Used LAURIER DS 6000 #142632 for sale

URL successfully copied!

Tap to zoom

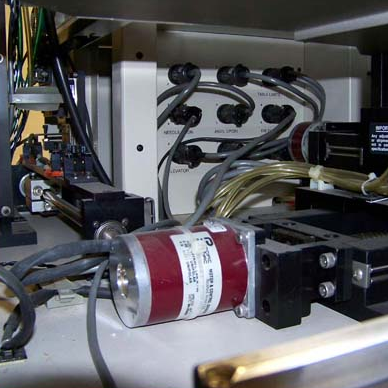

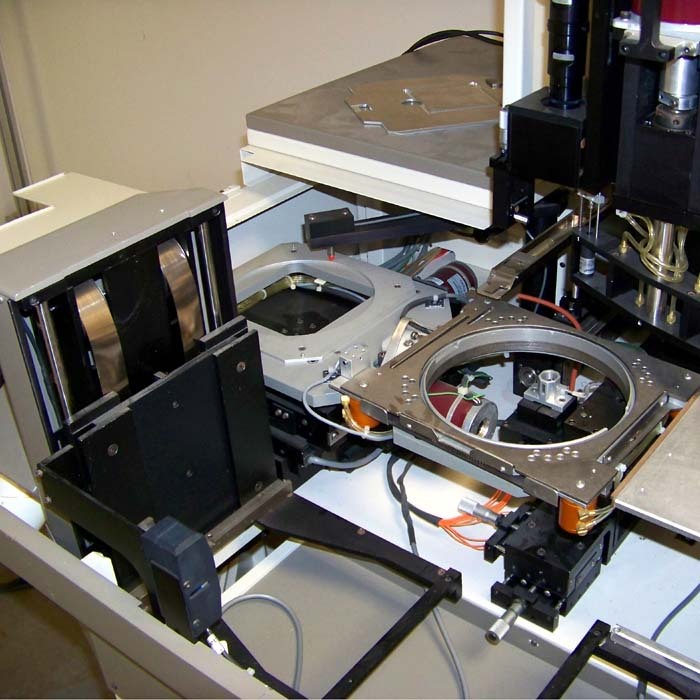

LAURIER DS 6000 is an automated die-attaching machine designed to provide a fast, accurate, and economical attachment solution for the semiconductor industry. The machine utilizes a combination of a high-resolution vision equipment and progressive robotic arm-loading technology to streamline the die-attachment process. The vision system is responsible for quickly and accurately locating and scanning the profile of each die before it is attached to the wafer or substrate. It uses its unique X-Y table and a Coordinated Motion Unit to rapidly locate and identify each die. The vision machine is also able to detect automated solder paste deposit and accurately measure the position of the solder ball. Once the die is successfully located, the robotic arm-loading mechanism precisely positions the die against the substrate for attachment. DS 6000 is equipped with a rotary motor and switching platform that drives the high-precision servo motor controlling the movement of the robotic arm. The rotary motor also provides an exact adjustment of the die-attaching pressure, in order to ensure optimal accuracy and integrity of the lines and bond of each die. LAURIER DS 6000 is programmed with a Windows-based operating tool for easy setup and control of the entire die-attaching process. A user-friendly graphical user interface (GUI) allows users to easily adjust the parameters of the machine, including movement speed, placement accuracy, and die-attaching pressure. DS 6000 is also equipped with numerous safety features to ensure the safety of users and their equipment. A door switch and safety interlock asset prevent unauthorized access to the machine while it is in operation. The machine also utilizes an emergency-stop function to immediately stop operations in case of an emergency. Overall, LAURIER DS 6000 is an advanced, automated die-attaching machine designed to provide a fast, accurate, and cost-effective solution for the semiconductor industry. Its high-resolution vision model, robotic arm-loading mechanism, and precise adjustability of die-attaching pressure make it an excellent tool for achieving efficient and accurate die-attaching results. Its safety features and easy-to-use Windows-based GUI also allow users to conveniently monitor and control the entire die-attaching process.

There are no reviews yet