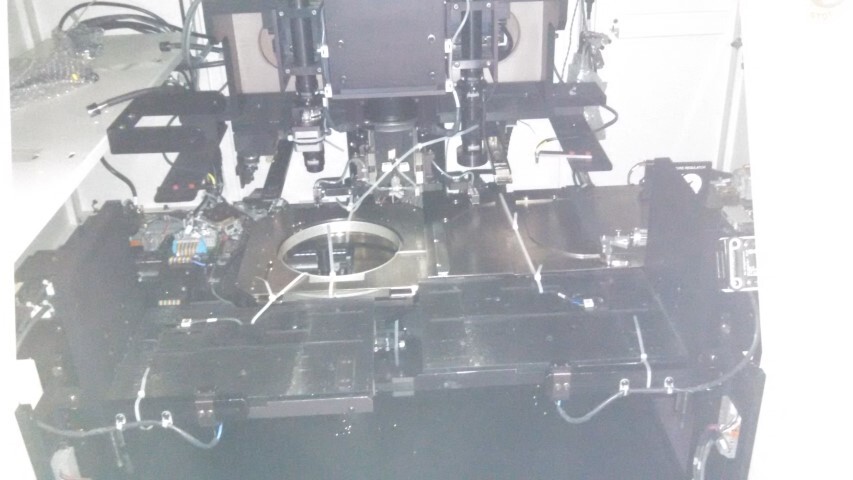

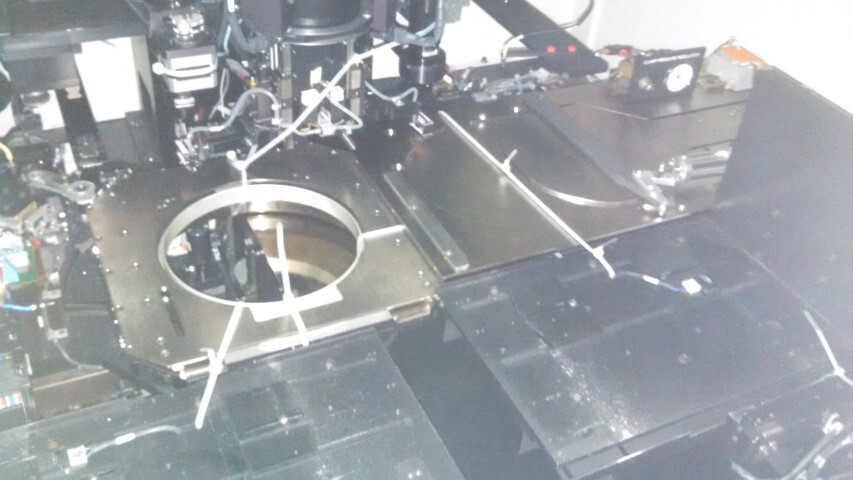

Used LAURIER DS 9000 #9065335 for sale

URL successfully copied!

Tap to zoom

ID: 9065335

Wafer Size: 5"-12"

Die sorters, 5"-12"

Capable, 8"-12"

Small die: 0.250 um - 2 mm

Input / Output tables, 6" (can be converted up to 8")

Mapping: Row / Column and array formats

Multiple inspections:

Ink dot recognition

Ink dot

Edge chipping

Bump

Mark

Throughput:

8,000 UPH Sprint rate

7,500 UPH Typical for die: < 5 mm

7,000 Typical for die: > 5 mm

Inspection:

Edge chip detection

2D Bump

Placement accuracy: ± 50 μm @ 3 sigma ± 1° theta - +/- 37um @ 3 sigma, theta is correct

Place position:

X

Y

Ø

Die size:

0.5 mm - 5 mm

5 mm - 32 mm

Cassette input:

Frames: 12" x 8"-8"

Network:

Ethernet or SECS

TCP / IP

RS232

Pneumatic:

5.8 - 7.5 Bar (85 to 120 PSI)

Dry air: 140 L / minute (5 SCFM)

Power supply: 208 / 220 / 230 / 430 VAC, Single phase, 2.0 kVA, 50/60 Hz

2004-2008 vintage.

LAURIER DS 9000 is an automated die attacher that is used to attach individual dies to a substrate in a precise, efficient, and cost-effective manner. The machine is equipped with a high-precision feeder that delivers individual dies to a precise location on the substrate. The die is then accurately positioned by pressing a foot pedal and the die is secured in place with a powerful electro-magnetic bond. LAURIER DS-9000 is housed in a robust die attacher body that features an ergonomically designed operator interface with easy to use control buttons. The equipment also features a microprocessor-based electronic control module that ensures precise and repeatable operations. To ensure safety and security, an emergency stop button has been incorporated into the system, as well as a built-in fail-safe mechanism that will automatically shut down the machine if any unsafe conditions or operation errors are detected. The minetrack ensures precision and accuracy in each die-attaching operation. The unit utilizes an innovative magnetic field sensor design and is capable of detecting location and orientation of a die with an accuracy of ± 0.2 mm. This allow for precise die attachment that does not require any re-bedding of the dies. The machine can hold a maximum of 15 dies and can handle miniaturized and intricate dies as small as 0.25mm in height and 0.5mm in dia. DS 9000 is equipped with sensors for quality control that help reduce defective parts on the production line. It is engineered with a unique double detection tool that confirms die position, allowing for superior attachment. The asset also has a built-in force control feature that limits the bond force to prevent excessive substrate deformation and reduce production downtime. To ensure maintenance and serviceability, a set of flexible and interchangeable modules have been designed into the model. This allows the user to customize DS-9000 to their particular needs. The equipment can be upgraded with additional features like high-speed operation, PLC interfacing, and Ethernet connection. In addition, the system has been designed to be easily dismantled and re-assembled, making maintenance and repairs fast and efficient.

There are no reviews yet