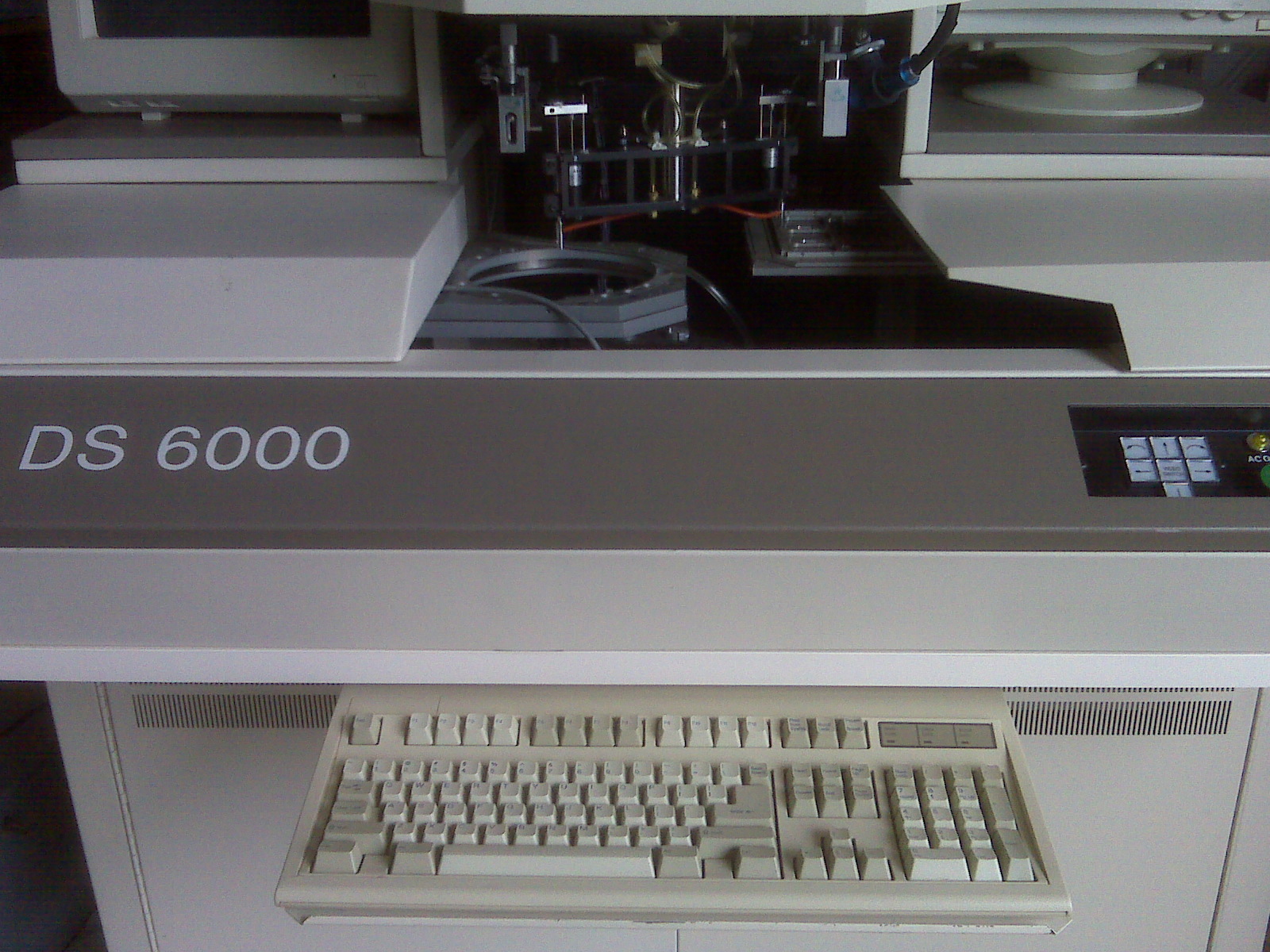

Used LAURIER DS 6000 #85370 for sale

URL successfully copied!

Tap to zoom

ID: 85370

Wafer Size: 6"

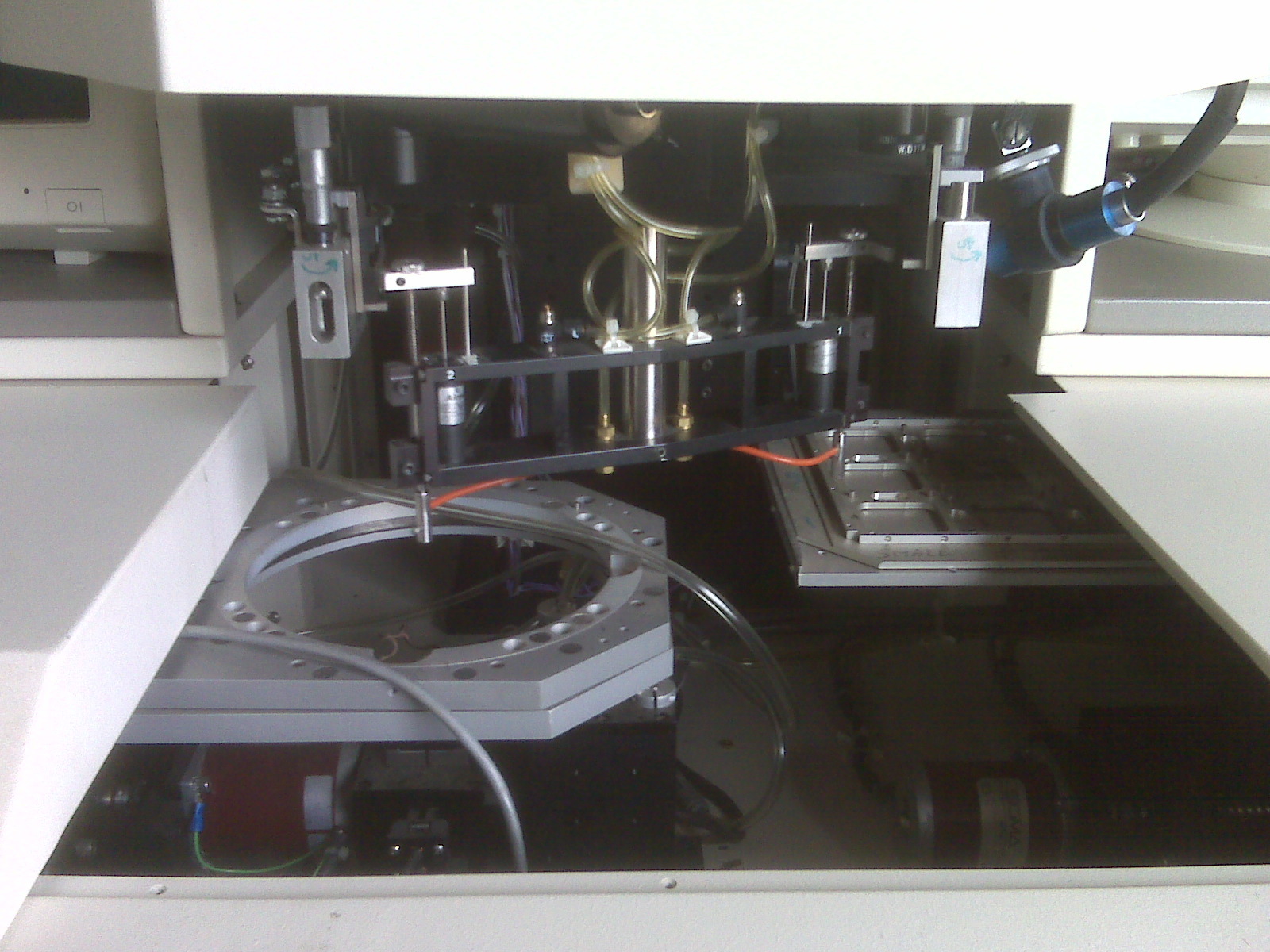

Die sorter, 6"

Loads waffle packs

Die per hour: Up to 8000

Input module:

Components:

Active / Passive components: 0.030" - 1.000"

Accuracy:

Stepper motor driven

Precision grade lead screws on X / Y table

Accuracy: +0.001"

Resolution: 0.00025"

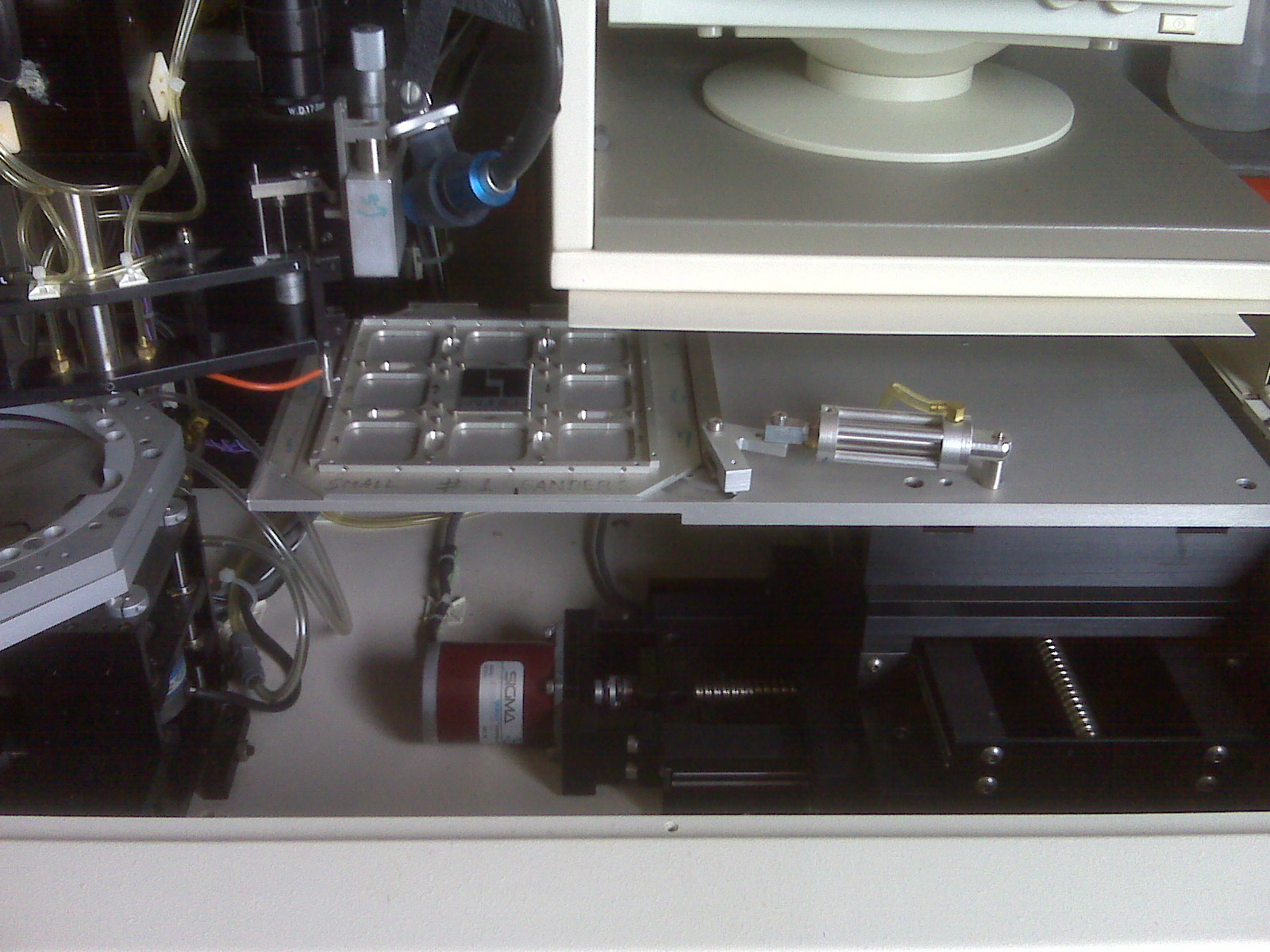

Output module:

Multiple configurations:

(4) Waffle pack work holders

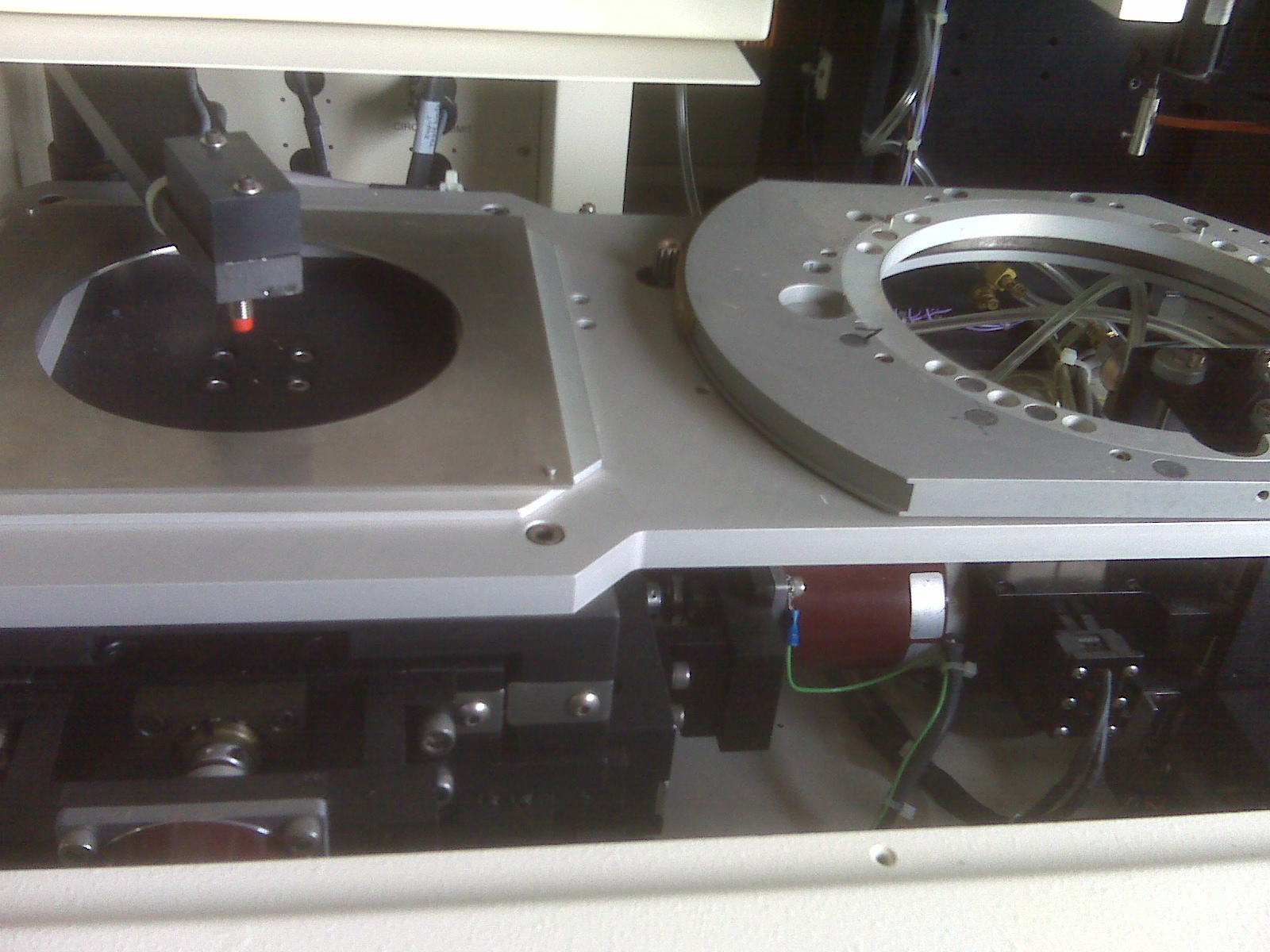

Rotary carousel:

(16) Position, 2" waffle packs / (5) Position 4" waffle packs

Single / Multiple wafer frame output

Reel-to-reel tape output

Transfer module:

Pick and place system:

Dual arm

Micro stepper motor driven rotary head

Accuracy: ±0.00025"

Resolution: 0.006°

Independently actuated Z-axis motion on pickup collects

Electronics module:

IBM PC-AT Compatible

Micro-computer MS-DOS based

Built-in diagnostics

Fast graphics enhanced programming

General specifications:

Multi-sorting capability

Wafer mapping

Utilities:

Air: 65 PSI

Vacuum: 25" Hg

Electricity voltage: 208-240 Volts

Power supply: Single phase, 50/60 Hz.

LAURIER DS 6000 is a fully automated die attacher for secure product marking. Manufactured by STAMPEX in cooperation with LAURIER, this machine features automatic die attaching, highly efficient manufacturing cycle control, and integrated safety systems. The high level of automation of DS 6000 makes it suitable for production lines that require a combination of large and small batches. By incorporating advanced motion controls, this machine reduces the time required for attaching each die and eliminates the need for manual handling. The robust construction of LAURIER DS 6000 offers users a level of durability and reliability that is unrivalled in its class. The drive hardware is housed in an anodized aluminum enclosure, with superior impact and vibration performance. The mechanical components are made of durable steel and are designed to withstand extreme industrial conditions. DS 6000 offers the convenience of one-step assembly, reducing the number of steps required to complete the attaching process and improving the speed of production. The unit also offers a speedy automatic die loading process and comes with robust, integrated safety systems. The intuitive and user-friendly layout of LAURIER DS 6000 makes it easy to access and use the functions displayed on the front panel. The intuitive LCD touch-sensitive panel provides detailed procedure indications and allows operators to monitor and control the die attaching process in real-time. DS 6000 is the perfect die attacher for high speed production lines where efficiency and security are paramount. It is ideal for a broad spectrum of industries and applications including automotive, aviation, electronics, medical, appliance, and heavy industry. This machine is user-friendly and provides an ergonomic working environment for users. Its robust construction and integrated safety systems ensure an efficient and safe working environment.

There are no reviews yet