Used MRSI 170 #116704 for sale

URL successfully copied!

Tap to zoom

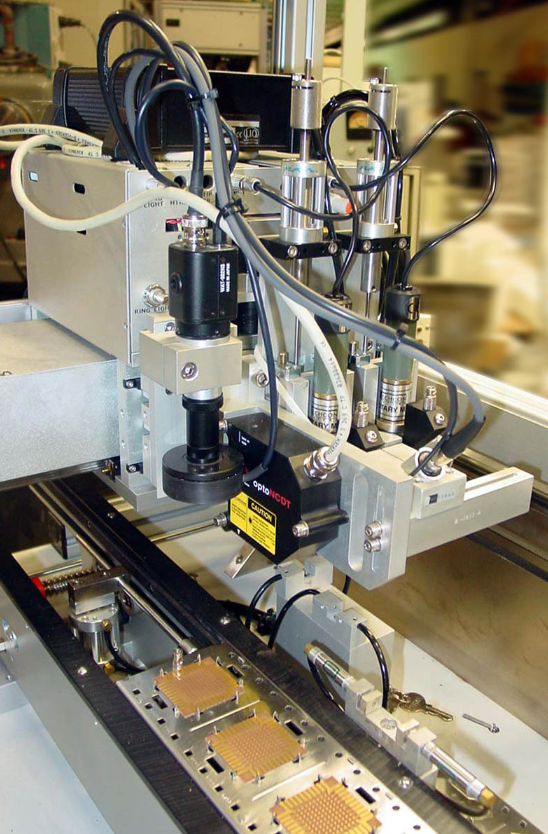

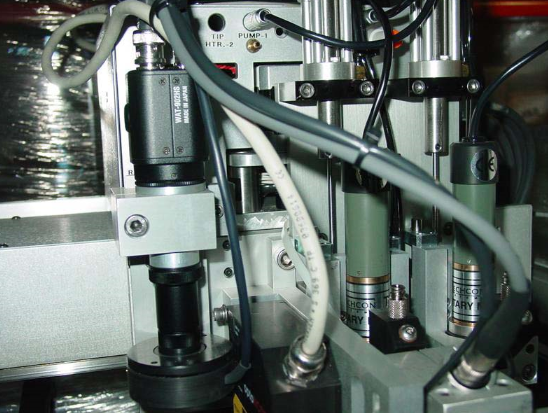

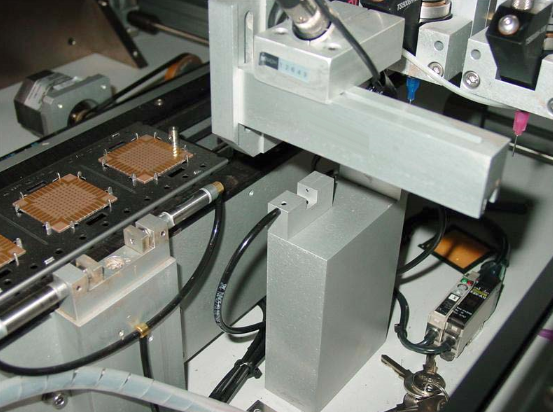

MRSI 170 die attacher is an industrial grade machine designed to attach precision components to one another. This process is commonly referred to as surface mount technology (SMT). 170 is a high-speed, high-volume system that can attach up to 17,000 chips per hour. It also features easy maintenance and setup. MRSI 170 consists of two components: the machine itself and a rotating disc drive that holds the components in place. The machine uses a vision system to identify each component's placement and then uses a specialized vacuum system to securely attach the pieces. A few parameters must be programmed into the machine such as the single or matrix pattern for the parts and the die type. 170 uses a high-precision precision printing technique to apply a low viscosity solder paste or film adhesive to each component. This process is also called stencil printing and it ensures a heavier and more even spread of material applied to the components. Once this process is complete a V-cut separatrix divides the components. Once all pieces are connected, MRSI 170 heats up the components with a solder reflow process. This process tempers the solder paste and creates a strong bond between the components. The solder reflow process is extremely delicate, so 170 has a unique aluminum alloy piezo heater which is capable of quickly and precisely adjusting the temperature of up to 17 zones. Finally, an upper conveyer is used to move the products to a receiving tray for further processing. MRSI 170's intuitive design makes this machine a great choice for medium to high-volume surface mount operations. Its accuracy and speed, along with its easy setup and maintenance, makes it a great option for most industries. 170 is also cost-effective, using only a small amount of energy and material, making it an even better investment.

There are no reviews yet