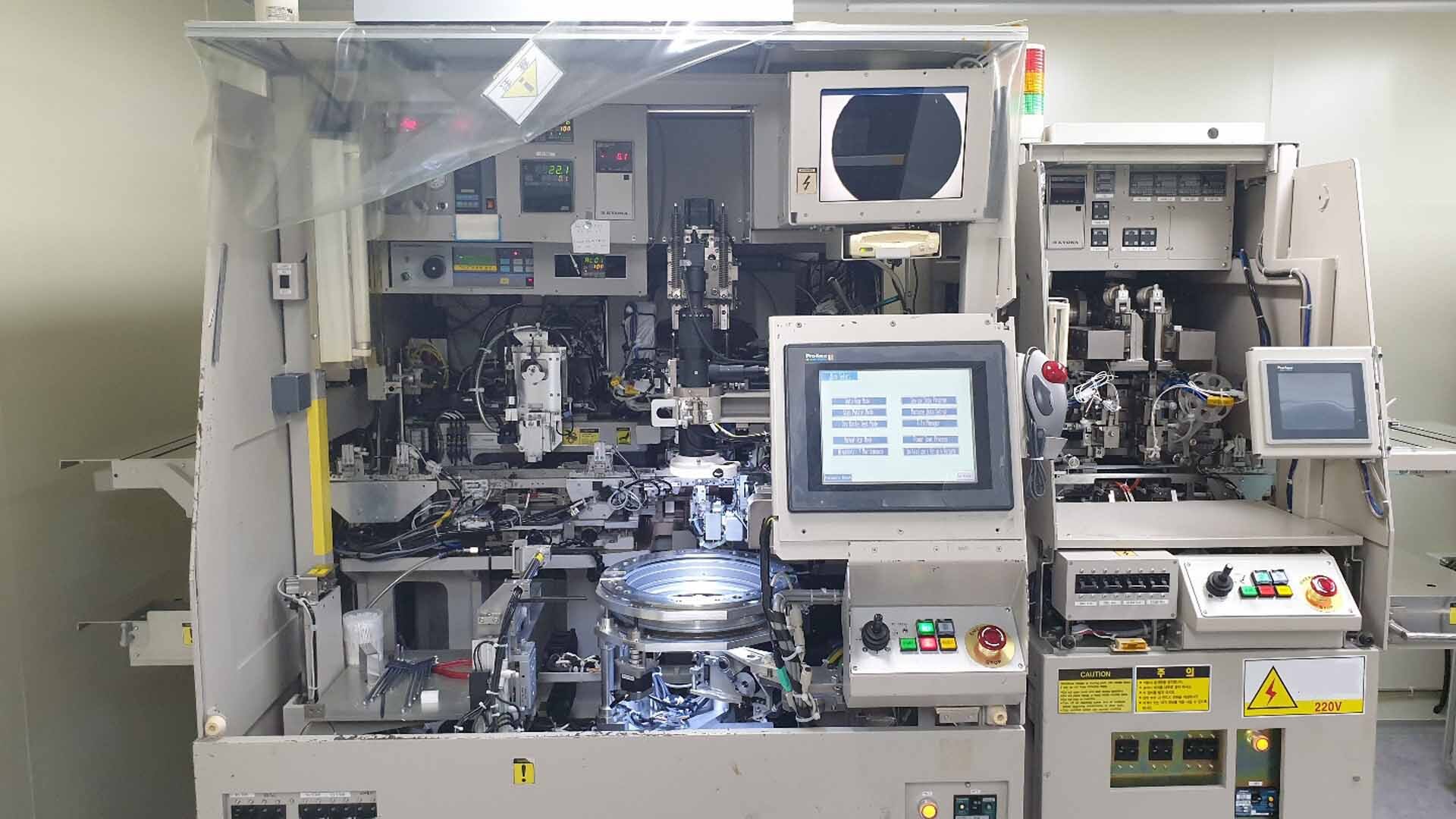

Used SHIBAURA TFC-FB1C #9379882 for sale

URL successfully copied!

Tap to zoom

ID: 9379882

Vintage: 2003

Flip chip bonders

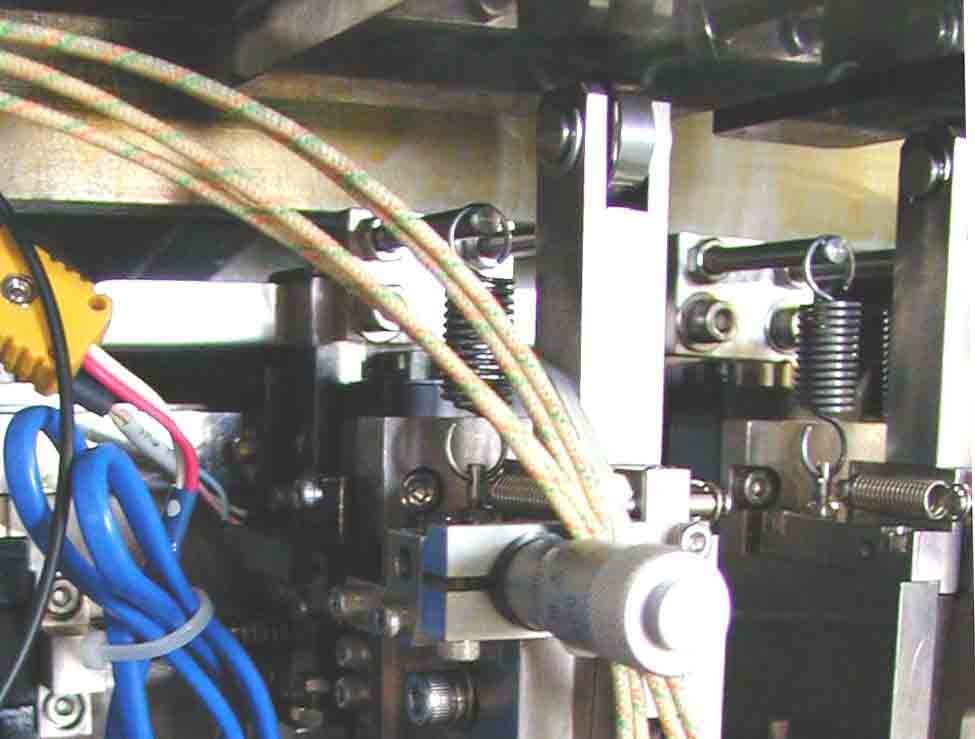

Bonding accuracy: 10~490 N

Accuracy load: Multi stage control

High parallelism:

Individual backup stage

Pressurization part

Tool part separation system

Versatility: (4) Units, (8) heads

Easy operation: Color touch panel

Signal tower

Front cover

Switch panel

Driver box

Controller box

Touch screen

Unloader

Main power switch

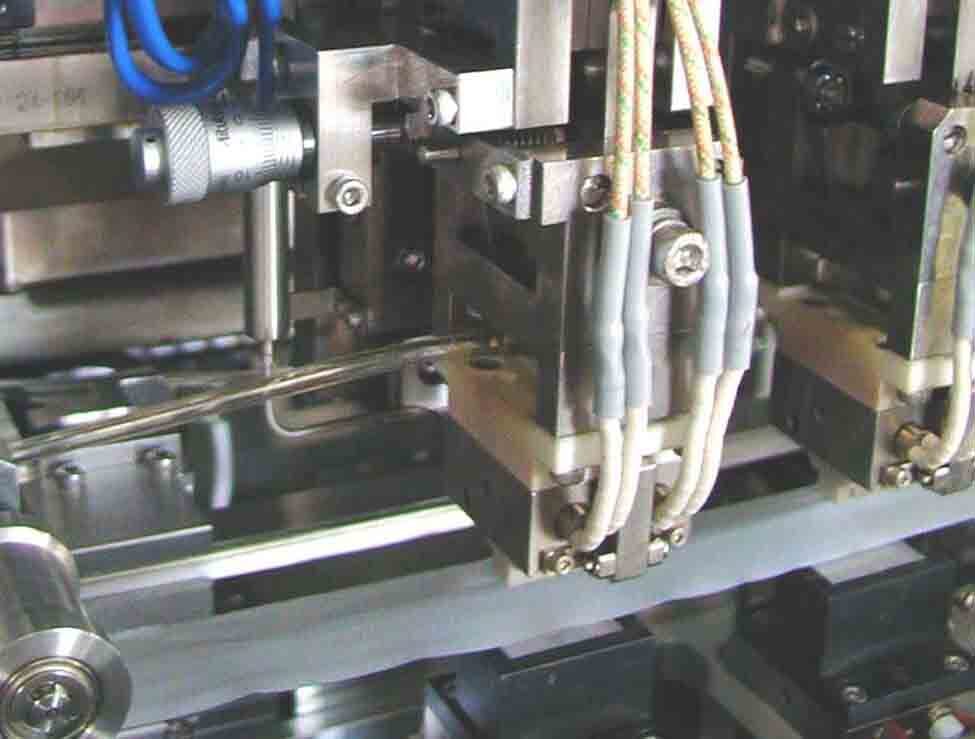

Bonding head: Left and right

Indexer

Bonding stage: Left and right

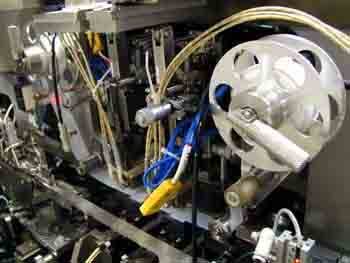

Teflon tape supply machine

Substrate feeder

New magazine input tray

Magazine supply pusher

Magazine elevator

Discharge magazine output tray

Pressure sensor:

Positive pressure / Base

Negative pressure / Base

Temperature controller: Left and right

Load cell amp:

Left head

Right head

MO Driver

Operation panel:

Touch panel

Switch panel

Signal tower

Flicker buzzer

Sensors:

Cover sensor

Air pressure

Vacuum pressure

Light

Air unit

Power supply: AC, 200/220V, ±10%, 3 Phase, 50/60 Hz

Power consumption: 2 kVA

Compressed dry air: 0.5 MPa (150 liter / min)

Vacuum: Over -80 kPa (100 liter / min)

2003 vintage.

SHIBAURA TFC-FB1C is an automated die attacher, specifically designed for use in die attach processes in the electronics industry. It is an advanced piece of machinery composed of intricate components, engineered with precision to complete complex tasks quickly and accurately. TFC-FB1C uses a camera-based equipment to accurately detect and pick die from the reel and place them onto the mounting surface accurately. It features a belt-driven motor system for smooth and precise positioning and transport of the die. The large work space allows for easy and efficient handling of die sizes ranging from 0.2mm up to 3.2mm in thickness, as well as die sizes between 20mm up to 300mm in length. The unit is also capable of accommodating die heights between 0.3mm up to 5.0mm. SHIBAURA TFC-FB1C is equipped with a sensitive vision machine with 2X and 3X digital zoom capabilities. It also features a stereo vision tool with up to 0.1 micron accuracy that allows for precise placement and alignment of the die. The asset is highly accurate and optimized for fast operation with minimal reject rate. It also includes a nozzle-mounted camera for monitoring of solder quality and prevent solder bridging. The control model of TFC-FB1C is composed of a touch panel and a PLC controller. The touch panel allows for easy adjustment and operation of the equipment, as well as monitoring of various machine parameters and data logging. This digital user interface also makes troubleshooting easier and faster. The PLC controller provides enhanced system stability, reliability and accuracy by providing accurate control of all components in the unit. SHIBAURA TFC-FB1C is a compact, flexible and easy to use die attacher designed to provide quick and accurate die placement in the electronics industry. It features a precise vision machine with digital zoom, stereo vision, and a nozzle-mounted camera to maximize accuracy and prevent solder bridging. Its PLC control tool provides enhanced asset stability, allowing for efficient, reliable operation. Whether you're in need of quick and accurate die placement or a reliable piece of machinery, TFC-FB1C is an excellent choice.

There are no reviews yet