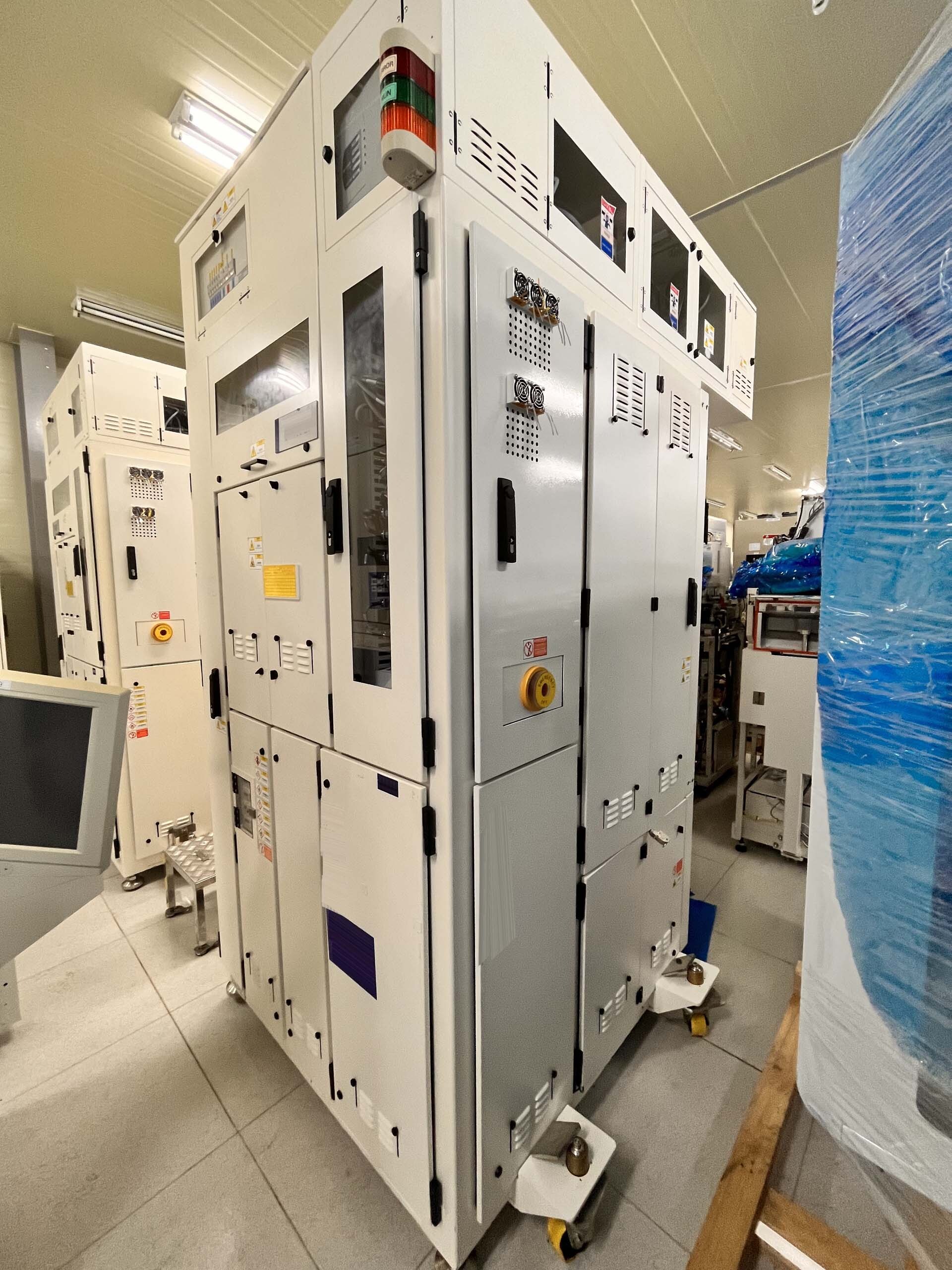

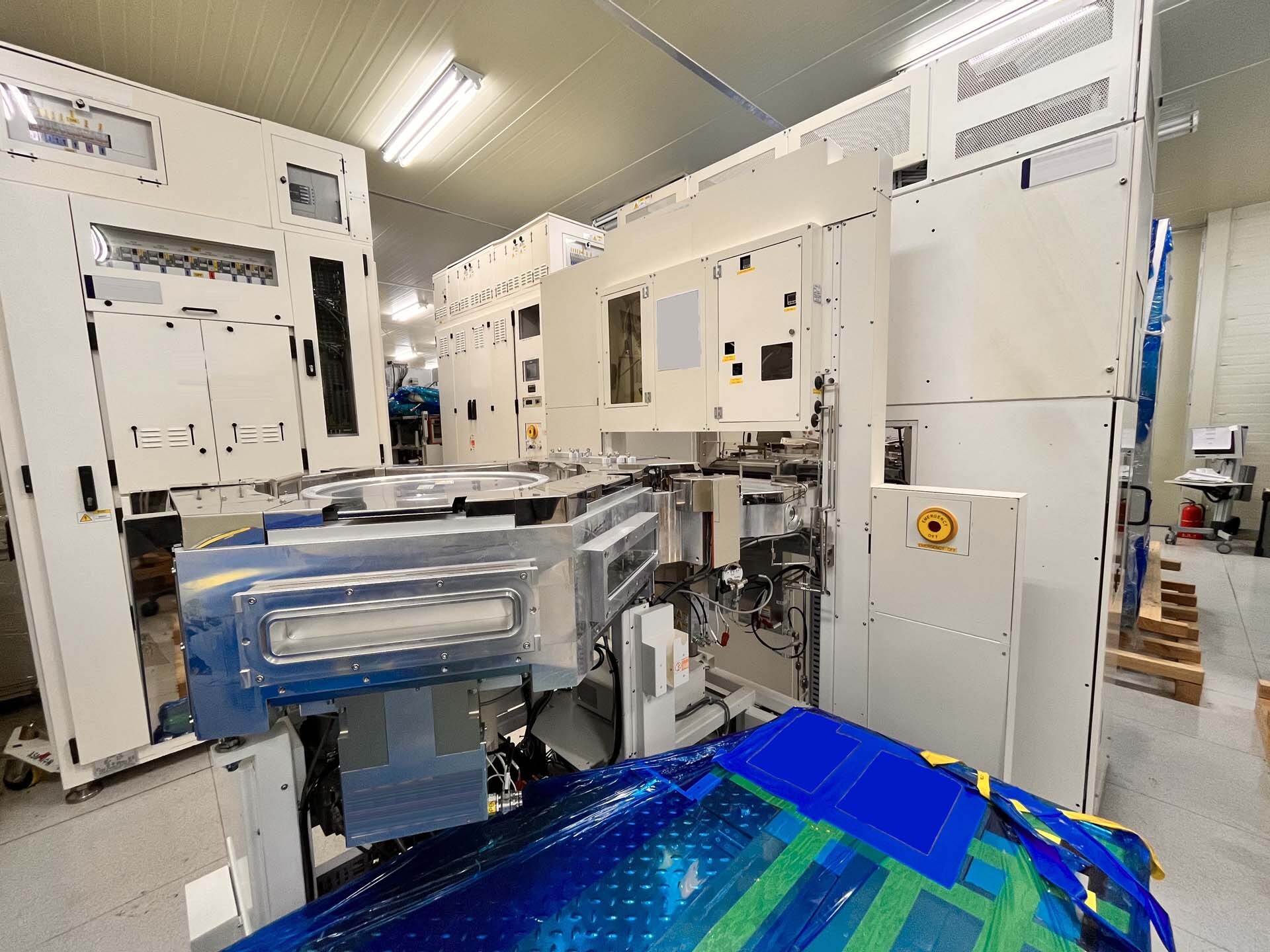

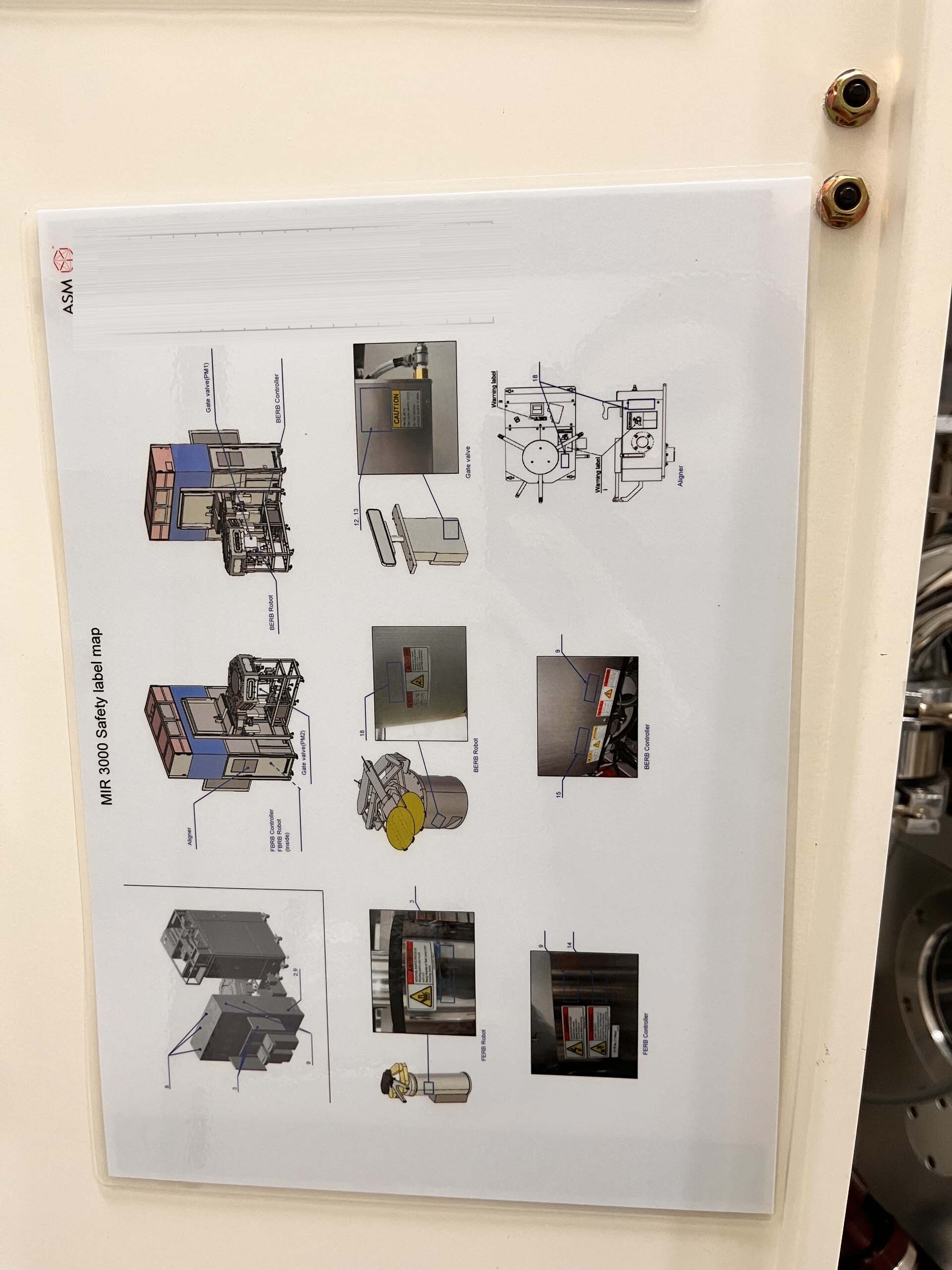

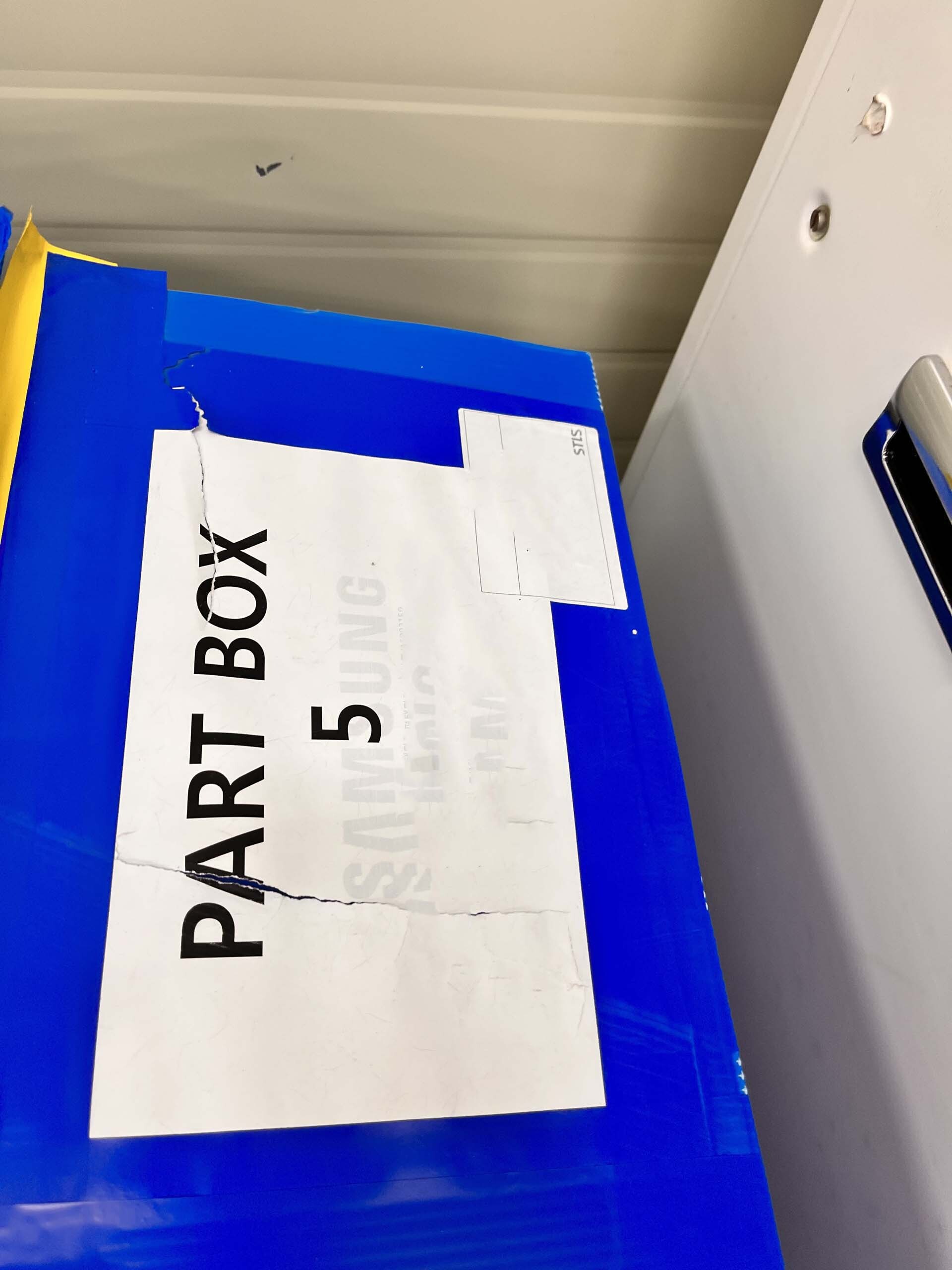

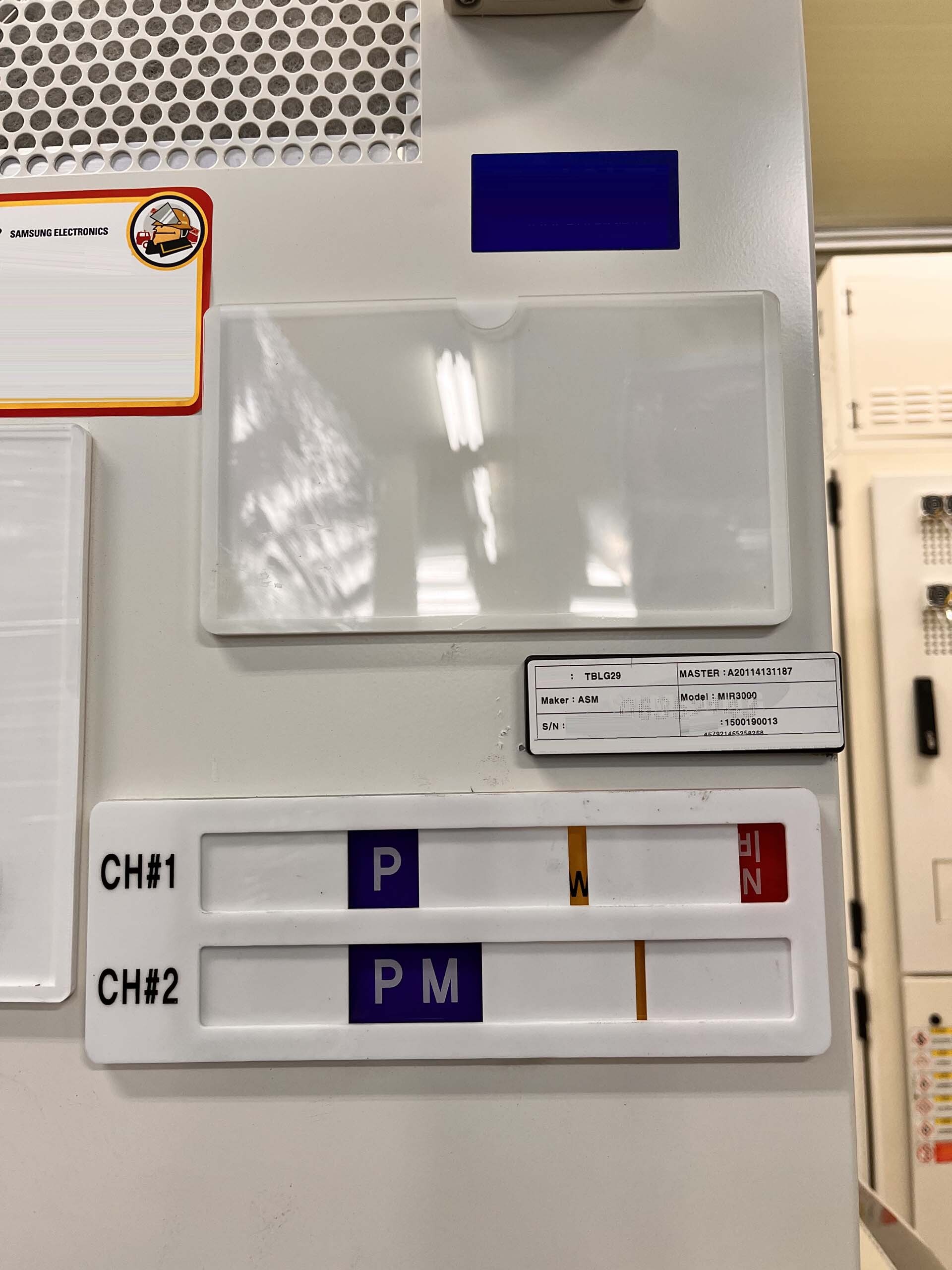

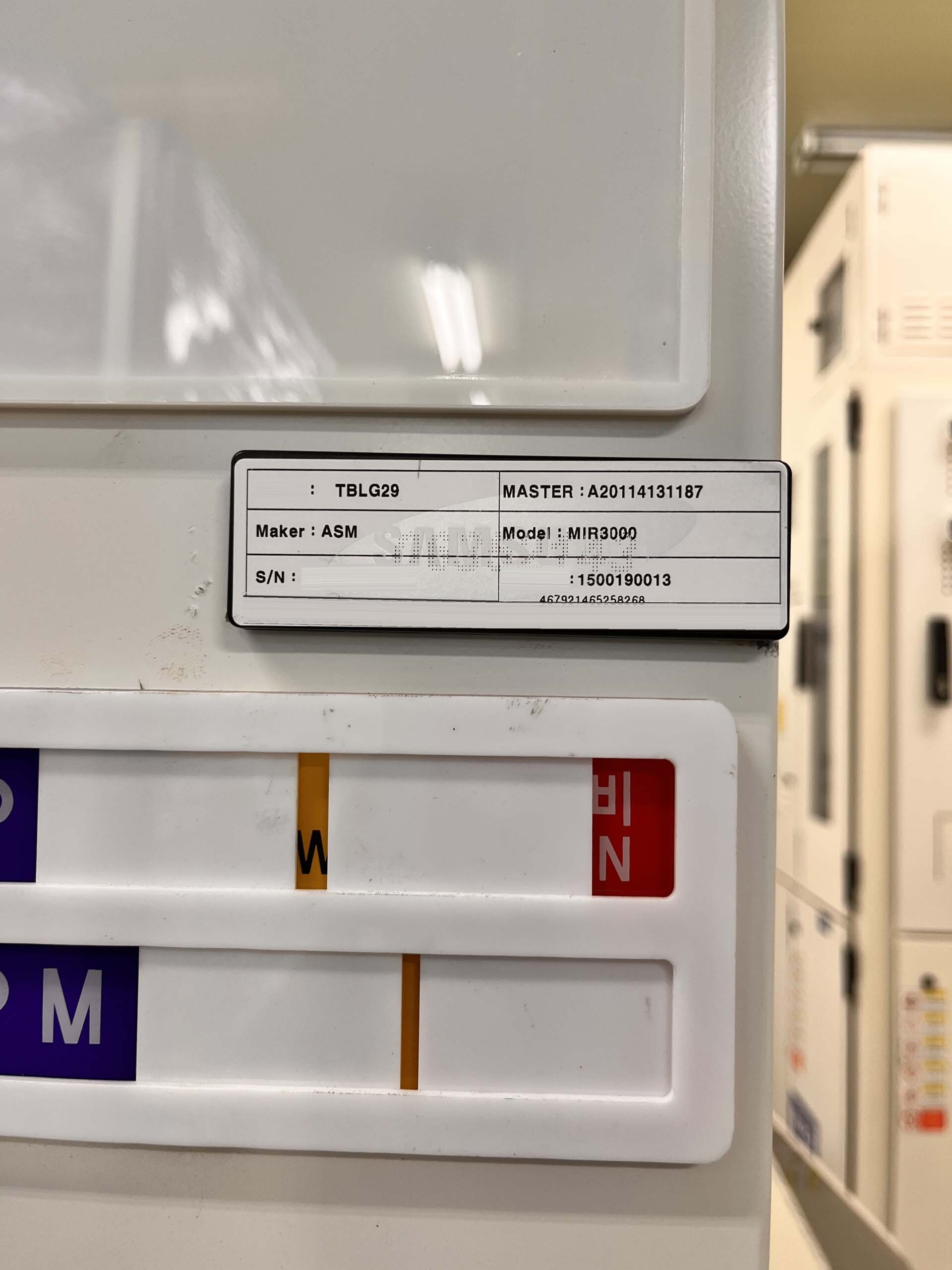

Used ASM MIR 3000 #9259684 for sale

URL successfully copied!

Tap to zoom

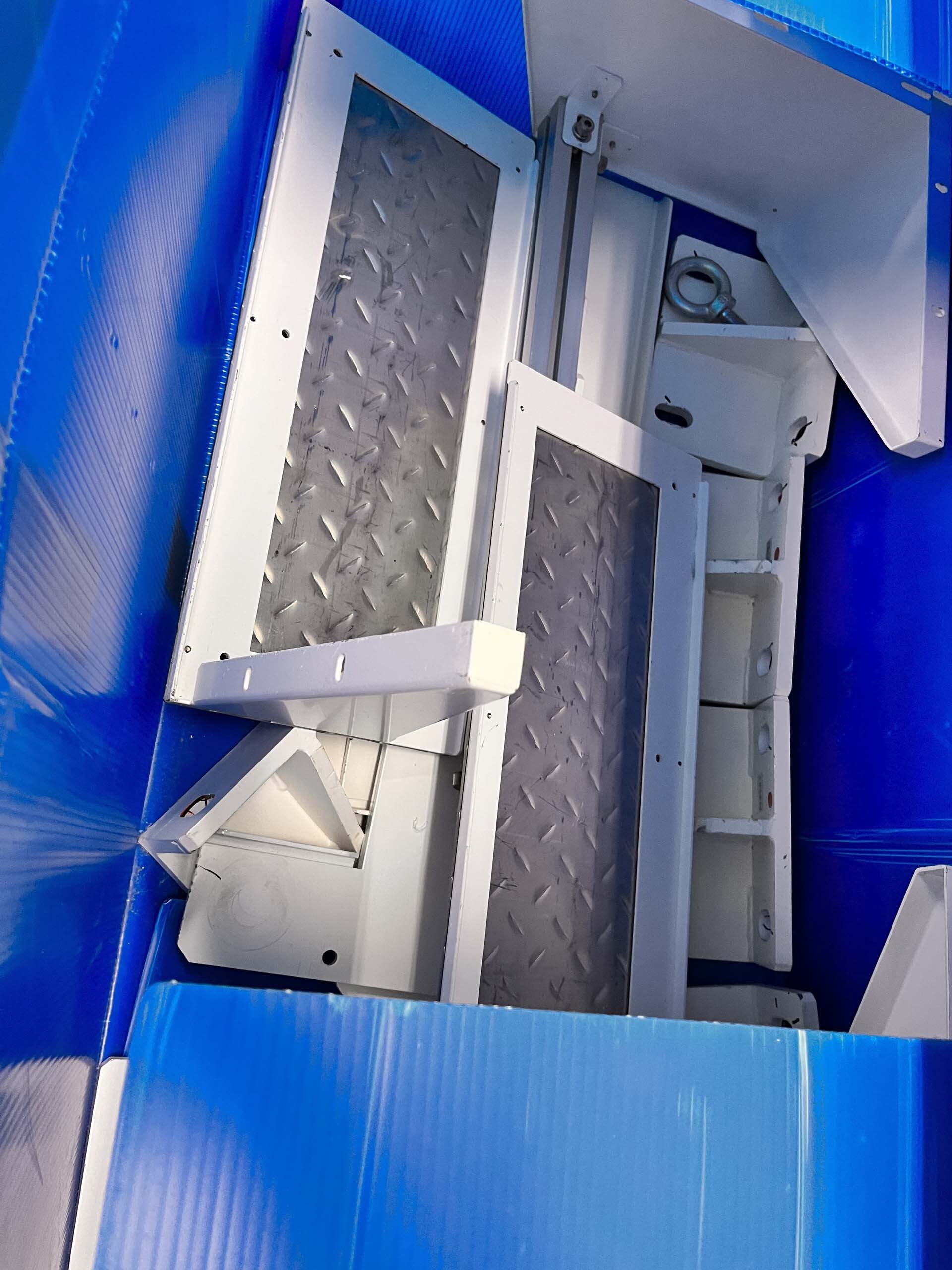

ID: 9259684

Wafer Size: 12"

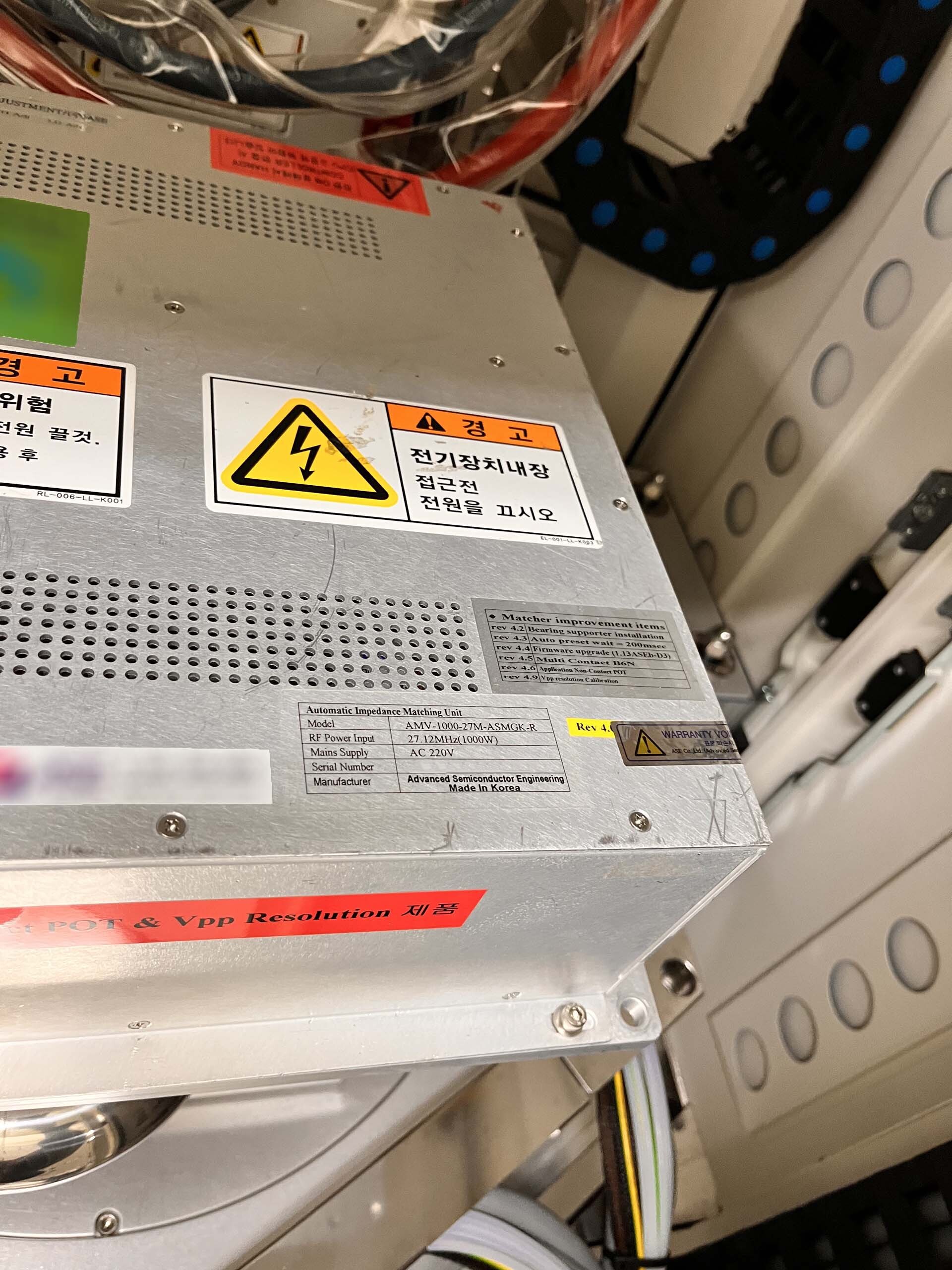

Vintage: 2011

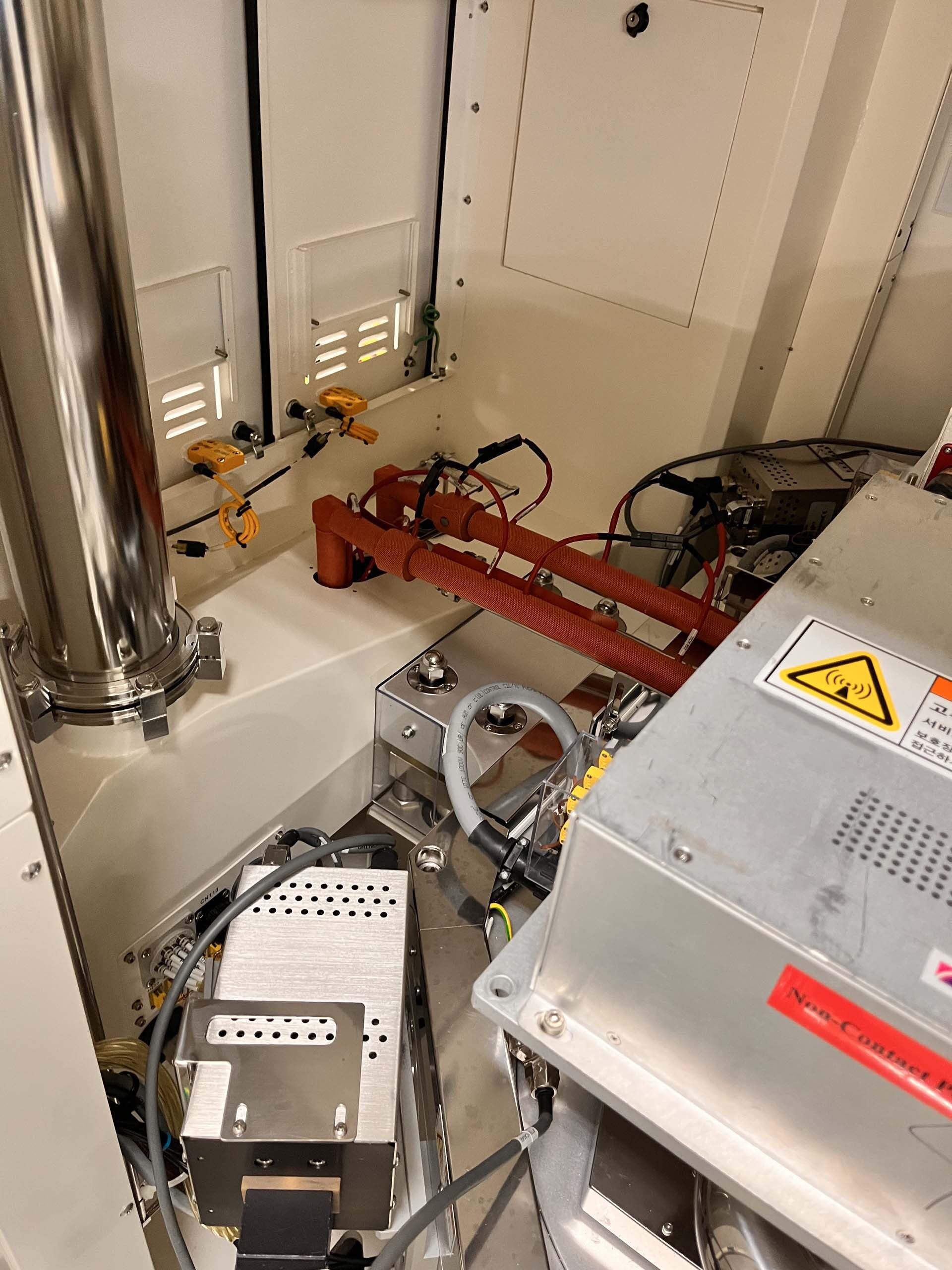

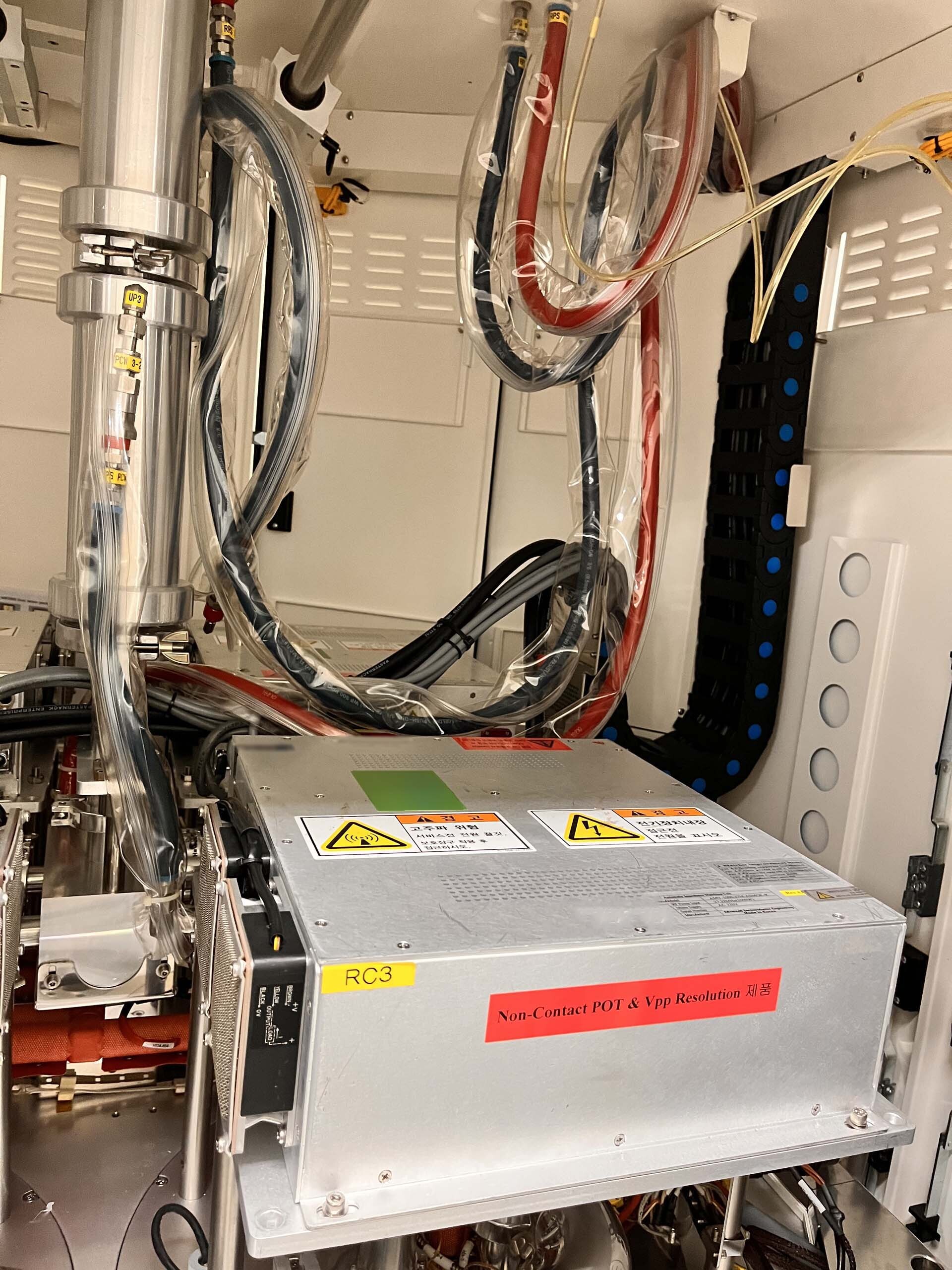

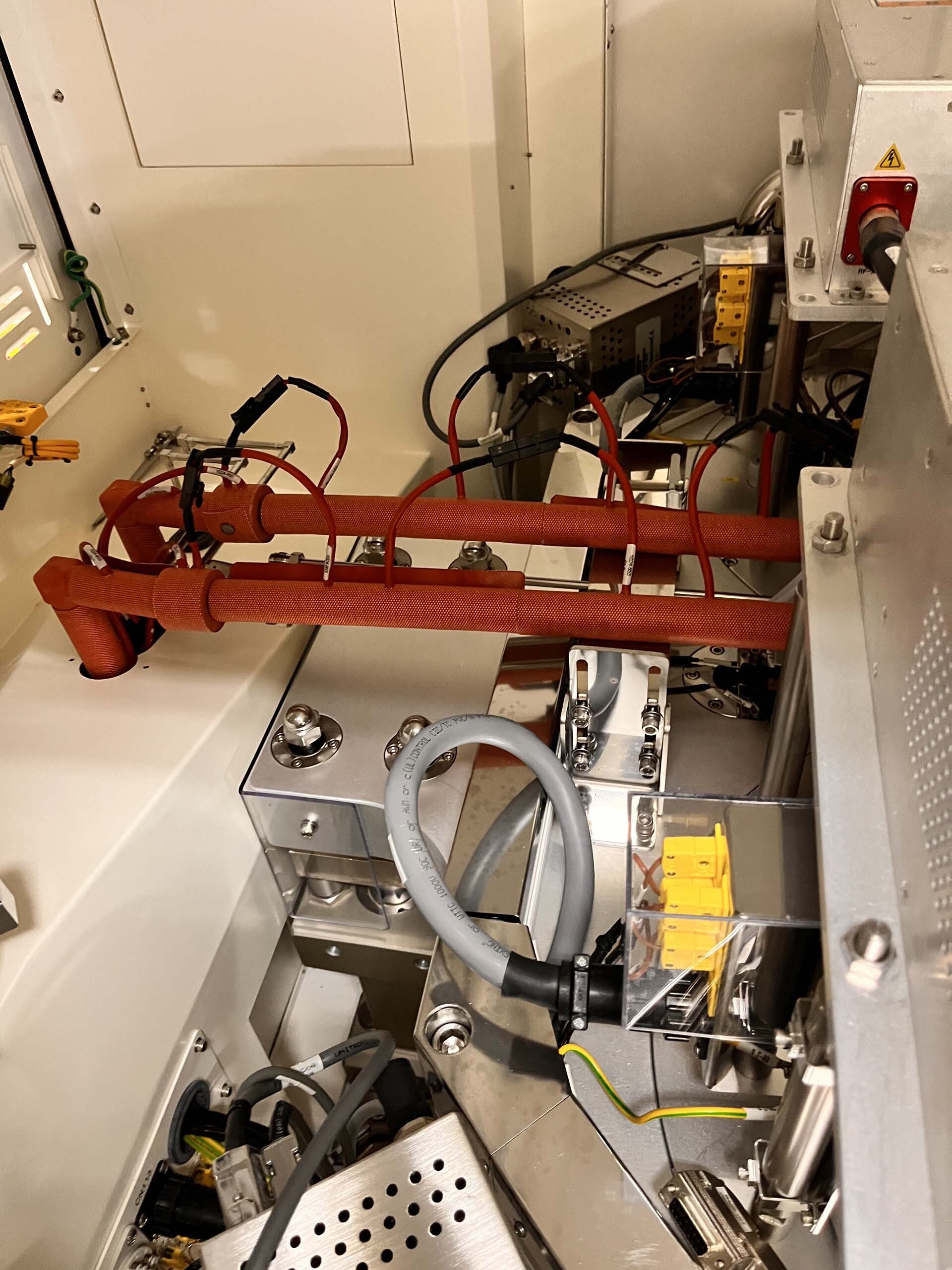

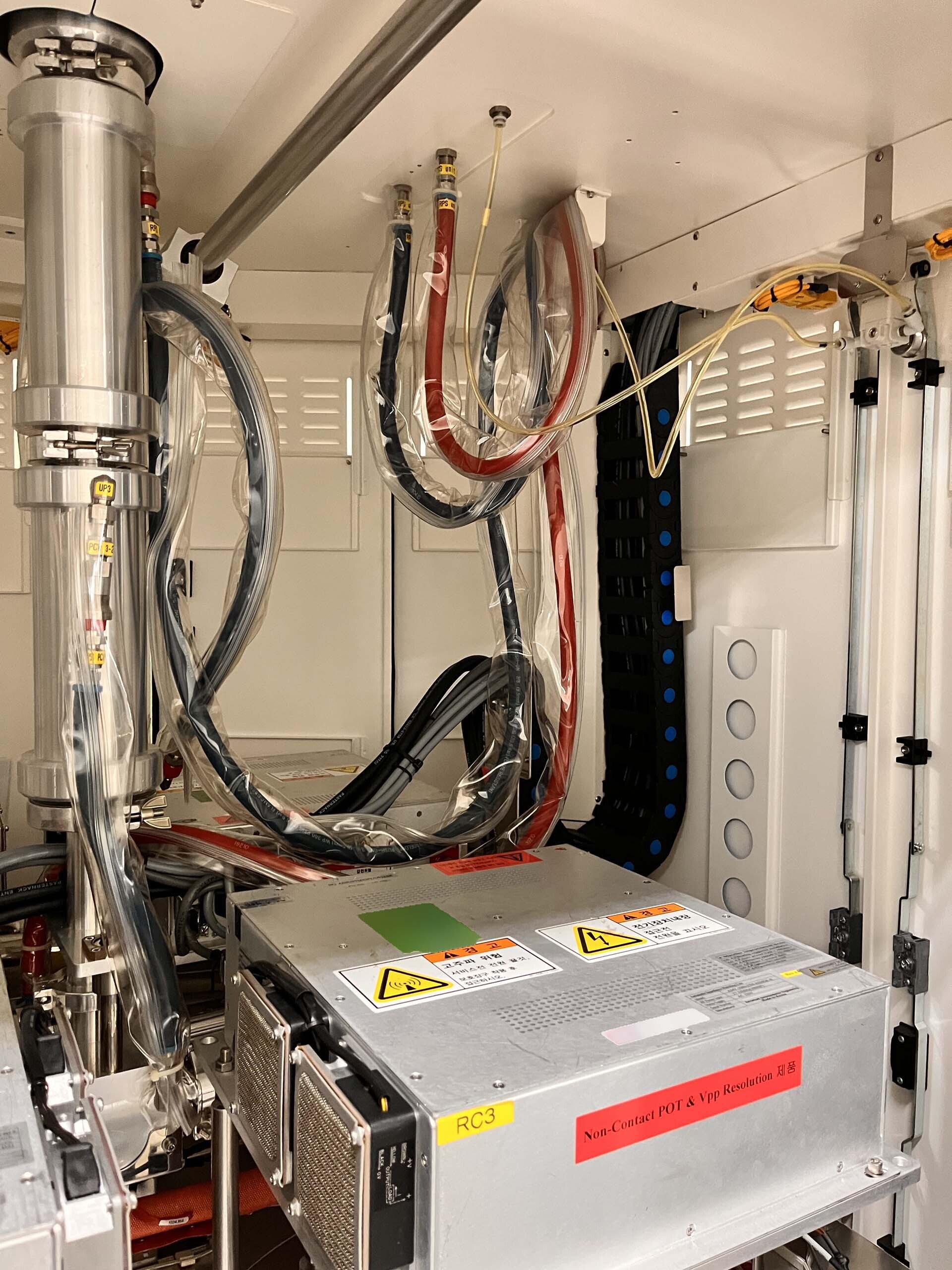

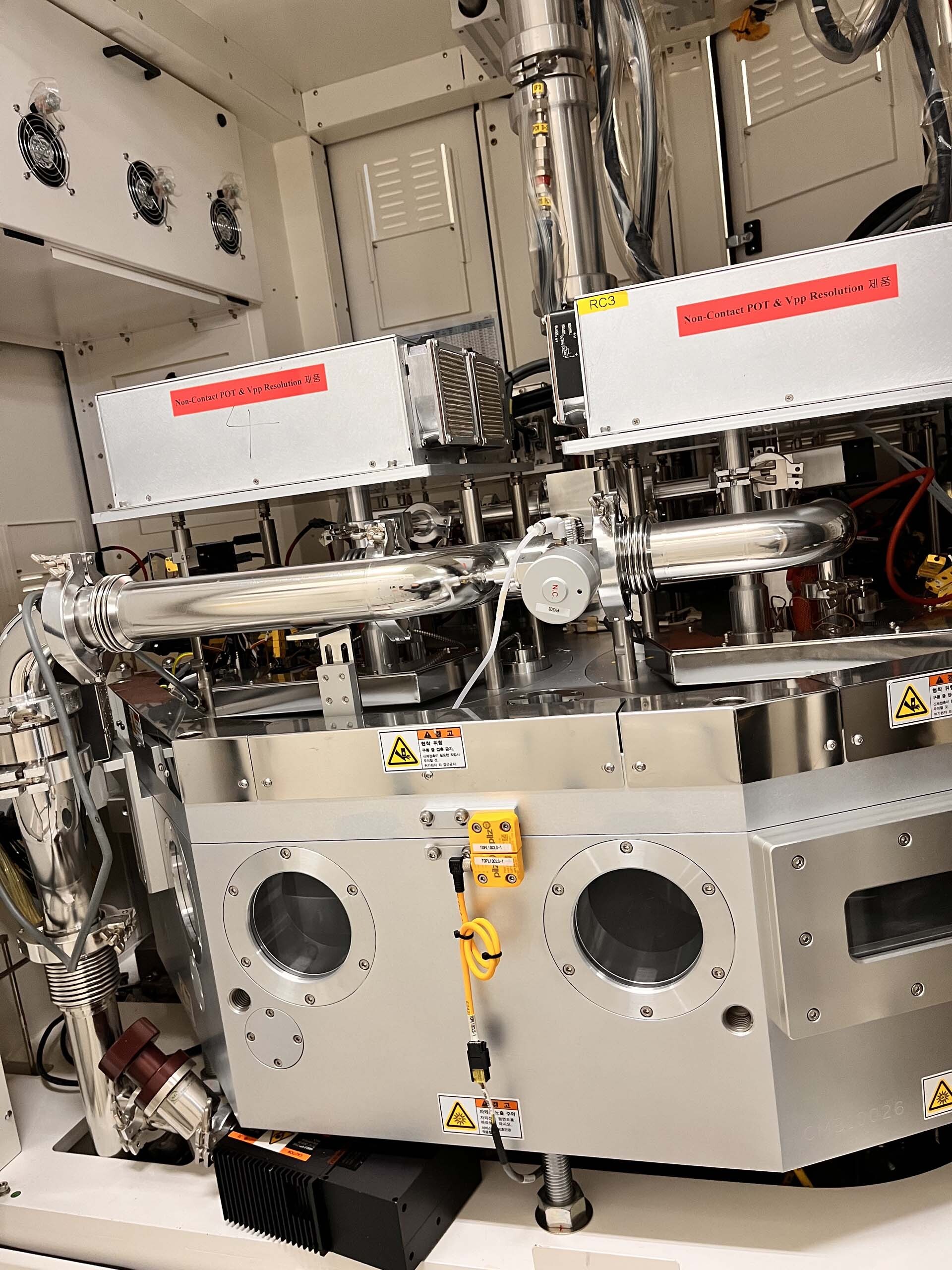

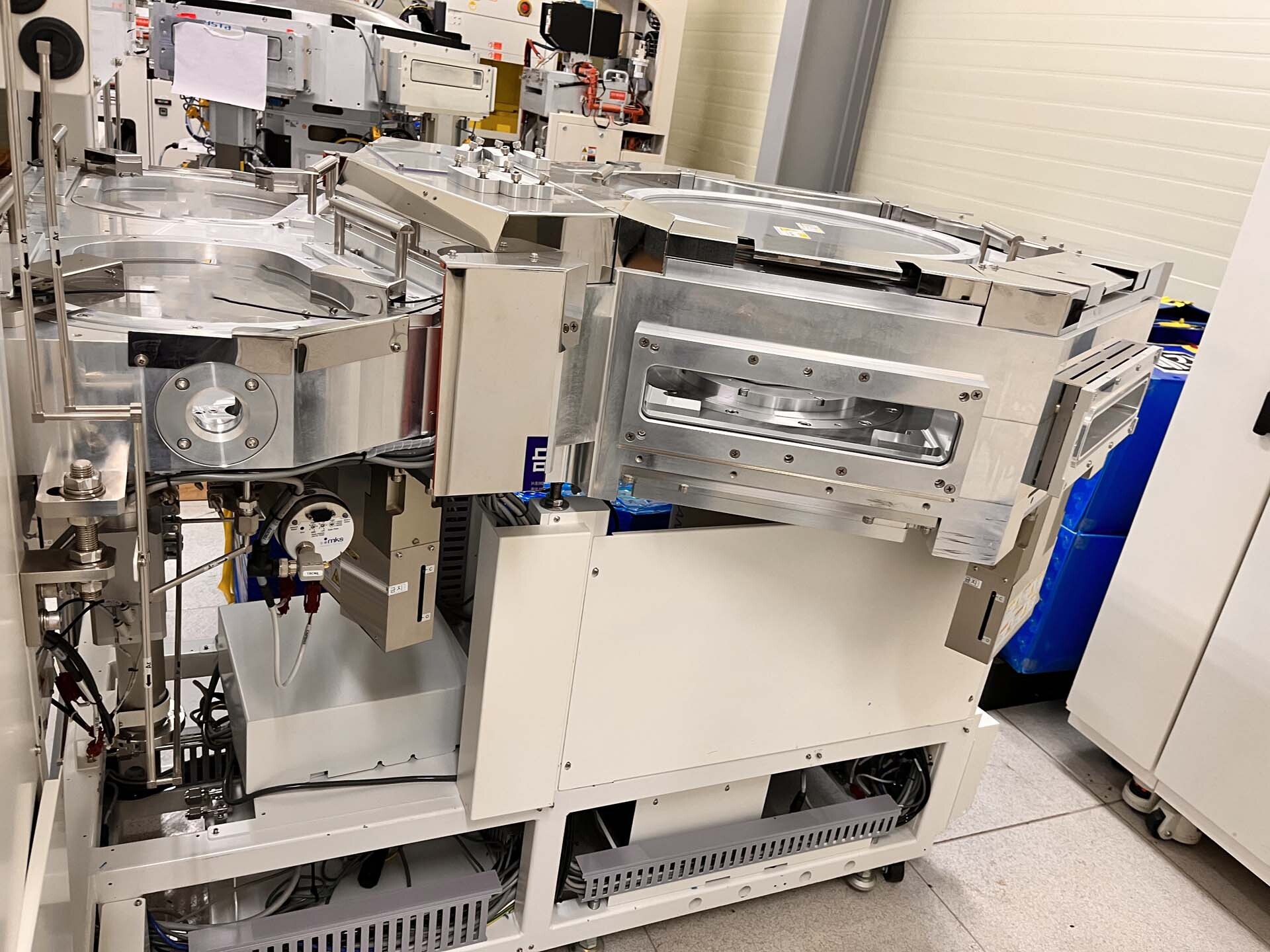

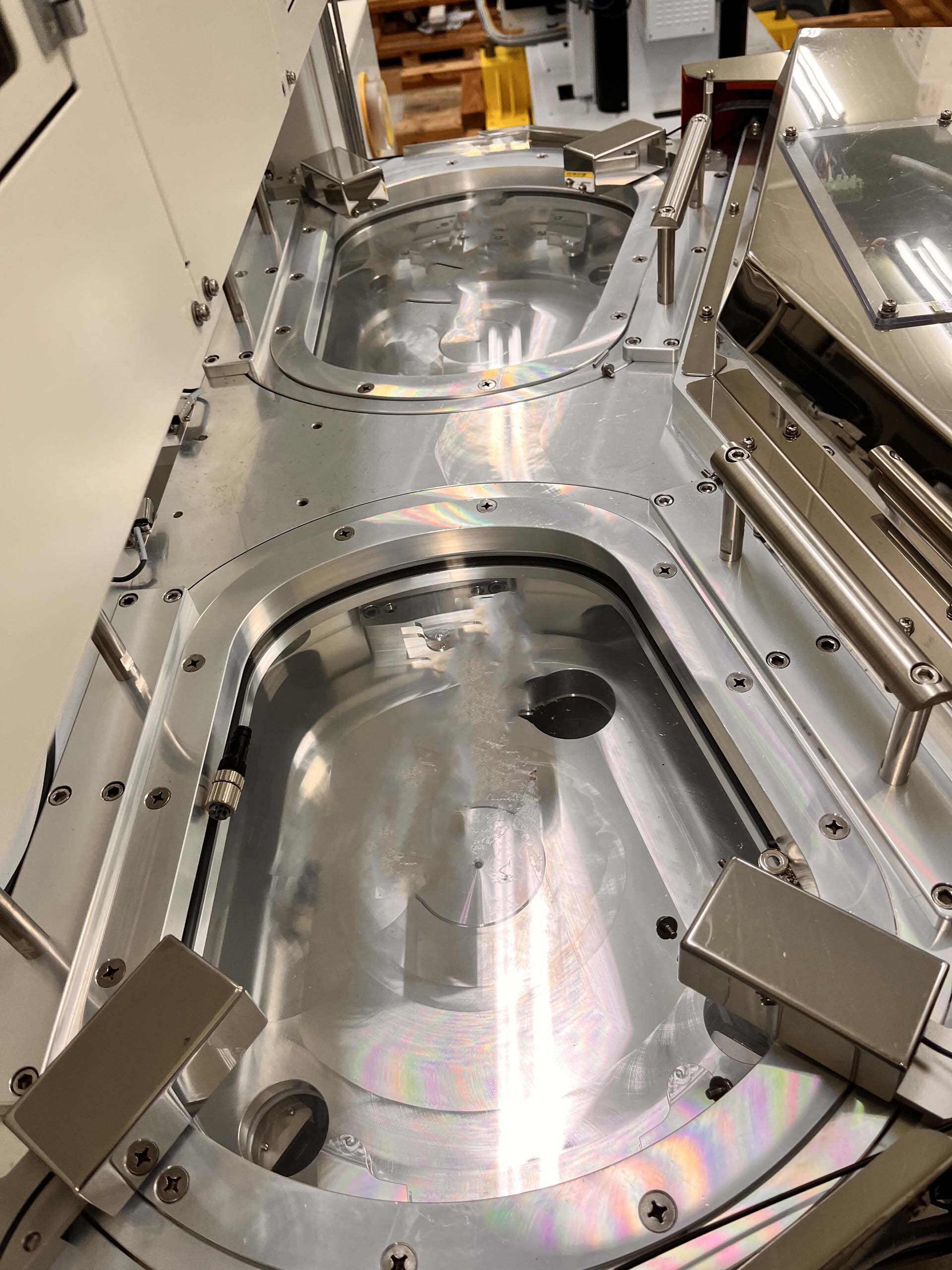

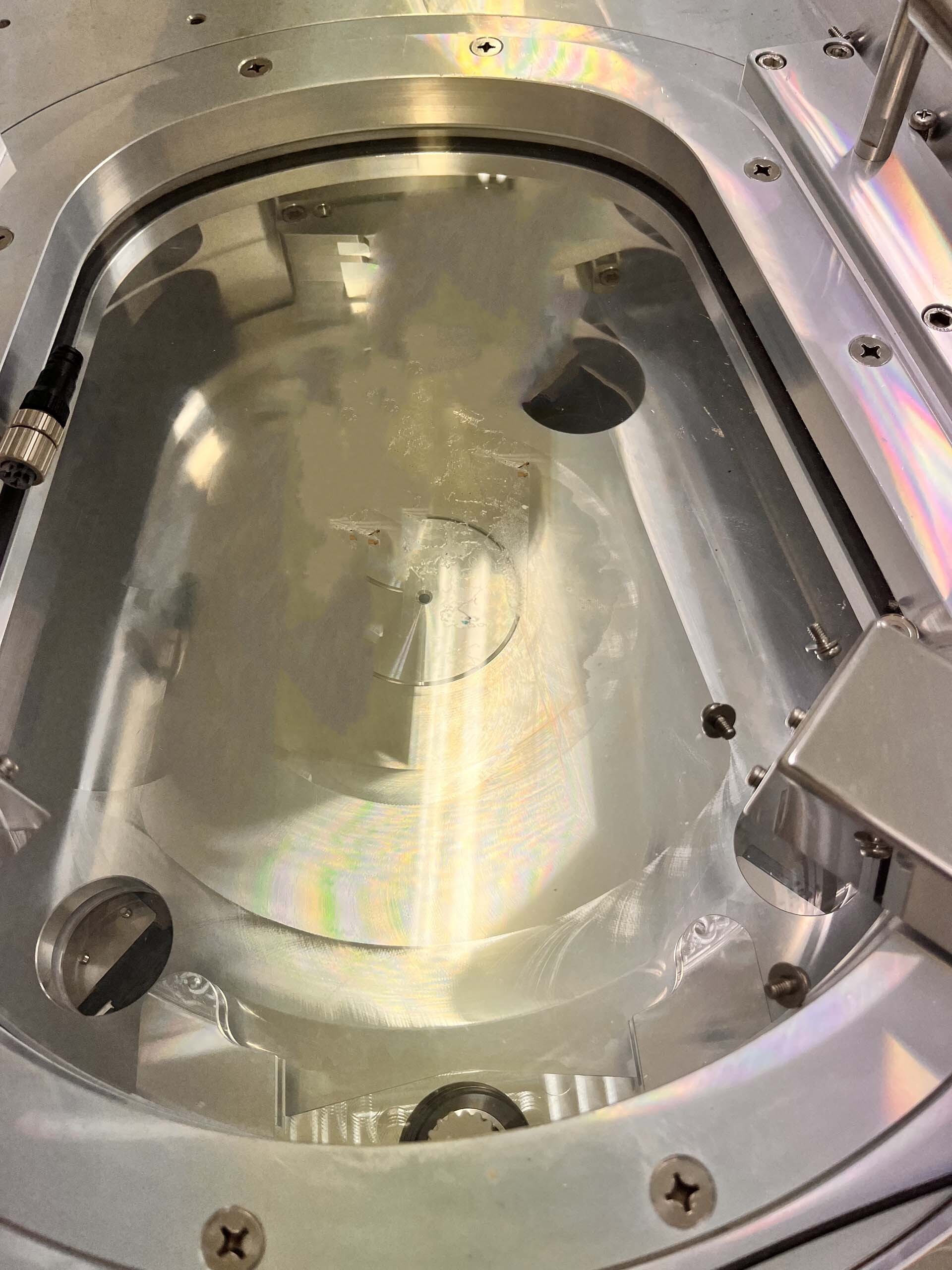

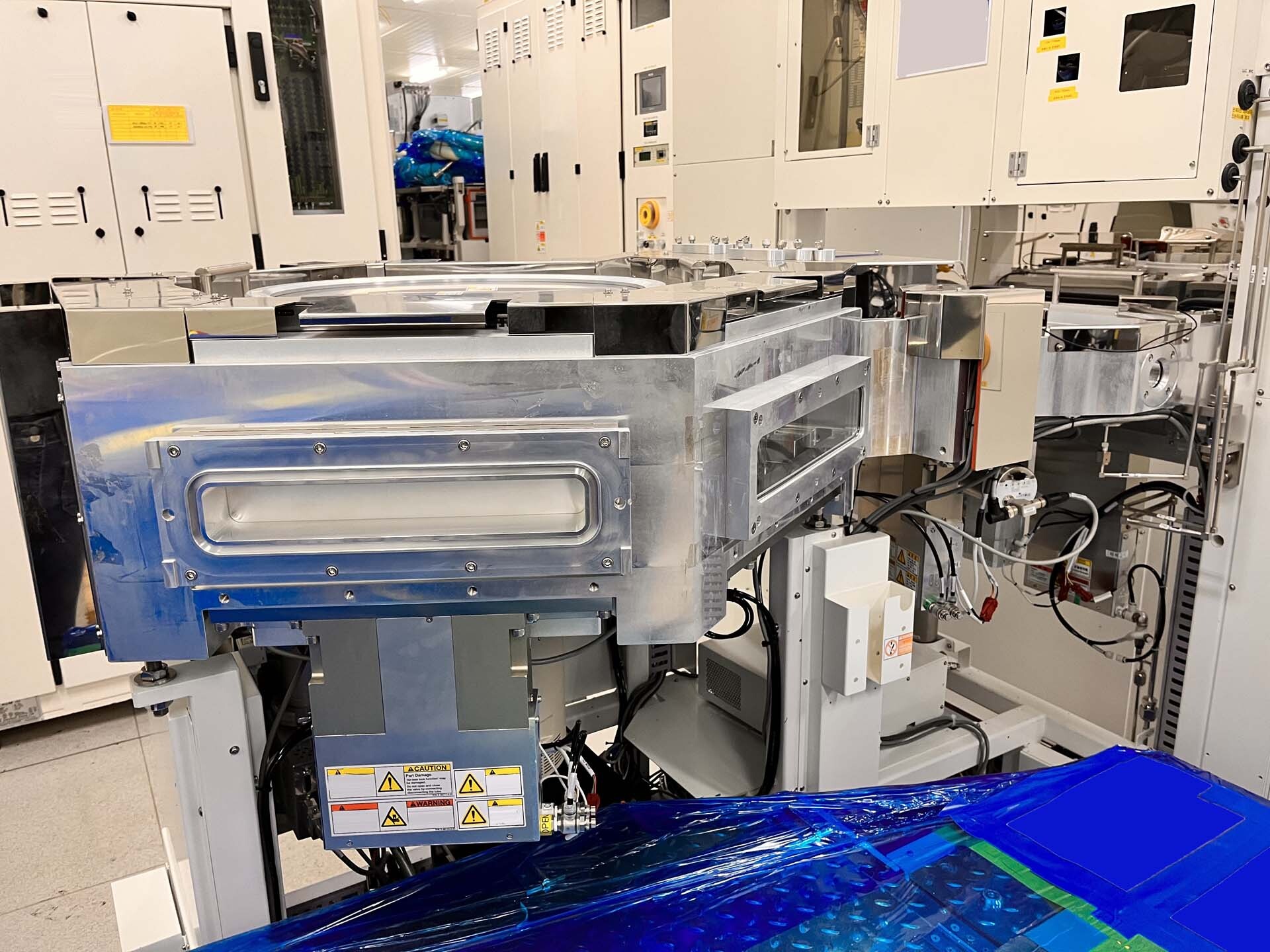

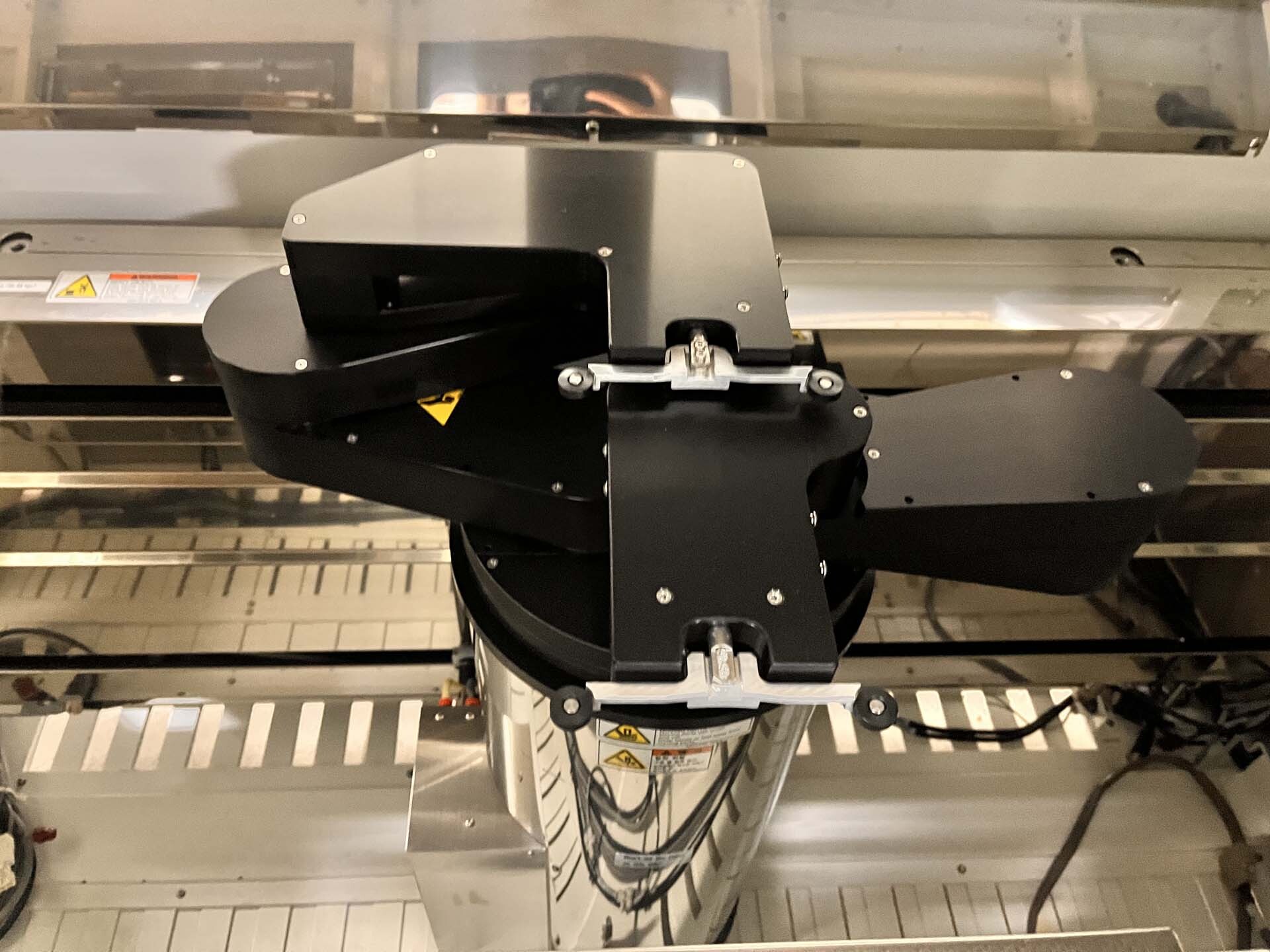

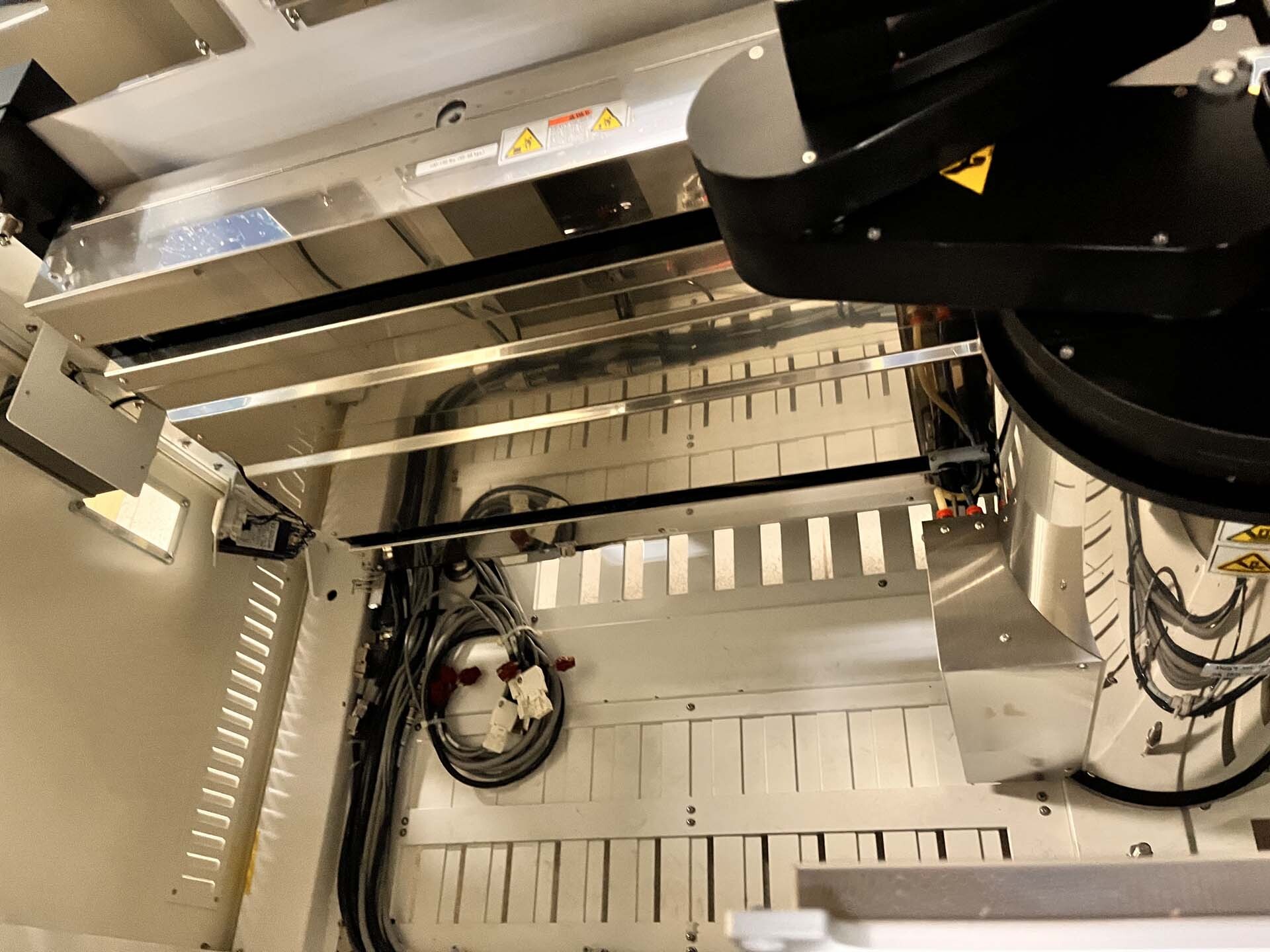

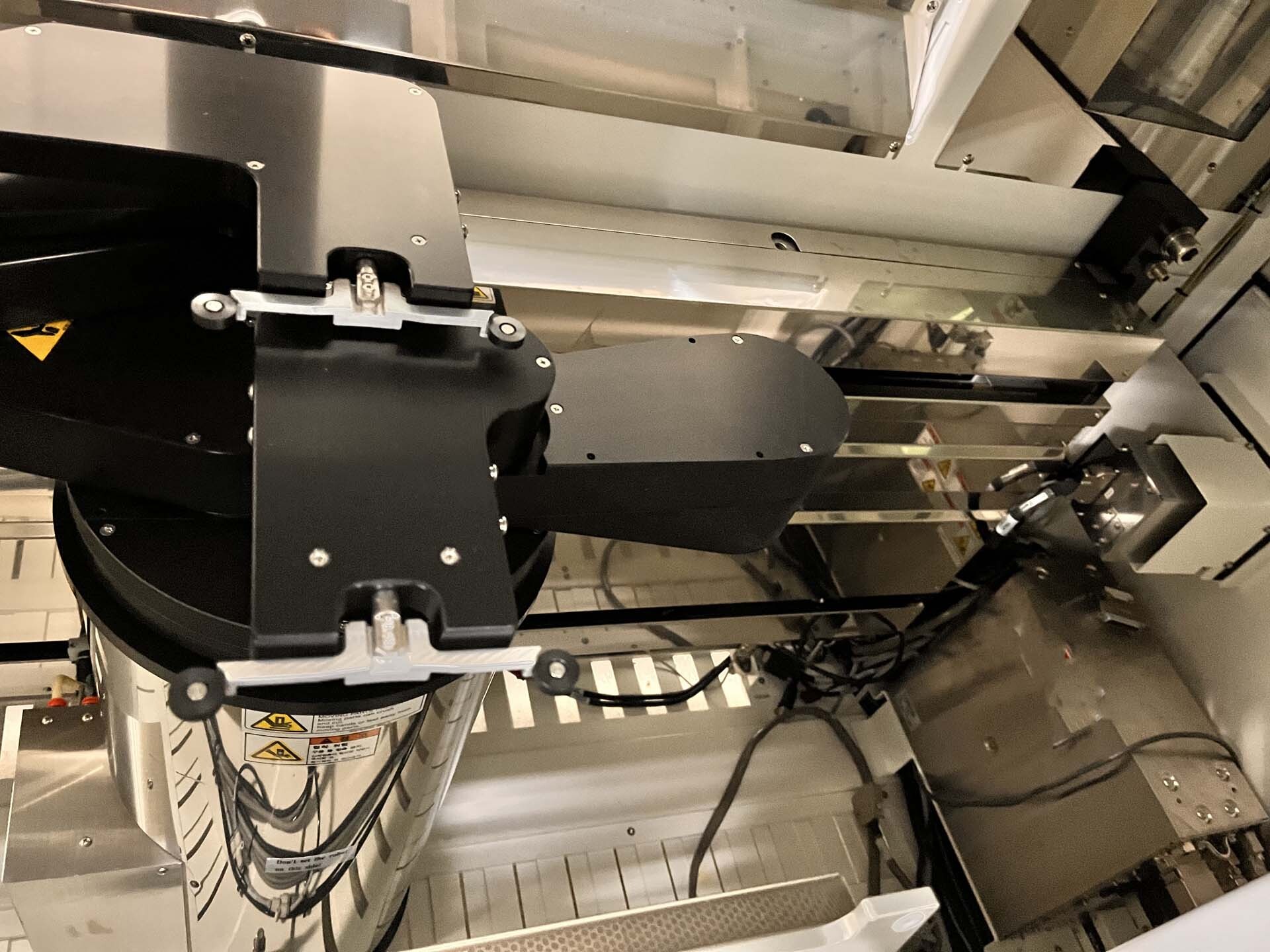

CVD Furnace, 12"

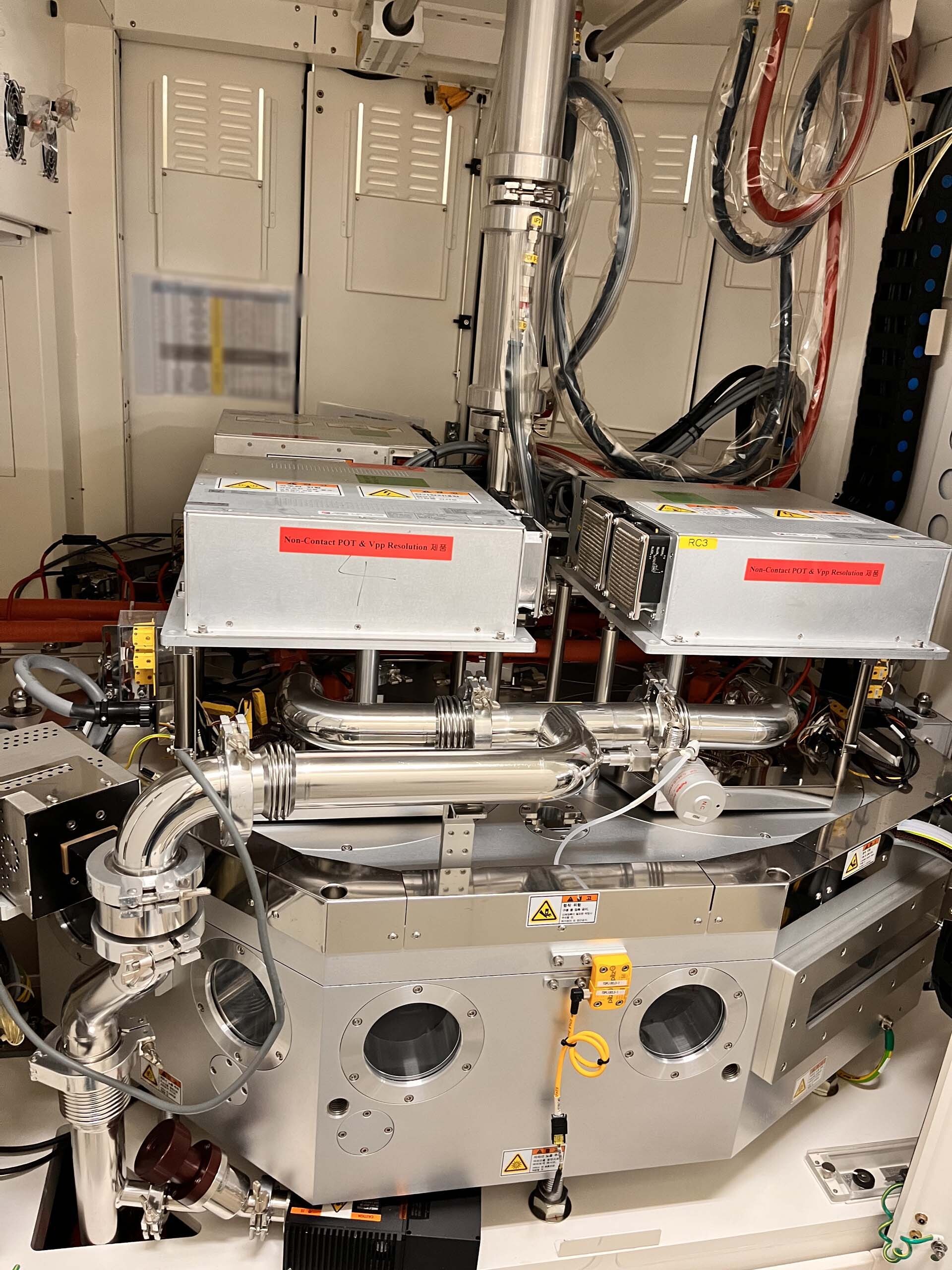

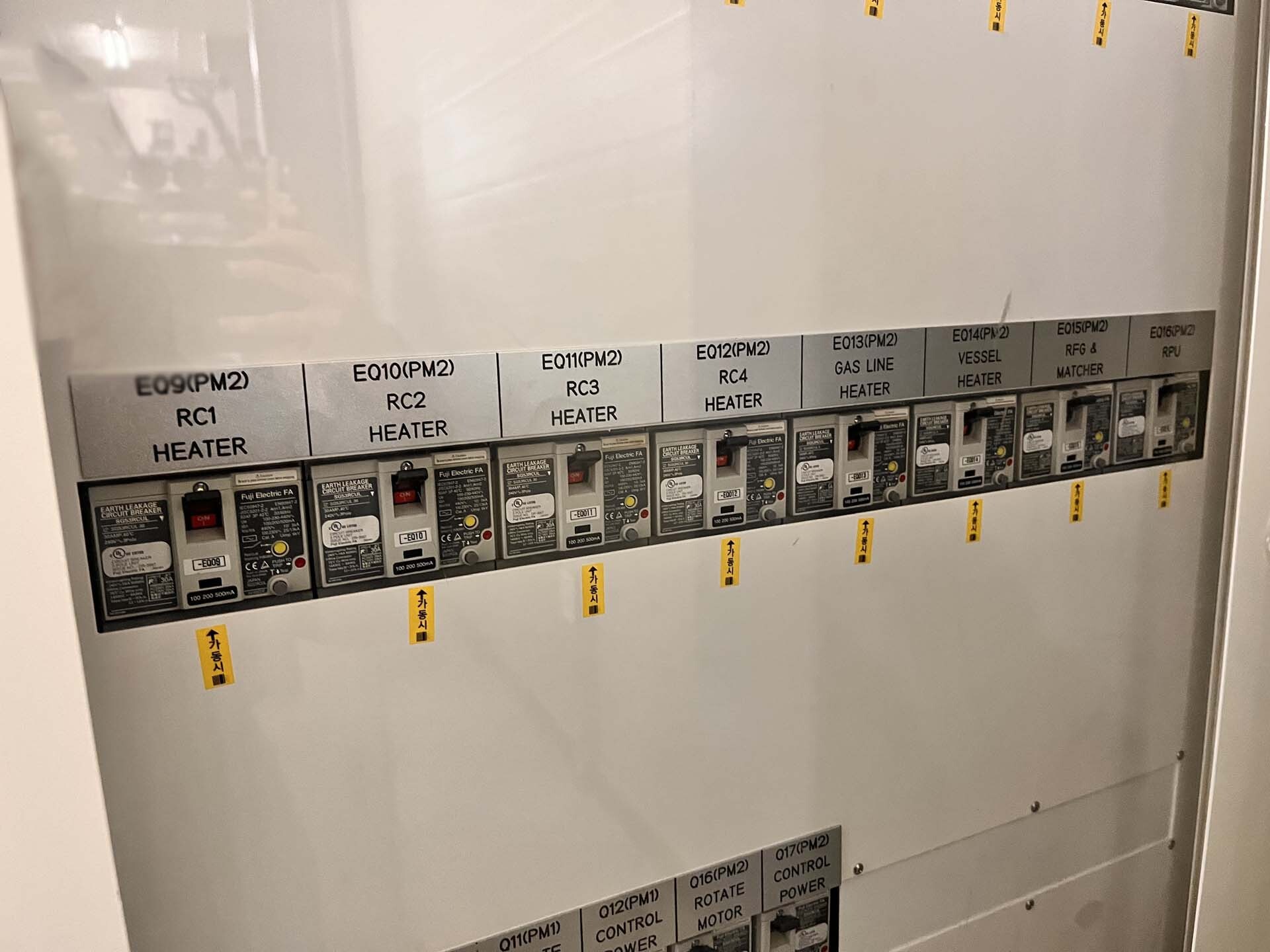

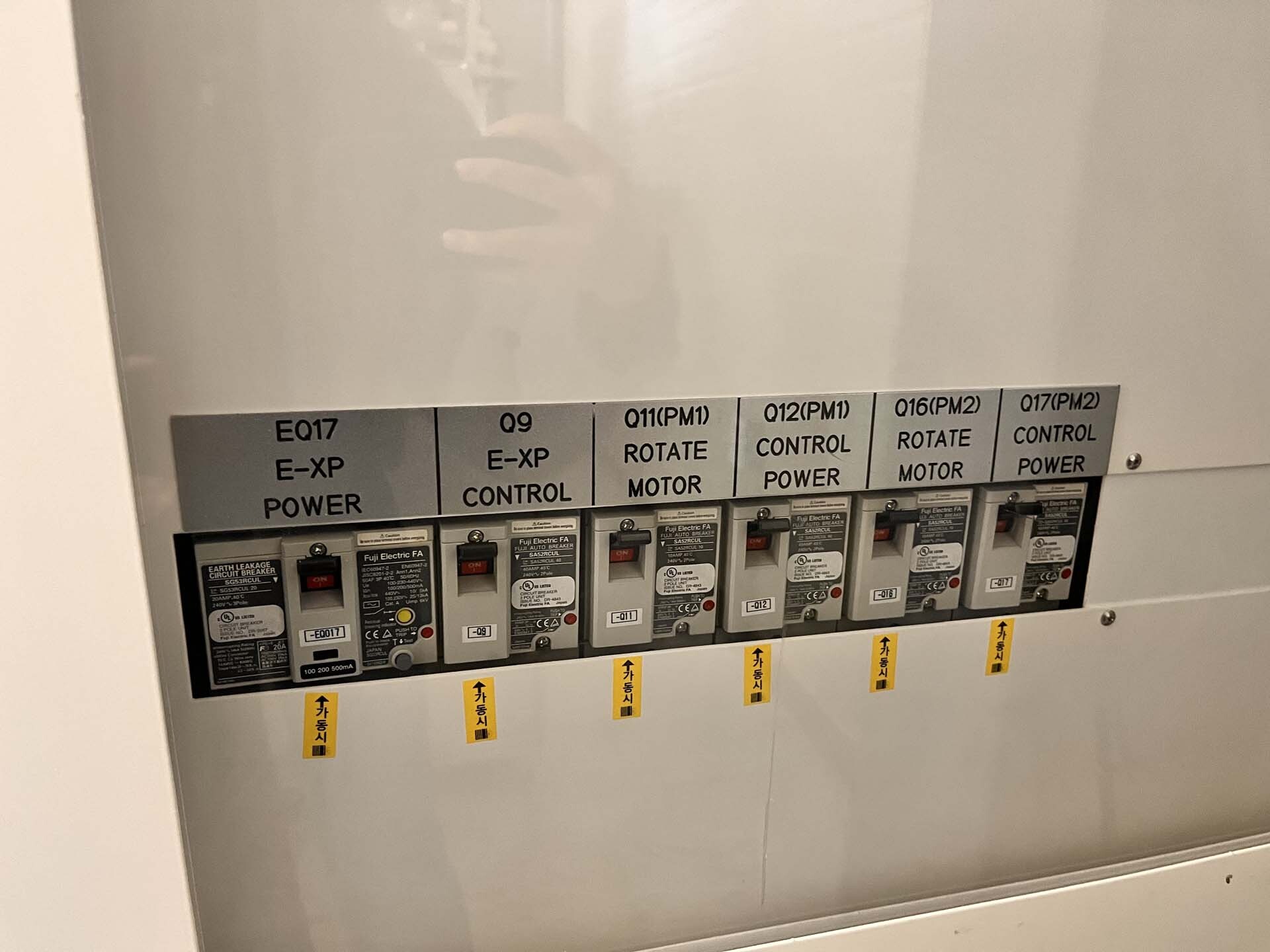

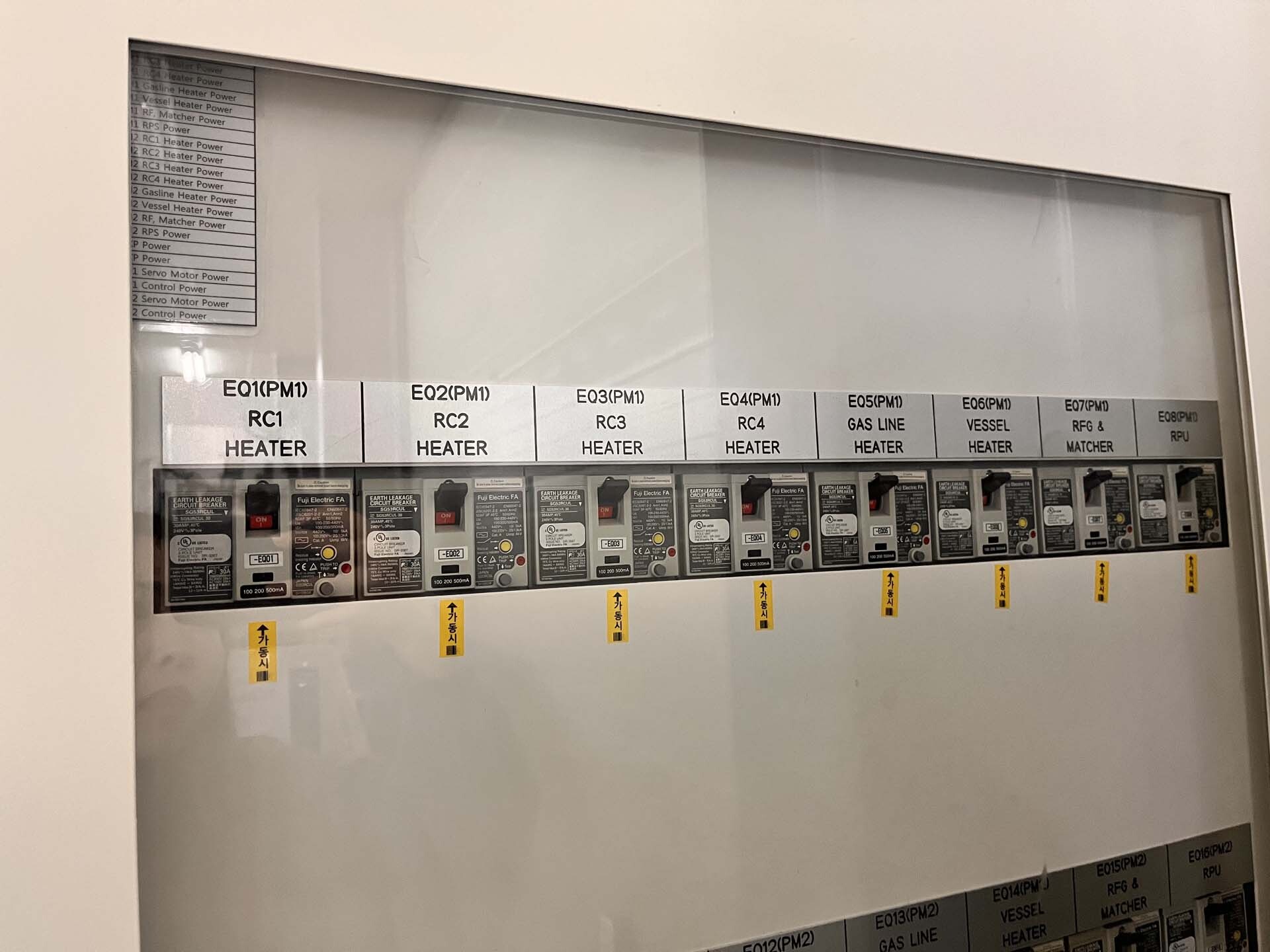

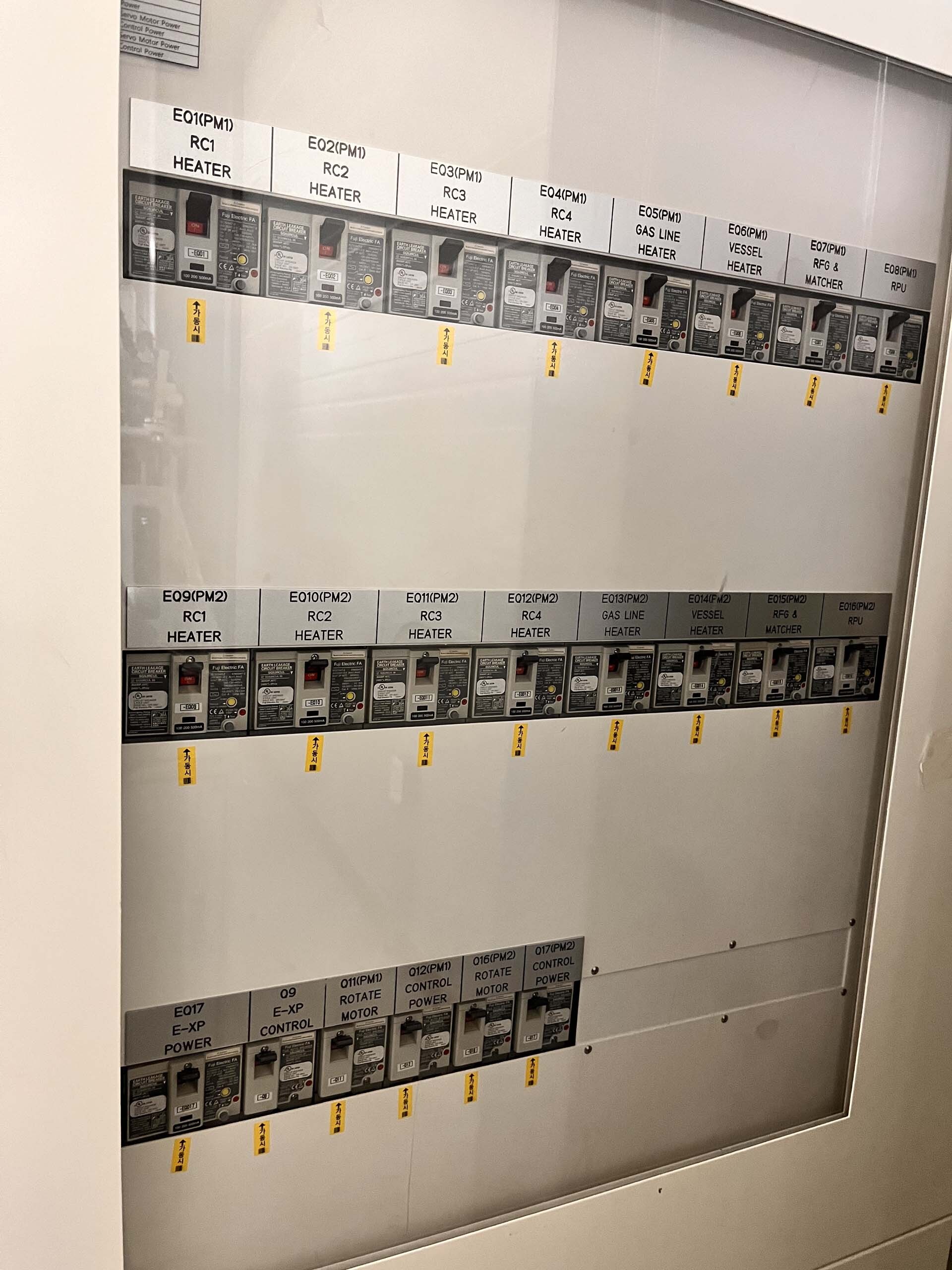

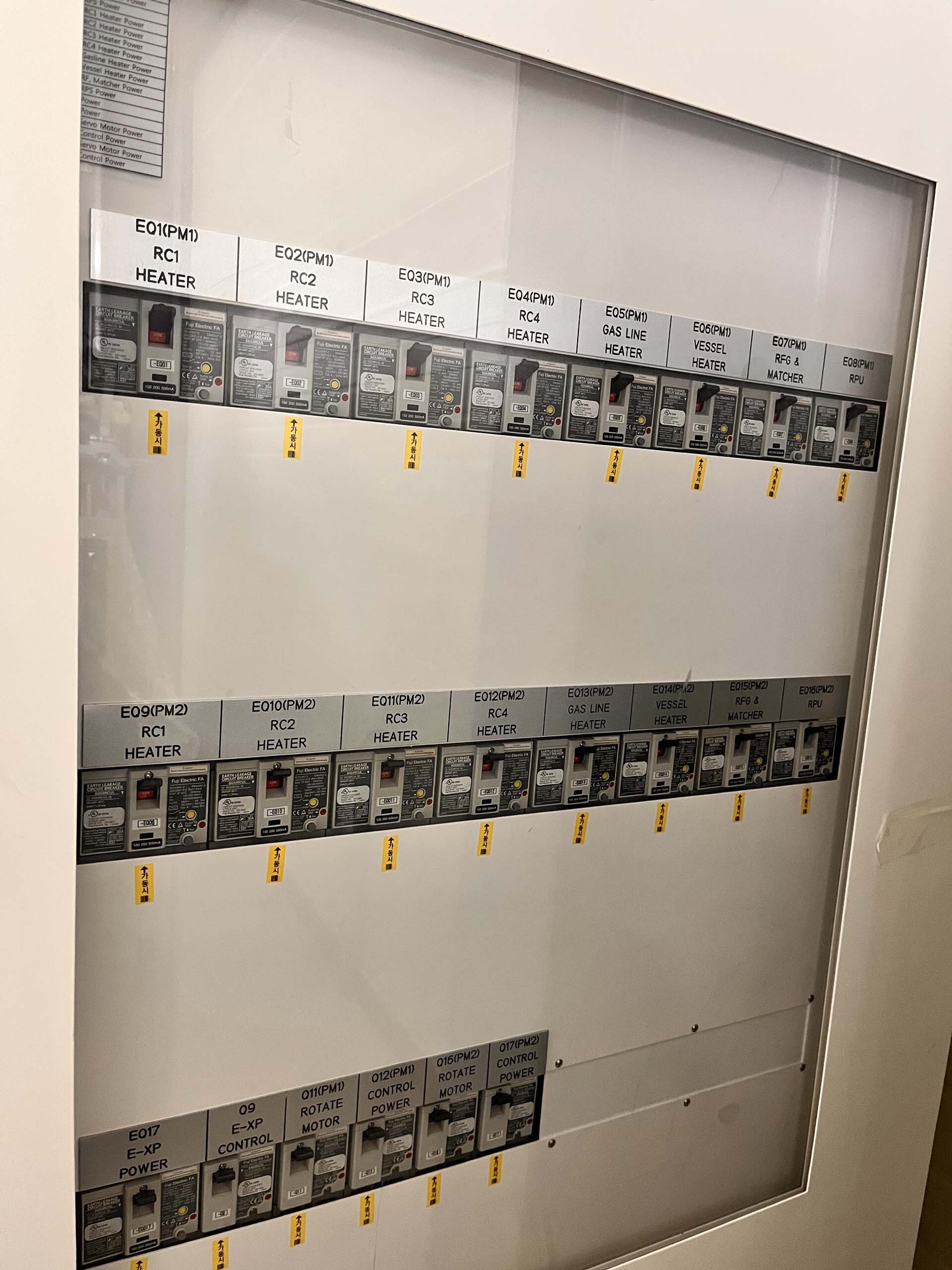

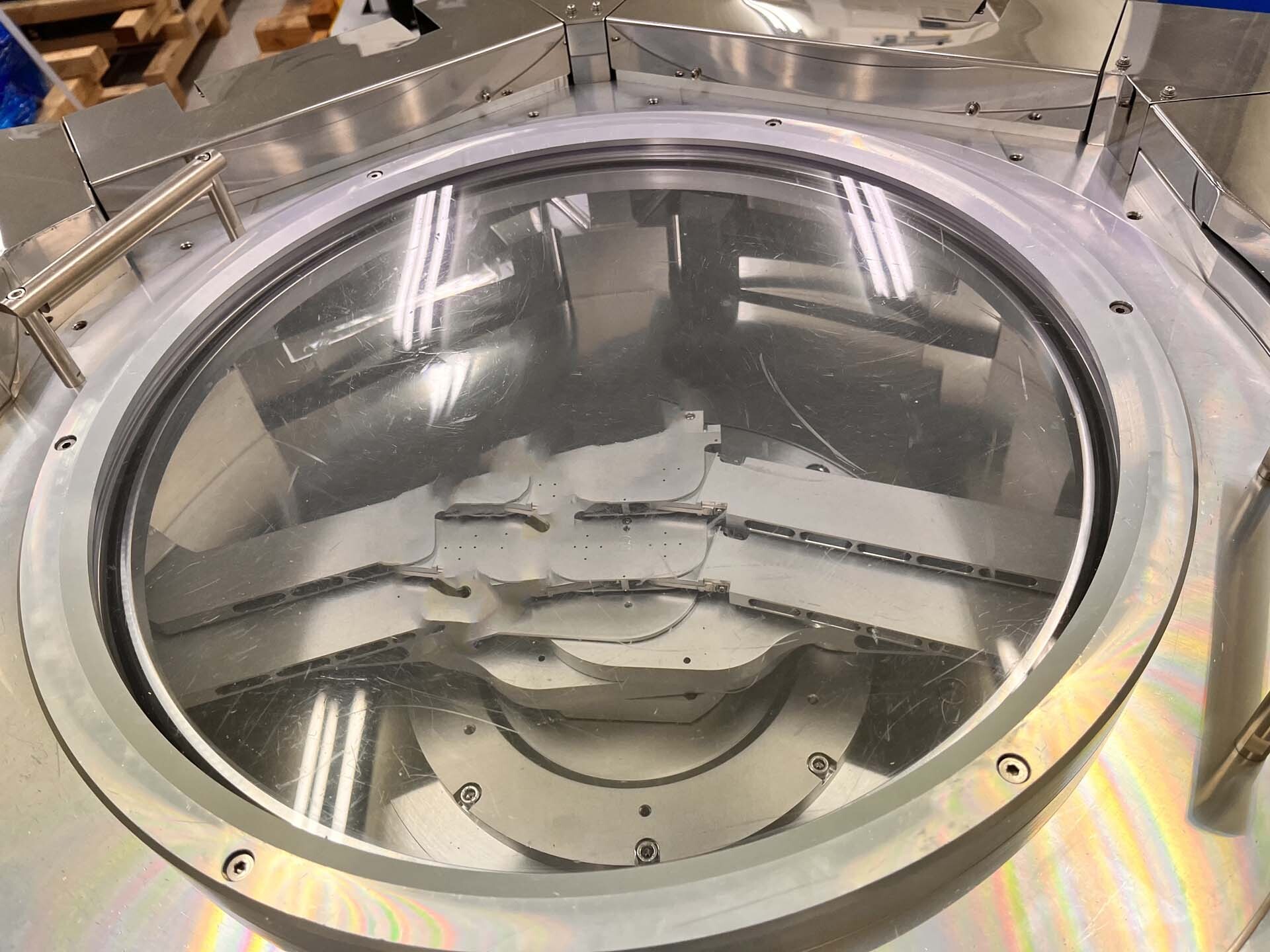

Dual chambers

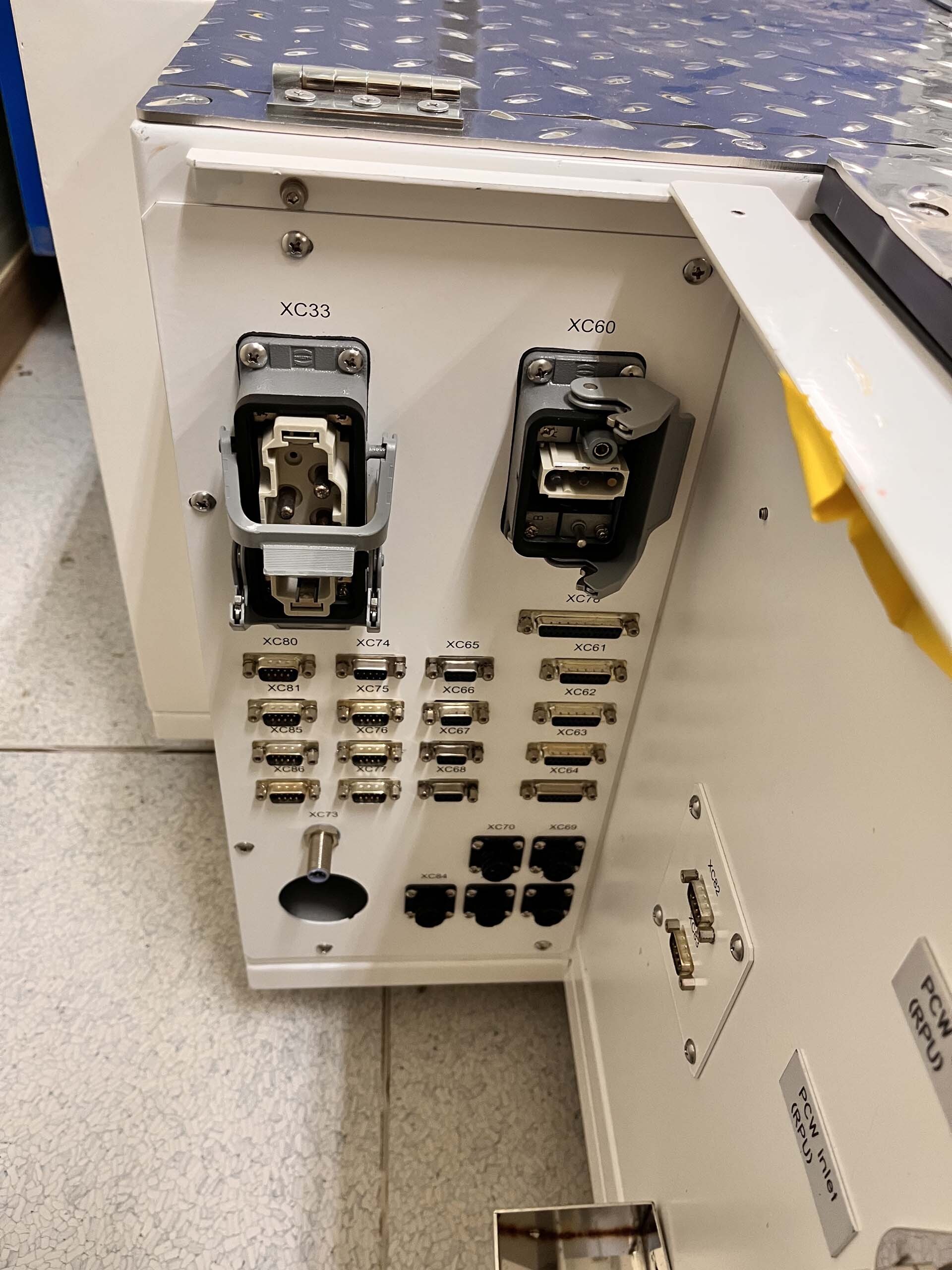

EFEM

XP Platform

2011 vintage.

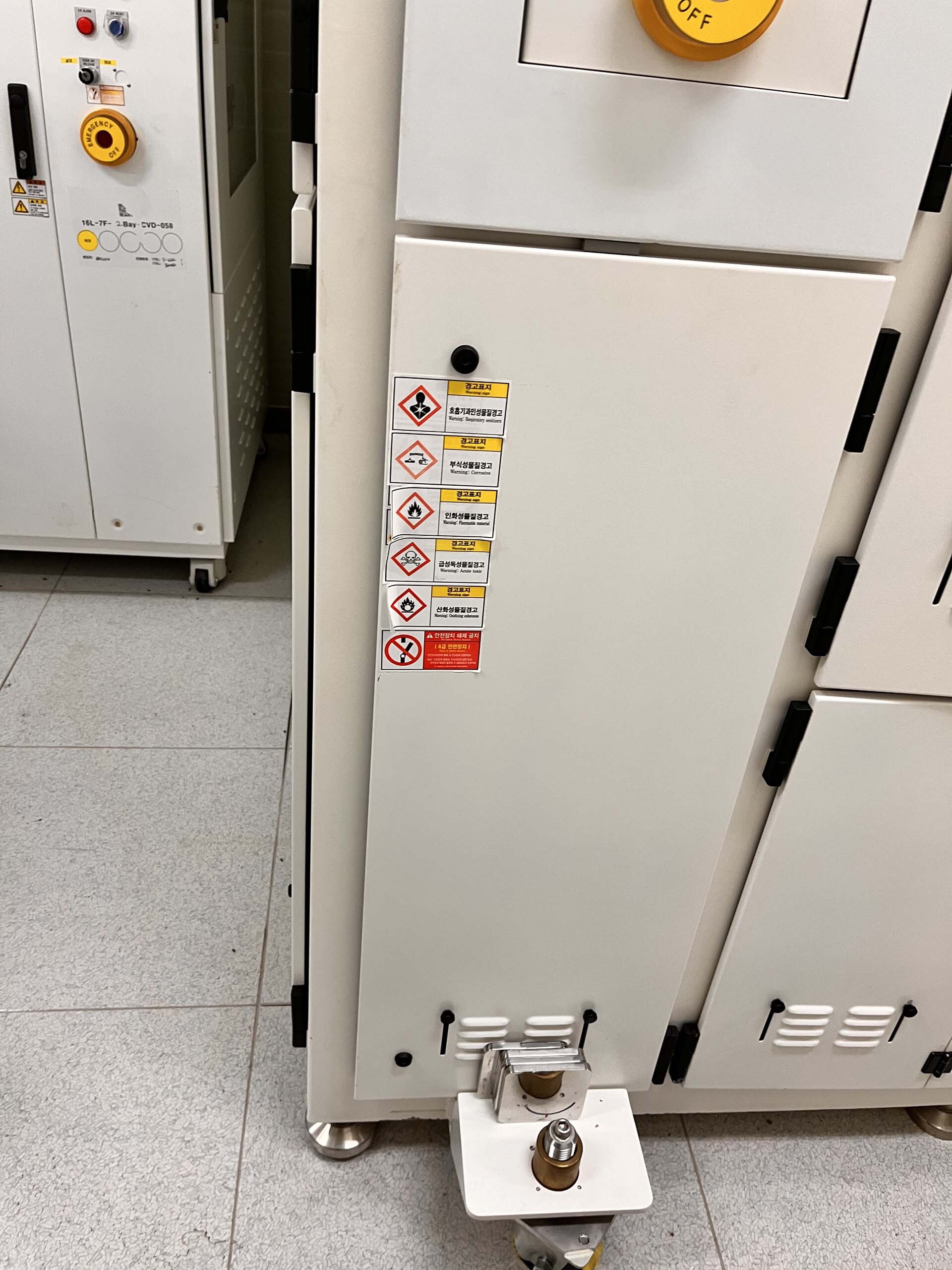

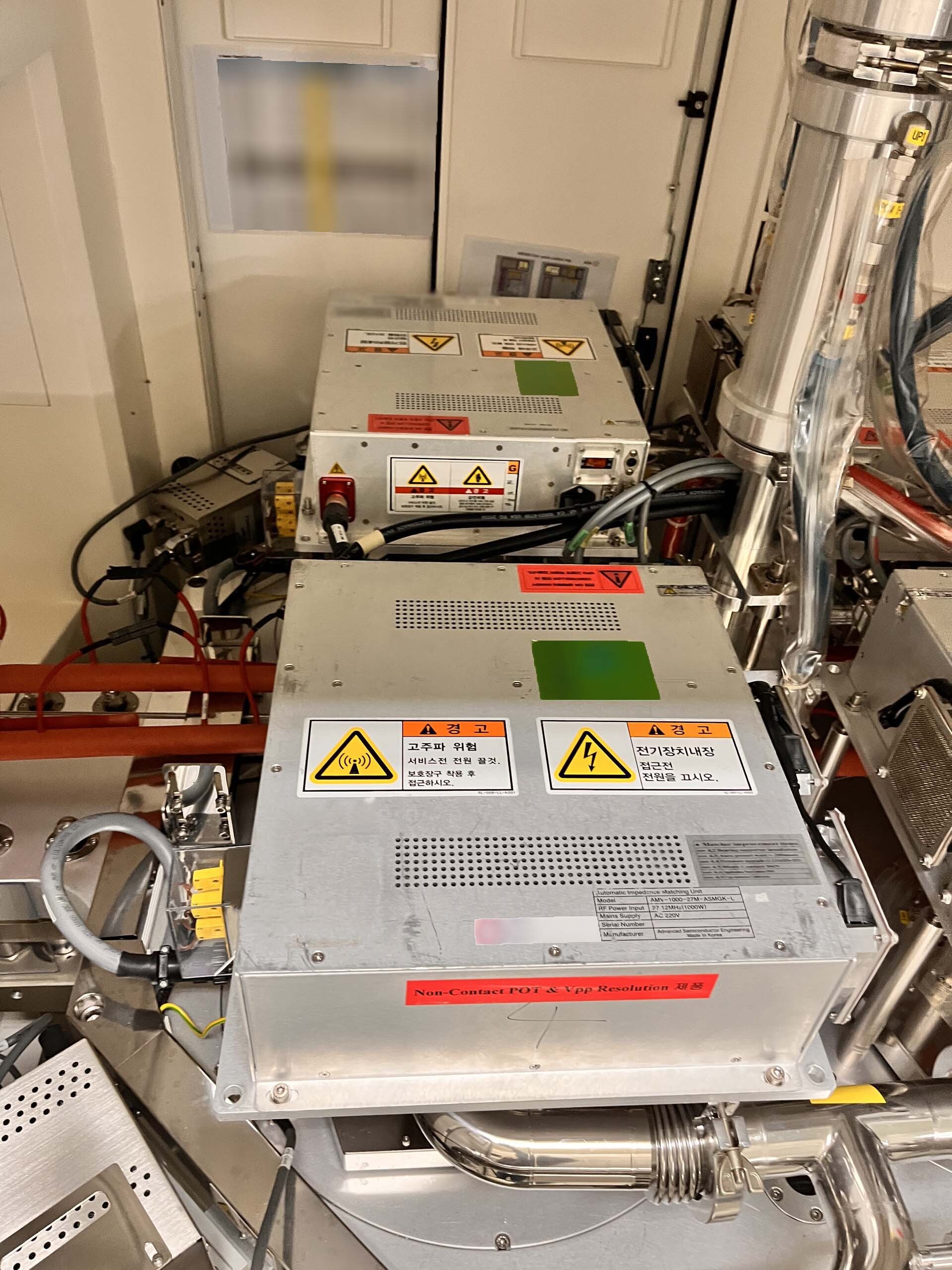

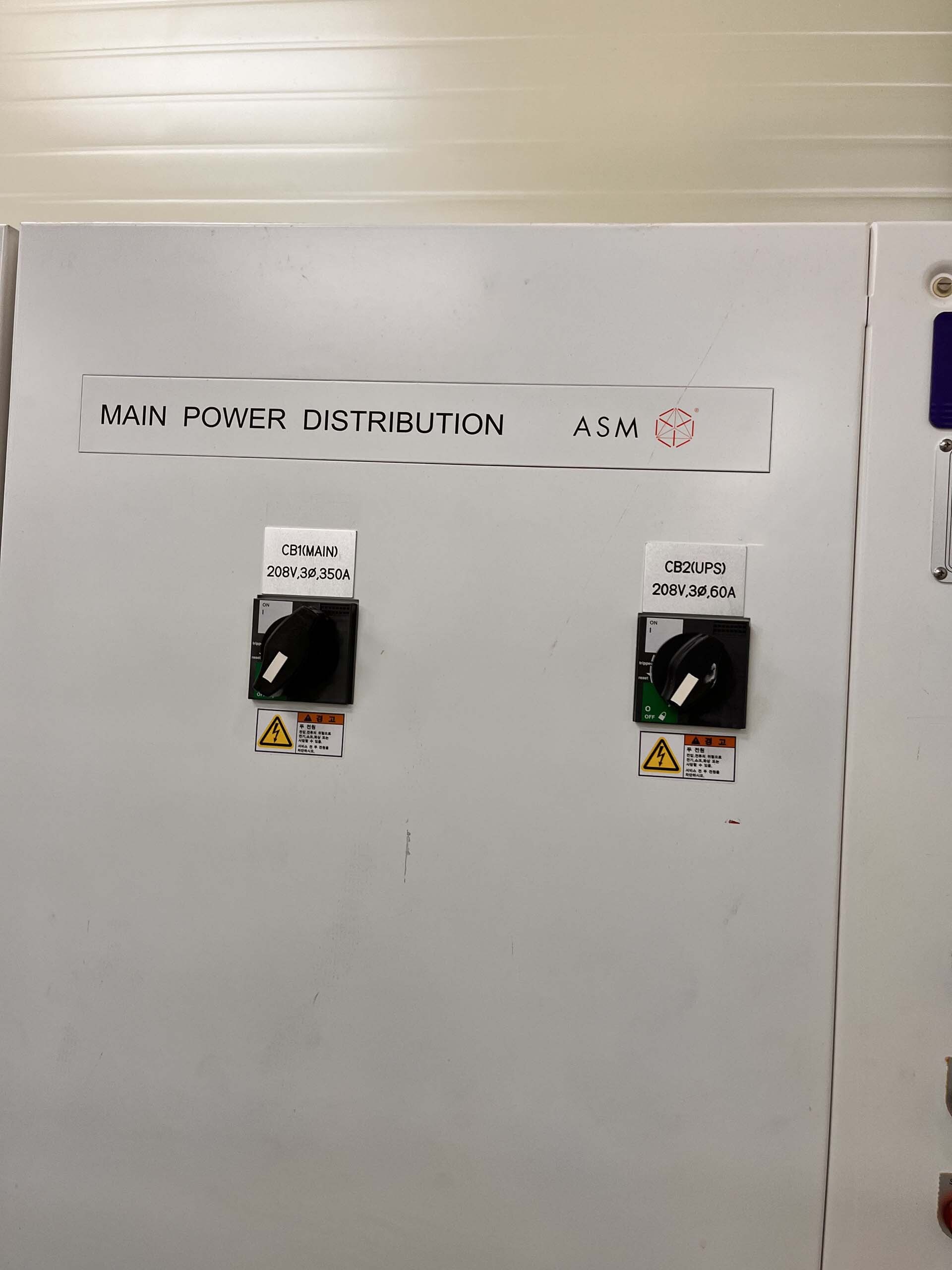

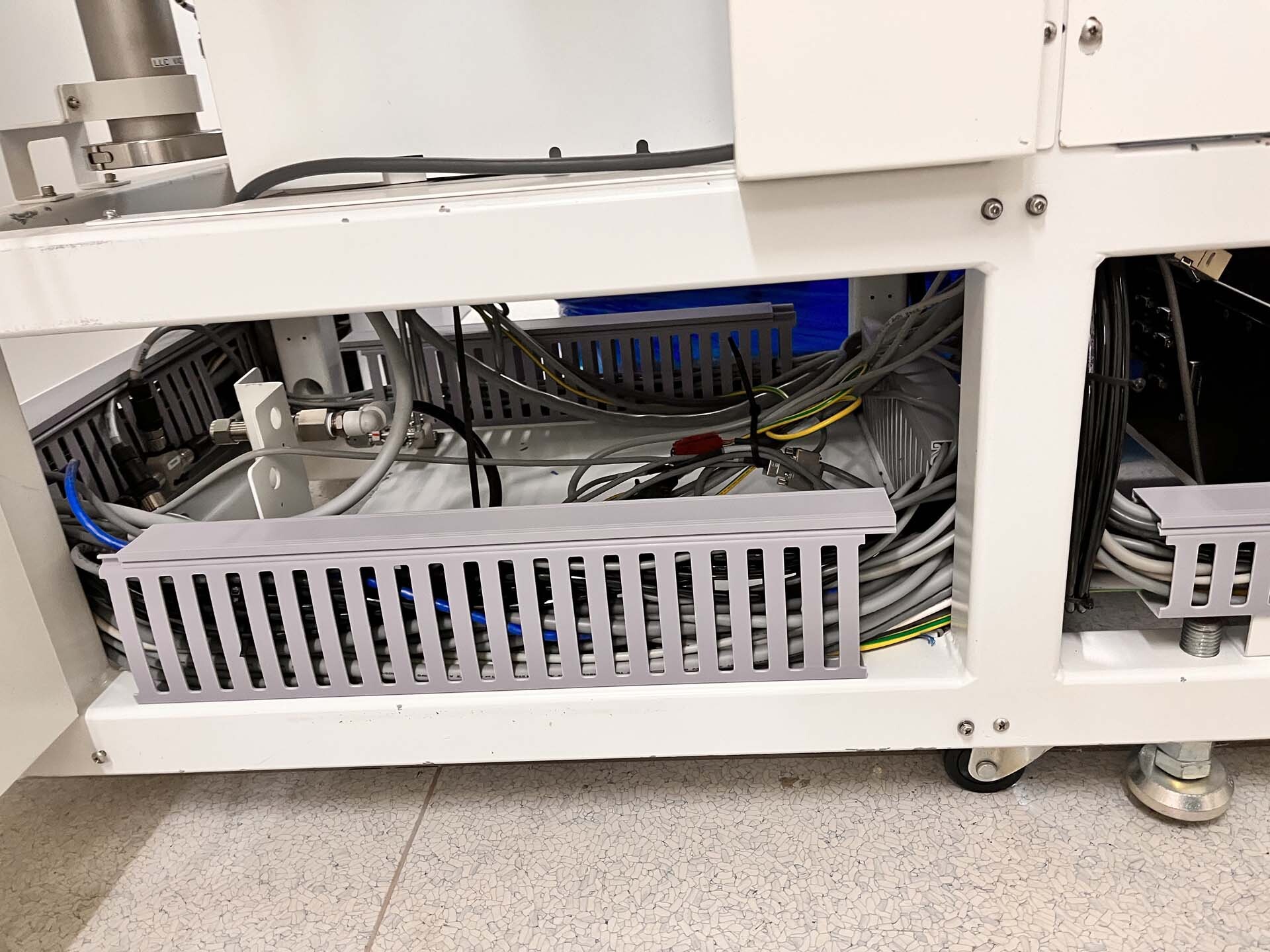

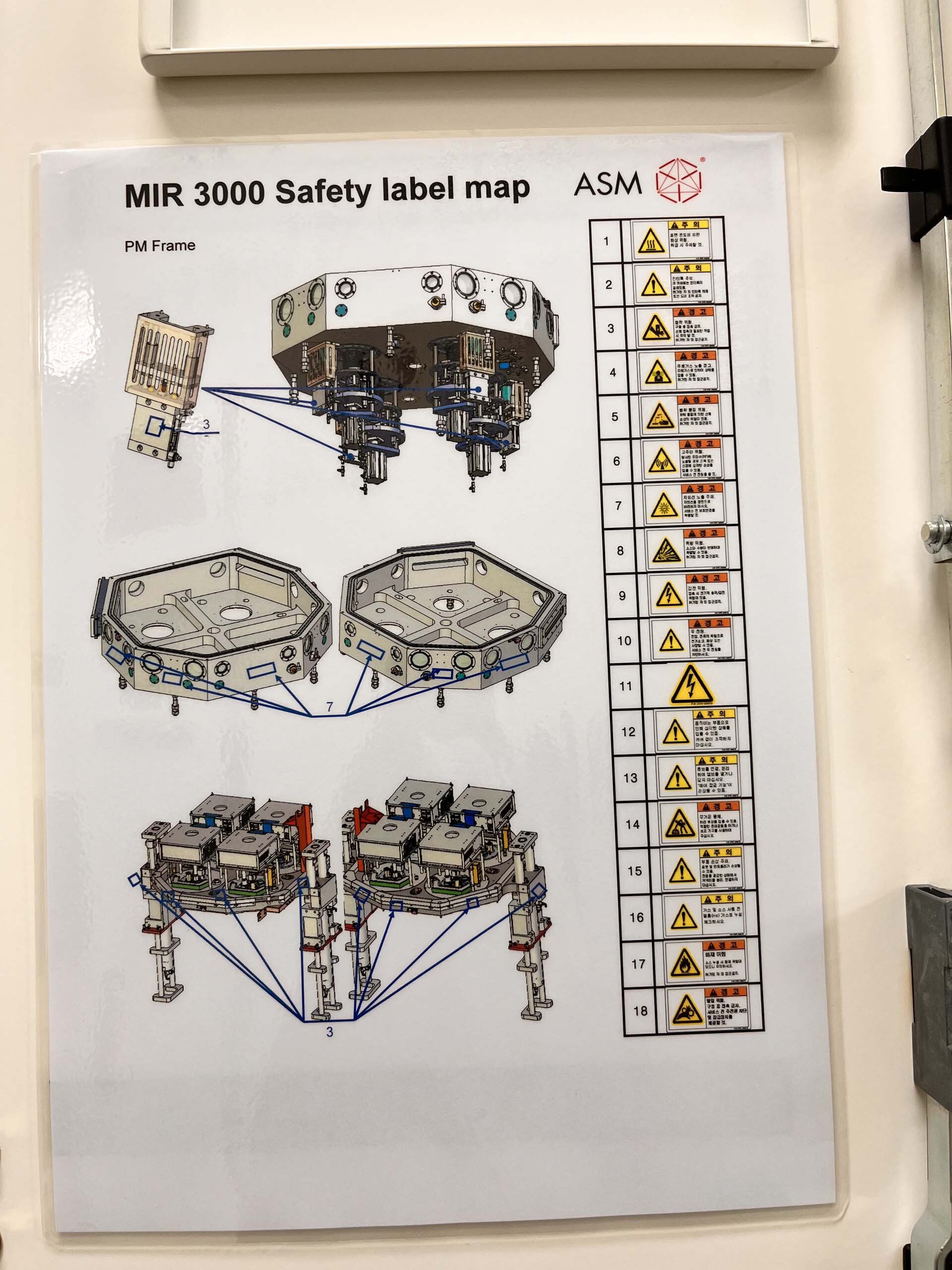

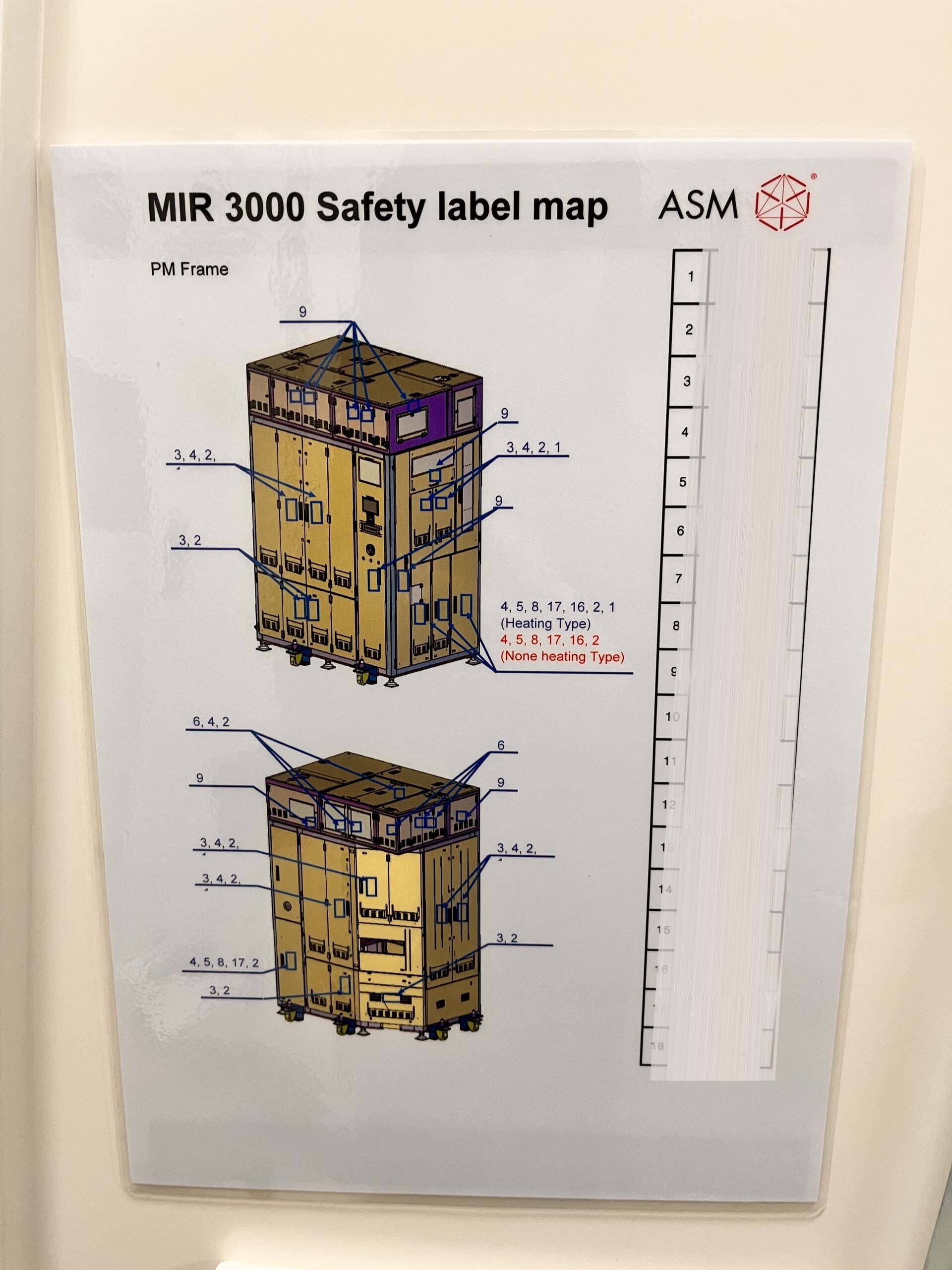

ASM MIR 3000 is a high-temperature vacuum diffusion furnace and imaging equipment designed for research and production processes. It is used for a wide range of applications such as Si integrated circuit processing and packaged devices, high temperature oxidation, deposition, thermal annealing, dopant activation, and more. MIR 3000 is a robust, automated system suitable for both laboratory and industrial applications, with an easy-to-use graphical interface. ASM MIR 3000 features dual wafer capability with a versatile execution environment, allowing users to load separate process recipes and execute them independently with precise temperature control and control over forced cooling segments. It has thermopiles and additional cold-wall tubes to monitor the temperature homogeneity of the hot zone, which can range up to 1650ºC. Gas flows can be precisely adjusted for optimal uniformity and the variable positioning of the hot zone lid provides precise pressure control for a variety of processes. MIR 3000 also features a high-resolution imaging unit with onboard E-beam and wafer cassette, multiple particle detectors, a built-in wafer stage, and frequency-based wafer orientation. It is also equipped with a full suite of automation capabilities, including on-demand wafer ordering, real-time process monitoring and control, recipe creation, and more. ASM MIR 3000 is designed for ease of maintenance and serviceability. It has a modular design for easy replacement of parts and its efficient cooling machine reduces downtime due to temperature fluctuations. MIR 3000 also has numerous safety features such as operator-controlled hot-zone dopant activation and automated pressure and temperature control. To ensure maximum process continuity and repeatability, ASM MIR 3000 is continuously monitored and adjusted to prevent the buildup of overspray or outgassing residue. Its integrated vacuum interlock tool provides fail-safe operation and its monitoring systems warn of any unnoticed process malfunctions. Overall, MIR 3000 is a versatile and powerful asset for a variety of production and research applications. It is designed to provide reliable, reliable performance, with highly automated processes and precise control of temperature, pressure, and flow. The different components of the model are user friendly and easy to integrate with other components in a production environment, allowing users to achieve process uniformity with maximum yields.

There are no reviews yet