Used DIRE 10 #9119220 for sale

URL successfully copied!

Tap to zoom

ID: 9119220

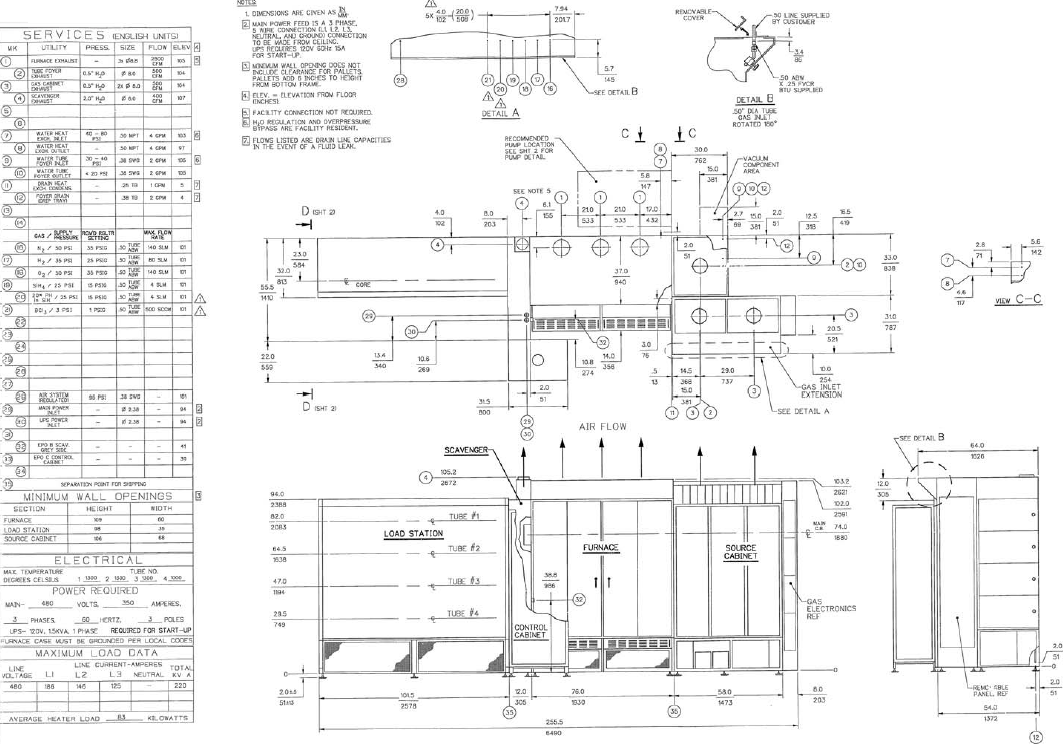

Wafer Size: 5"-8”

Vintage: 1992

Furnace, 5"-8”

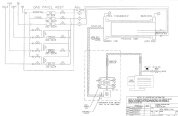

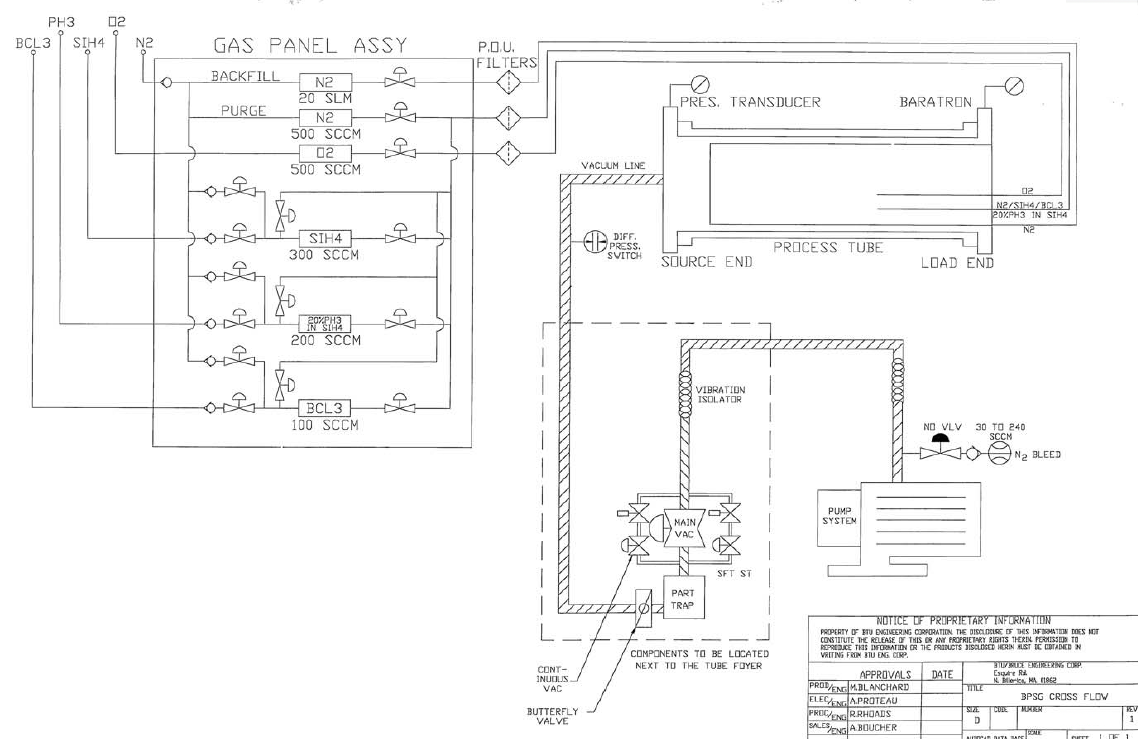

(2) Tubes of LPCVD (Flat Poly & BPSG)

(2) Tubes of Wet Ox

7680 Loaders

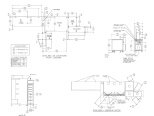

Direction Saddles and Door Closures

Breakers in Offset Shroud

ASEA Breakers

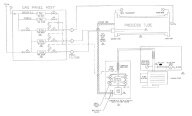

2962044 cores, 1150C max on tubes 1 & 2 (Wet Ox)

2962079 cores, 1000C max on tubes 3 & 4 (Poly & PSG)

Transformers ok for 8” and/or high temp

Setup for 5” wafers. Can be upgraded to 8”

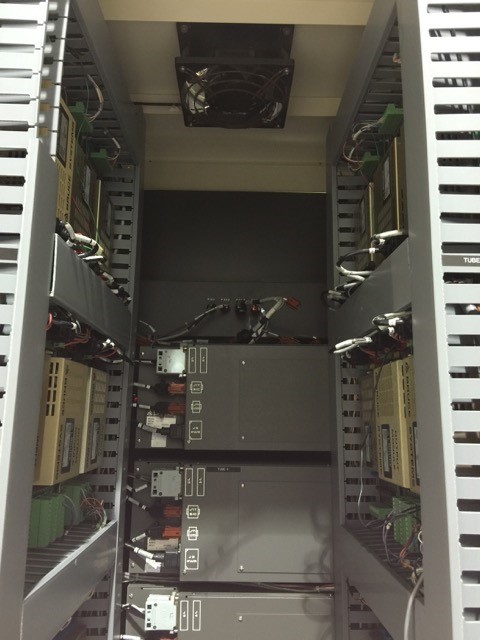

7630 Temp Controllers

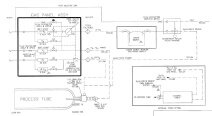

Internal Torch (Tube 1)

Old style 7618 External Torch (Tube 2)•

(2) Schumacher ATCS15 Bubbler controllers for TCA

Unit 1100 and 2020 MFCs

Internal UPS

Individual Input and Output modules

Bulkhead cabling

55x22 Software

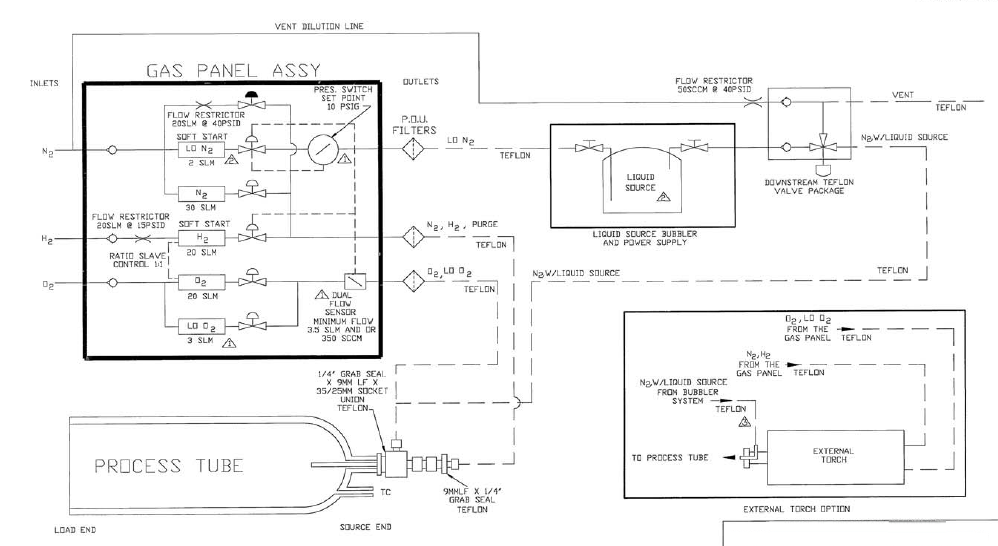

(2) 7900 Atmospheric Gas Modules (tubes 1 & 2)

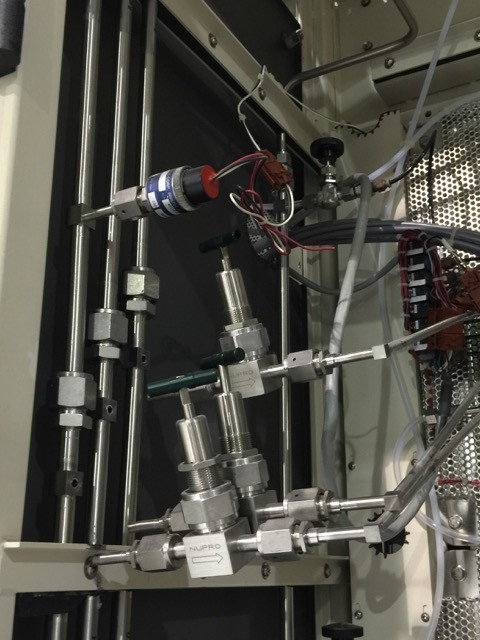

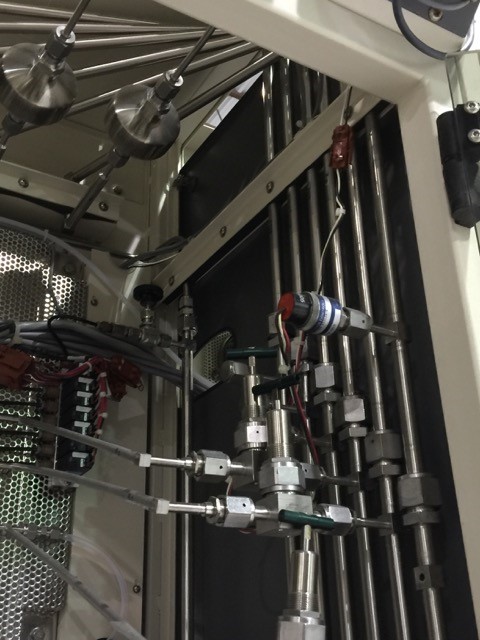

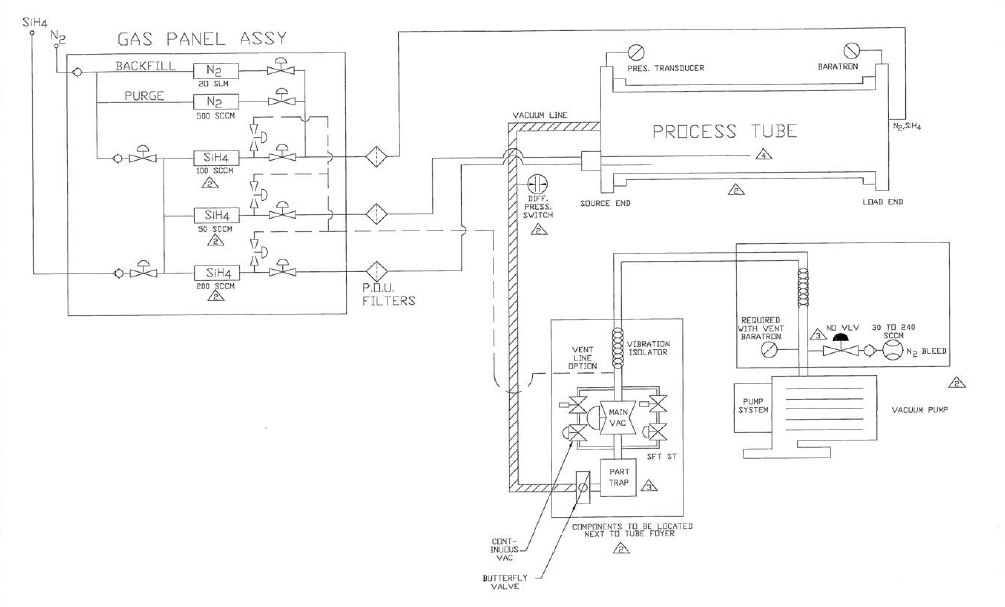

(2) 8100 LPCVD Gas Modules (tubes 3 & 4)

Pumps, fore lines, vacuum components for the two LPCVD tubes are not included

1992 vintage.

DIRE 10 is a diffusion furnace and accompanying accessories that is used for producing silicon (Si) and doped polycrystalline silicon (DPSC). The furnace and its accessories are invaluable tools for the development of high-performance semiconductors. 10 furnace can work at temperatures up to 1150°C and is capable of processing runs lasting up to 30 hours. It is equipped with an advanced automatic control equipment and utilizes seamless heating and cooling systems to ensure precision and efficiency. This system allows for tight temperature control and reliable results. The furnace is also equipped with automated quartz and alumina crucible systems to ensure uniform heating and homogenous doping. This unit allows for excellent lead doping by nitrogen, phosphorous and boron precursors, as well as Germanium doping. The crucible is powered by a high-powered lamp and can produce up to 7.5kW/cm2 of efficiently distributed power. The furnaces' accessories include quartz and alumina consumables and ancillary components that are designed for optimal performance and safety. The quartz and alumina consumables are designed to prevent contamination of the furnace and ensure that gases and reagents aren't mixed. The ancillary components allow for the efficient filling and draining of the furnace, as well as the precise control of the crucible temperatures. DIRE 10 also includes a gas and reagent delivery machine which is designed to provide accurate flow control and consistent results. This tool is completely automated and uses advanced sensors and controllers to ensure precise operation and reliable results. 10 is designed to provide users with a reliable and efficient diffusion process, which results in high yields and consistently excellent material quality. With its high-precision temperature control, efficient quartz and alumina consumables and automated gas and reagent delivery asset, DIRE 10 ensures consistent high-performance results.

There are no reviews yet