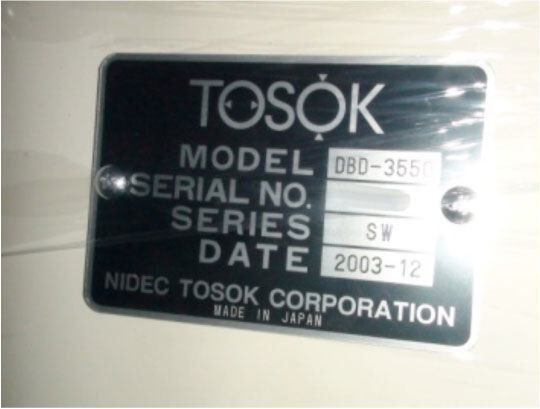

Used NIDEC TOSOK DBD-3550 SW Series #106015 for sale

URL successfully copied!

Tap to zoom

ID: 106015

Wafer Size: 8"

Vintage: 2003

Die attach machine, 8"

Bonding Method: Solder

Chip Size: 1.0mm - 6.0mm

Bonding Accuracy: XY = ±50 um, Θ±3° (Depends on chip size)

Bonding Weight: 80gf ~ 200gf (Digital setting)

Lead frame: Strip type lead frame. D-PAK, TO-126, TO-202, TO-220, TO-3P

Lead frame Length: 6"-10", Width: 15mm - 70mm

Machine Cycle Time: 0.6 sec./chip (depend on bonding condition)

Index Method: Pin Indexing

Loader: Vacuum stacker / Magazine stacker

Unloader: Magazine stacker (8 Magazines)

Dimensions: 1,900(W) x 1,245(D) x 1,680(H)mm Excludes signal tower

Weight: 1,200 kg (approx.)

Power : AC100 - 200V±10% ,50/60 Hz

Vacuum: -0.07 Mpa Over

N2 Gas: 0.2 Mpa Over

Forming gas: 0.2 Mpa Over

Air: 0.5 Mpa Over

Operation: Windows NT Touch-screen

2003 vintage.

NIDEC TOSOK DBD-3550 SW Series is a high-performance die attacher that is designed to effectively and accurately attach small devices, such as memory chips, on substrates. This die attacher uses advanced vision systems, vacuum-based pick-and-place technology and advanced motion control systems to ensure excellent accuracy and efficiency. The machine can be configured with three to five devices per substrate in up to six different kinds of substrates. It has a large load and unload area for handling large substrates, and a high-speed pick-and-place mechanism that can handle up to 30 devices at once. Its vision equipment has an RGB color sensor with a camera resolution of 1280 x 1024 pixels and a 5-micrometer accuracy in standard operating conditions. It also has an optional dual alignment station to enable high-accuracy die placement. DBD-3550 SW Series has an easy-to-use operator interface with intuitive controls and an automatic monitoring system that can detect any potential issues in its operation. It also has a safety feature that immediately shuts off the unit if any malfunction occurs. It has a built-in diagnostic machine which allows the operator to quickly identify any problems in the performance of the tool. The machine is designed for ease-of-use and fast production by minimizing setup time and minimizing fatigue. It has excellent repeatability, with a high-precision die placement repeatability of 0.0002". In addition, the machine is equipped with an advanced high resistance to shock and vibration, and an integrated inspection asset for quality assurance. This ensures that the devices are placed accurately and securely. Overall, NIDEC TOSOK DBD-3550 SW Series is a robust and reliable die attacher that provides excellent accuracy and efficiency for the placement of small devices on substrates. It has advanced features designed to reduce setup times and improve production efficiency, as well as safety features to ensure its operation is safe and hassle-free. With its range of features, excellent performance and robust construction, DBD-3550 SW Series is a great option for automated die placement of small devices.

There are no reviews yet