Used MANUFACTURING INTEGRATION TECHNOLOGY / MIT Optimus M2 #9245369 for sale

URL successfully copied!

Tap to zoom

ID: 9245369

Die sorters

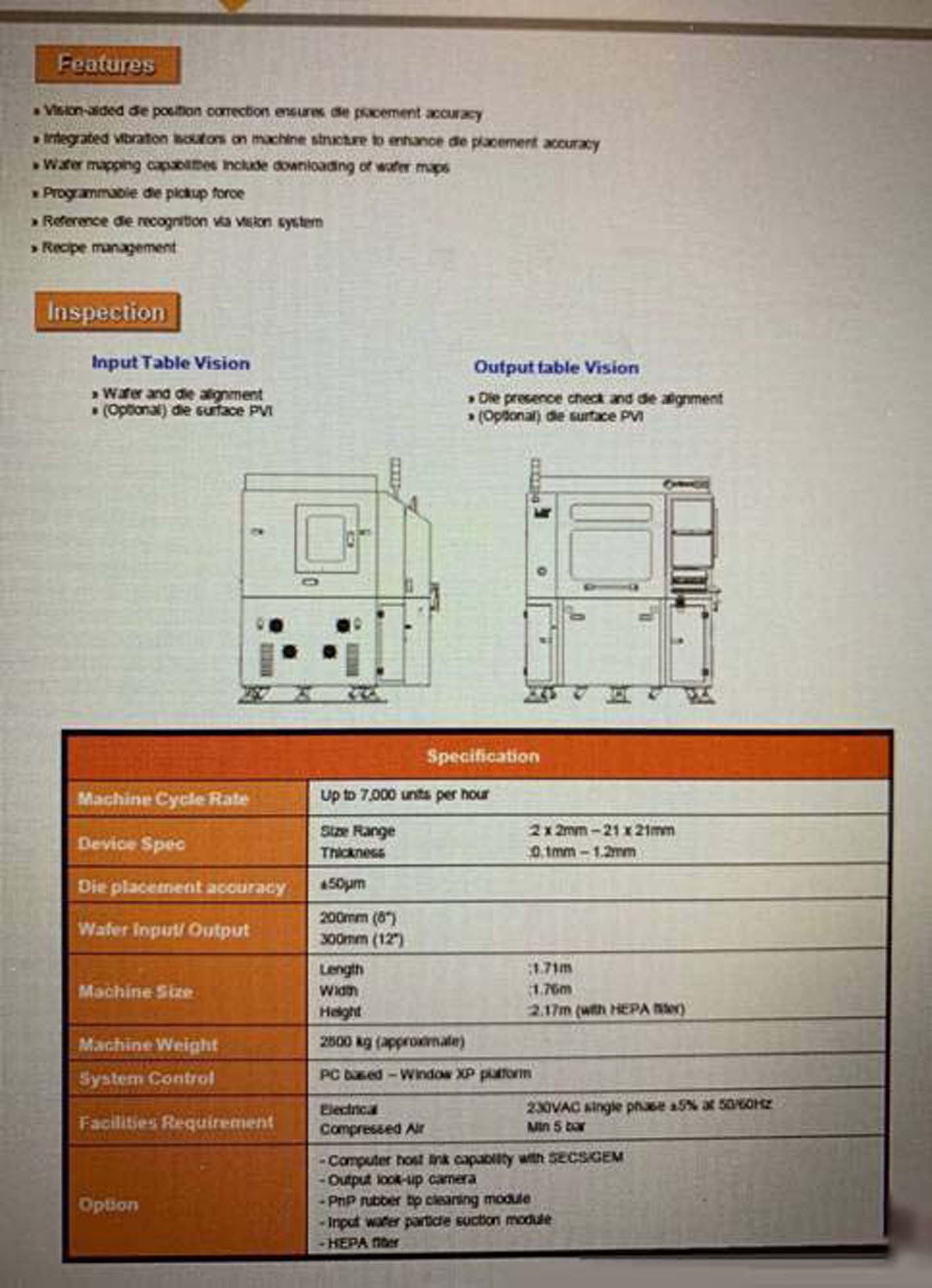

Input table vision: Wafer and die alignment

Output table vision: Die presence check and die alignment

Machine cycle rate: 7,000 units per hour

Device space:

Size range: 2 x 2 mm - 21 x 21 mm

Thickness: 0.1 mm - 1.2 mm

Die placement accuracy: 50 um

Wafer input / Output, 8" / 12"

Operating system: Windows XP Platform

Option:

Computer host link capacity with SECS / GEM

Output lock up camera

PnP Rubber tip cleaning module

Input wafer particle section module

HEPA Filter

Facilities requirement:

Compressed air: Minimum 5 bar

Power supply: 230 VAC, Single phase, ±5% at 50/60 Hz.

MIT (MANUFACTURING INTEGRATION TECHNOLOGY) MANUFACTURING INTEGRATION TECHNOLOGY / MIT Optimus M2 Die Attacher is a state-of-the-art die attach and wire bonding platform specifically designed for high-volume production requirements in semiconductor electronics manufacturing. It offers superior throughput performance and flexibility for different applications. It is well-suited for attaching die ranging from flip chip style to conventional die bond. MIT Optimus M2's advanced vision system enables accurate die alignment with its proprietary "Image Match" feature. The high precision precision alignment achieved with this feature increases yields and profitability. It has a durable attachment head with advanced control algorithm which virtually eliminates damage to delicate die during placement. The head can be easily swapped to allow attachment of various die sizes. The machine has a Small Buffer size of 7, which allows it to be quickly reset upon the occurrence of unforeseen situations, reducing the time required to start up. It also offers low maintenance cost due to its self-adjusting components that reduce the need for regular maintenance. The machine is also highly reliable and has a fast cycle time. It can be easily integrated into existing systems, with its simple user interface and intuitive graphical displays. The machine also offers full traceability of process data, enabling data collection for quality control and debugging processes. MANUFACTURING INTEGRATION TECHNOLOGY Optimus M2 also boasts automated tooling exchange, which enables rapid changeover between different die sizes. The tooling is designed for a wide range of contact force ranges and geometry, further enhancing its flexibility. The machine also offers a wide range of optional accessories, including contact spot welders, vision systems, and ambient light compartment, among others. This offers extra capabilities to suit different application needs. Overall, Optimus M2 Die Attacher is an excellent automated die attachment solution for high-volume production requirements. It provides superior placement accuracy and fast setup and cycle time while being highly flexible and reliable. Its optional accessories further bolster its already impressive capabilities.

There are no reviews yet