Used MRSI 505 #9364757 for sale

URL successfully copied!

Tap to zoom

ID: 9364757

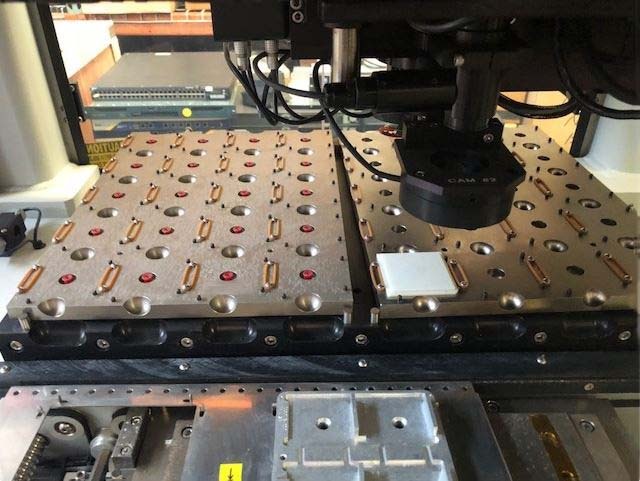

Die bonder

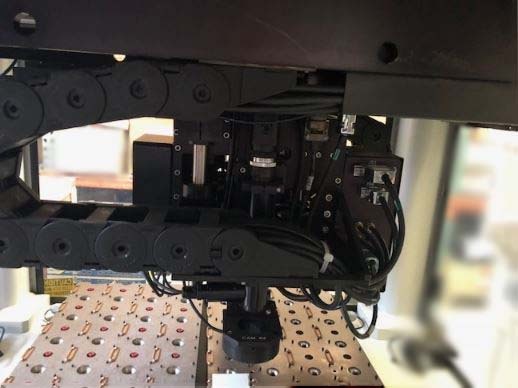

Inspection station with bottom mounted camera

Robotic assembly unit

PCB Pick and place boards

Brushless ball screw

Drive motor on Z Axis

3-Dual magnification IR camera with programmable lighting feeding

Single Control Unit (SCU)

Digital display

Power source

Card rack

Controller boards

Rack mount

2000 vintage.

MRSI 505 is a die attacher which forms an integral component of pick and place equipment used in a variety of electronic packaging and mounting applications. It is capable of accurately attaching dies ranging in size from 2 to 20mm at speeds of up to 1,400 parts per hour. 505 die attacher consists of a high vacuum pick up head and a heated die mounting platform. A dispenser deposits a specific volume of die attach material such as silver epoxy onto the surface of the mounting platform. An infrared heater then melts the epoxy, creating a textured flat. Next, the pick up head adheres to the die and holds it in place. The piece is then lowered onto the mounting platform and an ultra-sonic welder completes the attachment process. MRSI 505's accuracy and speed is ensured through the integrated control system. It allows the user to select an appropriate dispensing rate depending on the size and material of the die being attached. The system also includes a variety of safety features, including a die eject option to prevent potential mishaps during attachment. The controller also features a built-in process limit stop, which limits attachment cycle times and eliminates time-consuming manual adjustments when fine-tuning the cycle time. 505 is designed to be used with ROHS compliant die attach materials. Its compact design allows for easy integration into existing manufacturing systems. Furthermore, the intuitive operator interface provides user-friendly programming and easy adjustability of parameters from the front panel. Overall, MRSI 505 is a reliable, efficient die attacher that offers robust performance for longer life and improved productivity in a variety of pick and place operations. It is designed for optimal cost-effectiveness and reliability, making it an excellent choice for use in any die attachment application.

There are no reviews yet