Used DIAMOND Delta-8 #9168552 for sale

URL successfully copied!

Tap to zoom

ID: 9168552

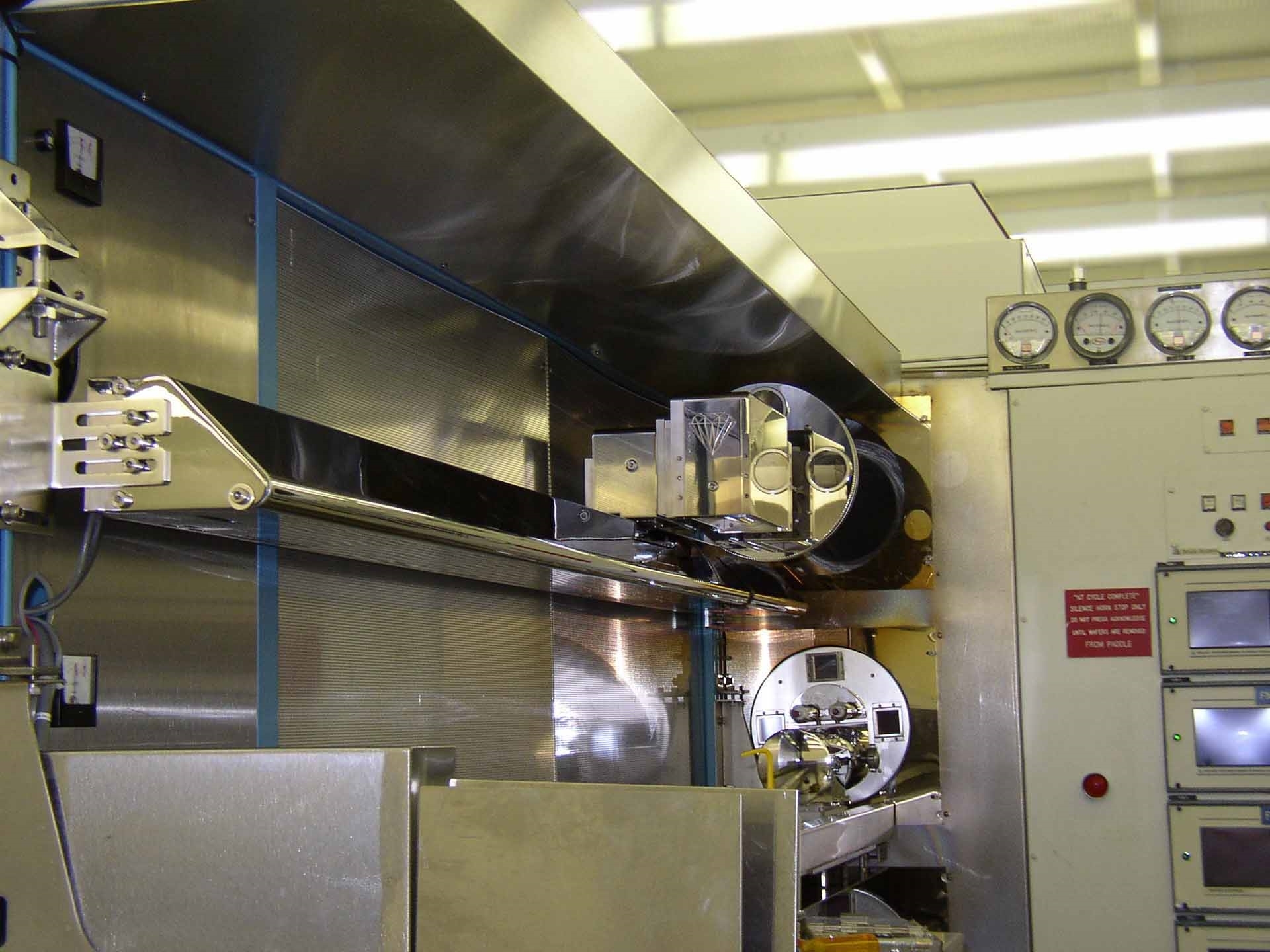

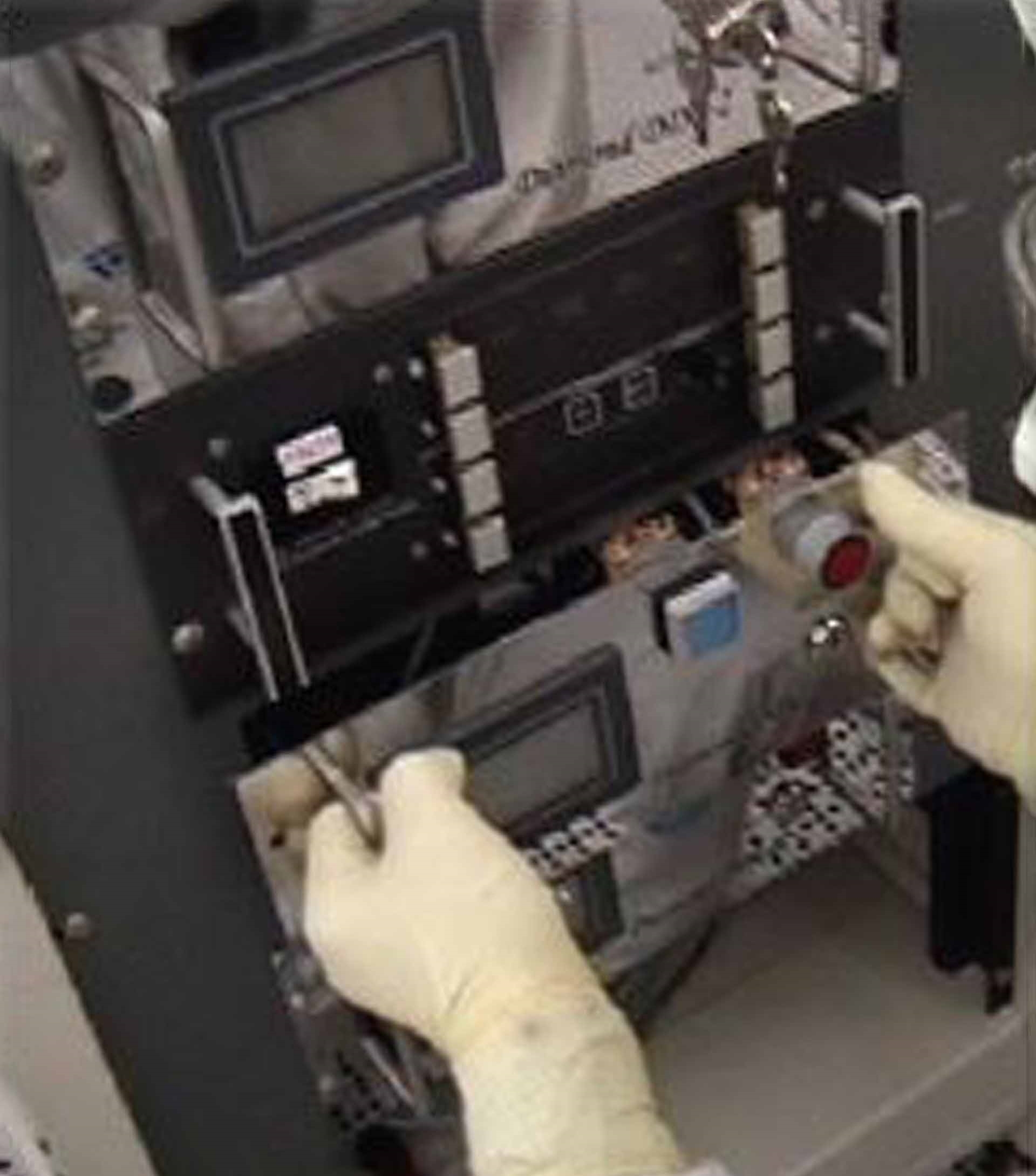

Loader

For BRUCE BTI BDF-41 / BDF-200 Furnace

Heavy duty side mount loaders

With door closure assembly

(16) Boat loaders

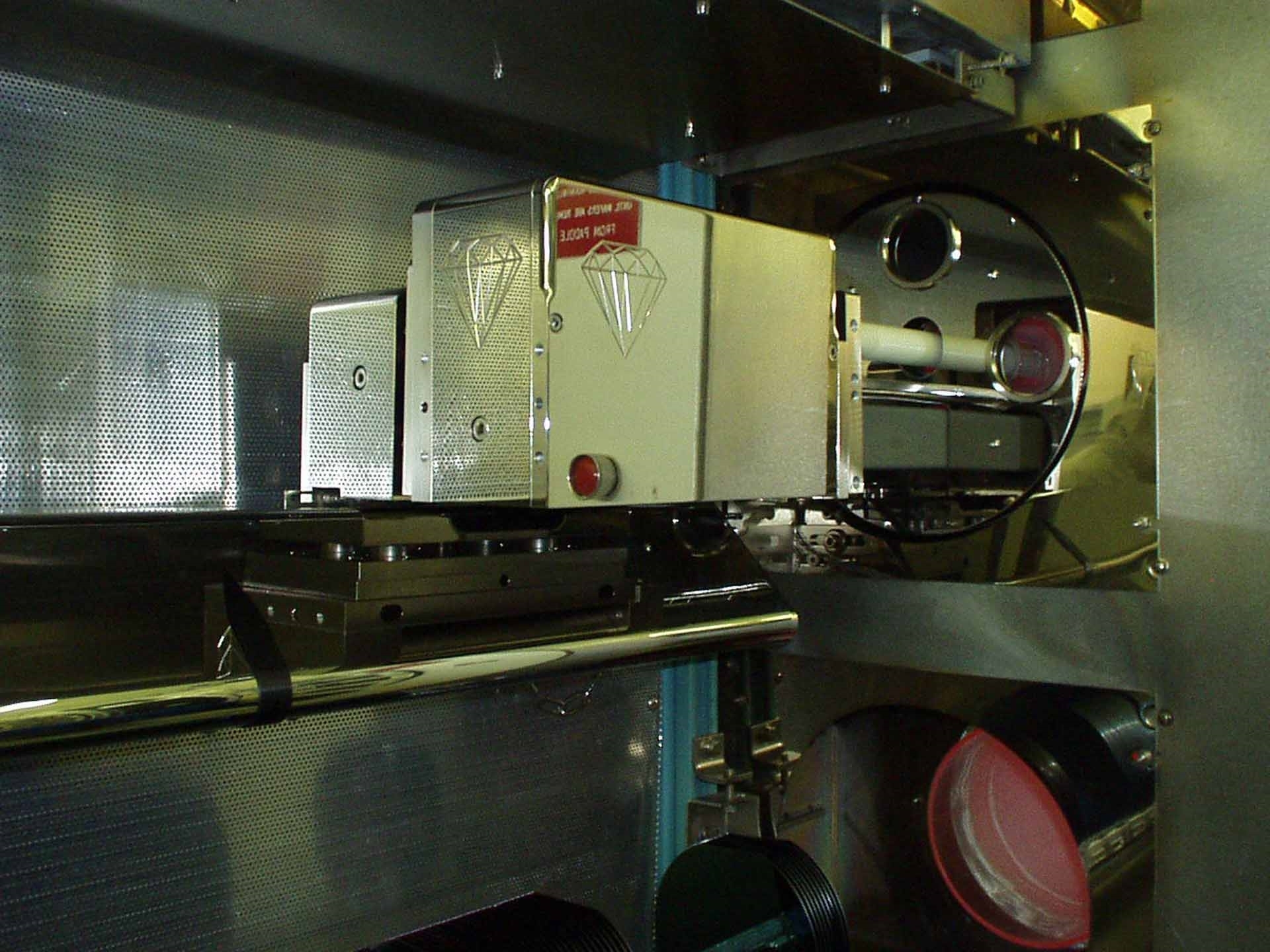

(16) Atmospheric head with SST doors

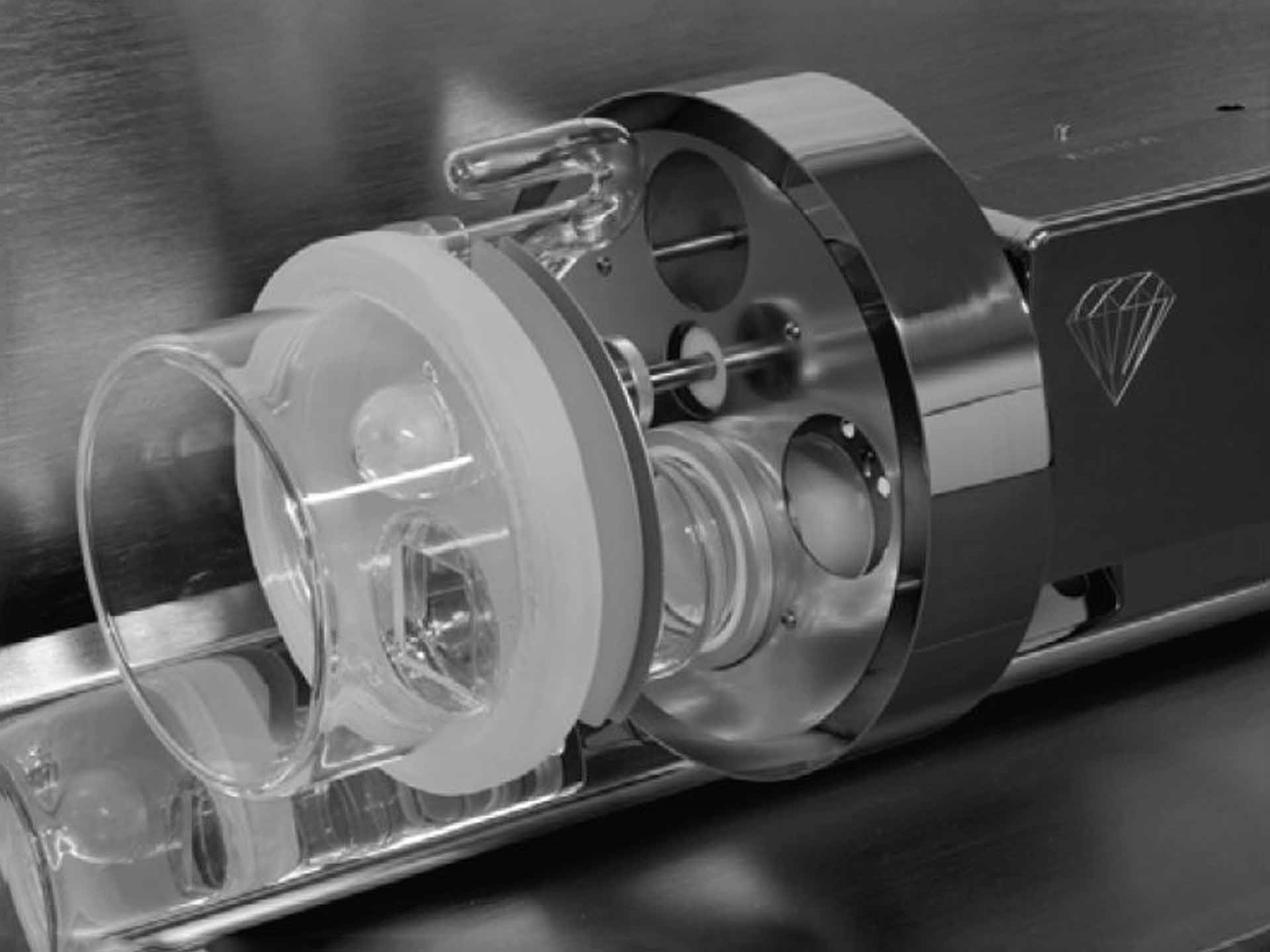

LPCVD Head with LP door closure

Plug-and-play controllers with BTI 7355 DDC

Controllers

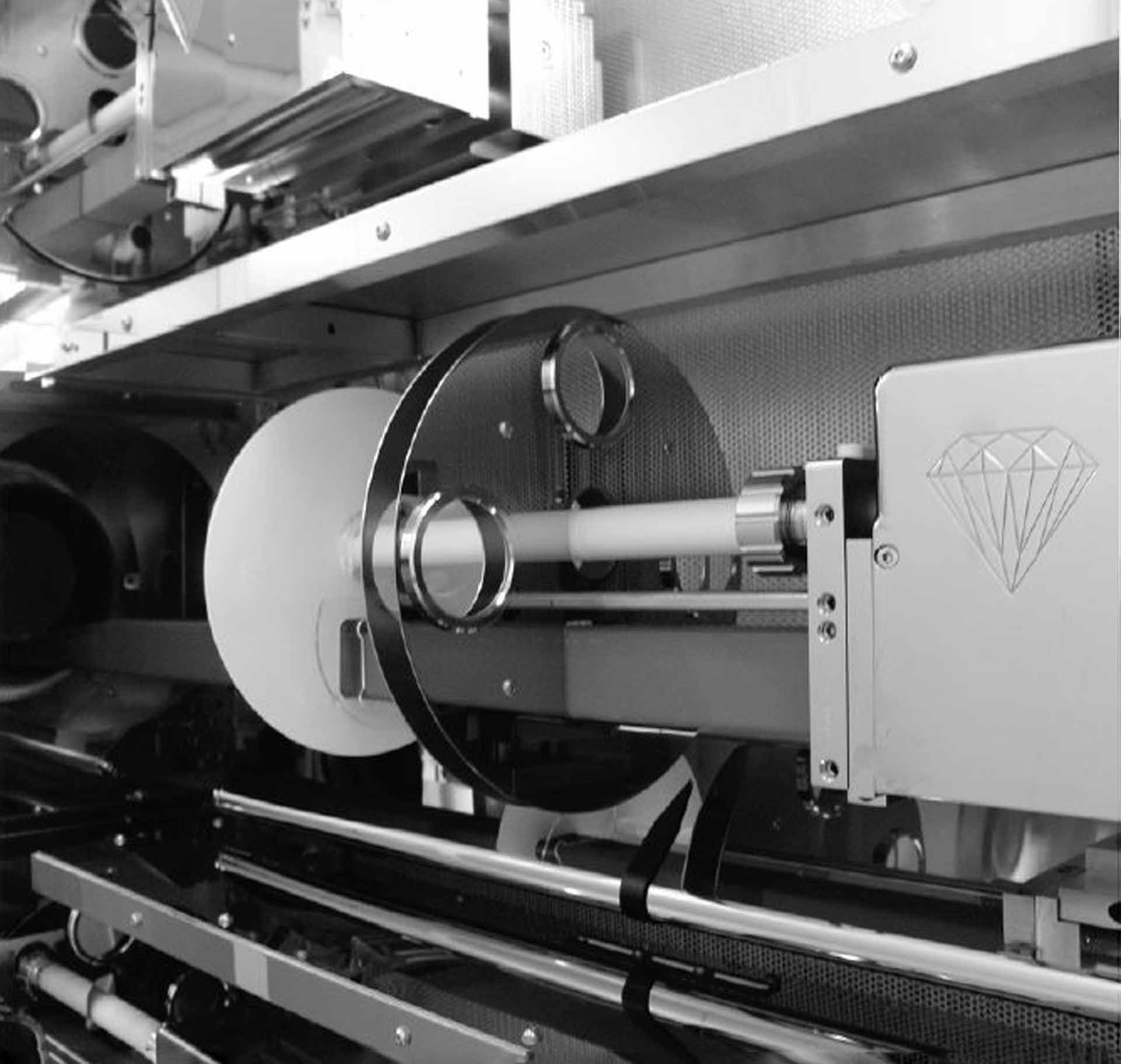

(16) Cantilever heads

X: Incremental ±12mm (3 Positions)

Fine: ±6mm (0.2mm) Resolution

Y: ± 30mm (Infinitely variable bevel gear driven)

Z: ≤ 0.2mm Position resolution (0-2100mm Programmable)

Pitch: +4° ≤ 0.1° Resolution (Compensation for load deflection)

Yaw: ±3° ±0.5° Resolution (Bidirectional, compensates for misaligned process tube)

Roll: ±5° ±0.5° Resolution (Bidirectional about the paddle axis)

Scavenger door: ±3" ±0.1mm Resolution about Z

Quartz door: ±3" Positioning ±0.1mm resolution about Z.

DIAMOND Delta-8 is a diffusion furnace and accessorie designed and manufactured by DIAMOND, a leading supplier of diffusion furnaces and related products. This furnace is designed to provide high-quality annealing treatments on samples up to 200mm in diameter. By using the latest technology, it's capable of processing a wide variety of materials, such as aluminum, copper, iron, and titanium. Delta-8 is an advanced diffusion furnace that features an auto shut-off switch which enables the user to limit the maximum temperature of the process. This ensures the safety of the sample being processed and the use of appropriate materials. The auto shut-off switch can also be programmed to prevent the temperature from going too high. DIAMOND Delta-8 is equipped with a special heat shield to ensure that the furnace and accessory remain at a low temperature to protect the samples from being damaged or fading and promotes a faster, more uniform heating of samples up to 200mm in diameter. The interior of the furnace is covered with high-density ceramic insulation and heat dissipation layer, as well as a thermal reflector underneath to reflect the heat back into the work area to ensure that no temperature gradient is felt throughout the entire heating process. Delta-8 is designed with multiple temperature control regions and an independent operating control panel. This lets the user easily adjust the process by controlling the heating time and power levels, along with parameters such as the furnace operating temperature and the speed of the process. This allows for precise control of a wide variety of applications. The furnace also features the best possible integrity with materials, including thick wall specimens, and an independent application control. DIAMOND Delta-8 is designed to be user-friendly with its easy-to-read GUI, while providing industry-leading power and temperature control. The furnace features a wide selection of shaft sizes, and the heating element can be configured according to application. In addition, the furnace comes with process automation software which can be programmed and updated with ease. Delta-8 is an advanced, automated diffusion furnace that can provide professional-grade, cost-effective diffusion treatments for a wide range of applications. Its features and advanced options make it an ideal choice for any commercial or industrial user who requires an efficient and reliable diffusion furnace.

There are no reviews yet