Used CENTROTHERM Centronic E1200 HT260-3 #65626 for sale

URL successfully copied!

Tap to zoom

ID: 65626

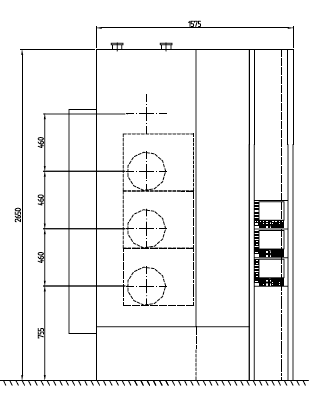

Wafer Size: 6"

Vintage: 2001

LPCVD diffusion furnace, 6”

3-Stack

Set up for: nitride, low-temperature oxide, and insitu low-temperature poly

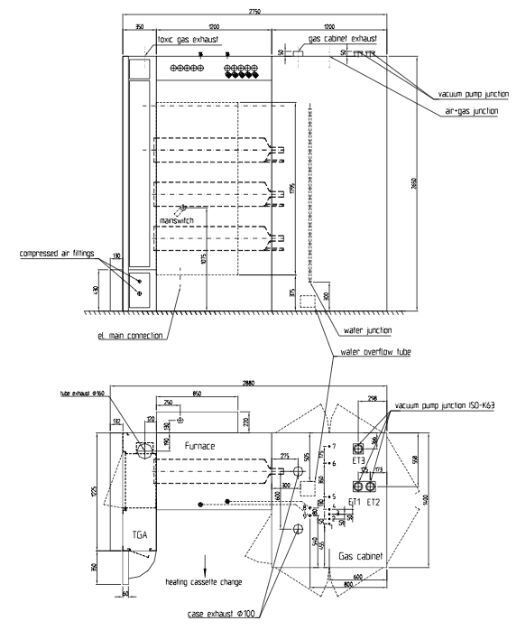

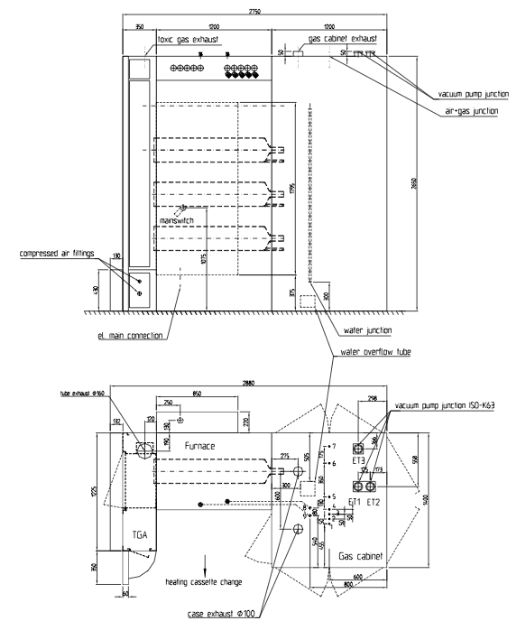

Toxic gas exhaust

Control cabinet

Gas cabinet

(2) Quartz tubes

Spare parts

CE Marked

3rd position configured with heaters, no tubes

Internal diameter of the quartz tube: ~245mm (9-5/8")

Software:

IBM OS/2 warp V4 OEM preload

IBM Assy for PC ASS UK media pack WAR 0400 P/N: 65H1169A

Spare parts included in several boxes:

Flanges

Fittings

Parts for assembly of the system

Additional items available :

Ammonia purifier system (this may be part of the furnace system as the drawing does show a scavenger)

(2) Edwards Q61-51-006 dry pumps

Used Air products gas guard cabinets for:

Dichlorosilane (2 bottles + N2)

Silane (2 bottles + N2)

Ammonia (2 bottles + N2)

5% Phosphine & Nitrogen (2 bottles + N2).

No loading system

No Computer

No vacuum pumps

48 kW, 0 A, 50 Hz

Crated

2001 vintage.

CENTROTHERM Centronic E1200 HT260-3 is a diffusion furnace and its accessories designed to deliver seamless, efficient and reliable operation. The furnace features a molybdenum heating element crafted from superior-grade materials for maximum performance. This ensures long operational life and a consistent and uniform temperature for any given substrate being processed. The Centronic E1200 guarantees a rapid and efficient cooling rate, reducing energy consumption and increasing the efficiency of any infra-red process. It is capable to reach the maximum heating temperature of 1350°C in only 30 minutes and has a maximum ramp rate of 8°C per minute ensuring quick and precise increases or decreases in temperature. Centronic E1200 HT260-3 has an impressive small footprint and is highly space efficient, fitting in just almost any environment. The furnace is equipped with inert hot zone and is suitable processing hazardous gases and mediums. It supports a two-piece vacuum sealed door and has an excellent filtration system that removes all particles and contaminants to ensure a high quality and clean substrate every time. The Centronic also features an integrated Point-to-Point controller which is user friendly and can be controlled manually, making it easy to operate and program via the on board touch screen interface. It allows users to set different targeted temperatures, times and can be used to track a process in order to ensure consistent replication. The furnace also has a flexible porting system which allows it to be connected to multiple devices and accessories like the different cooling and exhaust systems, ensuring the safe and proper disposal of fumes exhausted during the process. It also coordinates with a variety of power sources and has the capability to reduce unnecessary energy consumption. With its robust build, excellent performance and precision, CENTROTHERM Centronic E1200 HT260-3 is an ideal choice for diffusing a variety of substrates ensuring high quality material with excellent repeatability. It is perfect for lab testing, processing and production with its excellent temperature control and speed capability.

There are no reviews yet