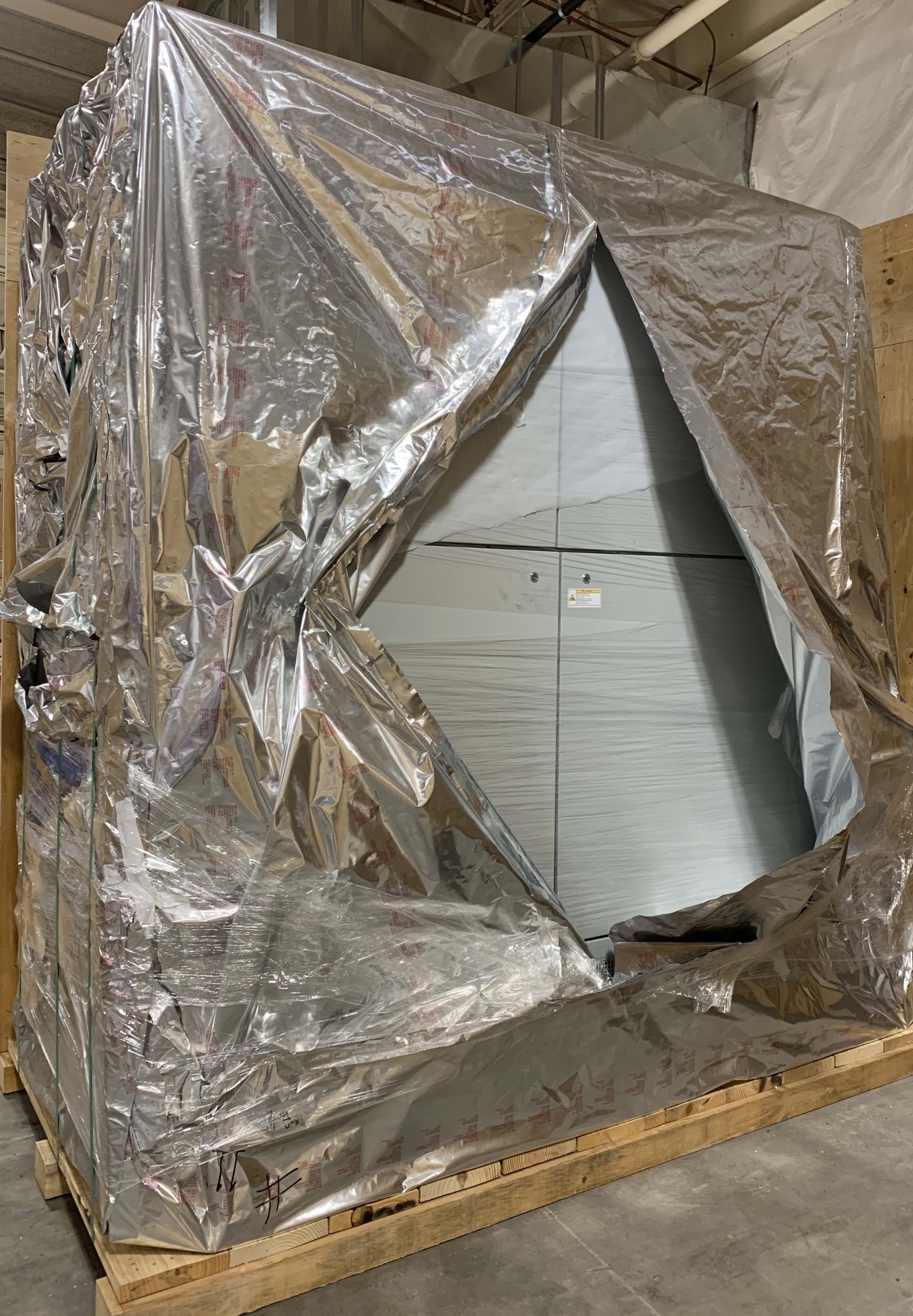

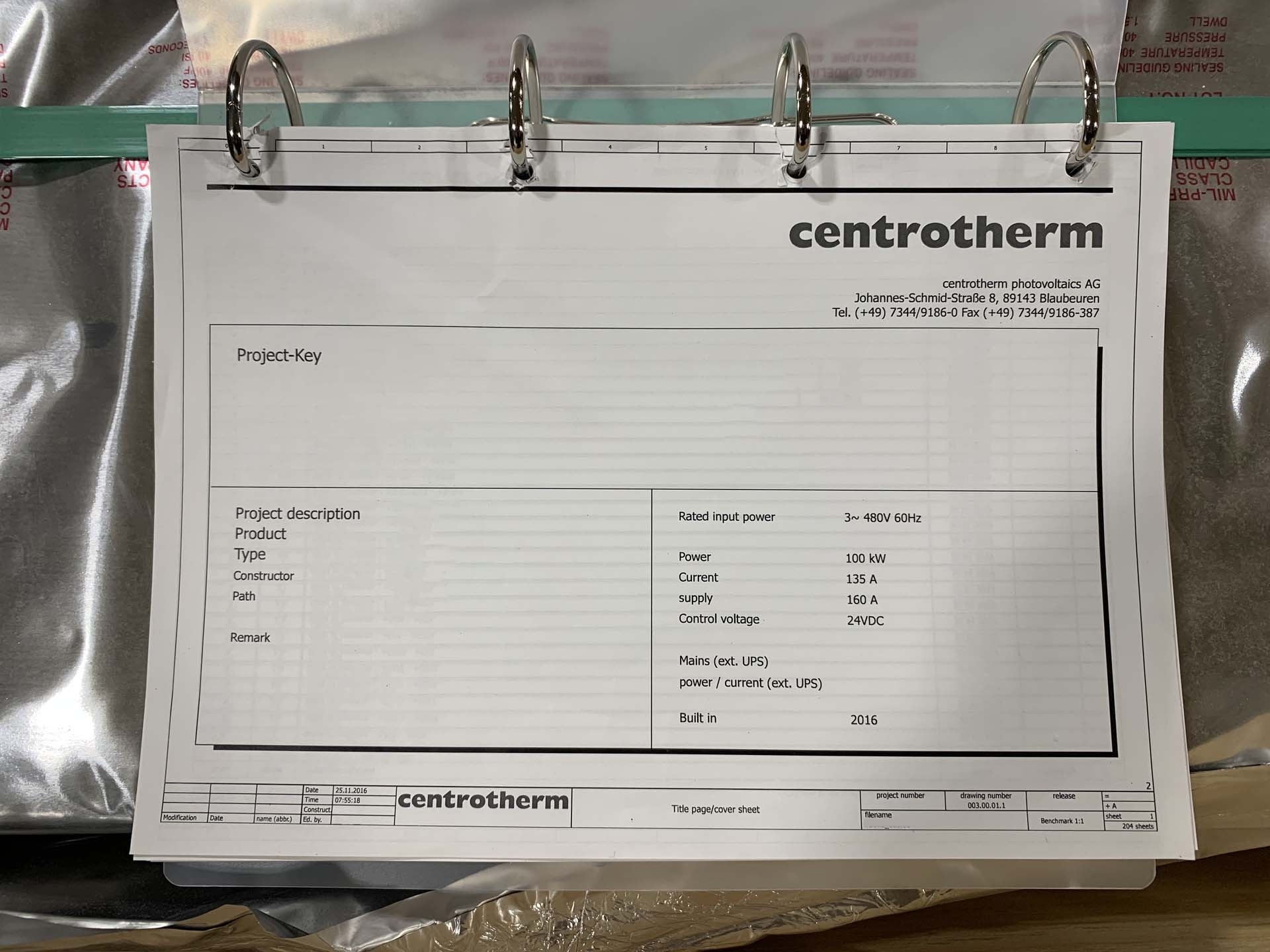

Used CENTROTHERM E1550 HT 260-4 #9260101 for sale

URL successfully copied!

Tap to zoom

ID: 9260101

Wafer Size: 6"

Vintage: 2016

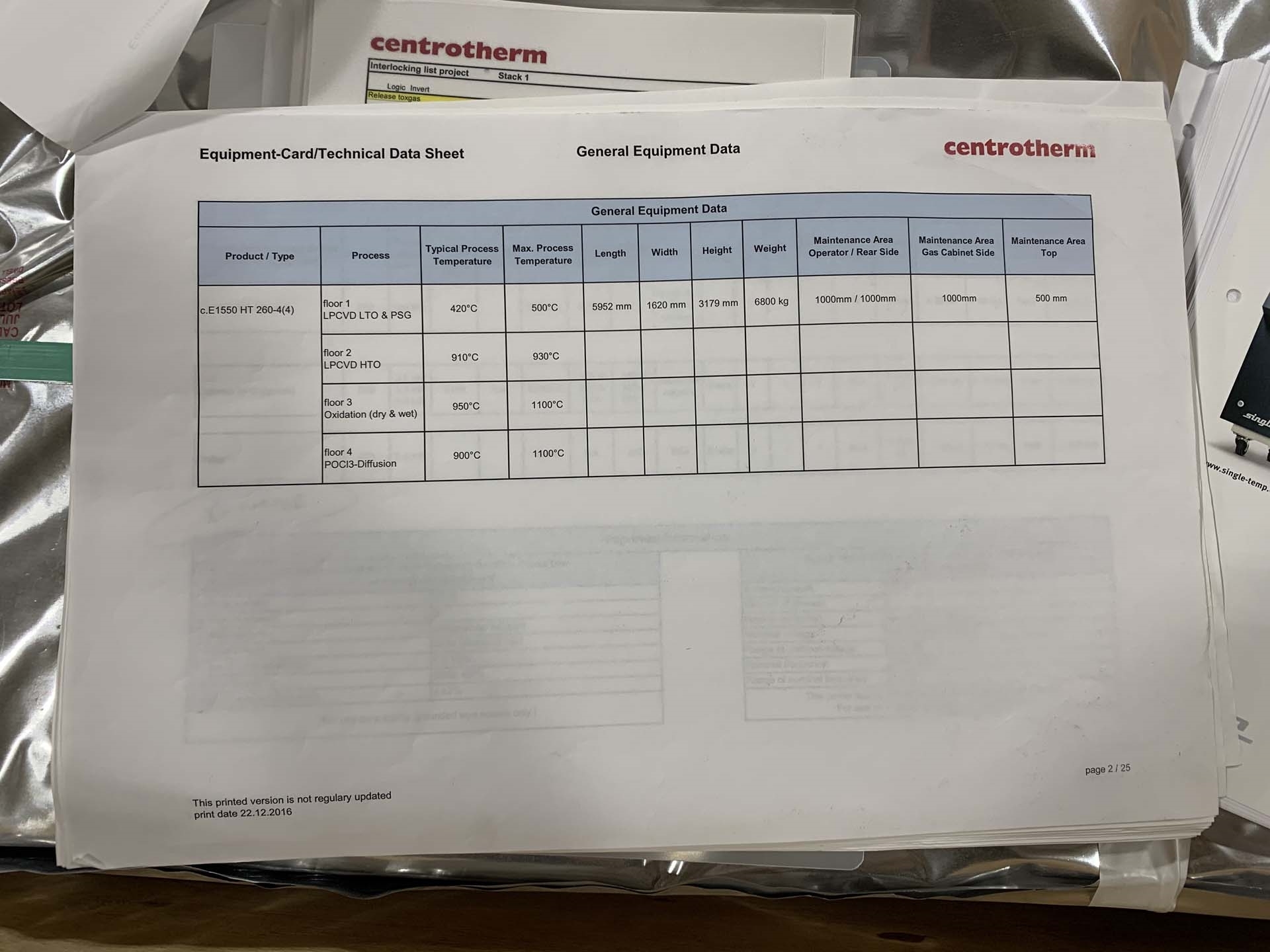

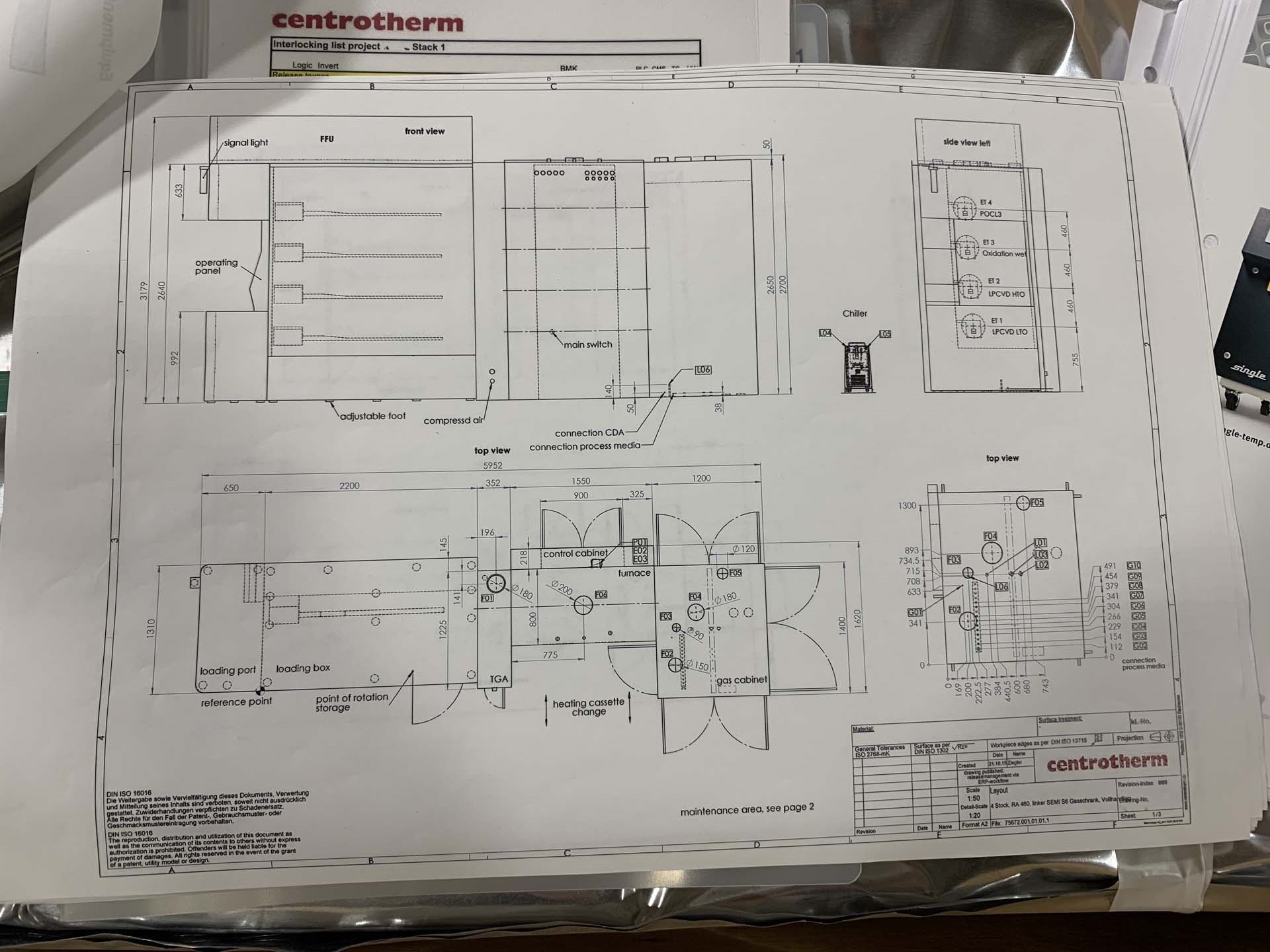

Horizontal furnace, 6"

(4) Stacks

(4) Tubes configuration:

LPCVD LTO-PSG

LPCVD HTO

POCl3 Diffusion

Wet oxidation

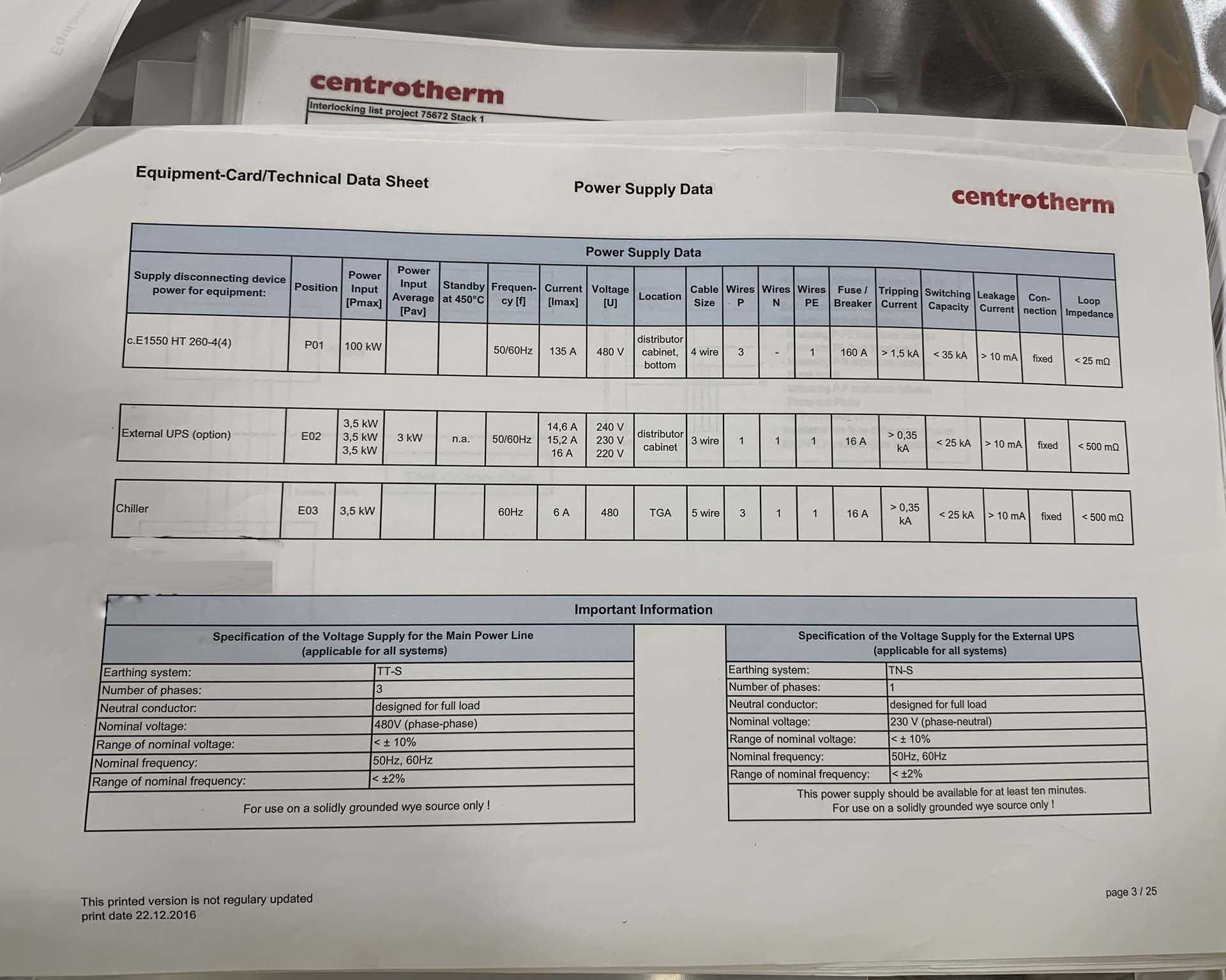

Heating element: 100-600°C

Flat length: 600 mm

Diameter: 260 mm

(5) Heating zones

Heating element: 400°C-1050°C

Flat length: 600 mm

Diameter: 260 mm

(5) Heating zones

(2) Heating elements: 600-1300°C

Flat length: 600 mm

Diameter: 260 mm

(5) Heating zones

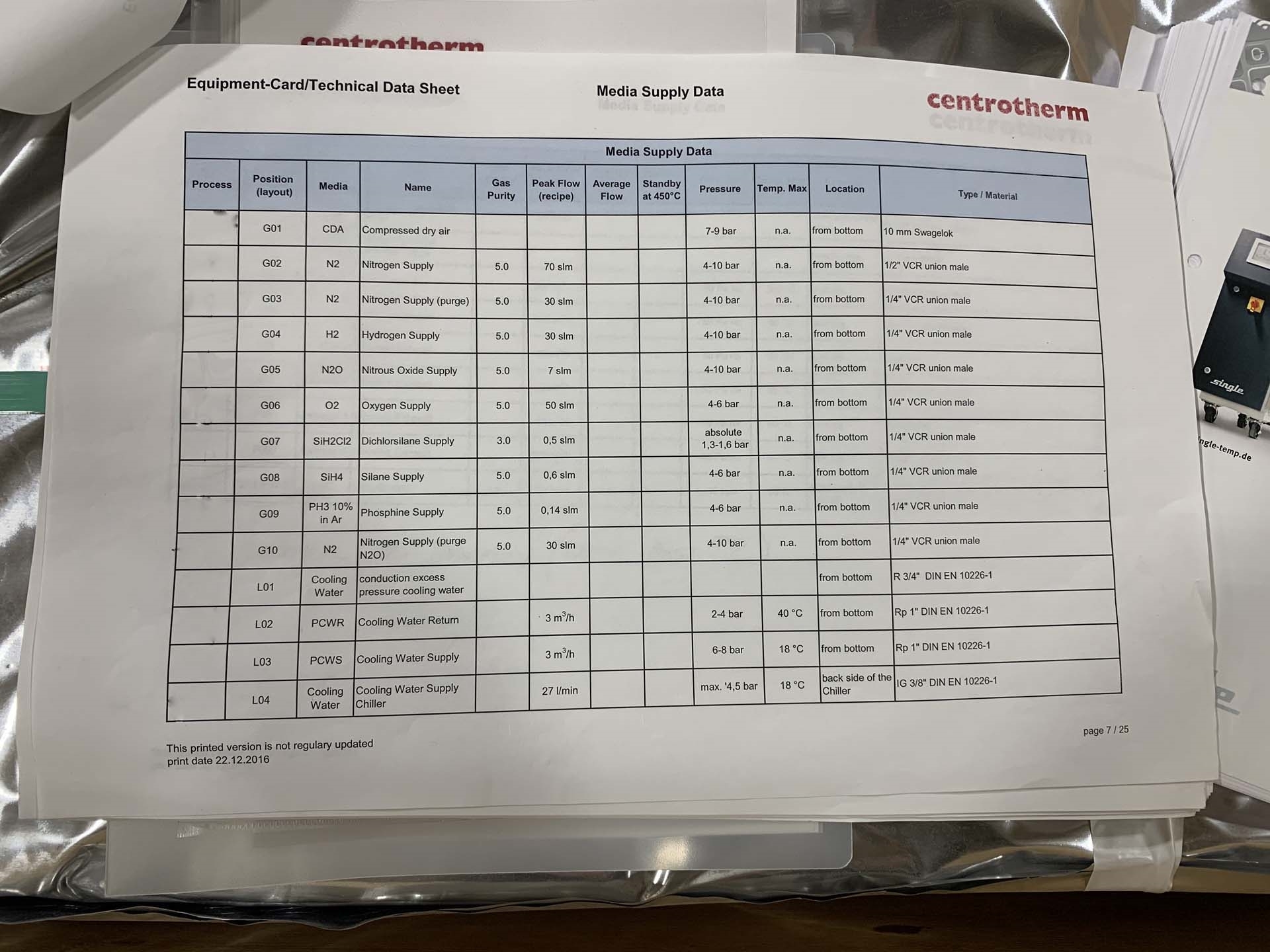

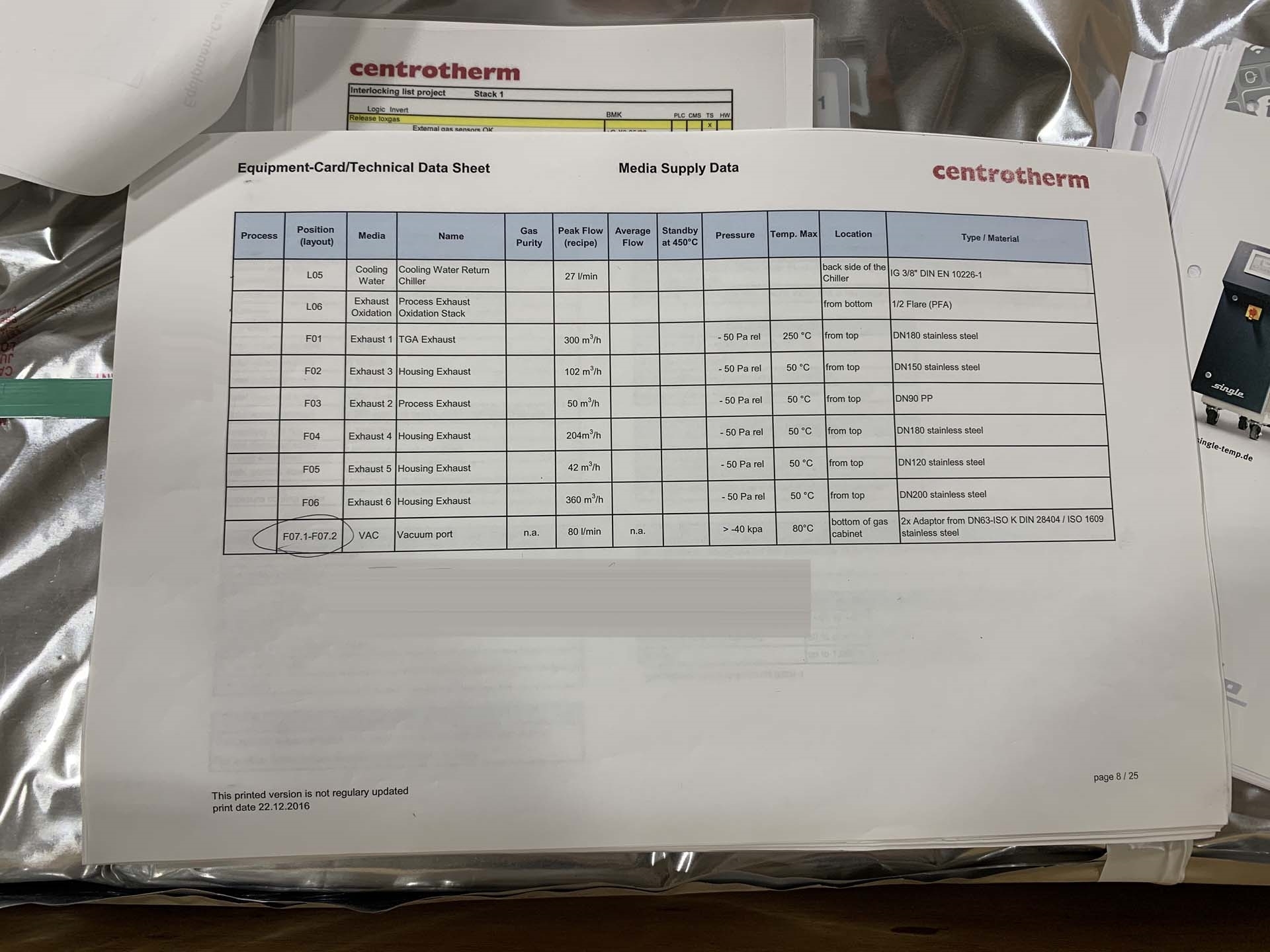

Furnace cooling system: Integrated gas system for DCS: HTO / TEOS process

(3) Standard cooling systems:

Tube closed cycle water cooling system

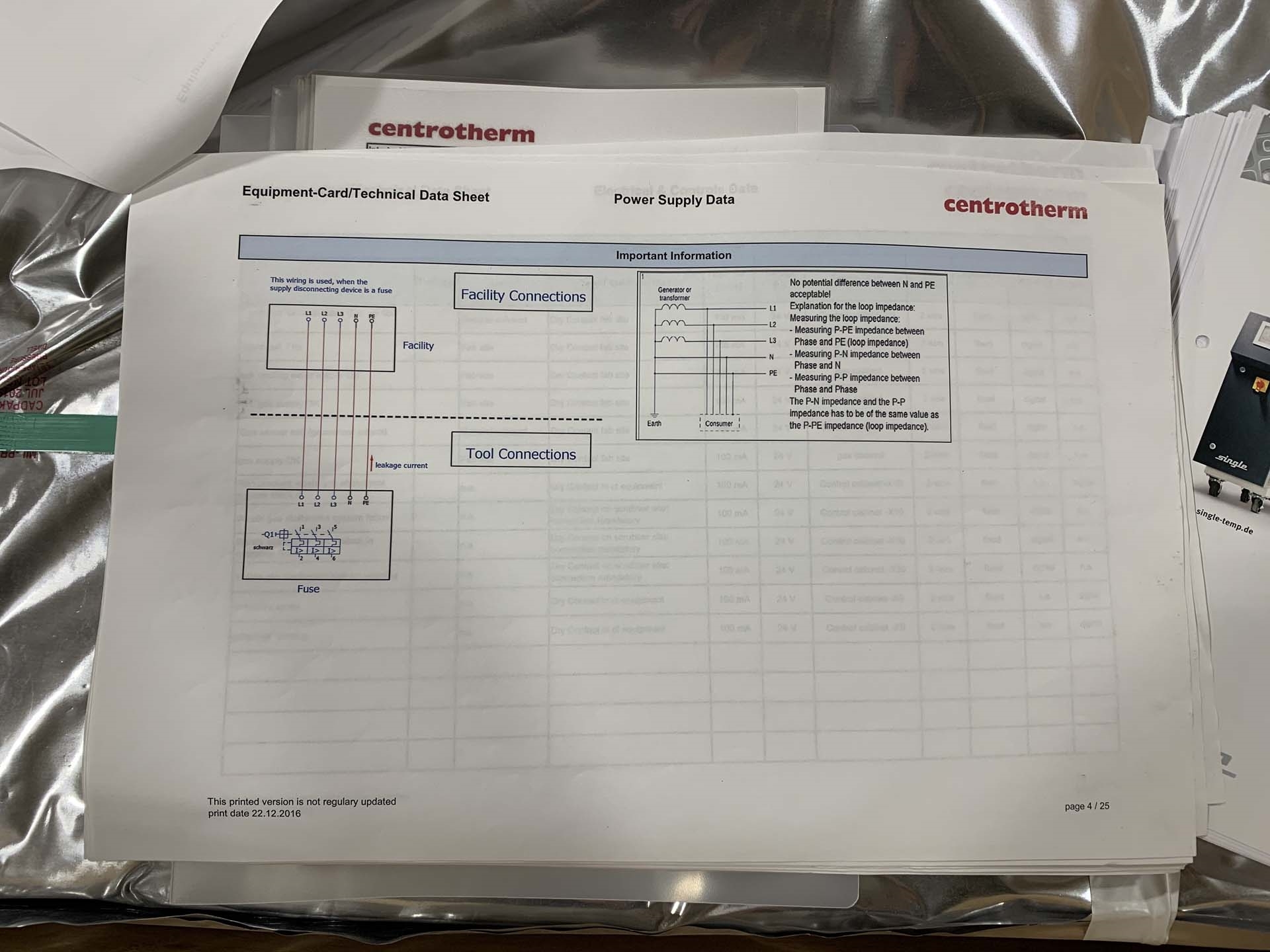

CENTROTHERM Machine Interface (CMI)

Graphical user interface

(4) Furnace control systems (Field bus: CAN)

(4) Temperature measurements

(4) REG 97 Temperature controllers

Fuzzy enhanced PID control

(4) Cascade temperature controls

(4) Profiling elements

For (5) zone heating elements: Type R

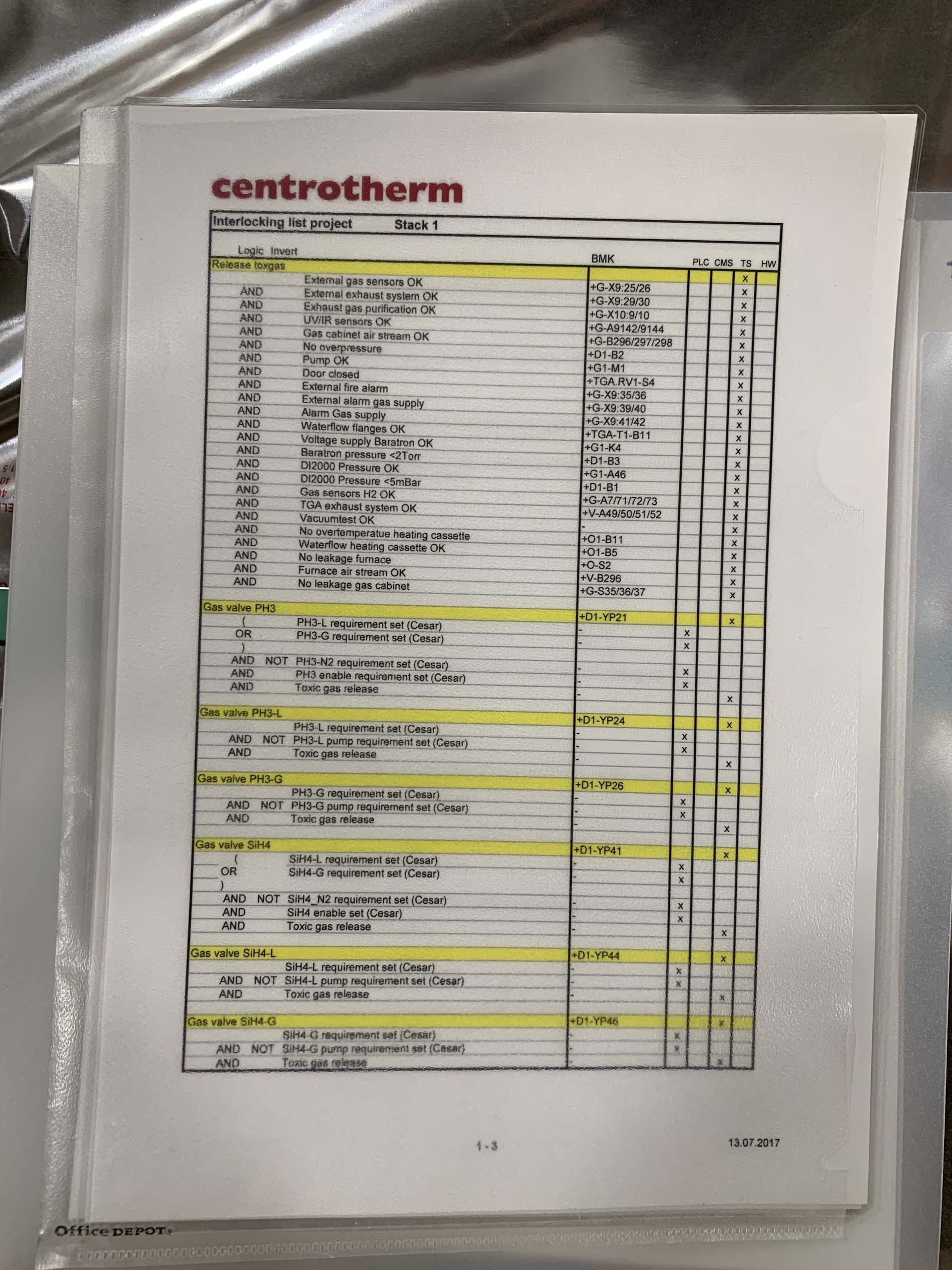

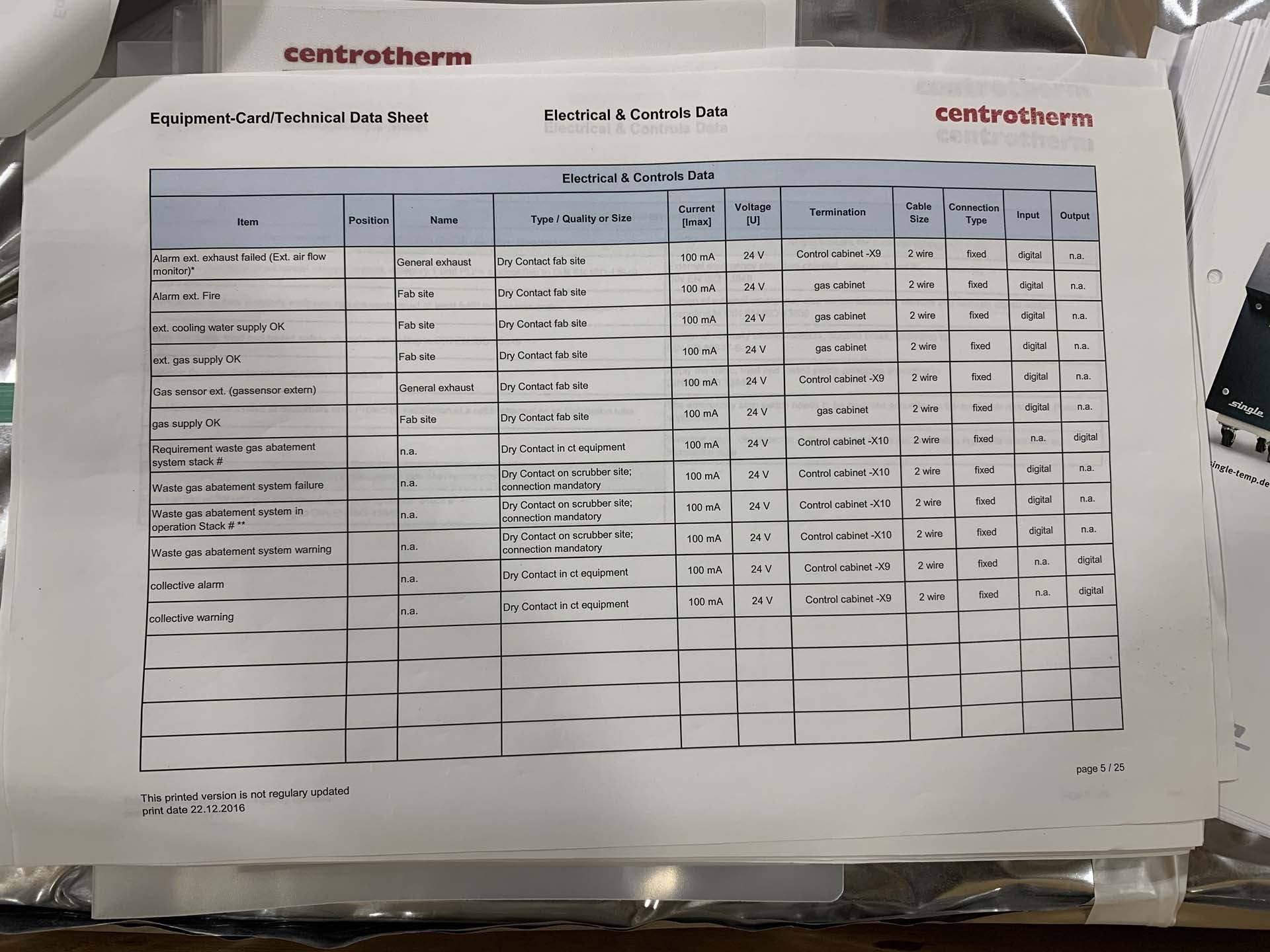

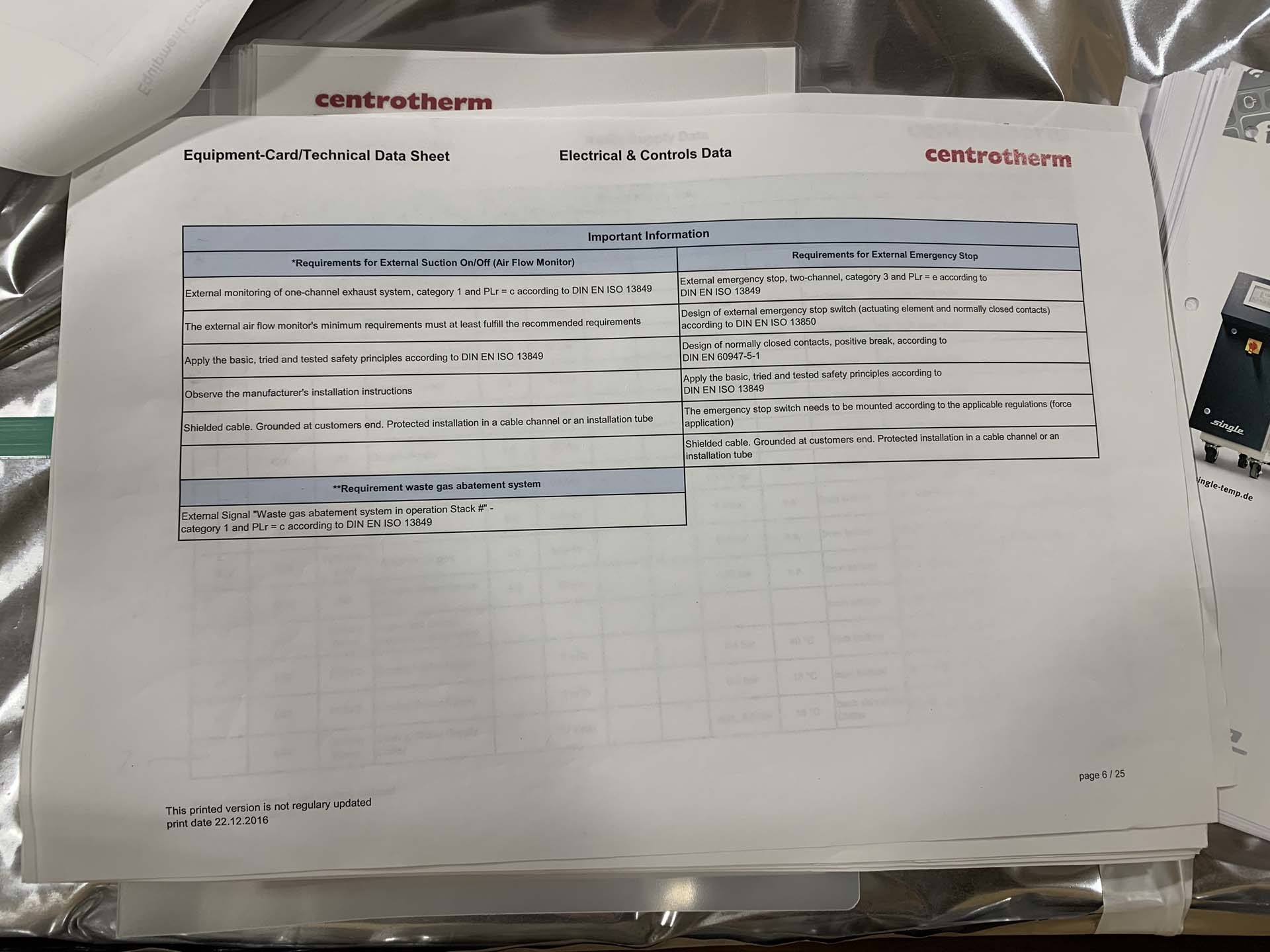

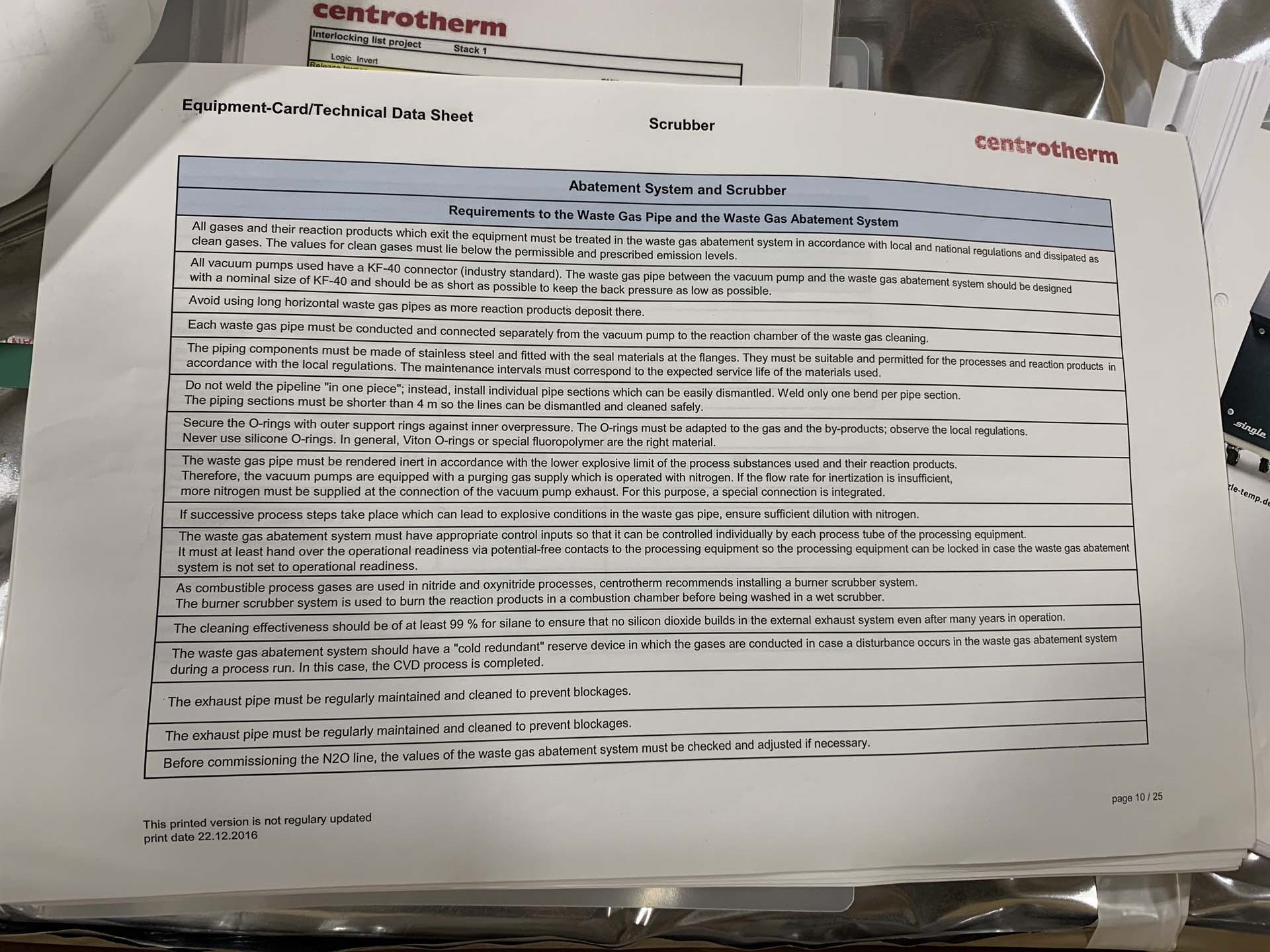

Security system CMS

Independent for up to (4) tubes

Automatic pressure tightness system for closed tube systems

Scavenger

(2) Tube closures

Closed tube for soft landing system

Vacuum door for soft landing system

(4) Tube loading systems:

For soft landing process boat

Gas system cabinet GVS

With main gas lines for N2, O2, H2, SiH4, SiH2Cl2, PH3, N2O

Gas / Vacuum system: LPCVD: LTO-PSG

Gas lines: N2, SiH4 (Rear), PH3 (10% in Ar) (Front, rear), O2 (Front, rear) without vacuum pump

Gas / Vacuum system: LPCVD: HTO

Gas lines: N2, SiH2Cl2 (front, rear), N2O (front, rear), without vacuum pump

Gas system: POCL3 Diffusion

Gas lines: N2, N2 (POCl3), O2, O2 (High)

Gas system: Wet oxidation (Hydrox - ext. torch, DCE – TransLC)

Gas lines: N2, O2, H2, N2O, N2 (DCE), O2 (DCE)

Laminar flow system:

For vertical flow

Process boat lift

Without storage and controlling computer, 6"

Process boat storage

Storage positions plus one manual loading storage, 6"

Loading port

Process boat transfer system

Flat aligner

Power supply: UPS10

No auxiliary equipment

2016 vintage.

CENTROTHERM E1550 HT 260-4 diffusion furnace is a professional-grade piece of equipment designed for a variety of bulk crystal growth processes. It is ideal for materials which require high temperatures for large-scale growth, such as gallium arsenide, silicon, and nitrides. This four-zone furnace can reach temperatures up to 1300°C, and is designed for either gas delivery or direct contact heating. The central part of the furnace is composed of a chain-driven rotary hearth, which houses the four heating zones. Each of these is independently controllable for precise temperature control across the entire volume of material. The four heating zones can be operated with either gas or electric heating elements as the source of energy. The gas delivery equipment consists of a three-way valve to control the flow of fuel gas into each of the heating zones. Additionally, CENTROTHERM E1550 features an endothermic gas injection system for fast cooling. The furnace includes a two-stage recirculating air unit, which is equipped with separate stack fans for each zone. The fans provide bulk cooling as well as a circulation of hot air for even heating across the entire material volume. Additional safety features such as an in-line emergency stop button, audible and visual alarms, and flame monitoring thermocouples further increase the safety of the machine. E1550 HT 260-4 diffusion furnace also comes with gas and electrical connections, as well as detailed operating instructions. For optimal performance and efficiency, we recommend pairing it with CENTROTHERM matching suite of support accessories, including refractories, piping, and other ancillary equipment. These accessories allow for even more precise control of the furnace's firing parameters, and ensure your work is of the highest quality. In conclusion, CENTROTHERM E1550 HT 260-4 diffusion furnace is an ideal choice for a wide variety of bulk crystal growth processes. Its advanced features and comprehensive safety systems make it the go-to device for any application requiring high temperatures and precise control.

There are no reviews yet