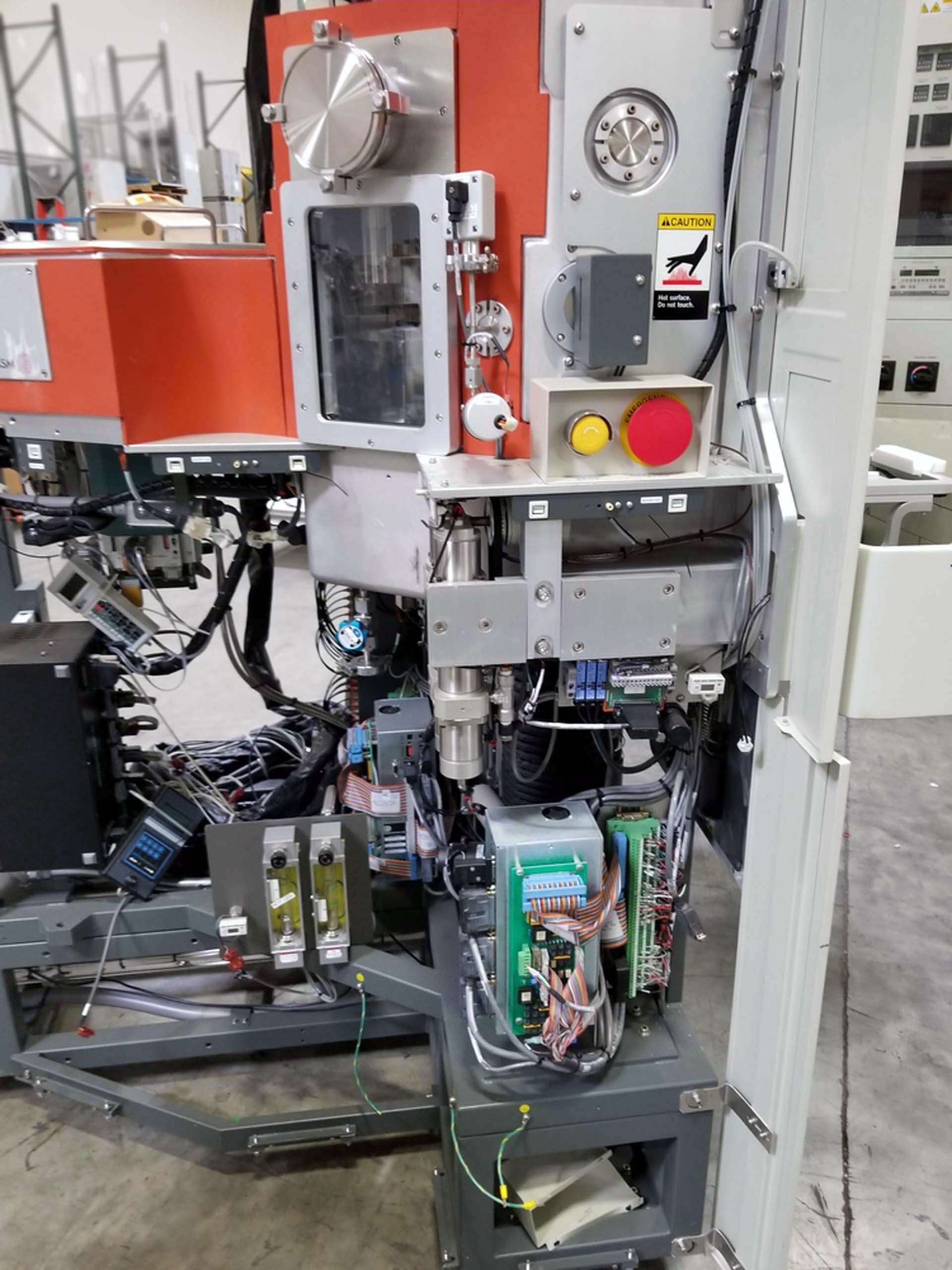

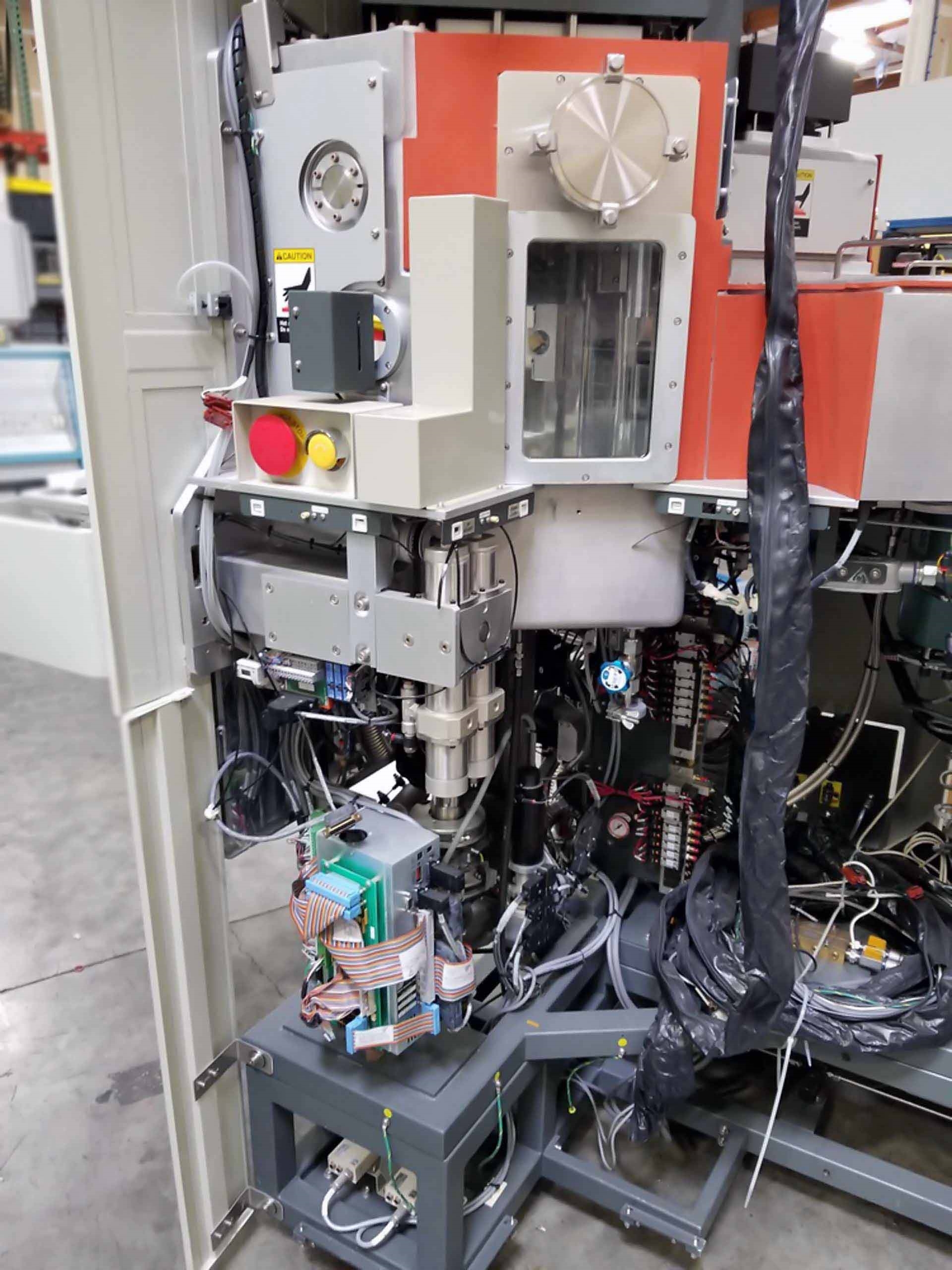

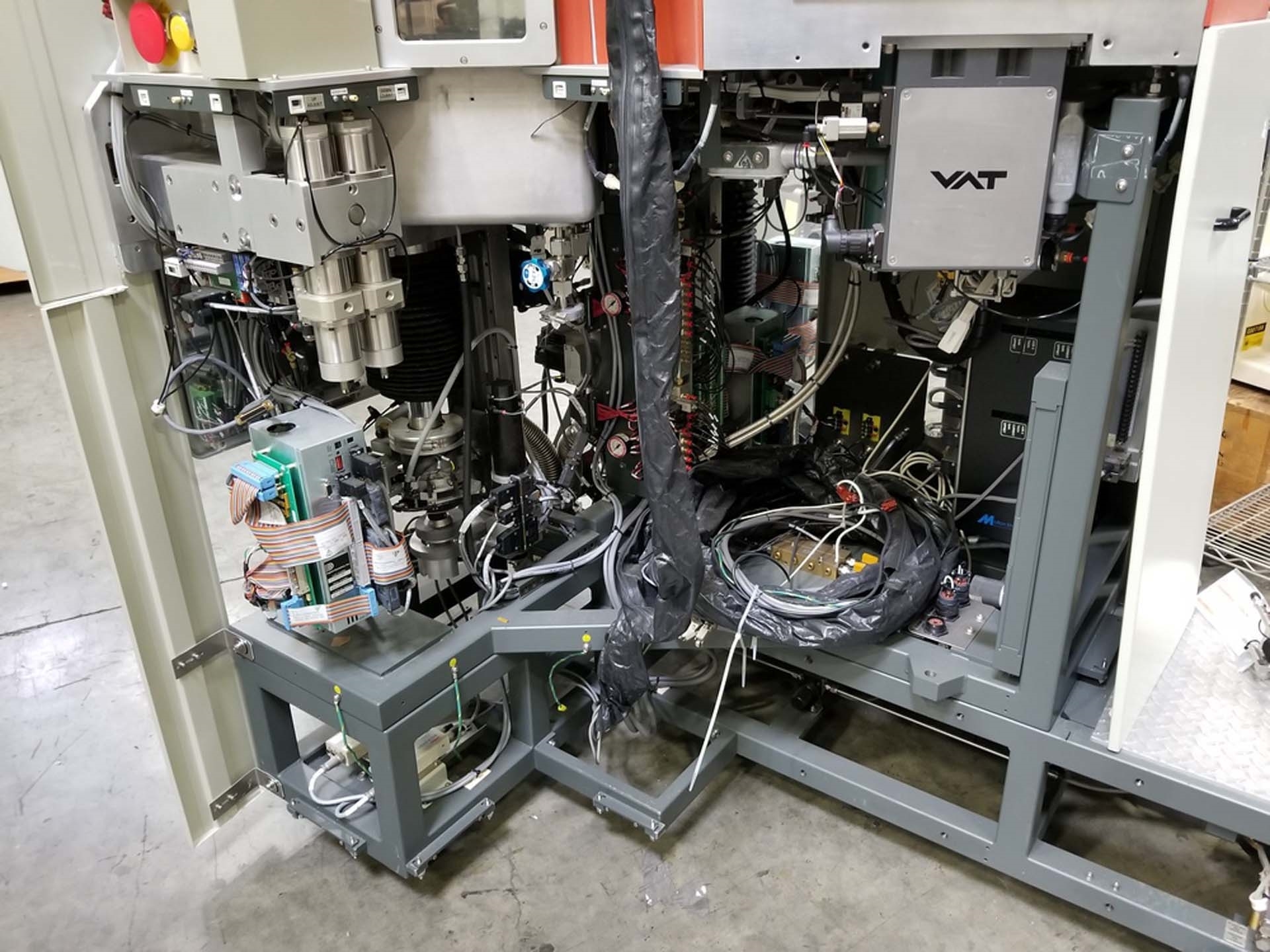

Used ASM A600 UHV-CP #9239202 for sale

URL successfully copied!

Tap to zoom

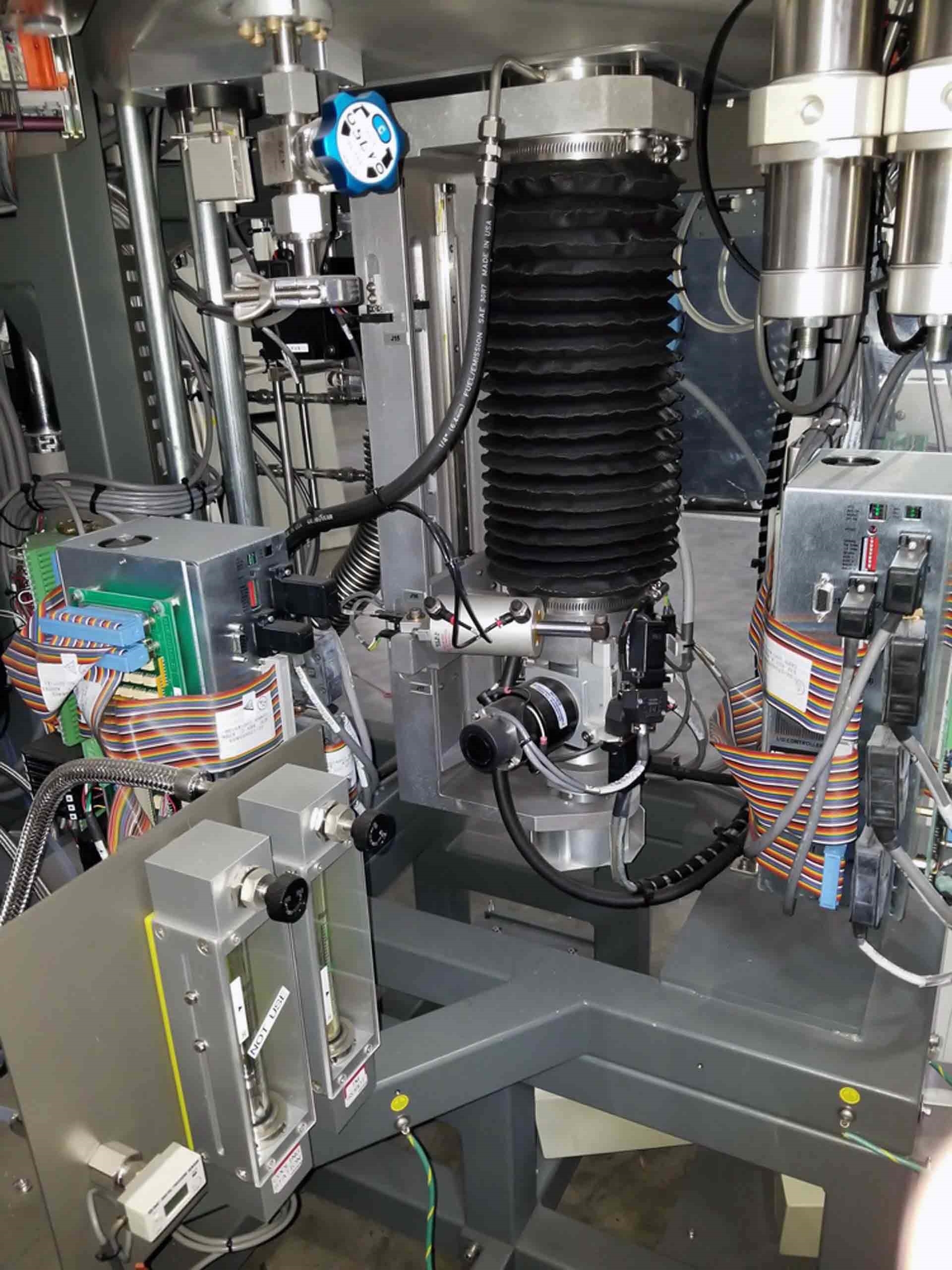

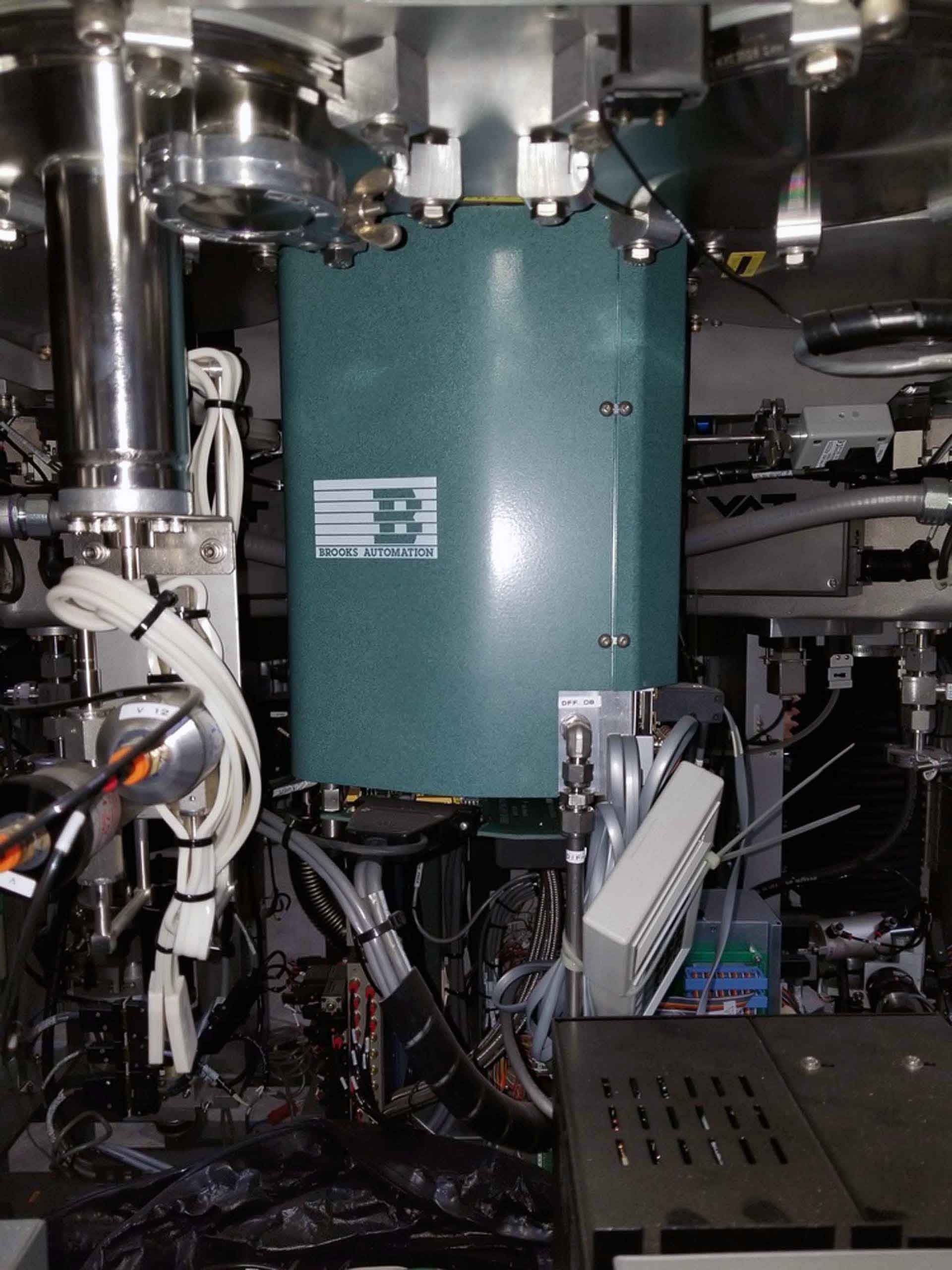

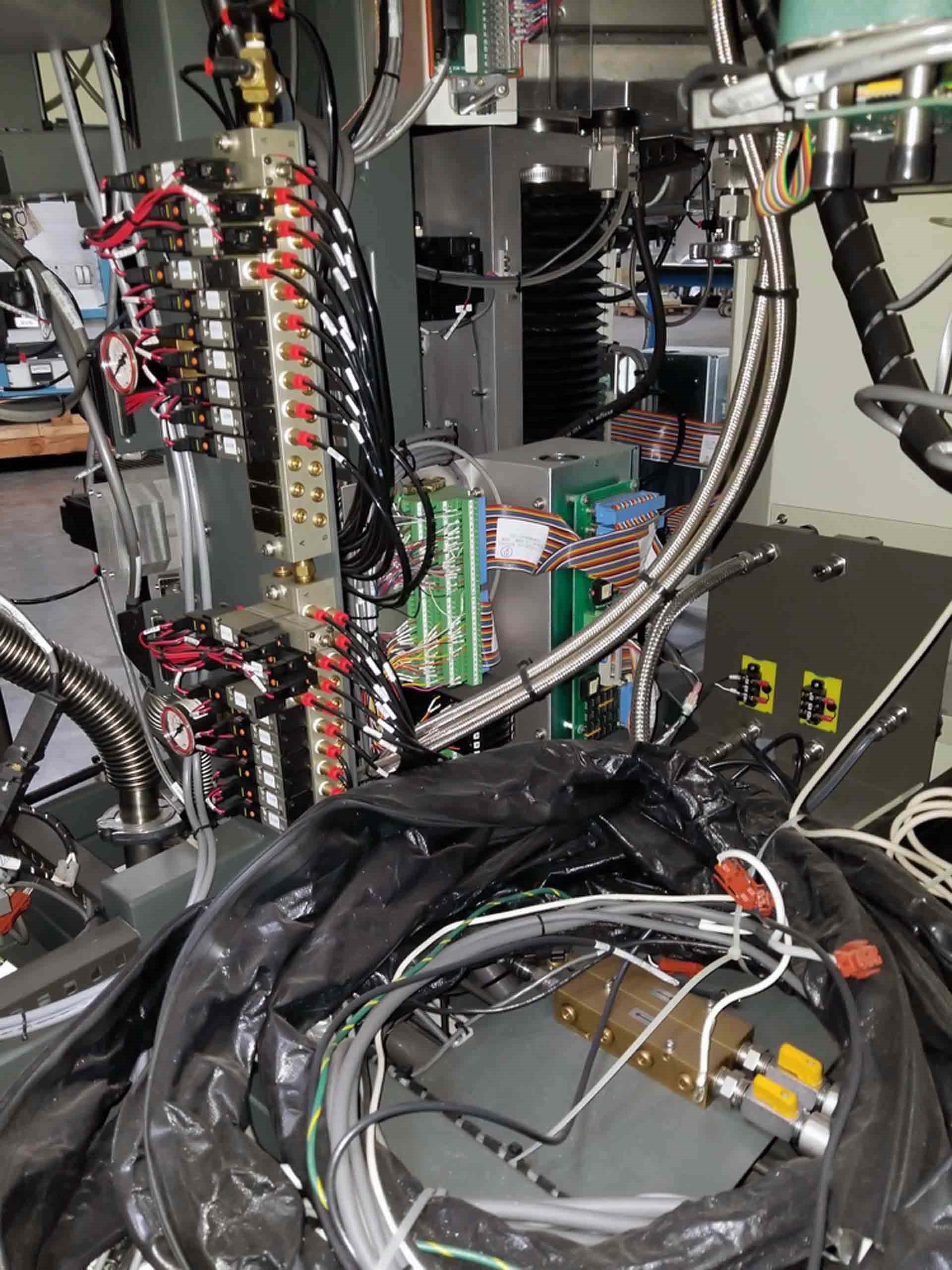

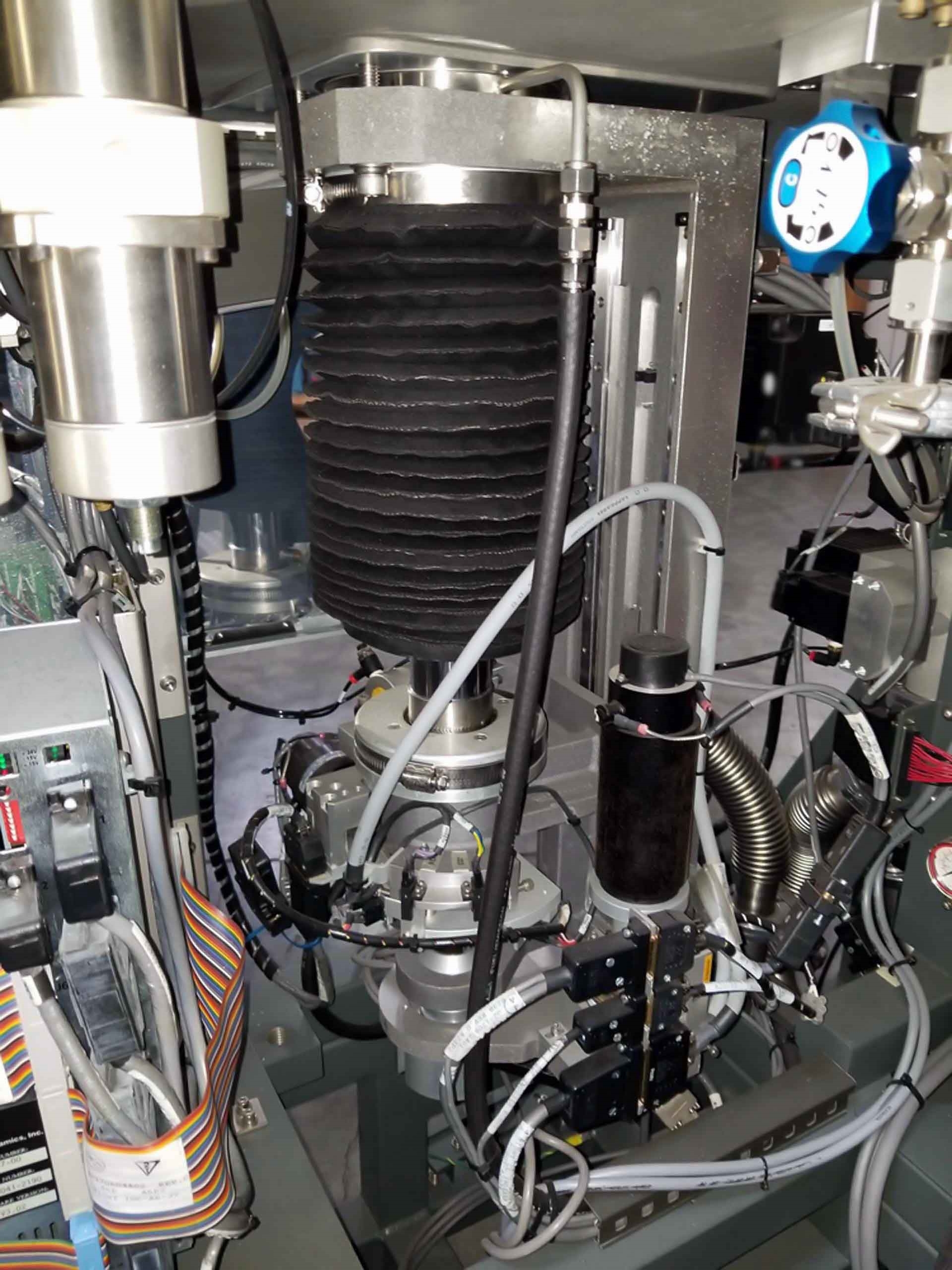

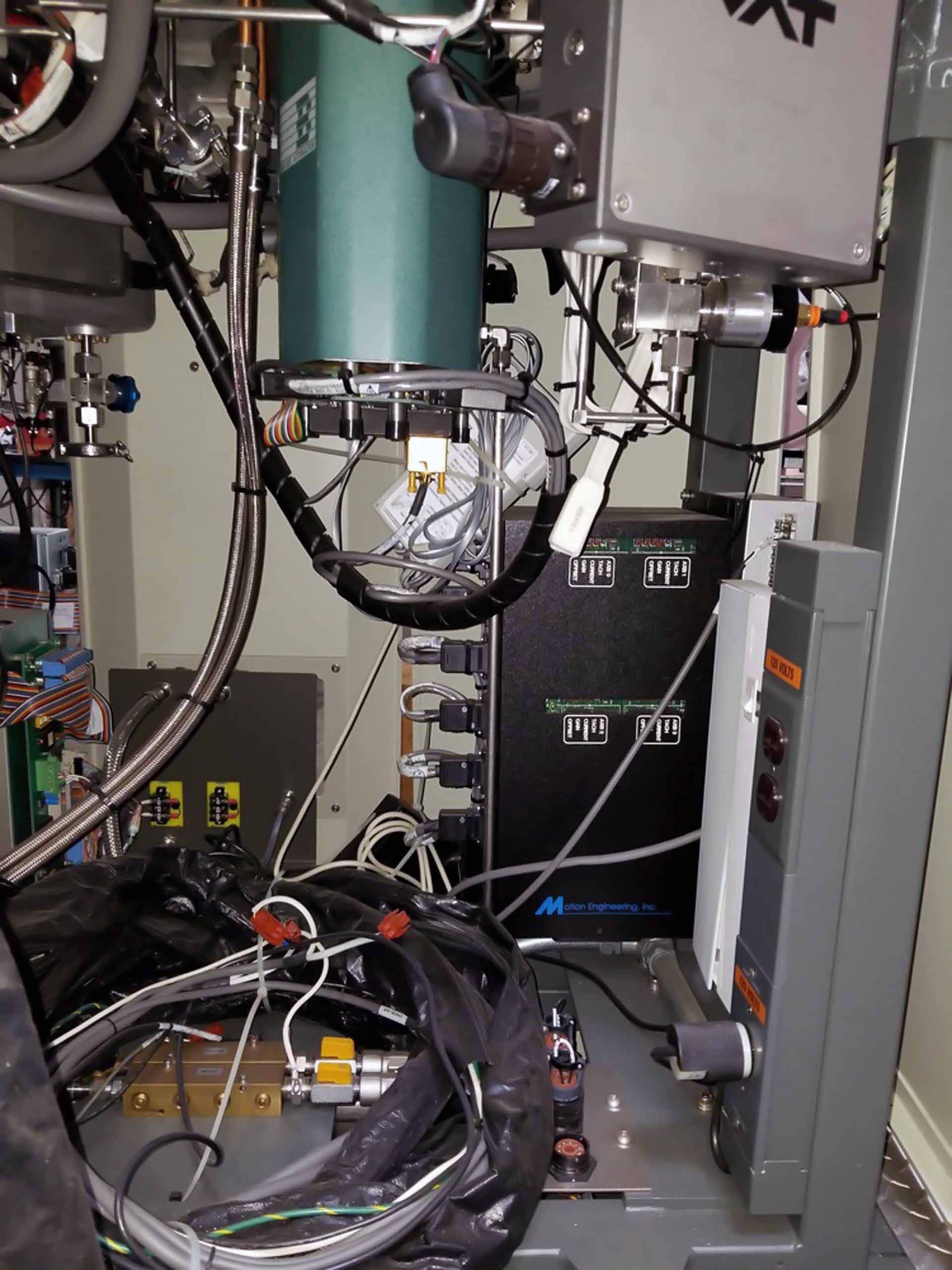

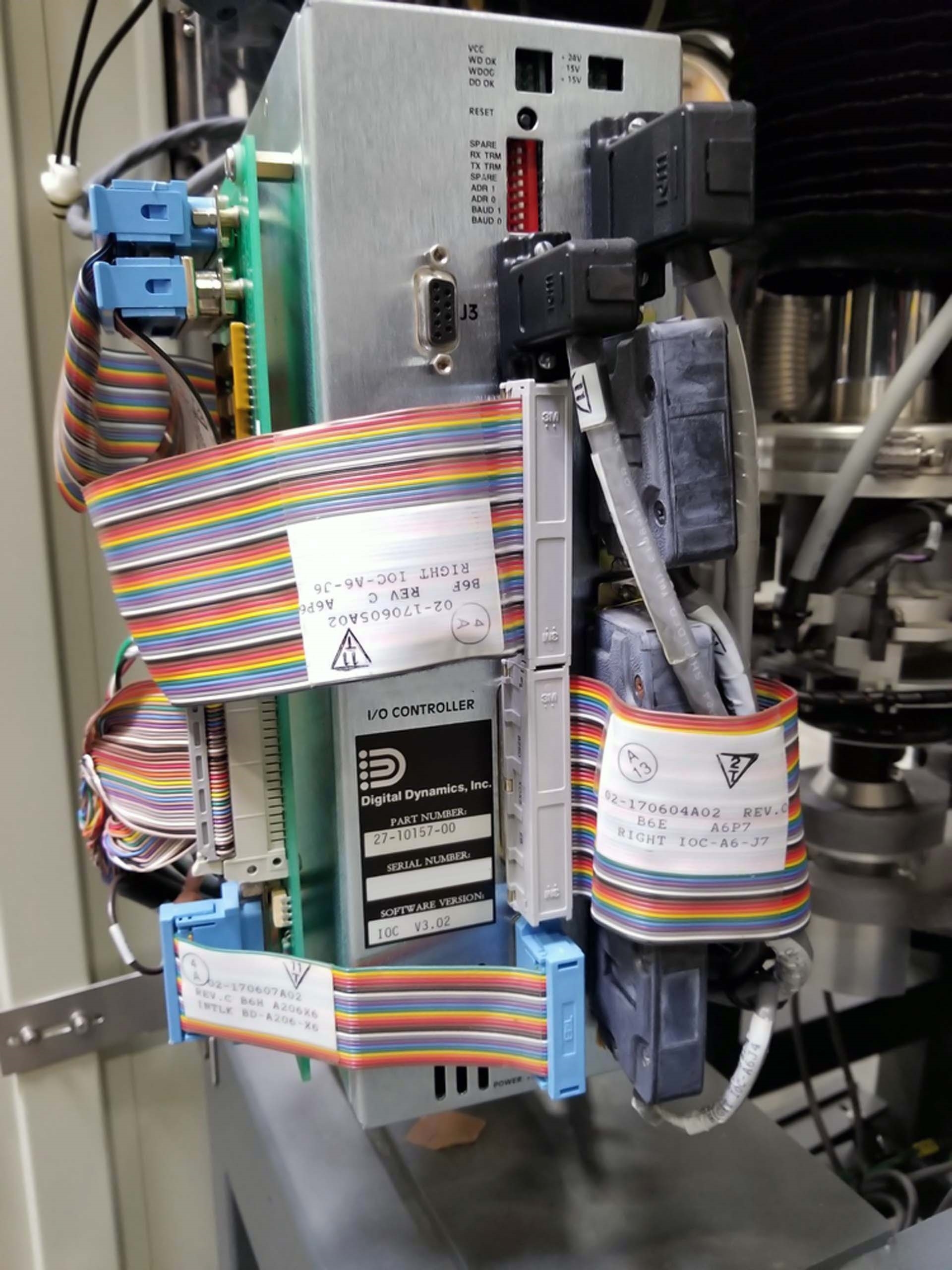

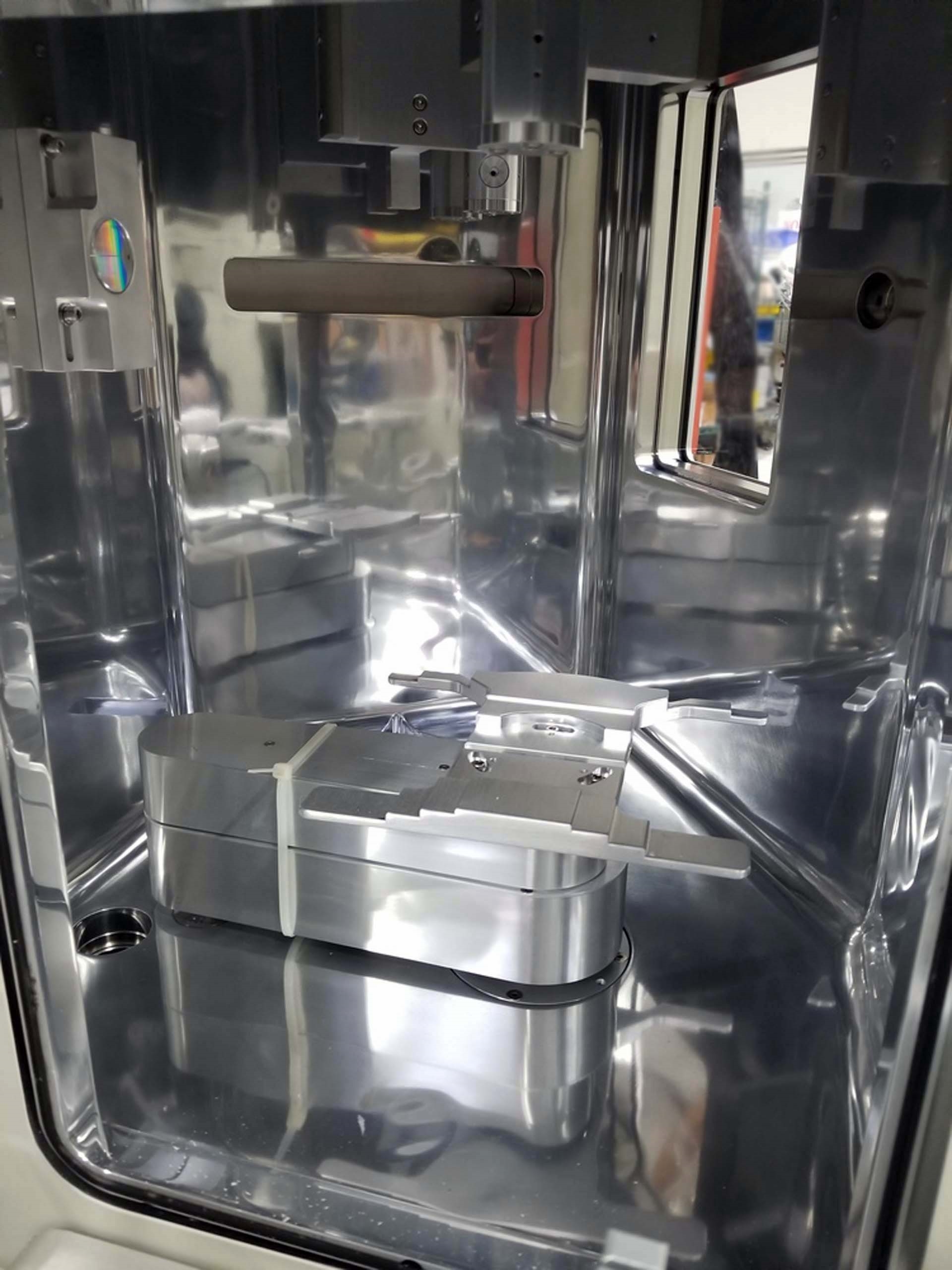

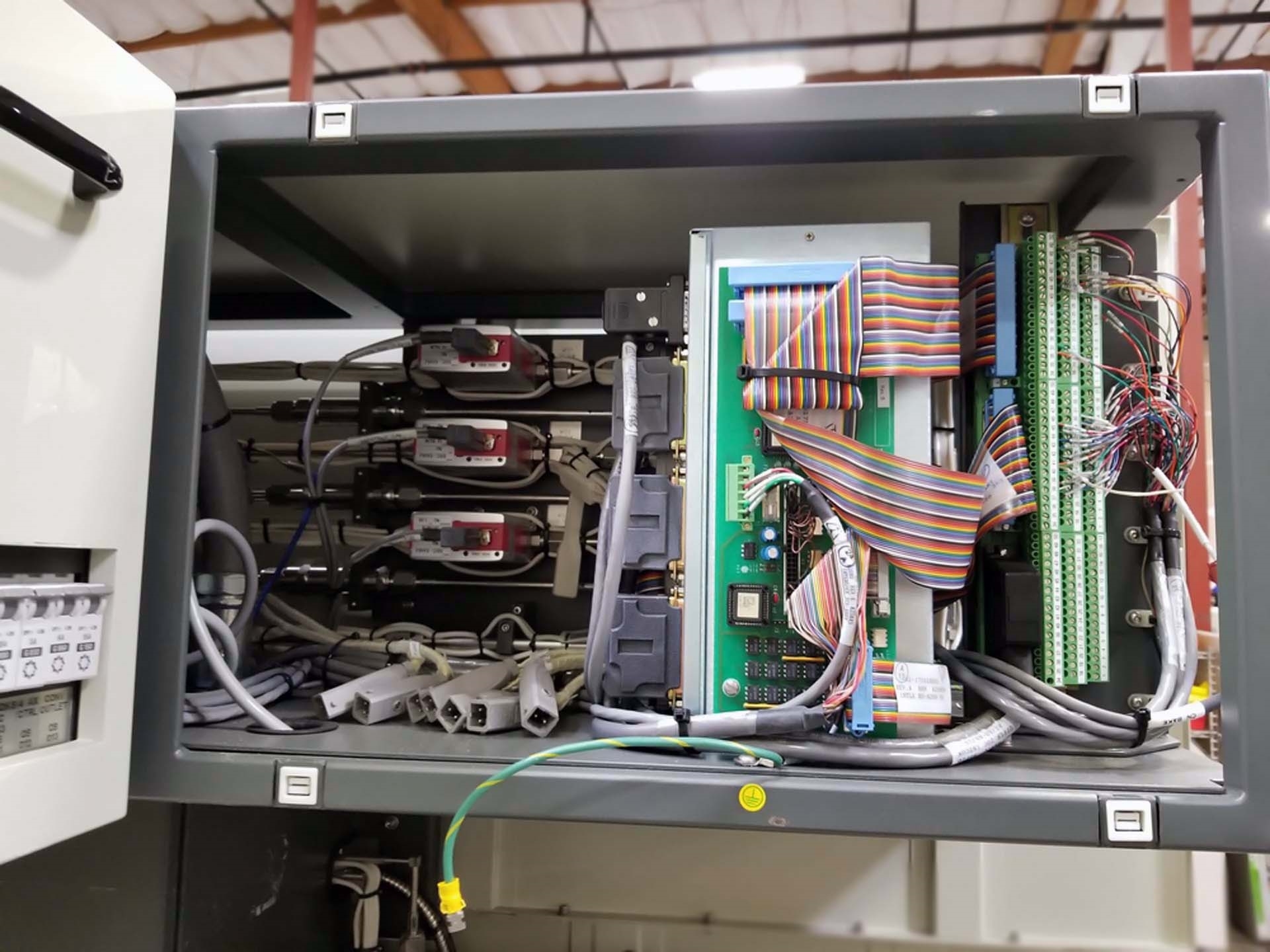

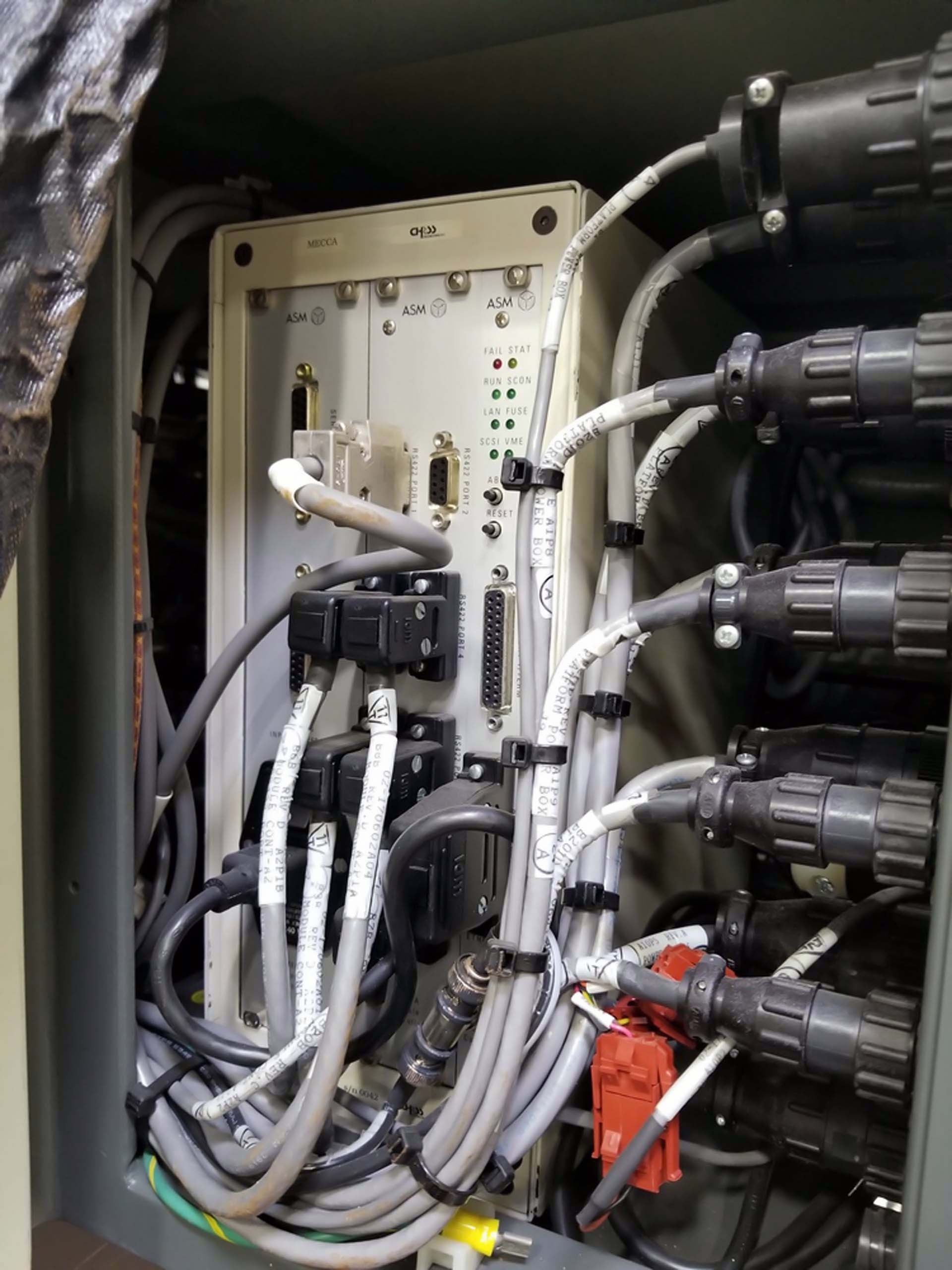

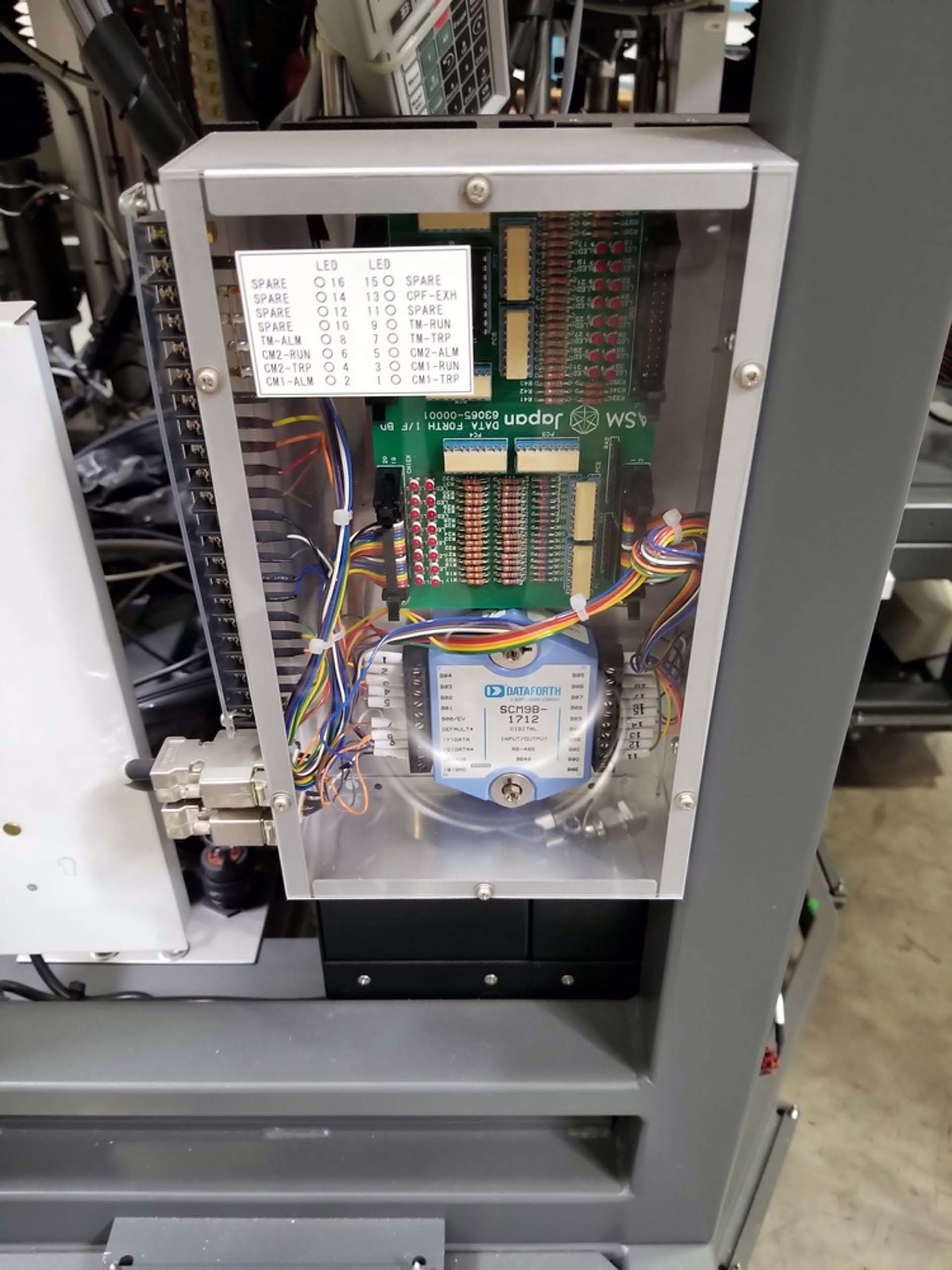

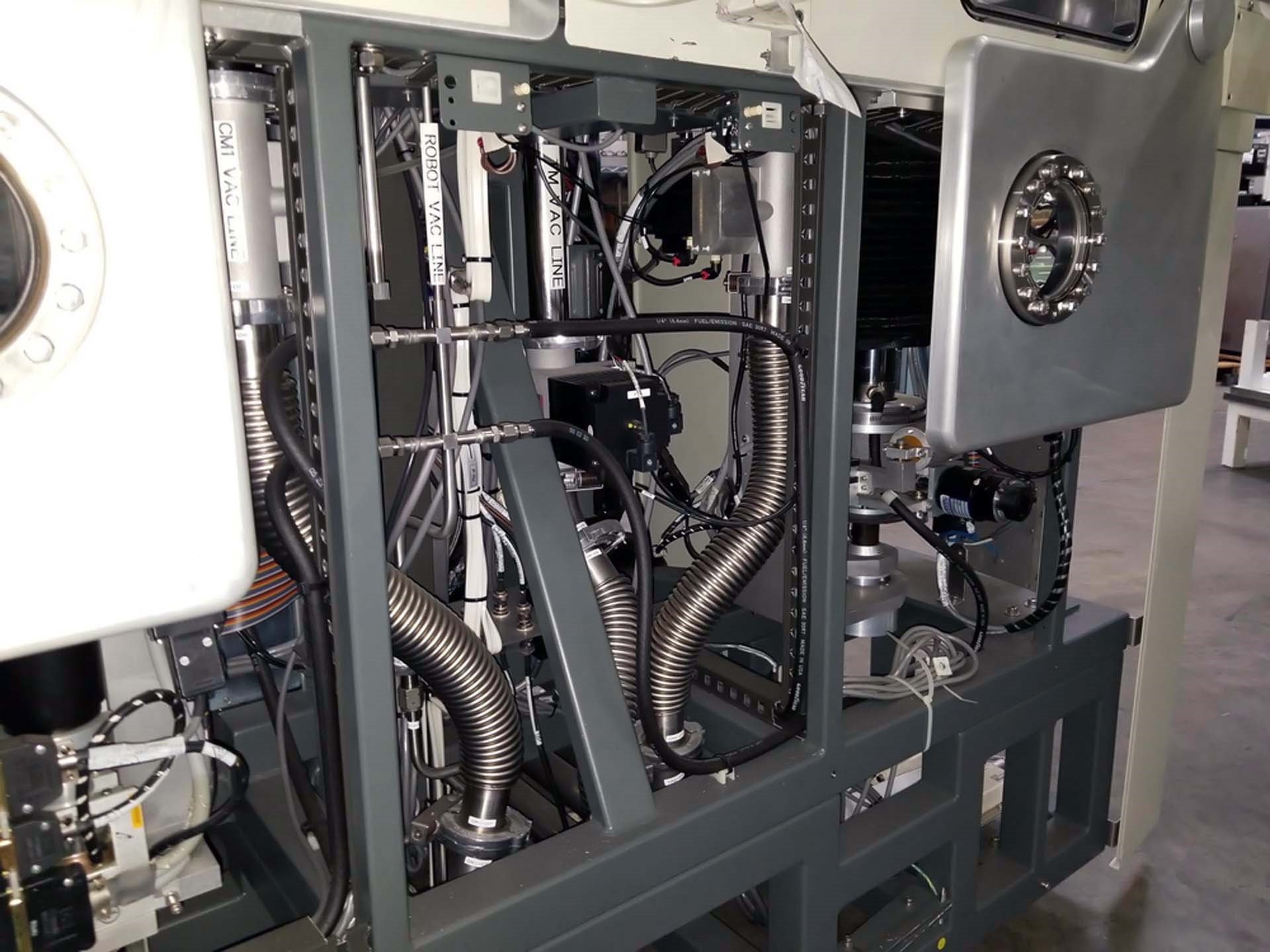

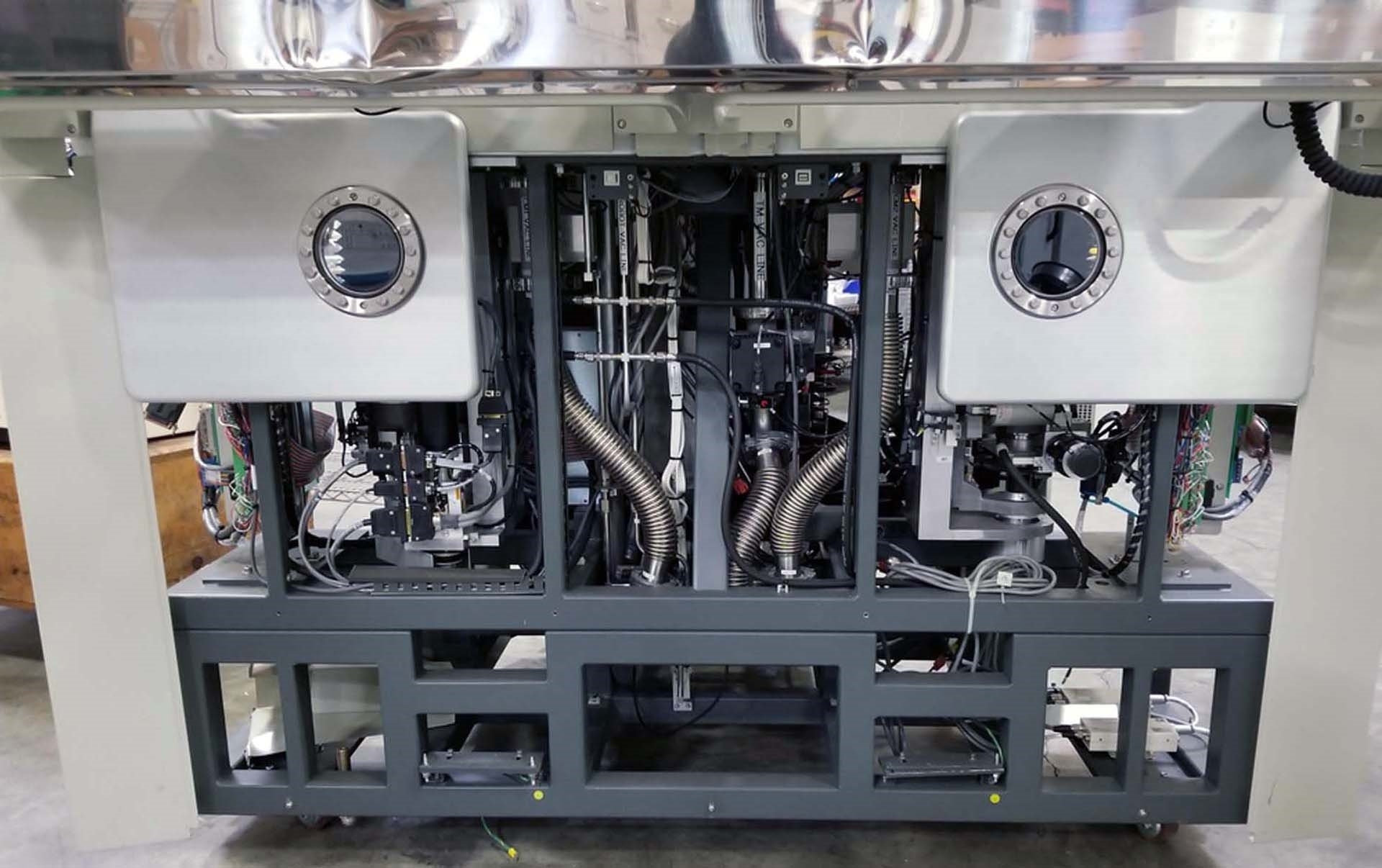

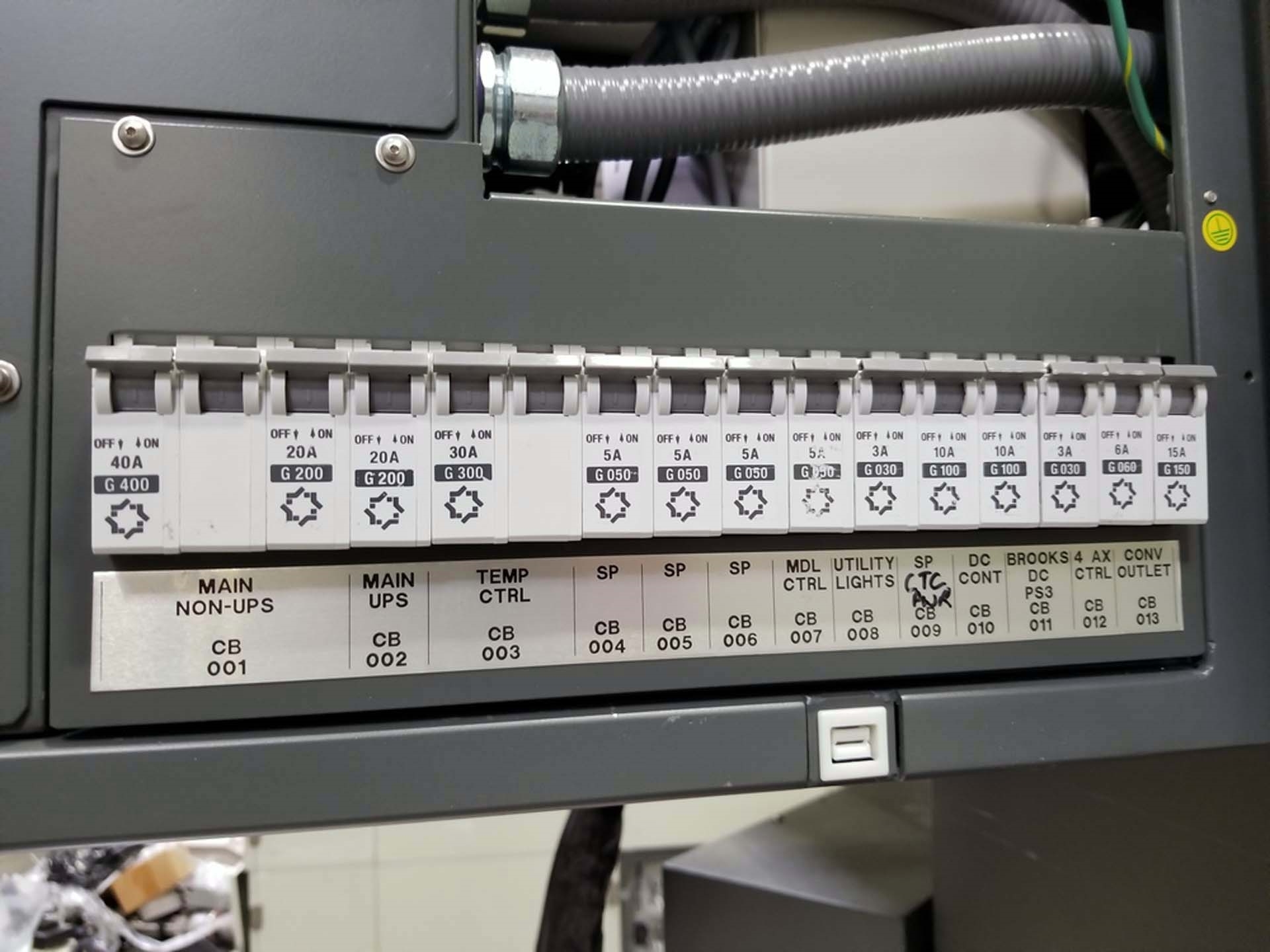

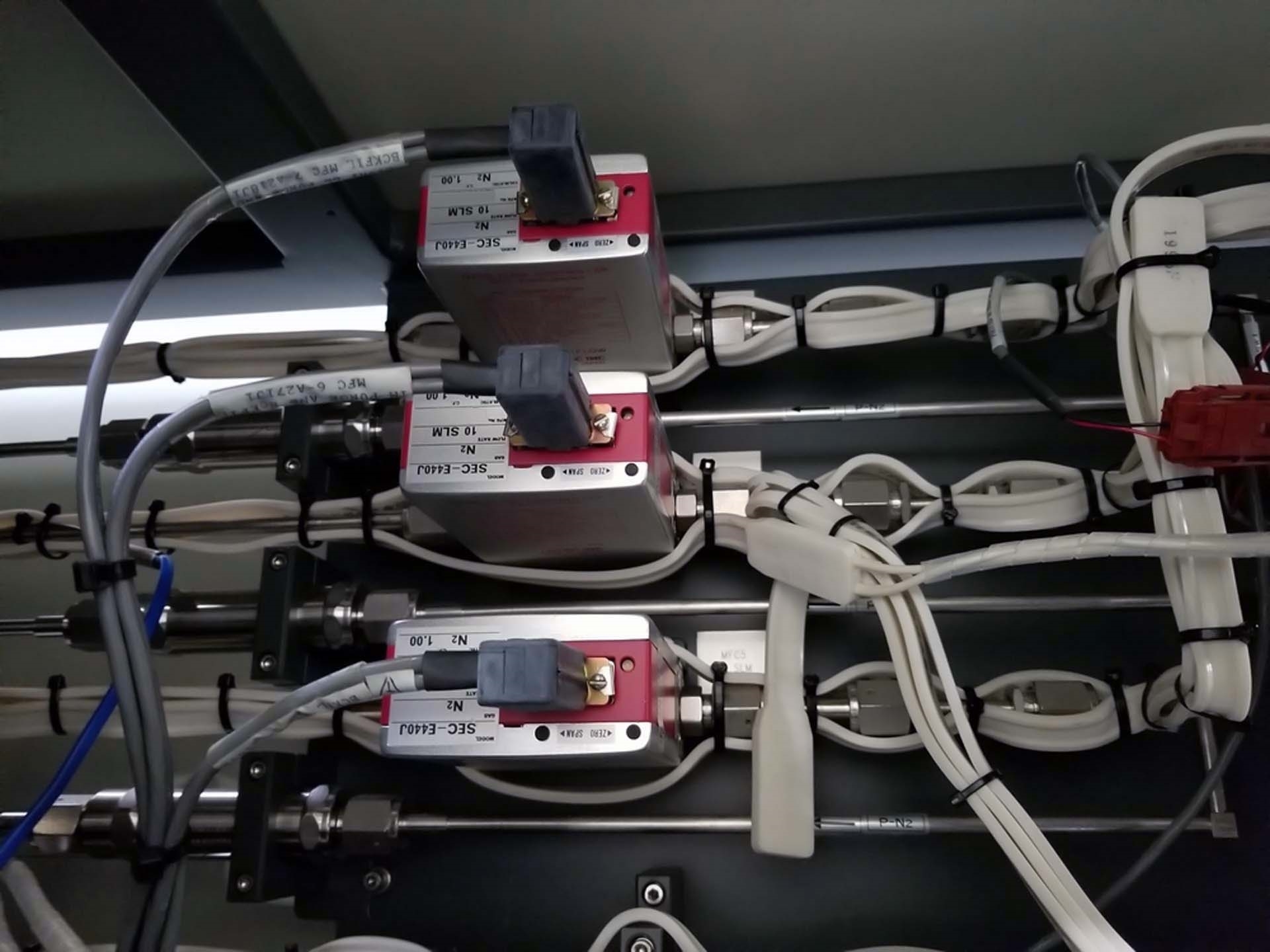

ASM A600 UHV-CP is a diffusion furnace and accessory equipment that provides high-temperature annealing, reactive-gas annealing, and high-vacuum annealing processes for semiconductor manufacturing. It is designed for applications including, but not limited to, deposition, annealing, plus etching and ion-implantation applications. The system consists of a high-temperature diffusion furnace as the main part, as well as a multi-zone gas delivery unit, and accessport for wafer loading and unloading, a vacuum pump, vacuum gauge, and a thermal mass spectrometer. The diffusion furnace is heated by an ultra-high vacuum electric furnace. This electric furnace features a uniform temperature zone to ensure a consistent temperature across the entire wafer, with adjustable temperature profile in up to four separate gas zones and two independent heating zones. It also contains a programmable controller that can store up to 32 recipes with different temperatures and gas flow rates. The furnace can reach temperatures up to 1900°C in the horizontal zone. The multi-zone gas delivery machine includes nitrogen, hydrogen, ammonia, argon, and carrier gases. Nitrogen can be used to maintain high oxygen-free testing address and to improve oxide quality. Hydrogen and ammonia can be used in a wide variety of standard doping applications. Argon is used to reduce oxide defects. And carrier gases can be used to control the tone and velocity of reactive species. The vacuum pump in the tool consists of a vacuum leak chamber with a rotary-piston pump and a cryopump. The rotary-piston pump can provide up to 25 mTorr of vacuum for short duration diffusion applications. The cryopump has a maximum capability of 10-8 Torr, making it an ideal tool for reactive gas annealing processes. The asset also includes a thermal mass spectrometer which is used to measure residual gasses in the furnace. This ensures a clean and pure furnace environment required for optimum device and process performance. Finally, the model is equipped with an accessport which is used for wafer loading and unloading and wafer holders. It is designed for maximum repeatability and enables easy exchange of wafers during processing. In conclusion, A600 UHV-CP is a high-end furnace and accessory equipment designed for semiconductor manufacturing processes. With its precise control of temperature and gas flow rates, the system is capable of producing quality wafer results in a safe and reliable manner.

There are no reviews yet