Used MRSI 505 #9096304 for sale

URL successfully copied!

Tap to zoom

ID: 9096304

Pick and place machine spare parts:

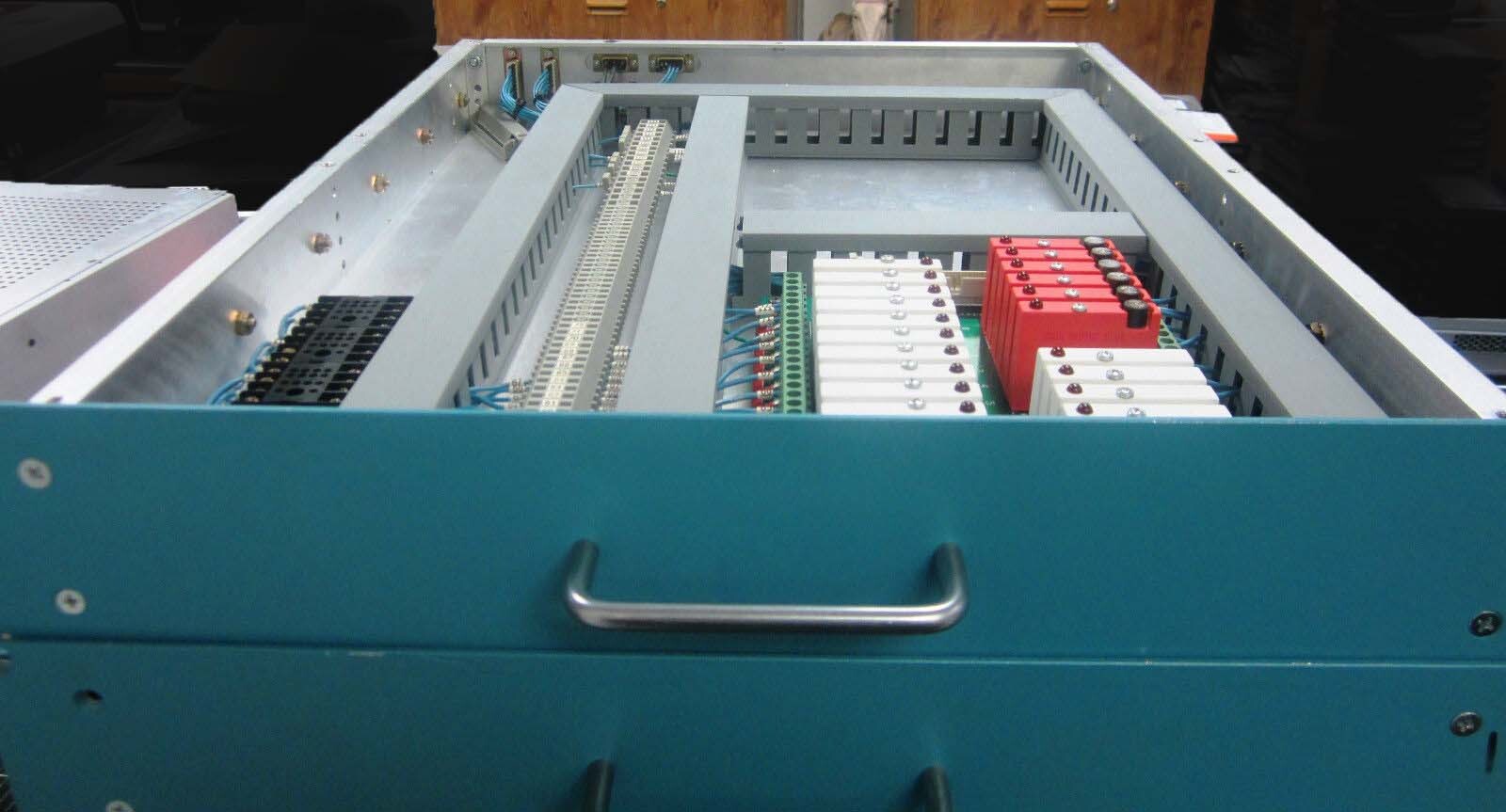

19" rack mounter

(5) Controllers

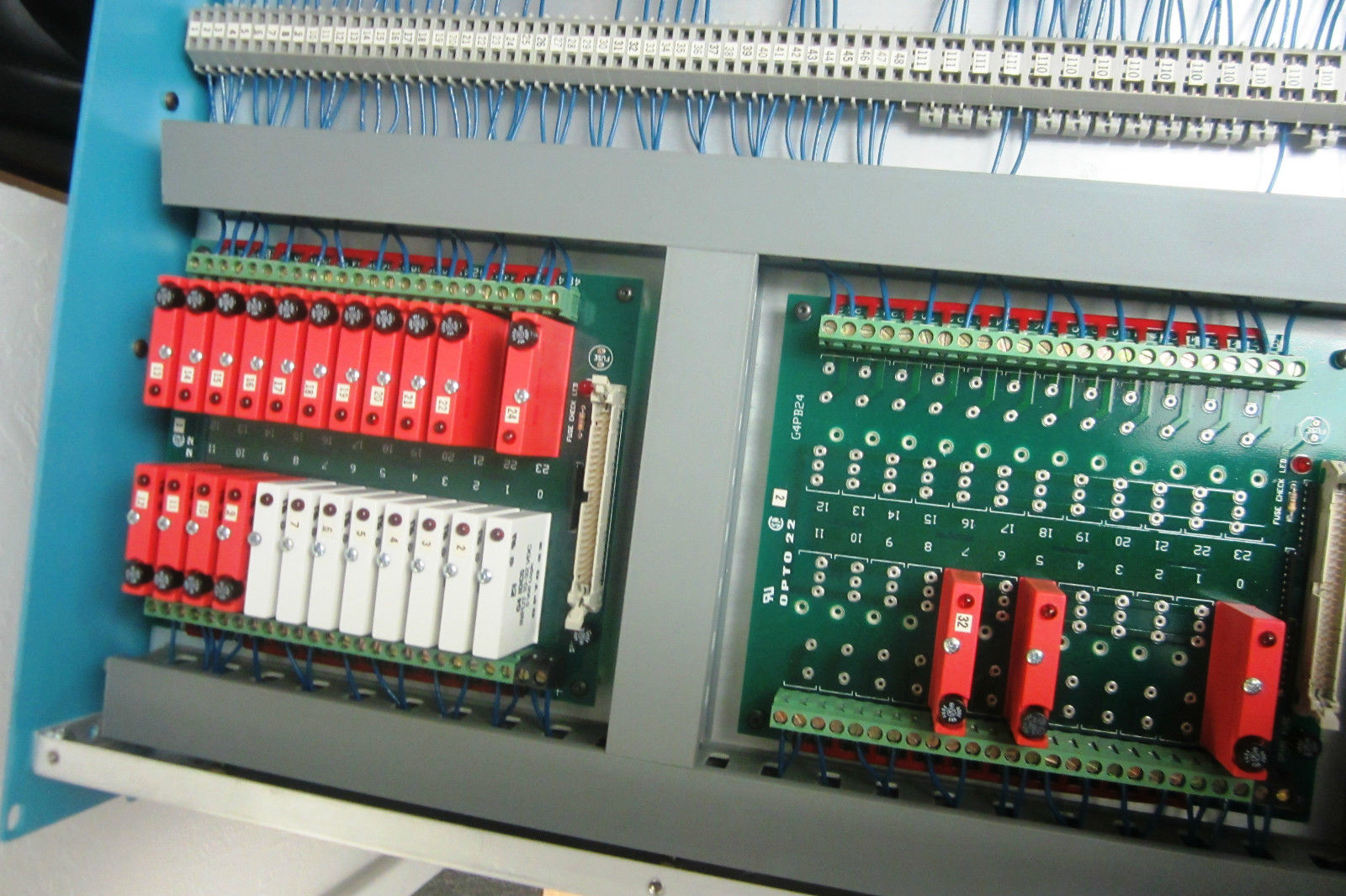

Main Opto controller

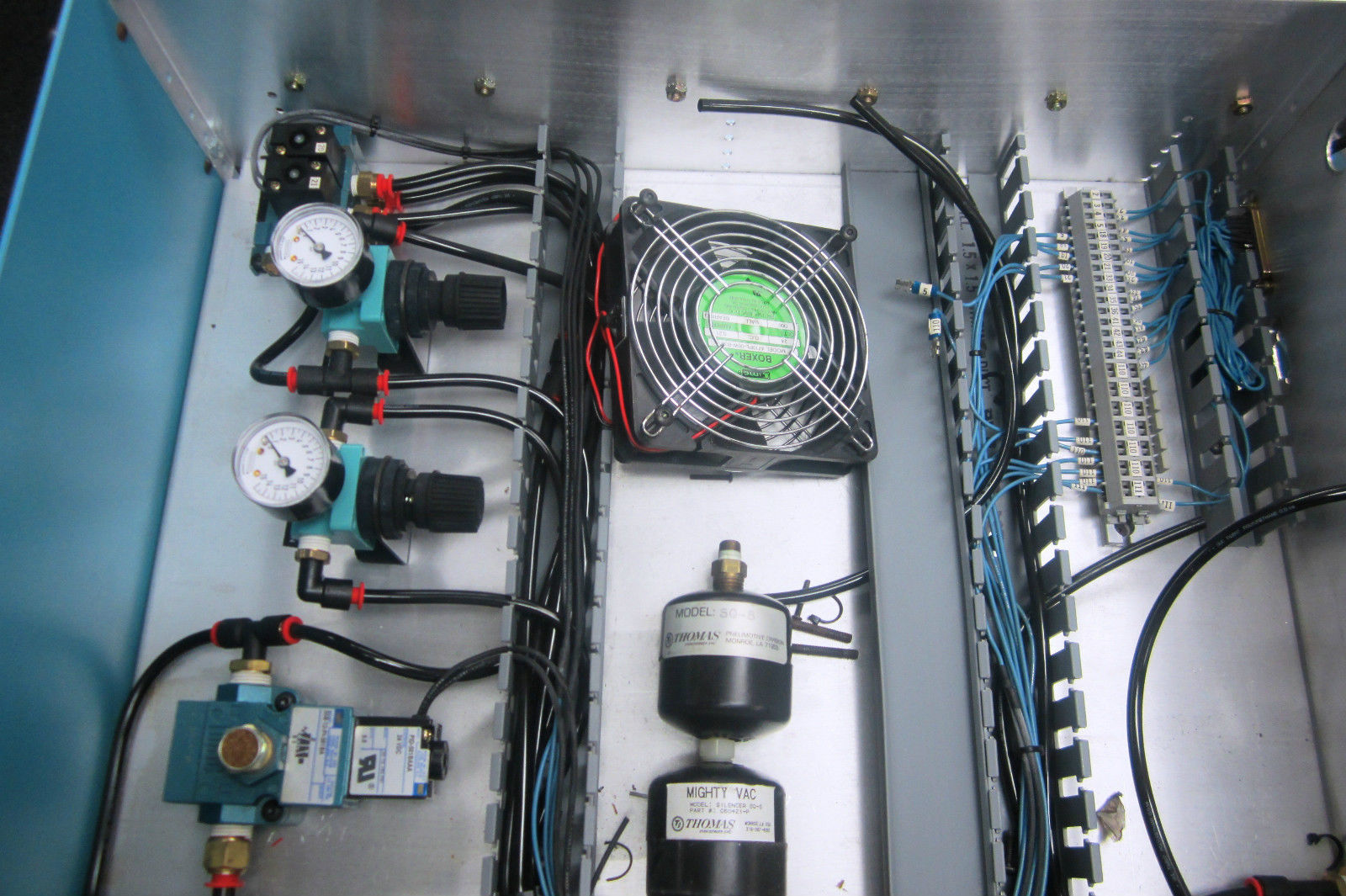

Conveyor pneumation controller

robot driver box

Conveyor robot.

MRSI 505 is a die attacher assembly equipment used for attaching pre-cut dice to PCB components. The system consists of a roller head for applying the die to the board, a press unit equipped with a travel unit for the precise placement of the die, and a vacuum chamber for the transfer of die from one substrate to another. The machine is driven by a stepper motor, allowing precise control of the travel, speed, and pressing force. The roller head is equipped with a guide mechanism for precise alignment and an air pressure tool for step and profile adjustment when rolling the die onto the substrate. The dispenser has a capacity of up to 125 die, each with a die size of 34 to 38 mils. The die is transferred to the press unit via an automated unloader, where it is held in place by a jig clamping asset. The press unit is composed of two separate heads, each equipped with a vacuum chamber and latching mechanism. The heads also have a proximitor sensing model for precise die placement. The vacuum chamber is designed to provide a consistent pressure during the entire transfer process. The chamber is adjustable to determine the proper pressure for specific die types. A vacuum level monitor is included for precise die release. In case of troubleshooting, 505 is equipped with a diagnostic equipment that can detect errors like: over-pressing, poor alignment and insufficient pressure. MRSI 505 possesses a steady positioning of the die and a programmable flip-flop feature, allowing easy and immediate die flipping to the same position. It also incorporates a die-encapsulation feature, designed to protect chips from environmental factors such as moisture and airborne particles. 505 is ideal for high-volume production in the assembly of complex modules, fine-pitch components, and integrated circuits. It is accurate and reliable, enabling superior quality die attachment and extended process control. The system is easy to operate and eliminates manual steps, resulting in improved efficiency and lower overall cost.

There are no reviews yet