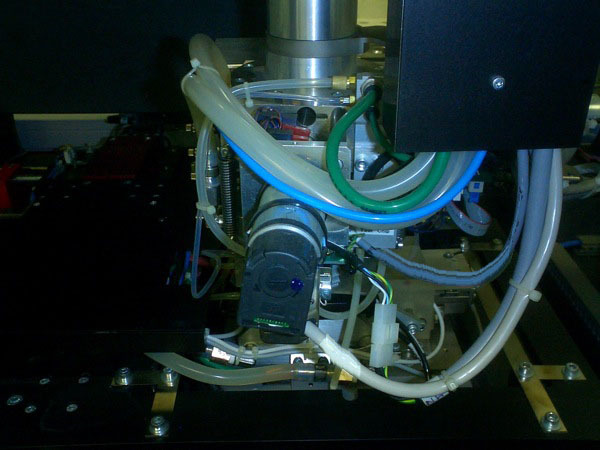

Flip chip bonder

Universal bonding / Transfer arm

Universal bonding: Up to 200kg force

Die bonding / Soldering applications

With production rates up to 120 bonds per hour

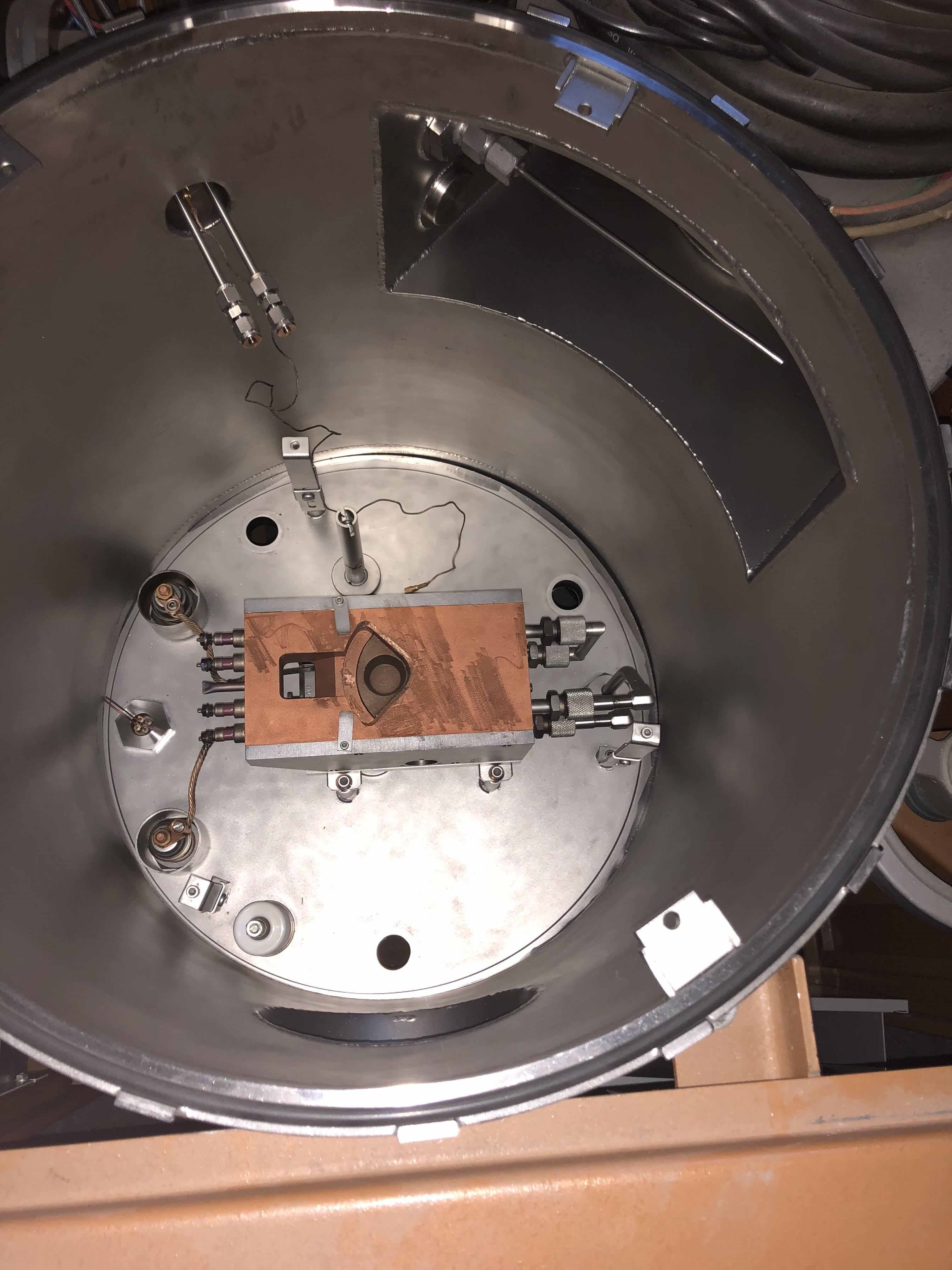

Chuck size: 2"

Waffle / Gel packs: 2" to 4"

Solder universal bonding capability

High temperature bonding capability: Maximum stage / Tool temperature 450ºC

High-precision (± 5 um post bonding accuracy)

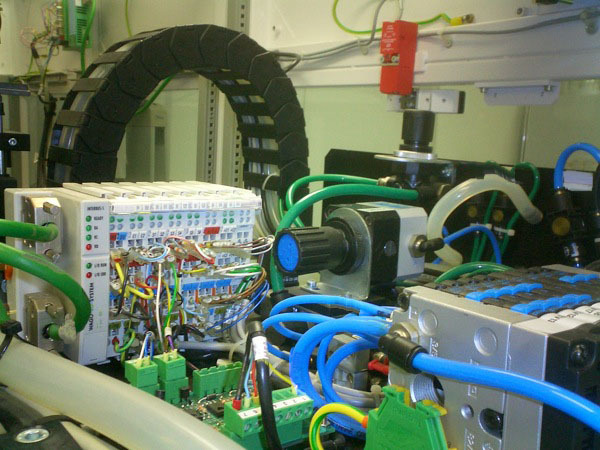

High-speed multi-axis (6 dof) cartesian coordinate articulation in conjunction

With advanced machine vision technology facilitates:

Laser stacks

Memory stacks

Optical switches / Other 3-D assemblies

Bonding applications includes:

Optical packaging using high speed alignment

FPAs

LCD Drivers

MCMs

MEMs

MOEMs

Most micro-scale components

Assembly capabilities includes:

MCMs

Chip-wafer bonding

Missing parts: SMAC Chip

Last PM performed Q1 of 2009

Shrink wrapped / Stored in warehouse

2000 vintage.

KARL SUSS / MICROTEC FC 250 is a die attacher, used in the production of semiconductor devices. It is a fully automated equipment that offers a reliable and repeatable process for attaching and affixing dies, wafers, and circuit components to a substrate. MICROTEC FC 250 provides high accuracy and stability, allowing for tight process control and extremely low levels of process variation. KARL SUSS FC 250 utilizes a high-precision servo-driven x-y-z stage to accurately position the substrate and die. It is equipped with an advanced die pick and place system, which is capable of picking up and positioning individual components and die with a high degree of accuracy and repeatability. The unit also features a robust temperature control machine, ensuring precision placement and temperature performance for a variety of die and substrate materials. FC 250 also offers enhanced production capacity with up to four lanes of production and up to 160 dies per batch. Each lane can be independently programmed, allowing for maximum flexibility in production set-up and throughput rates. The design also helps to increase efficiency by providing a smooth transition from substrate feeding to die pick-up, placement and heating operations. KARL SUSS / MICROTEC FC 250 is portable and easy to use, with intuitive touch-screen controls and real-time process feedback. Additionally, it is easy to maintain, thanks to its robust design and quality materials. The tool is compatible with numerous die and component carrier options, including tape-and-reel and trays, allowing for maximum process flexibility and cost efficiency. Overall, MICROTEC FC 250 is a premier die attacher, offering high-precision, robust, and reliable performance for a variety of semiconductor device production processes. Its automated control asset, robust temperature control, and multiple lane production capabilities make it a must-have for any facility looking to efficiently manufacture high-quality semiconductor devices.

There are no reviews yet