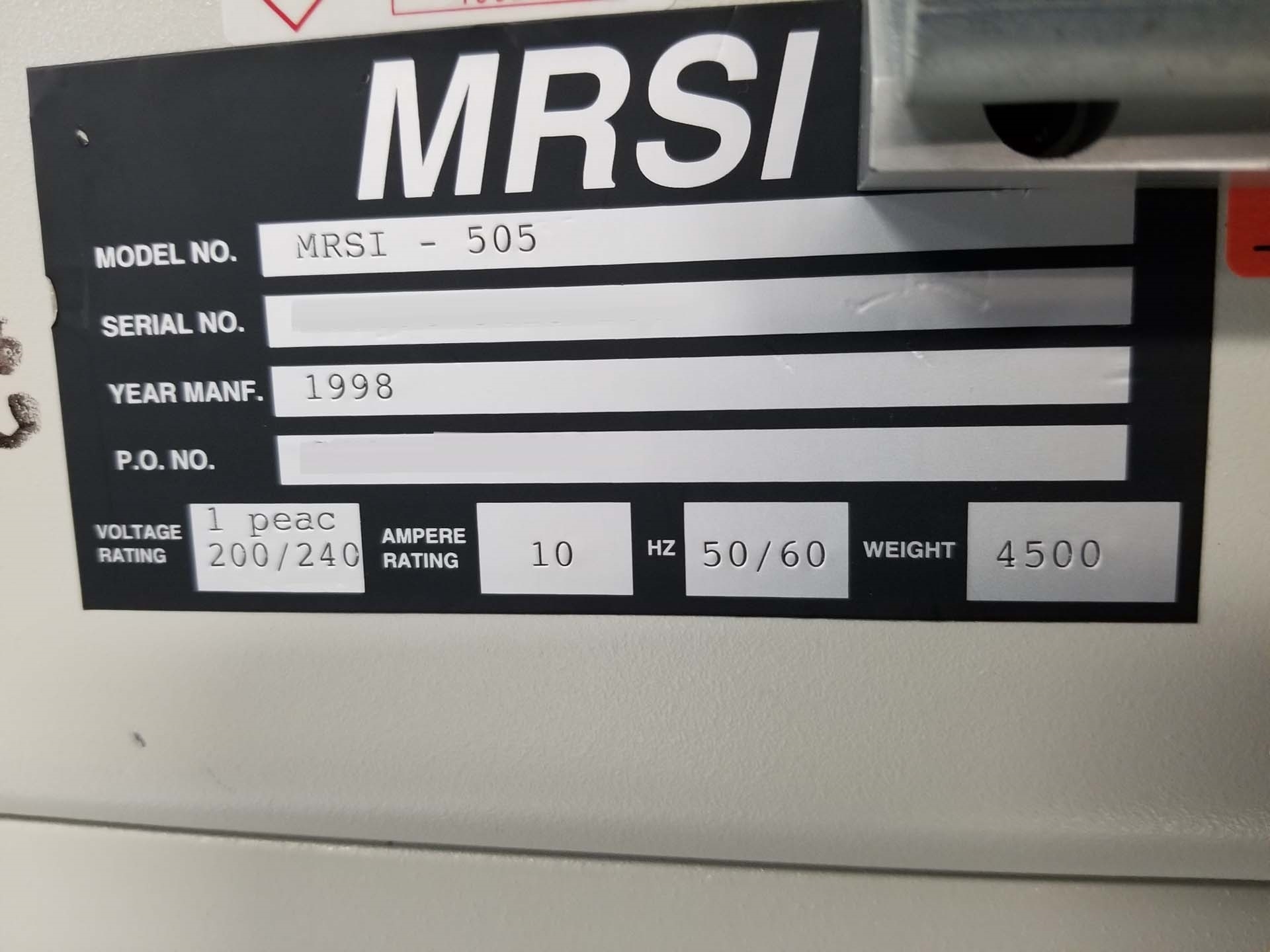

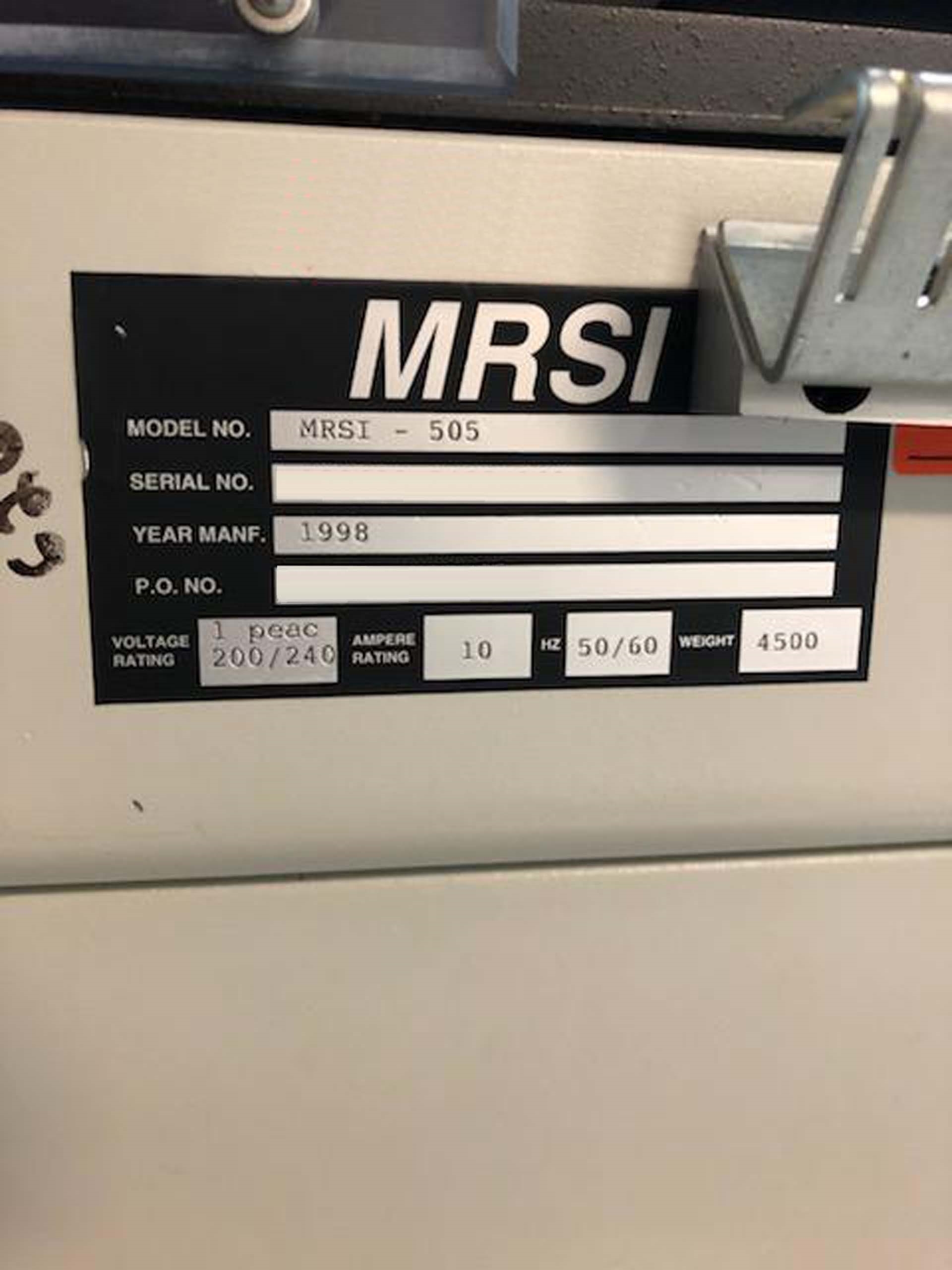

Used MRSI 505 #9240168 for sale

URL successfully copied!

Tap to zoom

MRSI 505 is an advanced die attacher designed to increase the productivity of die bonding operations. It features a user-friendly, intuitive interface and dependable performance. This is a two-axis equipment, designed to handle reel-to-reel processing quickly and efficiently, with the capability of attaching die in accurately located pitches down to 10 microns. The system is designed with a fast, accurate and high-speed X-Y positioning unit, high-precision Z-Axis encoder and precise vision machine to ensure precise placement of the die. The vision tool also features built-in inspection capabilities, which allow users to quickly verify that the die is correctly placed, as well as flag any misalignments, voids or drops. The asset also includes vision-guided tray handling and automated tray exchange, allowing for quick changes in tray sizes for different die sizes. 505 has a maximum travel range of 149.23mm in the X-axis, 115.894mm in the Y-axis, and 10mm in the Z-axis. It has a maximum resolution of 10 microns in each axis, and a maximum bonding speed of 2.5 bonds/sec. The model is compatible with most die bonders, including hybrid die bonders, die to die bonders, and die to substrate bonders. The machine also features automated exchangeable sample loading tray and can accommodate tray sizes up to 250mm. The tray-less Exchangeable Sample Loading (ESL) is designed to ensure no misalignment in die placement and maximum throughput. The equipment is customized to the speciic die bonding application, saving set-up time and ensure accurate die-to-die canister placement. Finally, MRSI 505 is designed with an automated reference system, which is capable of making fine-tune adjustments to the CCD stand to ensure that the die will be accurately located. This unit is capable of detecting any errors that have been made during die placement, preventing misalignment and enhancing the machine's performance. Additionally, this tool is capable of performing the traditional manual alignment procedure, as well as the automated alignment settings. The asset is equipped with dual view cameras, which allow users to inspect the CCD stands from both above and below. This ensures consistent, accurate placement, as well as ensuring maximum precision when locating each die.

There are no reviews yet