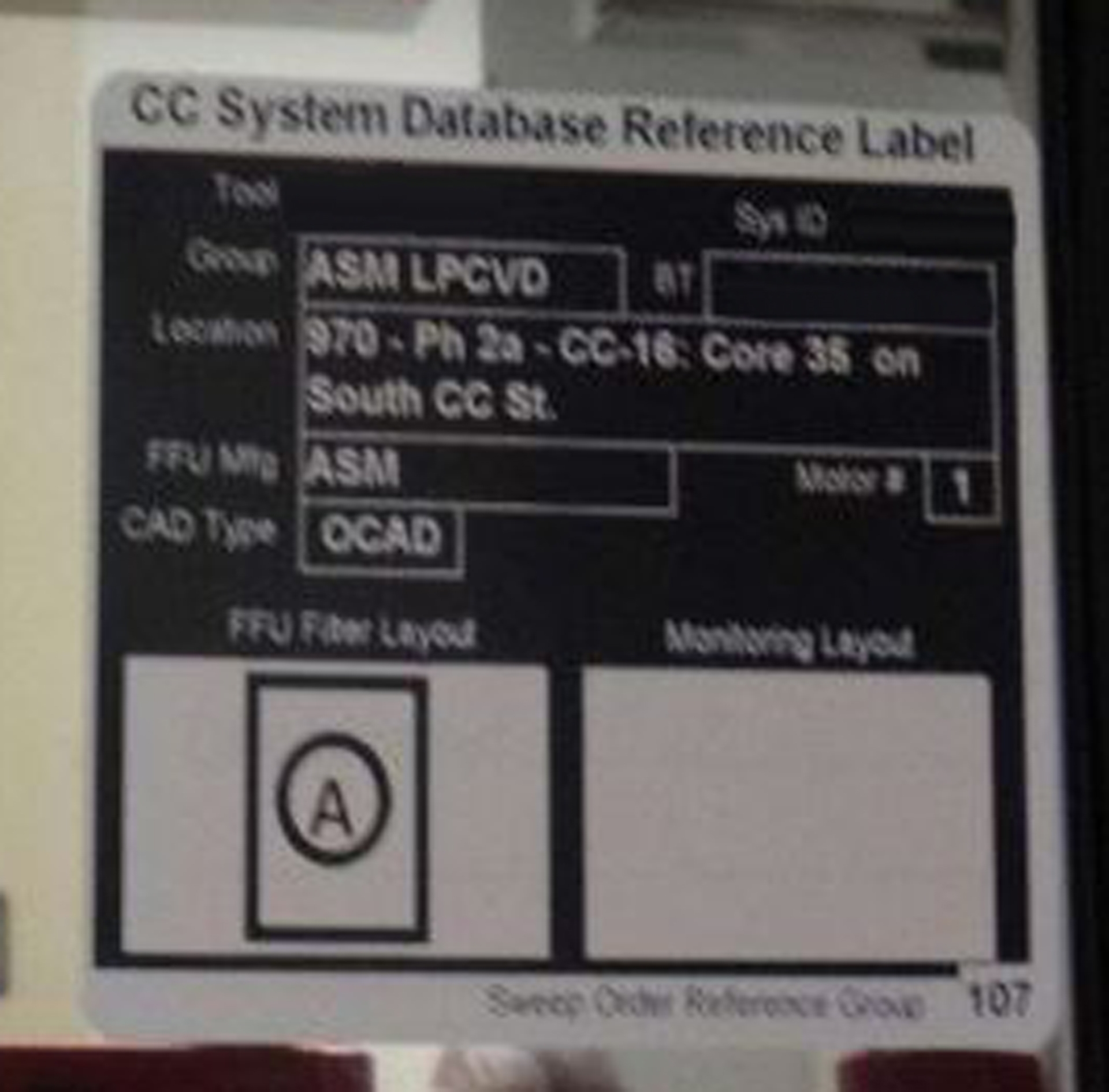

Used ASM Advance 300 VT #9206104 for sale

URL successfully copied!

Tap to zoom

ID: 9206104

Vertical LPCVD furnace

Process: Oxide

CIM

Hardware configuration:

Main system:

Main body (Carrier stage)

Utility box

Handler system:

Wafer handing robot

Boat elevator

Cassette loader

Configuration:

Safety specification: ASM Standard

System layout type: U/Box type (I)

System hand: LL

N2 Load lock

Heater type: Temp wire

Torch heater

Process gasses:

Process gas 1 / N2 (30SLM)

Process gas 2 / O2 (20SLM)

Process gas 3 / HCL

Process gas 4 / N2O

Process gas 5 / H2O

Gas distribution system:

Basic style: Conventional gas system

Tubing material: Stainless steel

Tubing finish: Electro-polished

Manual & air-operated valve: Nupro

MFC Unit

Wafer / Cassette handling:

SEMI STD-Notch, 8"

Cassette type: Entergris / 704-503T2

Cassette number of wafers: 25

Cassette storage: 16

Fork type / Material

Fork variable pitch

Boat / Pedestal: 2 Boat

(150) Production wafers

Boat rotation not installed

System control:

System controller: IBM 486 OS2

Torch controller: H2O Separate element Pre burner

Signal tower colors: G / A / B

General pressure display unit: Pressure PSI

Cabinet exhaust display unit: H20

ASM Furnace temp controller:

Host communication

Host communication: User host computer

User host computer I/F: SECS I / II (RS232)

Information transfer protocol: GEM

Equipment host I/F connection: U/BOX Top

Group controller: HIA

Facility electrical equipment power input (2 Lines):

Voltage: 208 VAC, 3 Phase

Voltage: 120 VAC, 1 Phase

UPS Input / Output voltage: 120V / 100V

1997 vintage.

ASM Advance 300 VT is a next-generation diffusion furnace designed to provide a reliable, high-precision atmosphere for metal treatments. It is equipped with a wide range of accessories, enabling it to perform a range of processes including hardening, tempering, annealing, coating, and carburizing. The furnace is constructed from heavy-duty stainless steel and has a robust design for longevity and reliability. It is equipped with a separate diffusing chamber to ensure the highest degree of accuracy. Easy-to-use touchscreen controls are also included, allowing for precise temperature and atmosphere control. With an active volume of 100 liters, Advance 300 VT can heat up to 1 350°C (2 460°F) and can be adjusted to any temperature between 25°C (77°F) and 1 350°C (2 460°F). It also features a powerful heating element and water cooling system, ensuring rapid, controlled thermal cycles. In terms of accessories, ASM Advance 300 VT is equipped with many features that can be tailored to your needs. It comes with a range of crucible configurations for crucible treatments, including square and round versions. Also included are switchable oxygen probes, which detect the oxygen concentration in the gas during a run and can be adjusted accordingly. Other optional accessories include a stainless steel filter unit, temperature sensors, a coolant flow meter, multi-column trays for hardening, tempering, and annealing, special pyrometers for the crucible, and a vacuum system for treating non-oxidizing materials. Advance 300 VT is a powerful diffusion furnace valued for its accuracy and performance. With its wide array of accessories, it is an excellent tool for metal treatment. It is perfect for a range of professional and industrial applications, and provides reliable results and long-term performance.

There are no reviews yet