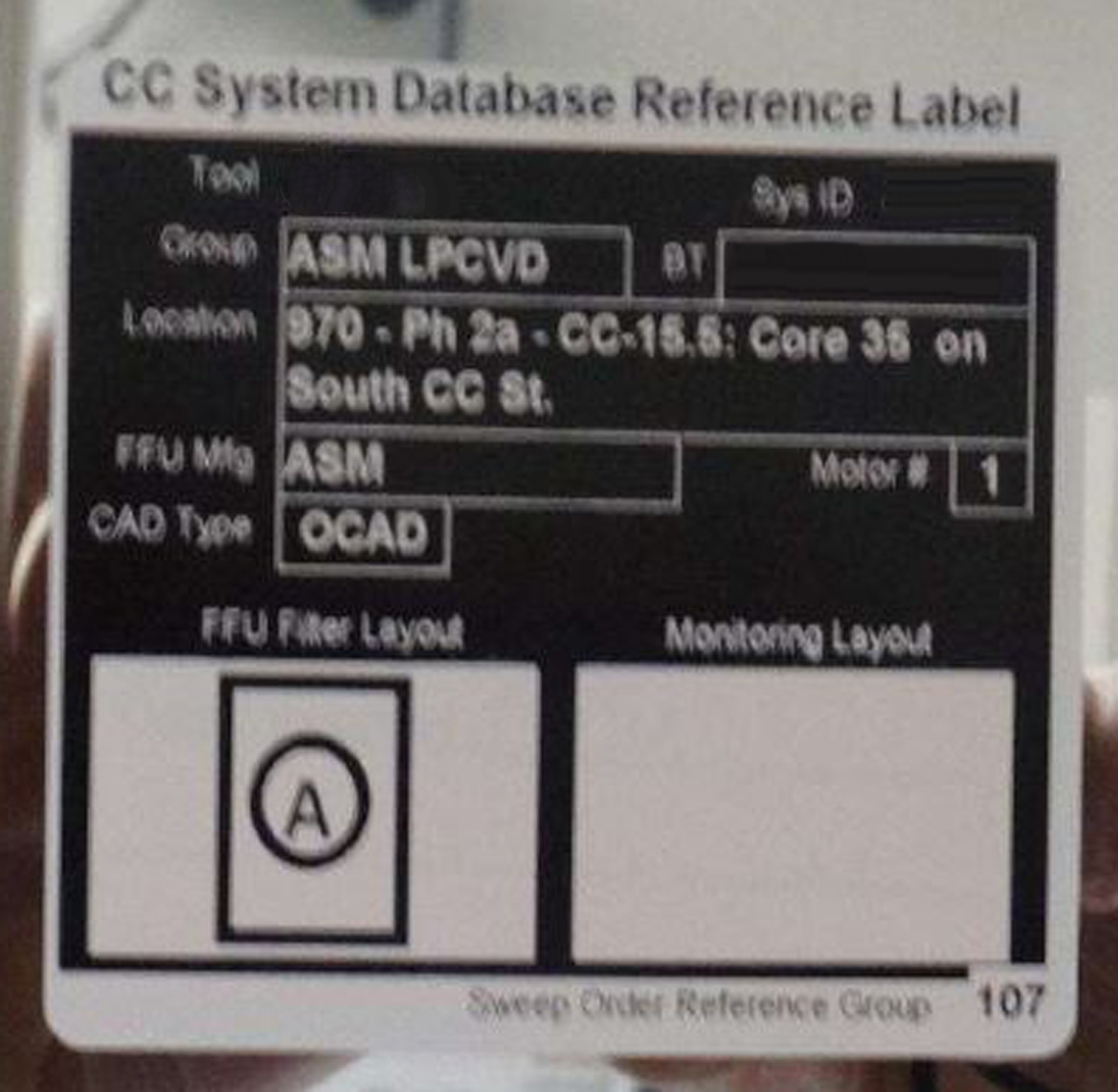

Used ASM Advance 300 VT #9206100 for sale

URL successfully copied!

Tap to zoom

ID: 9206100

Vintage: 1997

Vertical LPCVD furnace

Process: Oxide

CIM

Hardware configuration:

Main system:

Main body (Carrier stage)

Utility box

Handler system:

Wafer handing robot

Boat elevator

Cassette loader

Configuration:

Safety specification: ASM Standard

System layout type: U/Box type (I)

System hand: LL

N2 Load lock

Heater type: Temp wire

Torch heater

Process gasses:

Process gas 1 / N2 (30SLM)

Process gas 2 / O2 (20SLM)

Process gas 3 / HCL

Process gas 4 / N2O

Process gas 5 / H2O

Gas distribution system:

Basic style: Conventional gas system

Tubing material: Stainless steel

Tubing finish: Electro-polished

Manual & air-operated valve: Nupro

MFC Unit

Wafer / Cassette handling:

SEMI STD-Notch, 8"

Cassette type: Entergris / 704-503T2

Cassette number of wafers: 25

Cassette storage: 16

Fork type / Material

Fork variable pitch

Boat / Pedestal: 2 Boat

(150) Production wafers

Boat rotation not installed

System control:

System controller: IBM 486 OS2

Torch controller: H2O Separate element Pre burner

Signal tower colors: G / A / B

General pressure display unit: Pressure PSI

Cabinet exhaust display unit: H20

ASM Furnace temp controller

Host communication

Host communication: User host computer

User host computer I/F: SECS I / II (RS232)

Information transfer protocol: GEM

Equipment host I/F connection: U/BOX Top

Group controller: HIA

Facility electrical equipment power input (2 Lines):

Voltage: 208 VAC, 3 Phase

Voltage: 120 VAC, 1 Phase

UPS Input / Output voltage: 120V / 100V

1997 vintage.

ASM Advance 300 VT is a diffusion furnace and accessory equipment designed for modern wafer fabrication processes. It offers state-of-the-art, high-temperature annealing control and delivers precise uniformity for complex diffusion processes. Advance 300 VT features a unique vertical technology design for increased uniformity, and an innovative two-zone control for superior process control and temperature accuracy. Advanced cooling control system using a combination of cold wall and distributor plate designs ensure maximum throughput and unit efficiency. The machine is equipped with three thermocouple sleeves and up to 24 thermocouple points for superior temperature sensing across the entire wafer. The vertical design of ASM Advance 300 VT eliminates temperature variations across the wafer, ensuring high precision and reproducibility for critical processes. This high-precision tool also provides unparalleled process capabilities, allowing for precise temperature control and tight tolerances. Advance 300 VT is capable of supporting process requirements from conventional wafer manufacture up to very high temperatures for advanced processes such as nanomaterial fabrication. In addition, the asset has the flexibility to accommodate a variety of quartz boat configurations, especially those with intricate design features such as channels and other intricate features. This allows for maximum process flexibility and helps to optimize production operations. ASM Advance 300 VT is capable of sustaining exceptional uniformity of temperature across all wafer positions, due to its advanced heat distribution systems and thermal control systems. Furthermore, it has considerable engineering advantages in terms of its technical design and product flexibility, including low power consumption, a low-profile design, and easy access to all components. It also offers a wide range of options, including a low thermal cycle switch for process optimization, as well as a gravity hinge model for greater flexibility. Overall, Advance 300 VT is a highly reliable and precise diffusion furnace and accessory equipment for modern wafer fabrication processes. It has an advanced temperature control system, superior uniformity, and flexible design capabilities for optimized production operations.

There are no reviews yet