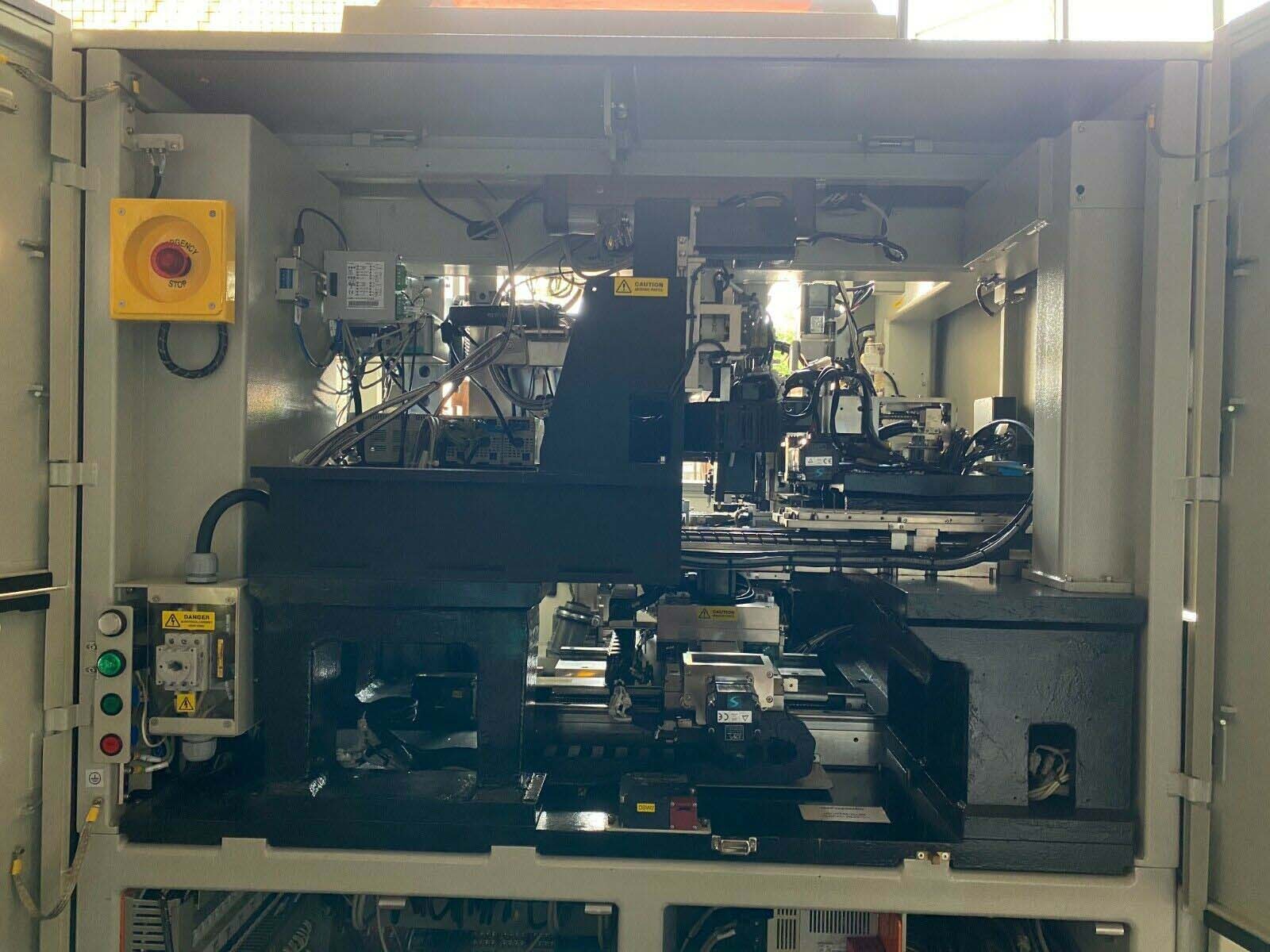

Used STI Isort #9378022 for sale

URL successfully copied!

Tap to zoom

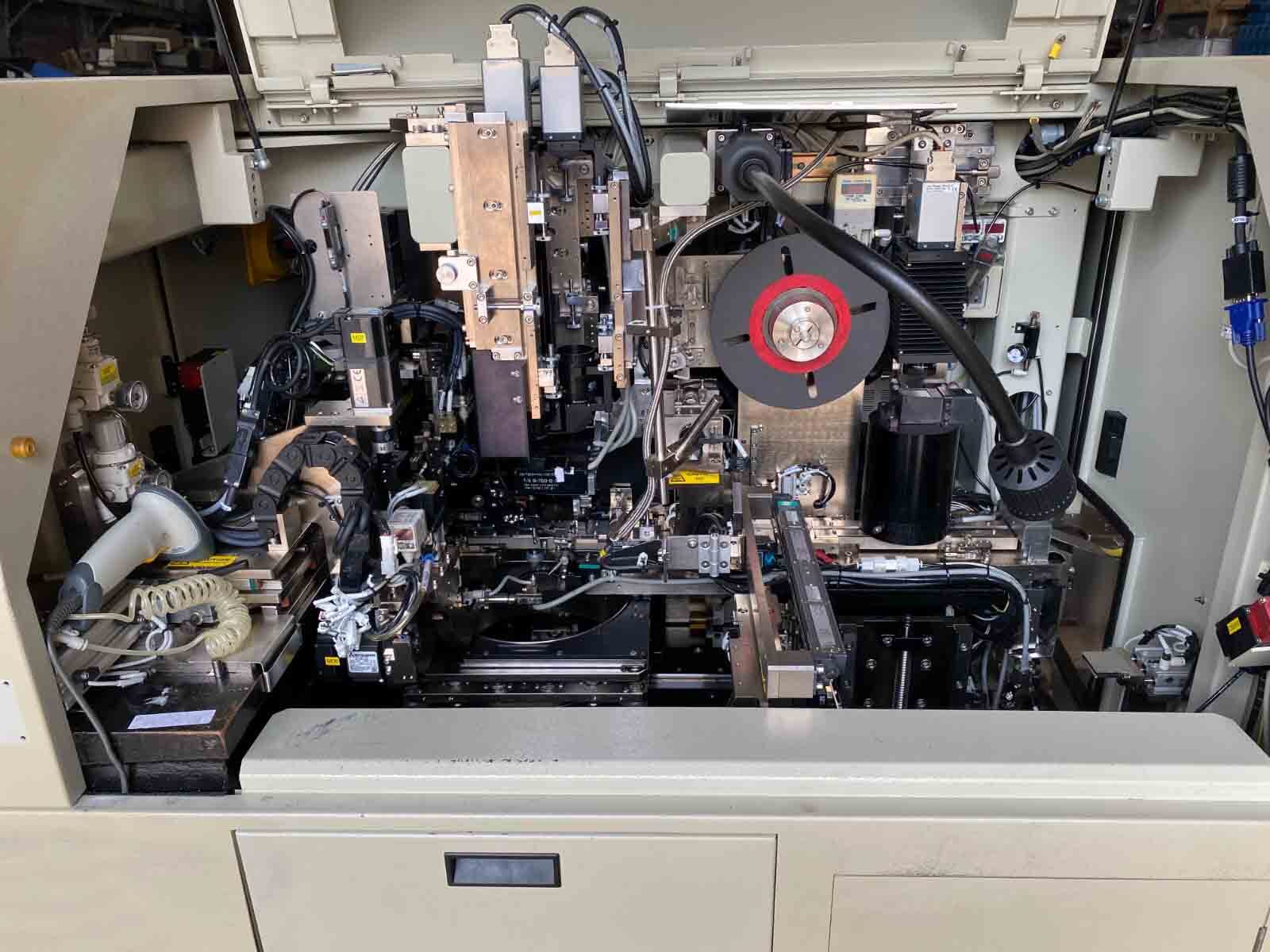

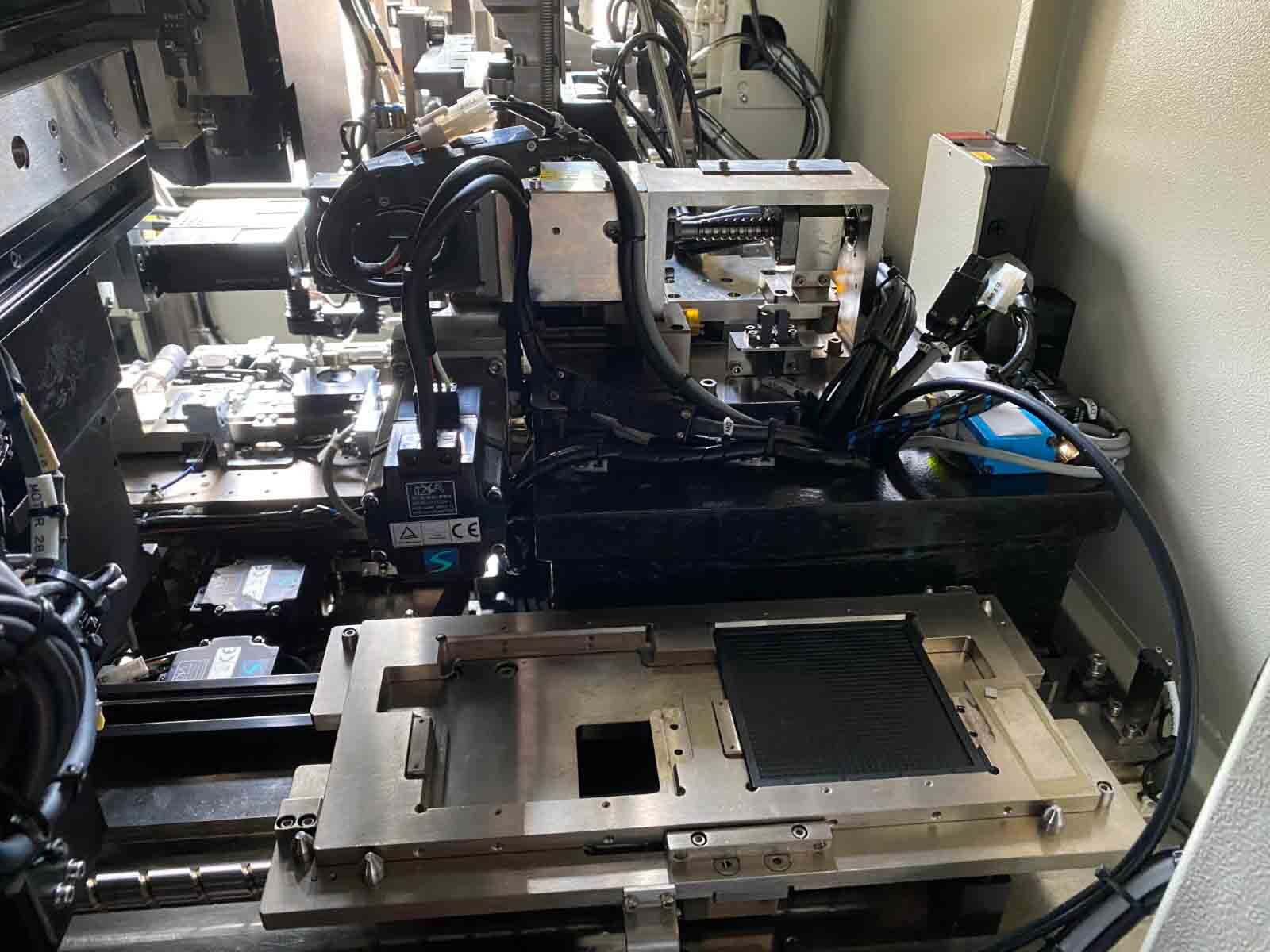

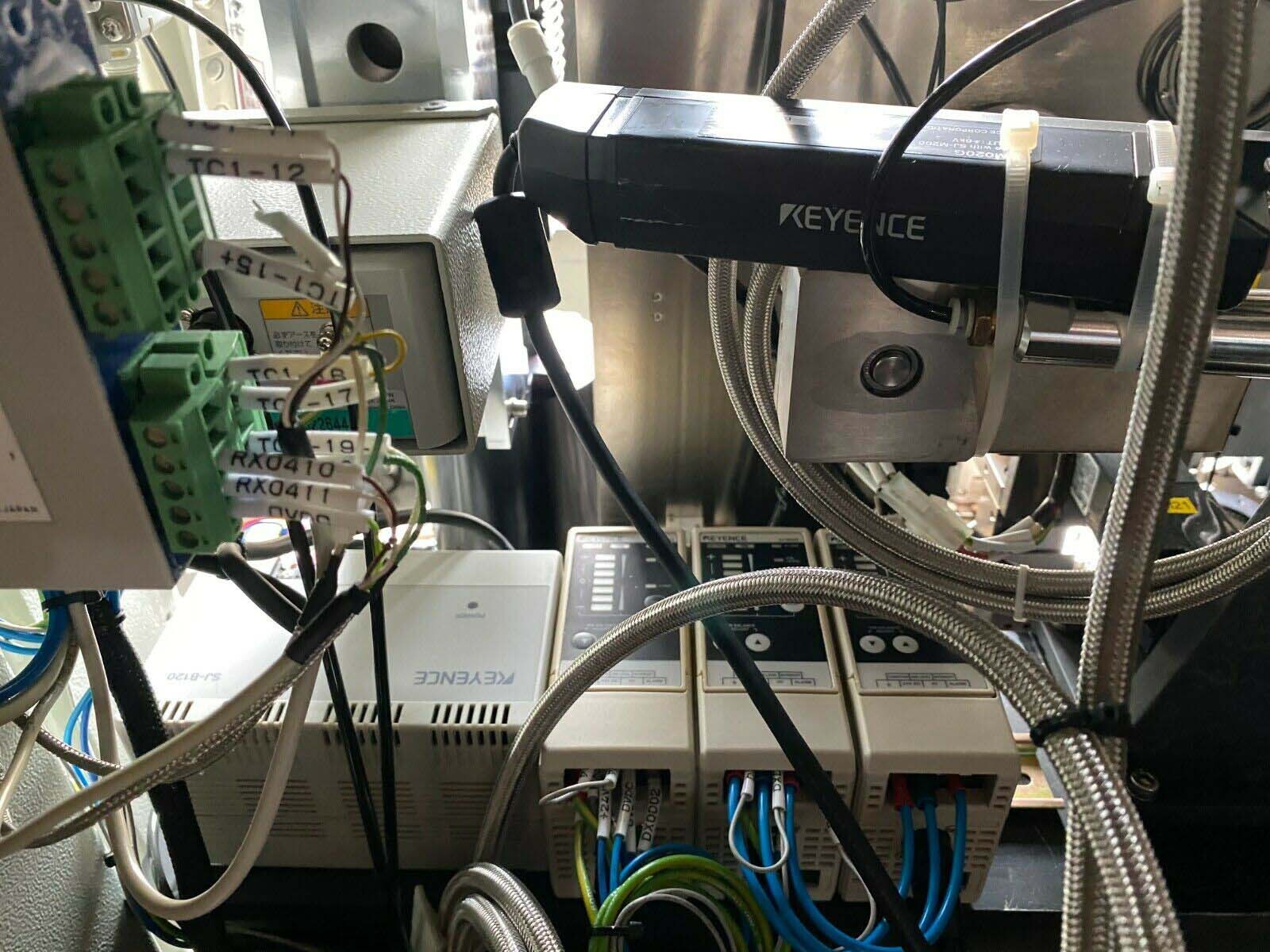

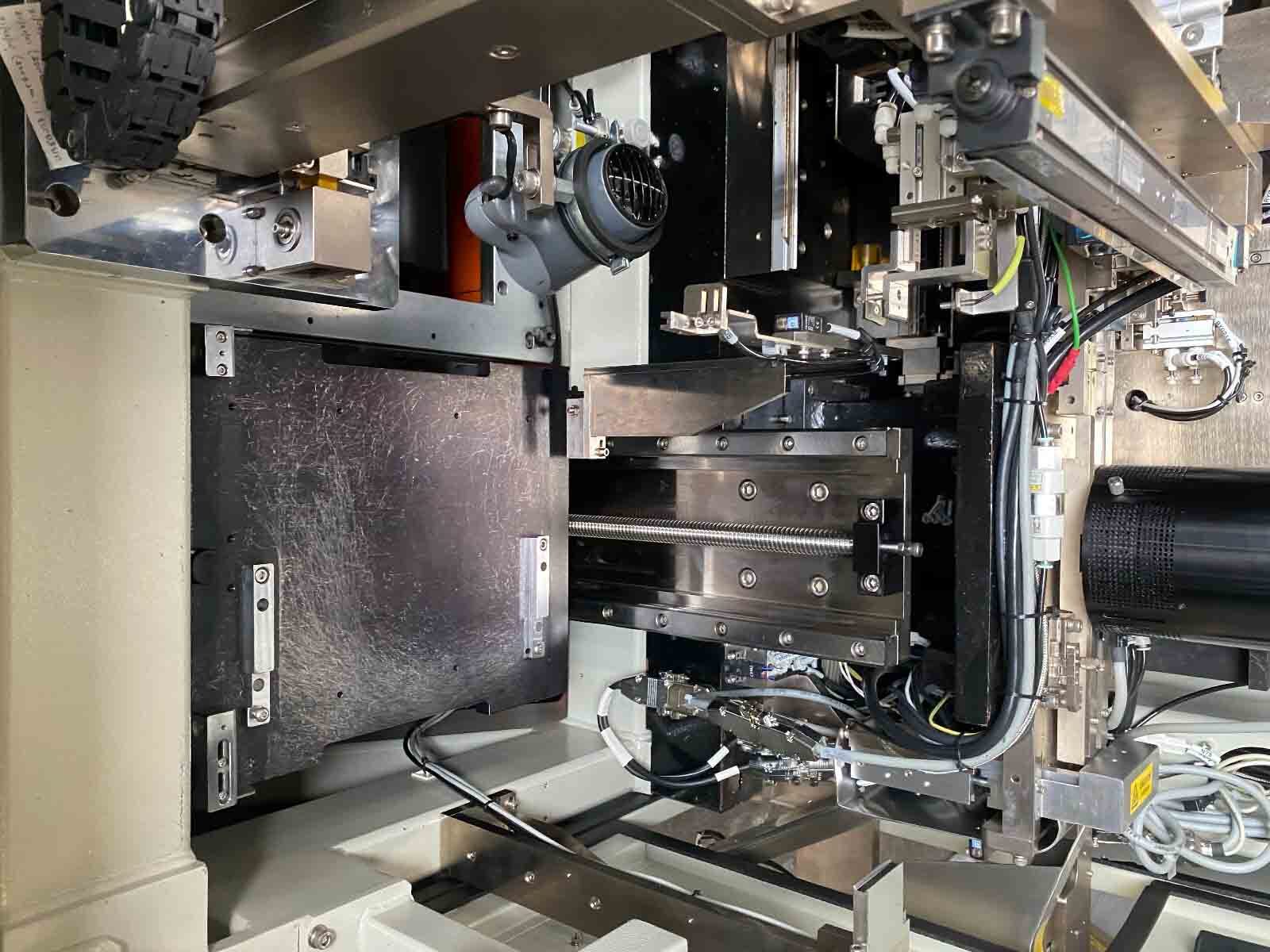

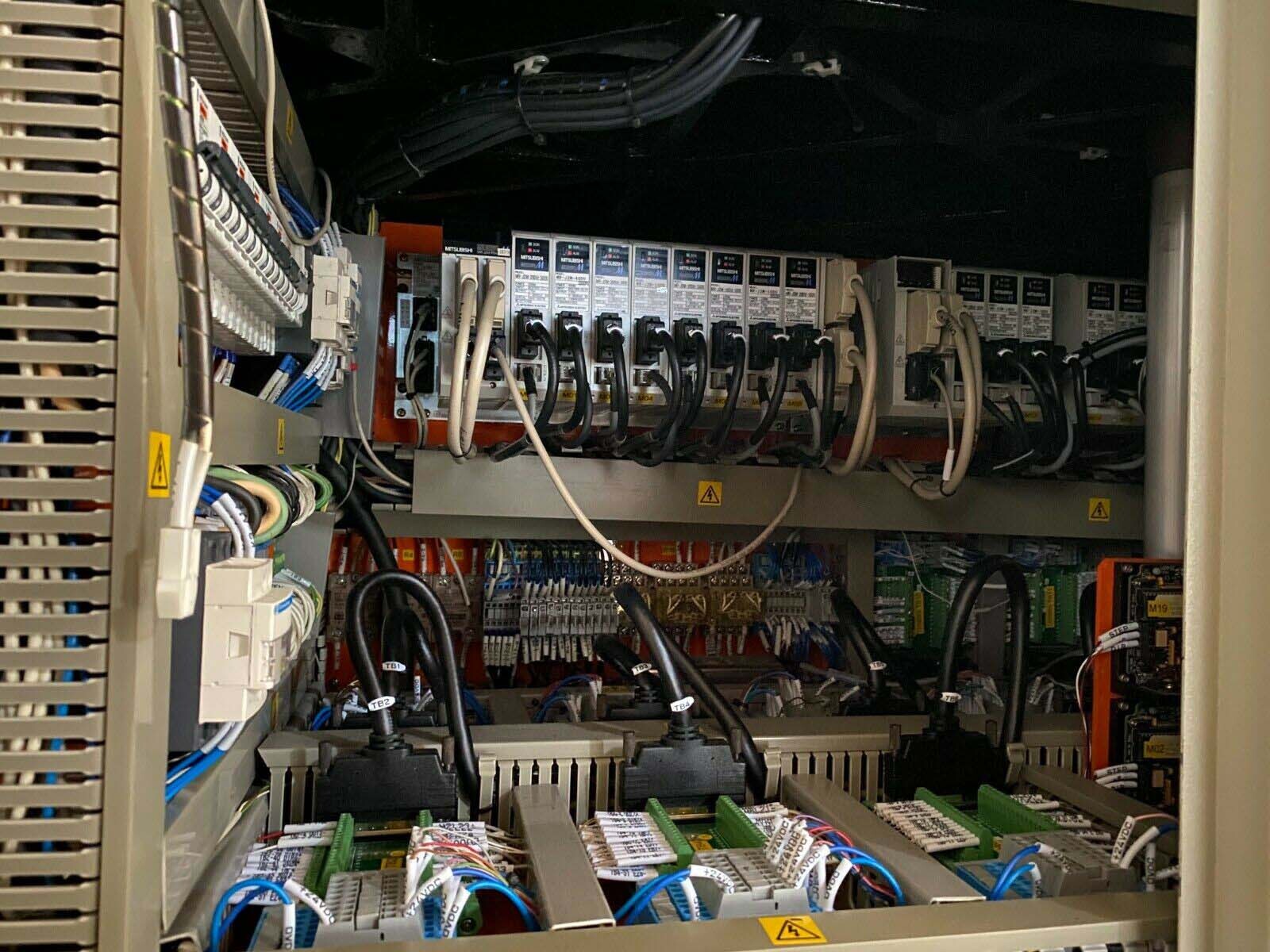

STI Isort is a modern, PC-based board assembly and manufacturing equipment designed to streamline and simplify surface mount and through-hole board assembly processes. It is designed to bring greater accuracy, speed and efficiency to the manufacturing of printed circuit boards. The system is composed of several components. The major components include a software manager, data capture module, main controller, real-time robot, and printing stage. The software manager provides the user with an intuitive graphical user interface. The data capture module is responsible for capturing board assembly data in real time and transmitting it to the main controller. The main controller then transmits the data to the real-time robot, which then positions the board for the printing stage, where it is printed with components in their precise location. The software manager enables the user to enter component information such as type, position, and size. This data is then transmitted to the main controller. The main controller then processes the data, and transmits it to the robot for manipulation and positioning of the board. Once in place, the printing stage prints the board with components in their specified positions. After the board is printed, the robot moves on to the next board. The unit is designed to be highly flexible, allowing the user to adjust settings to improve efficiency and accuracy. The user has the ability to customize features for their particular needs. The software manager also offers features such as batch processing, part ID printing, and pick and place simulation. The overall machine provides an efficient, automated solution for board assembly and manufacturing. It is designed to improve accuracy, reduce production costs, and reduce the amount of time it takes to assemble boards. The tool can also be used to assemble complicated boards that require multiple levels of components, as well as single-level boards. STI I-SORT asset is a powerful tool, which can drastically increase production throughput and accuracy in board assembly and manufacturing. It offers great flexibility and control, enabling the user to customize settings to their particular needs. This is an excellent solution for companies looking to increase their production process.

There are no reviews yet