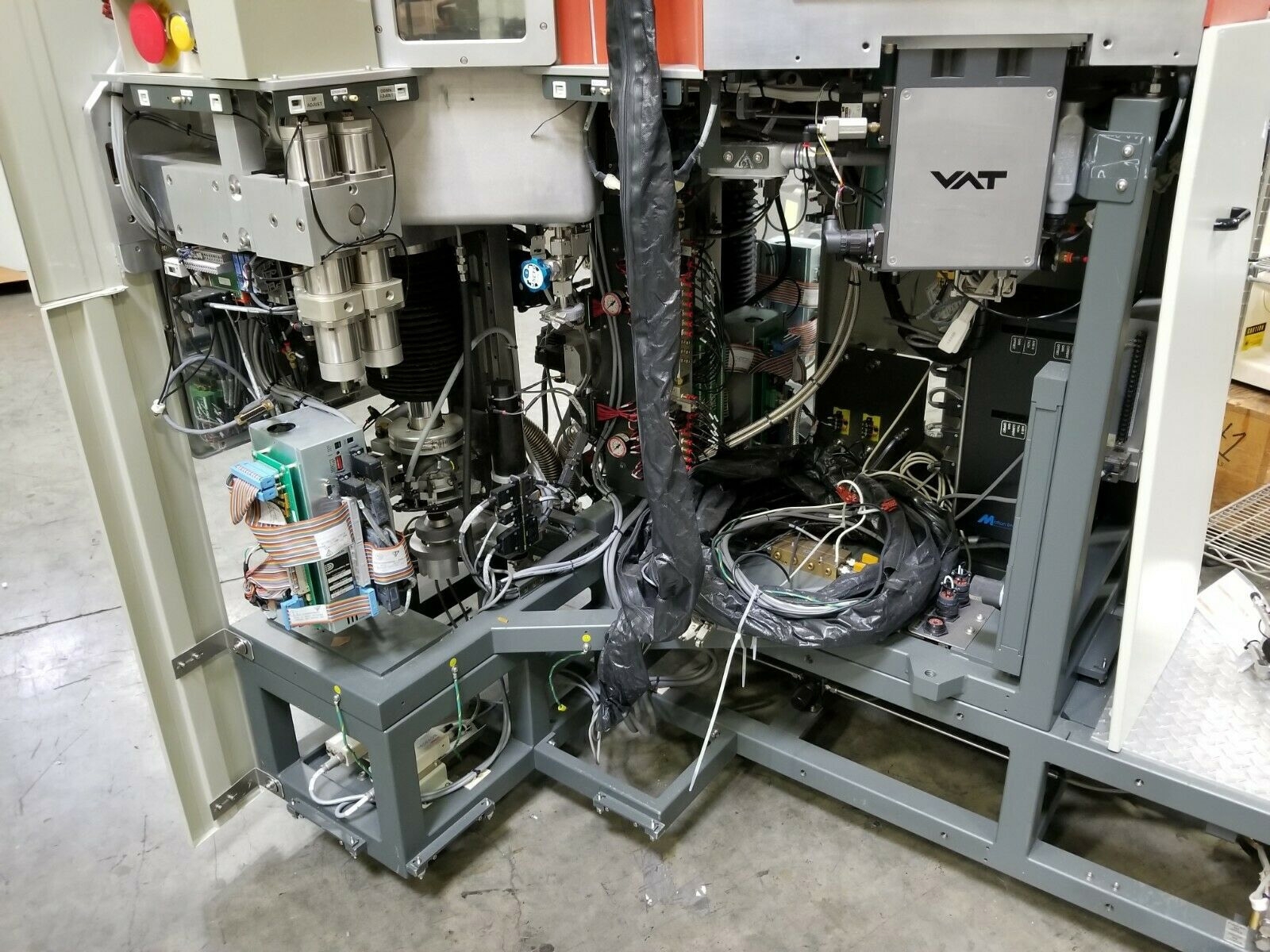

Used ASM A600 UHV-CP #9249525 for sale

URL successfully copied!

Tap to zoom

ID: 9249525

Wafer handler

(2) Wafer handling robots: Front and back

BROOKS AUTOMATION 001-7500-05 With pendant

Controls:

Digital dynamics controls

Motion engineering controls.

ASM A600 UHV-CP Diffusion Furnace is designed for high-efficiency production of large-area, compound semiconductor materials. It is designed to safely and reliably process substrates up to 6-inches in diameter. The diffusion furnace features a 600 mm long process chamber, equipped with an advanced pressure control equipment. The chamber's Ultra High Vacuum (UHV) operating environment ensures clean, low contamination levels, while ensuring fast nitridation, diffusion and dopant encoding of materials. The Dynamic Pressure Control system allows for precise temperature control and a rapid cooldown rate. This allows precise up/down times for diffusion of wafer substrates, reducing and maintaining total process times without sacrificing quality. The furnace also includes a heating power supply that is capable of output up to 25kW, and a compression ash-free muffle design. The combustion unit provides a very clean environment for material processing, while eliminating smoke and other environmental contaminants. The muffle design enables rapid heat dissipation, eliminating the need for cooling zones. In addition, the furnace includes a high-precision control machine that provides comprehensive process monitoring and safety programs. The tool includes a variety of interfacing modes and Supervisory Control and Data Acquisition (SCADA) to easily integrate the furnace into any existing manufacturing environment. The integrated safety systems offer operators a comprehensive suite of safety features, and the ionization protection asset helps eliminate the risk of electric arcing and/or spark-over in the process chamber. A600 UHV-CP Diffusion Furnace provides remarkable efficiency through its modernized design and safety features, and can be easily integrated into existing production lines and processes.

There are no reviews yet