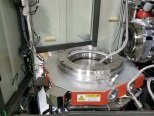

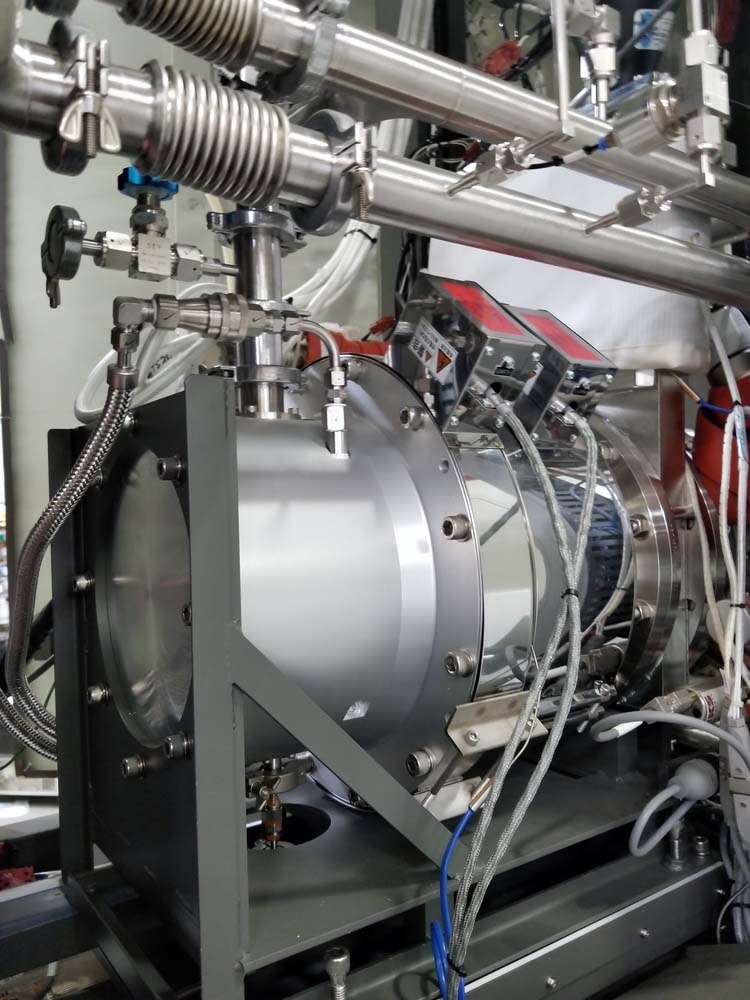

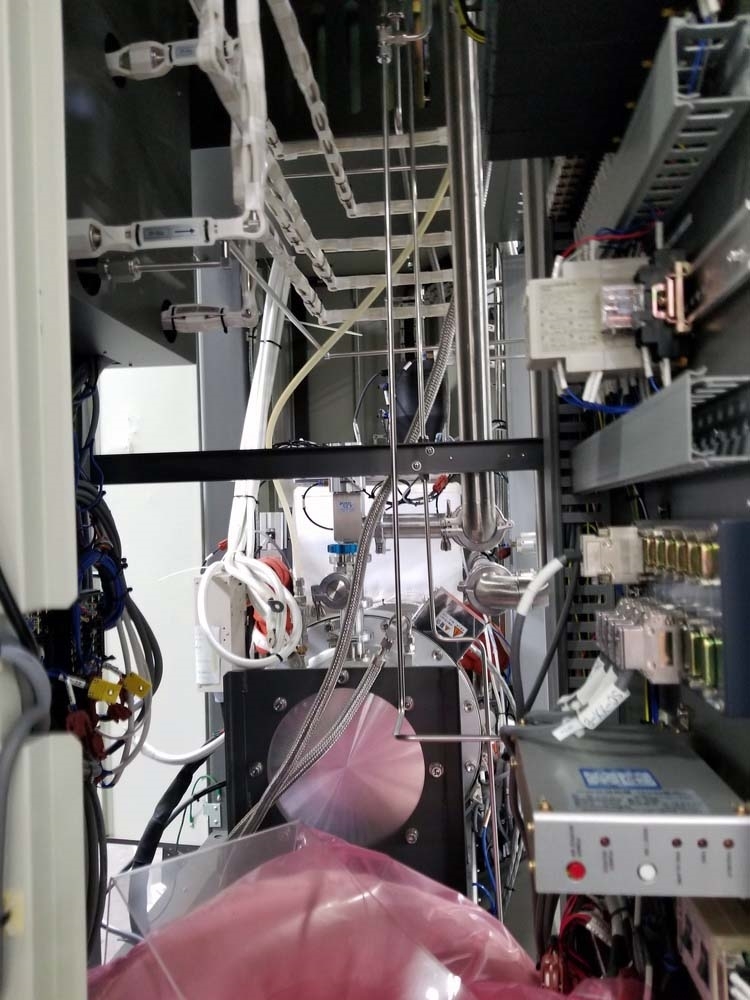

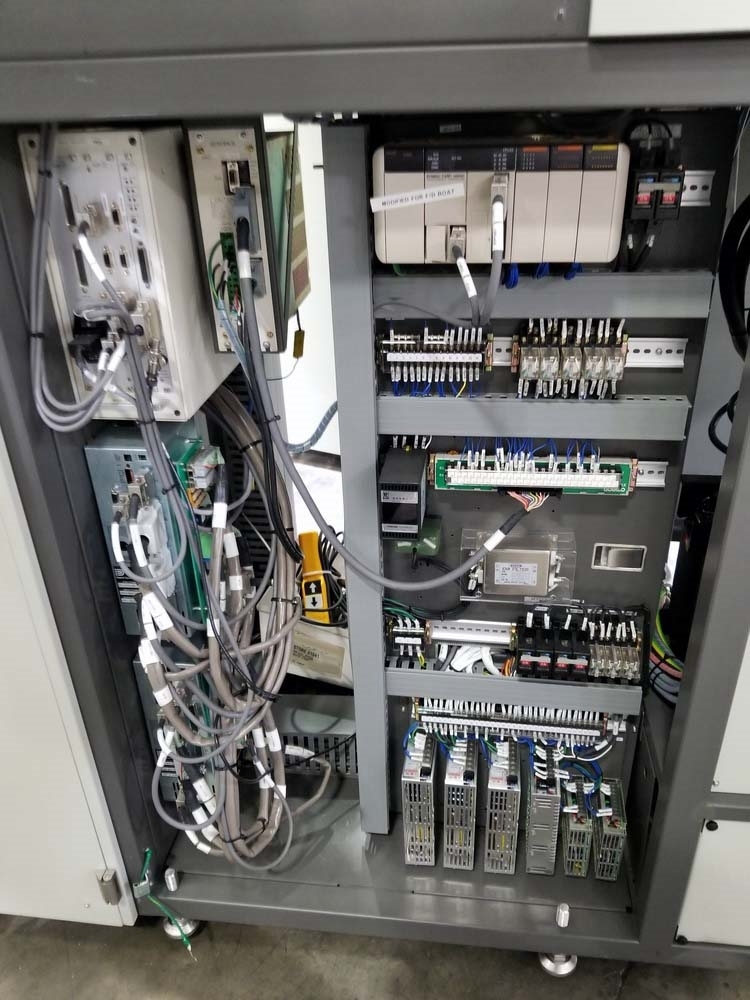

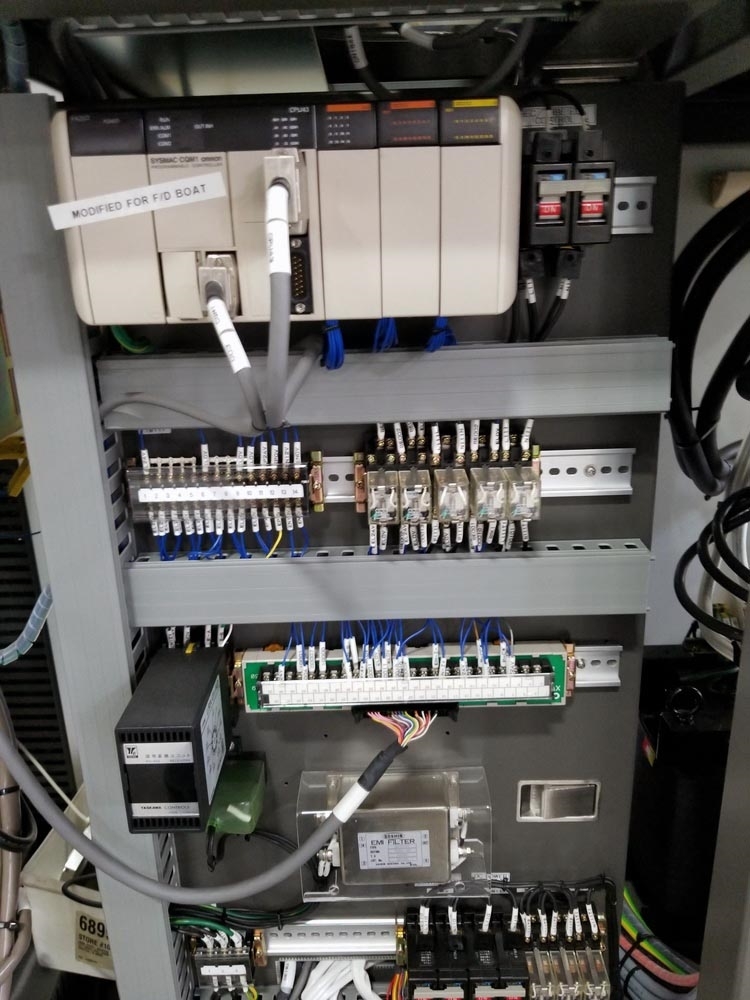

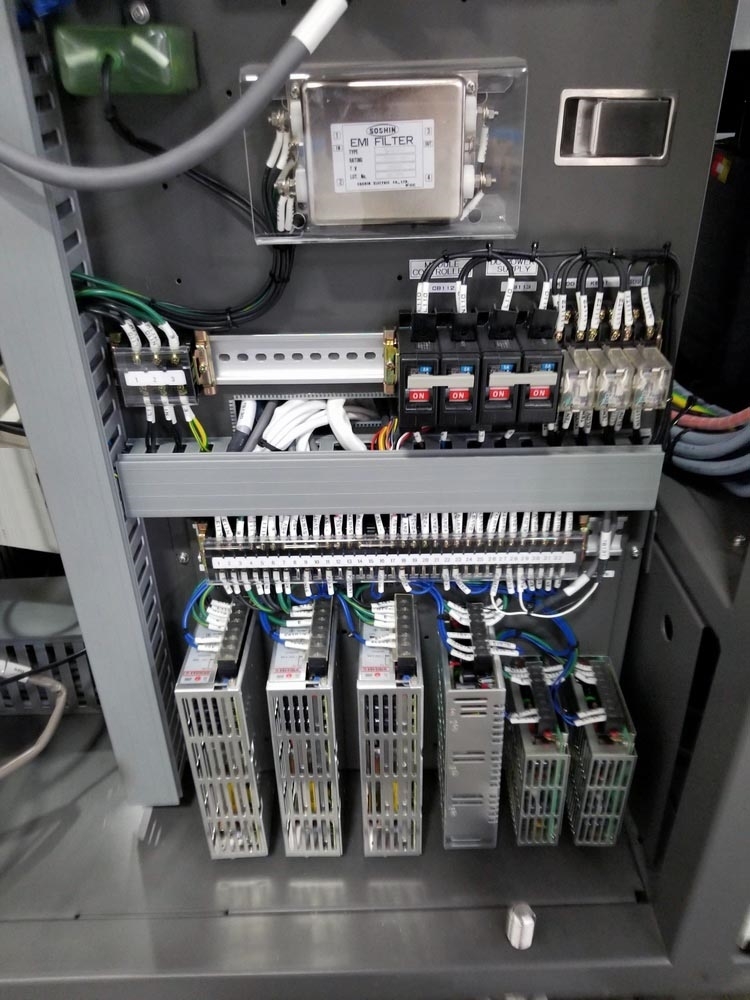

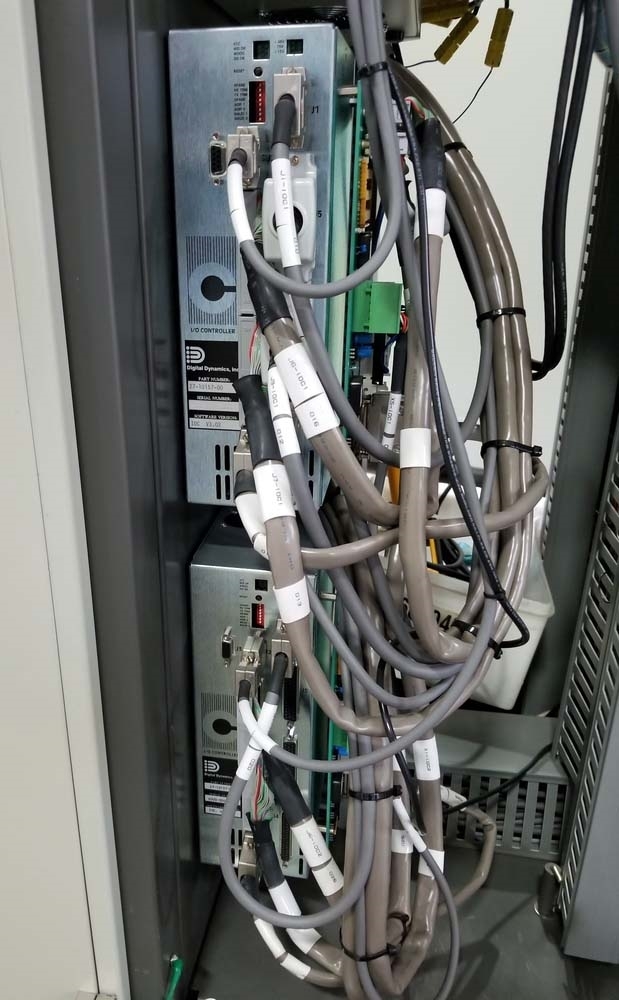

Used ASM A600 UHV-CVD #9239207 for sale

URL successfully copied!

Tap to zoom

ID: 9239207

Vintage: 1997

CVD System

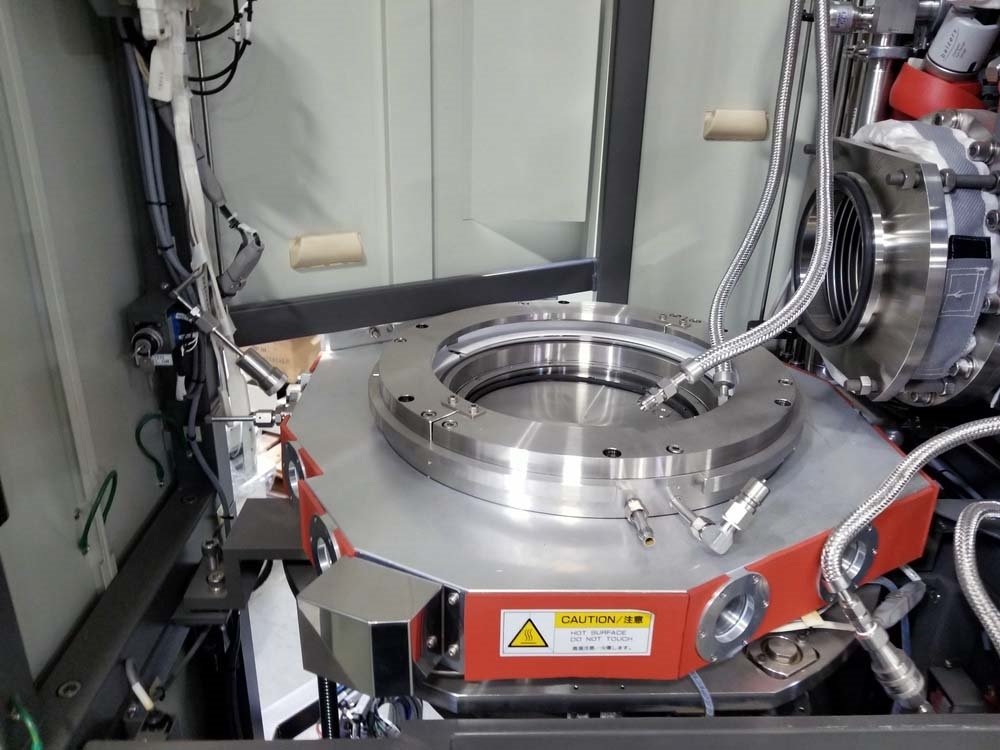

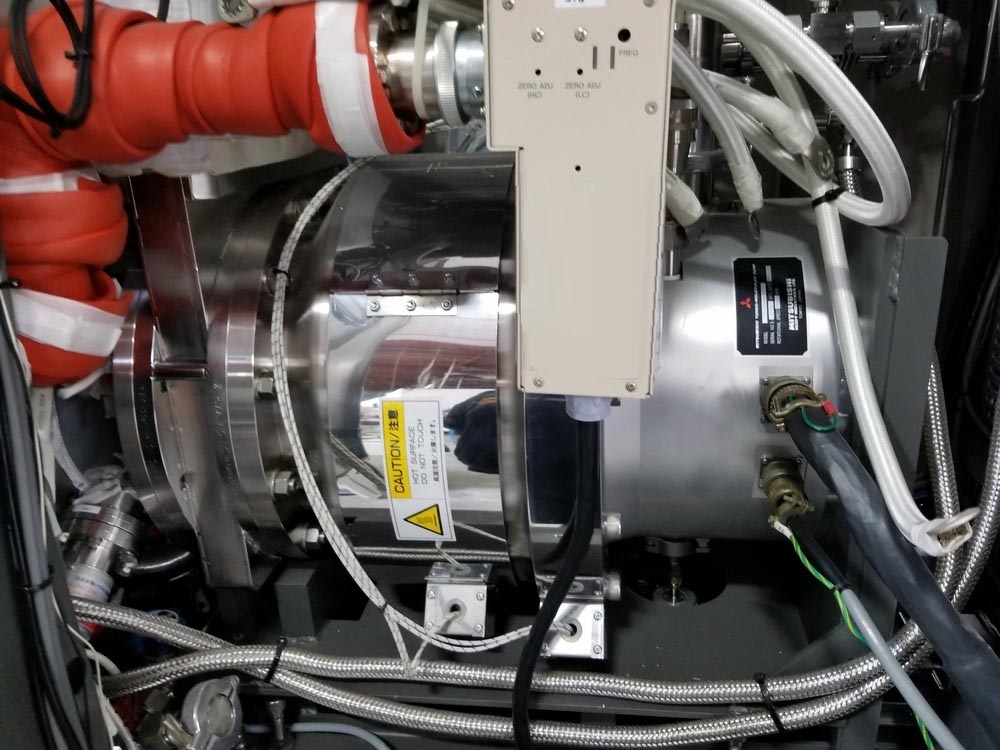

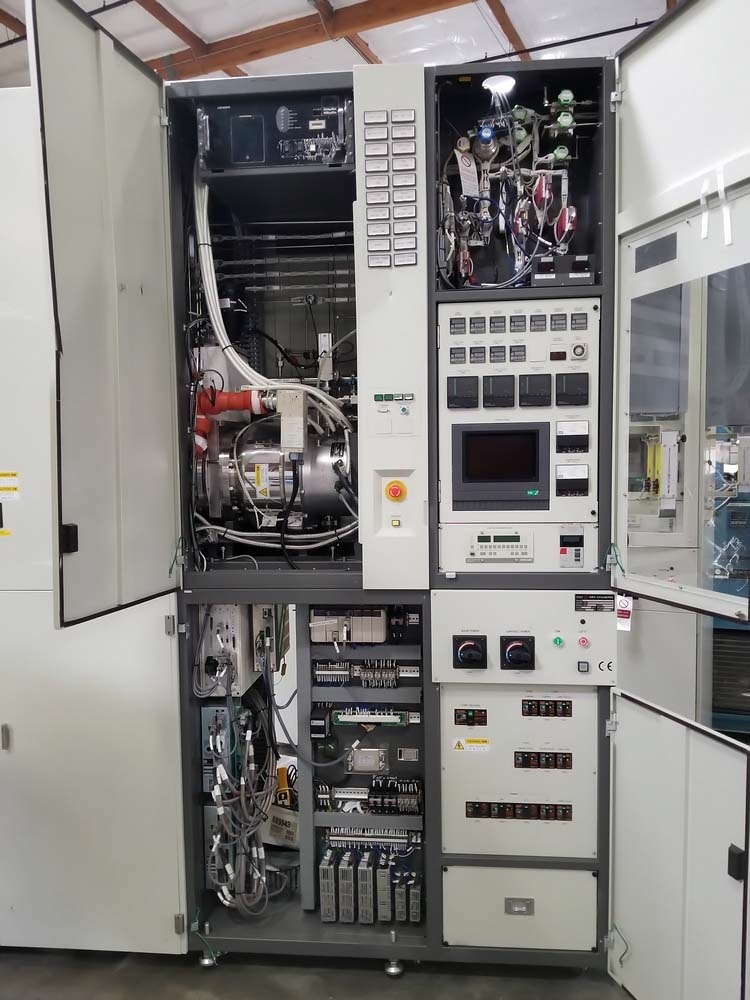

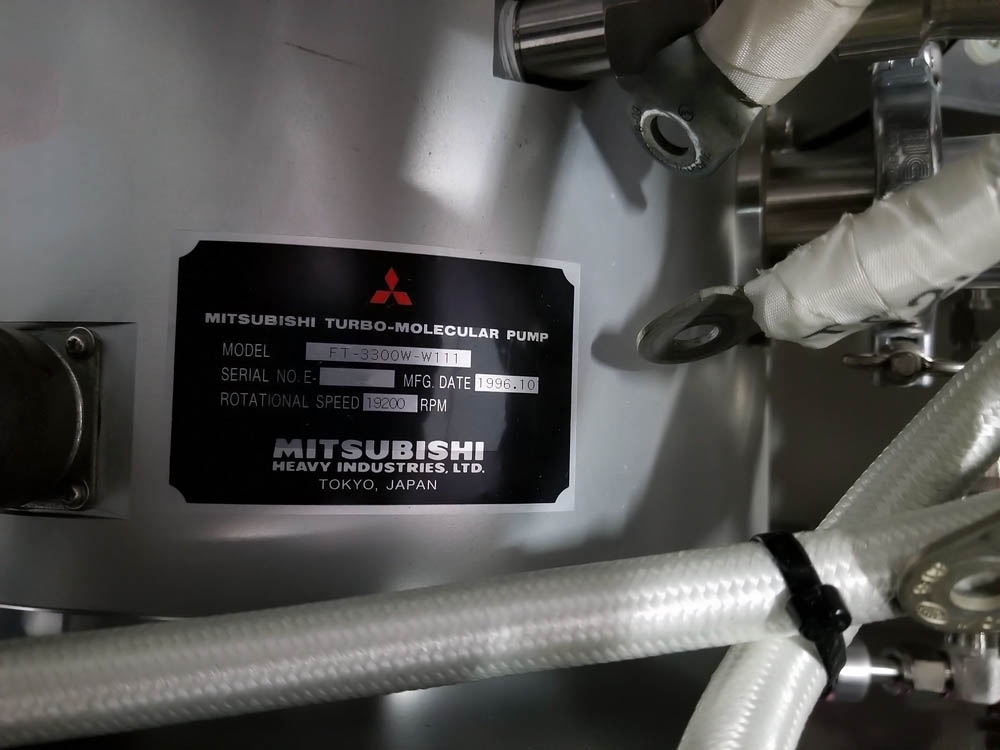

MITSUBISHI FT-3300W-W111 Turbo pump and controller

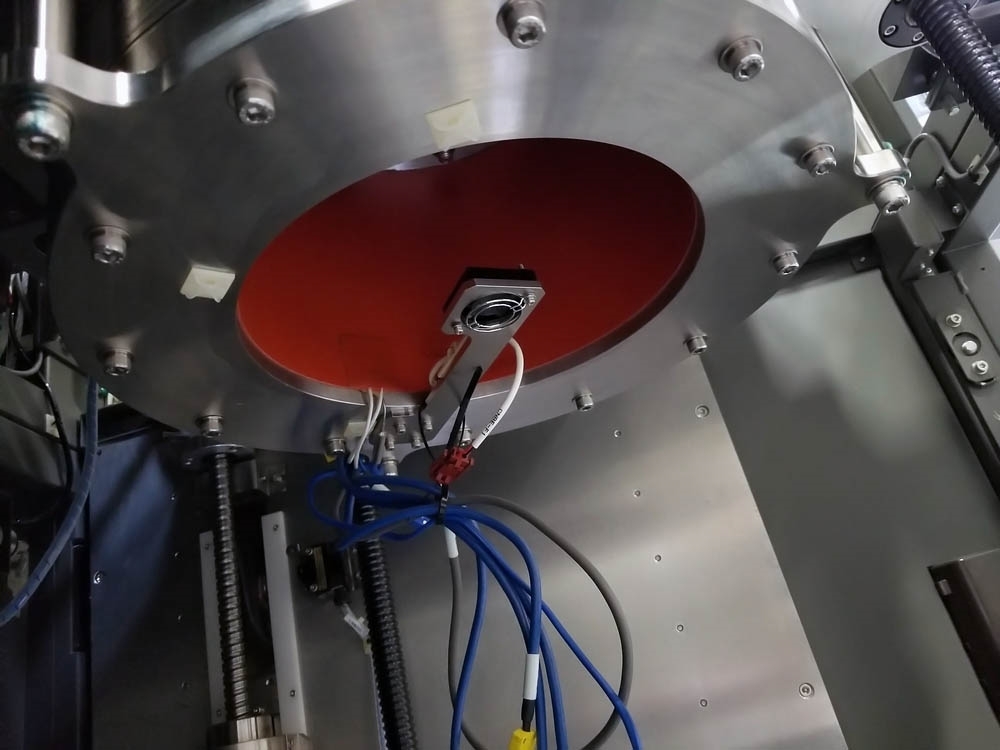

BROOKS 001-7500-05 Robot

BROOKS Controller and teaching pendant

1997 vintage.

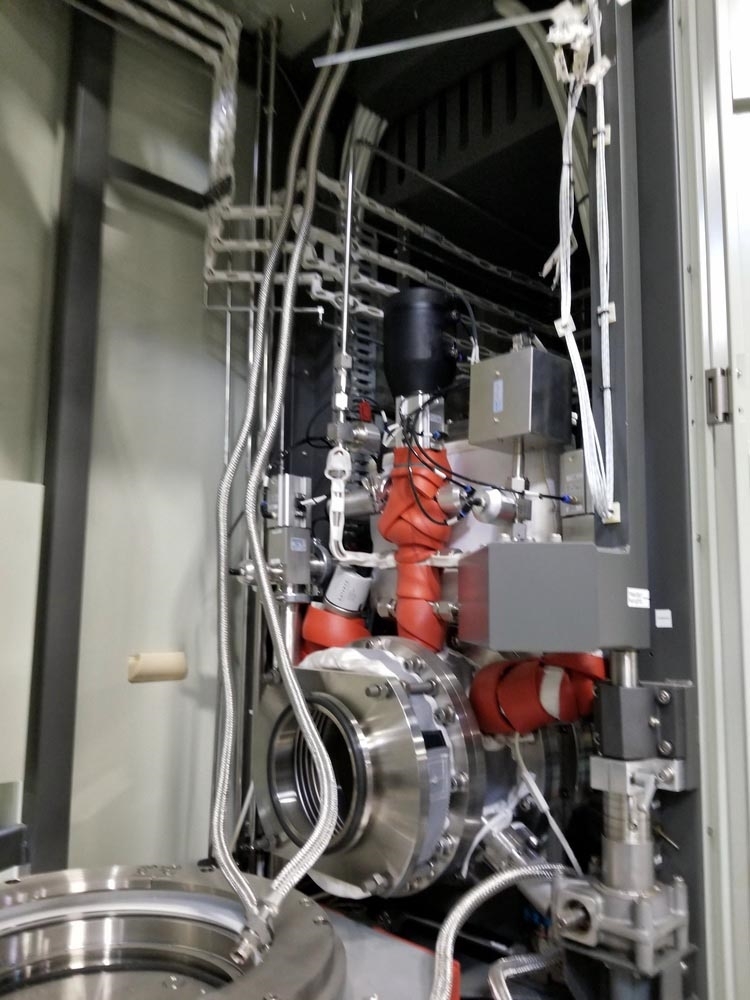

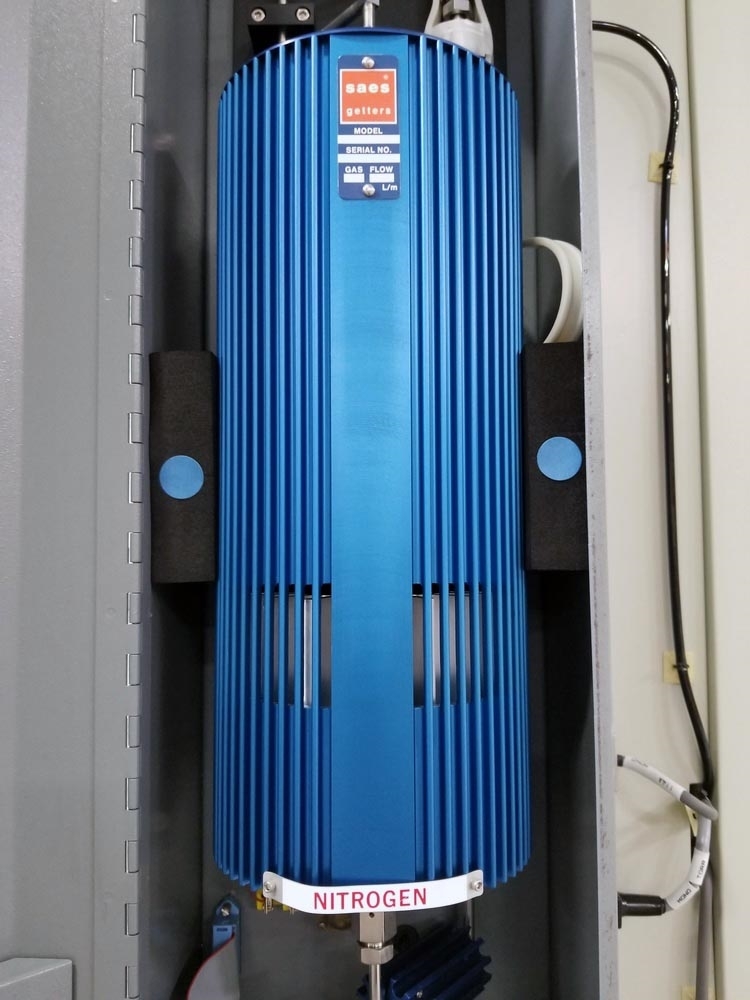

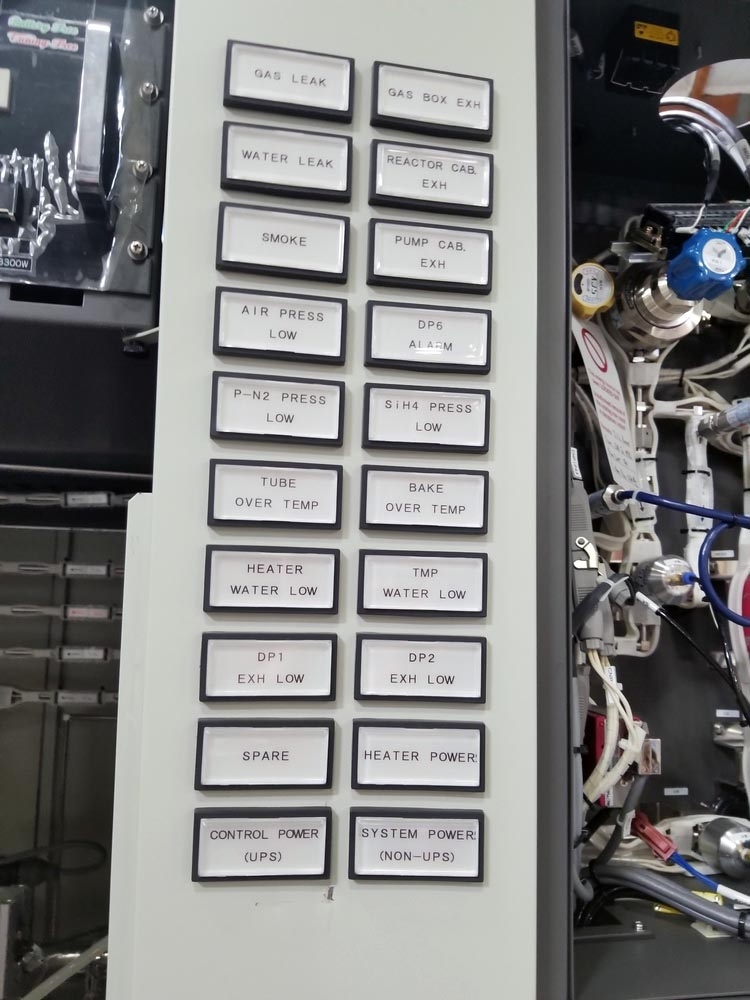

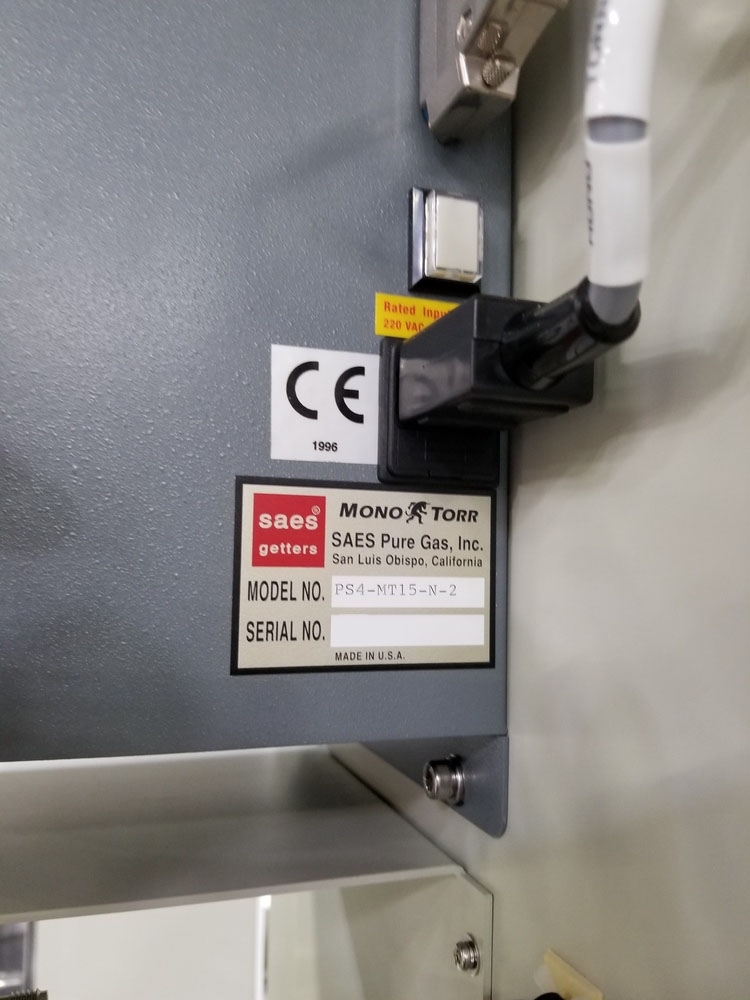

ASM A600 UHV-CVD is a diffusion furnace with accessories that enables the growth of highly uniform thin films of materials. It is specially designed to be utilized in ultra-high vacuum chemical vapor deposition (UHV-CVD). This chamber is often used for the deposition of thin films composed of metals, oxides, nitrides and also other materials. A600 UHV-CVD features an all-metal, flanged design which provides a secure seal between the interior chamber and the exterior vacuum environment. It is equipped with high temperature heating elements which allow for sublimation and deposition of materials from the vapor phase. The chamber includes 3 heating zones, with the temperature adjustable from 40°C to 900°C. In addition, the chamber includes a precise temperature control equipment and also ports which allow access for in situ monitoring and analysis. The system offers a viewport that provides direct observation of the deposition process and an inbuilt cooling unit to quickly cool down the chamber after deposition is complete. There are also several safety features like overpressure, low pressure, and over temperature alarms that can be set to ensure optimal safety during the deposition process. The machine is designed to minimize contamination levels. It has a number of features which ensure a clean environment such as gas purq, static headliner, Teflon® gas traps, internal pumping tool, and temperature-controlled getters. The chamber also includes a particle monitor to detect particles of size 0.1 and smaller in order to maintain cleanliness. The chamber includes two sample holders. The upper holder is for wafers and slides, while the lower holder is for chips, pieces, and samples with smaller dimensions. It is made of high grade stainless steel and is designed to provide rapid thermalization and great precision for sample placement. The asset can be used for deposition of thin films of various materials and thereby produces samples with excellent uniformity. It is equipped with advanced software and an intuitive user interface that enables users to easily control and manipulate parameters during deposition. The model is an important tool for researchers in fields such as microelectronics, optics, and material science.

There are no reviews yet