Used HITACHI / KOKUSAI DD-1206VN-DM #9281054 for sale

URL successfully copied!

Tap to zoom

ID: 9281054

Wafer Size: 12"

Vintage: 2004

Diffusion furnace, 12"

Quixace I / QWM

Furnace:

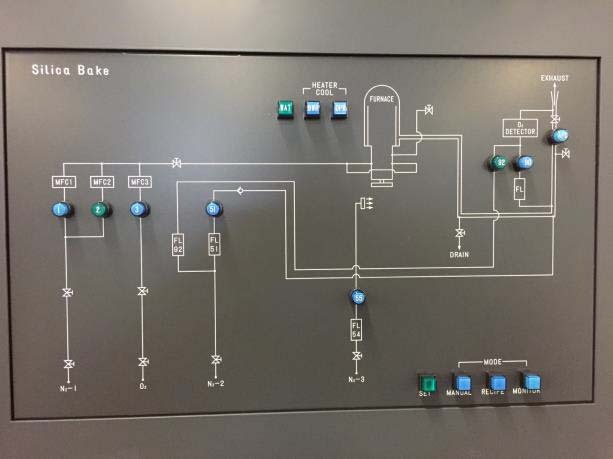

Quixace-mini (Silica bake) furnace

D4EX25085 Heater

RHC Heat (Quick-cooling)

RC-100 Exhaust pressure controller

Furnace mount

Scavenger

Process exhaust duct

Automation:

I/O Shutter

FOUP Transfer unit and loader

Rotation FOUP rack unit: 12-Step carrier stage

FOUP Opener unit

Wafer detect unit

Notch detect unit

Wafer transfer unit

Boat elevator unit: Up/down

Boat rotation unit

Furnace shutter unit

Gas (N2, O2):

Gas pressurized unit: Silica bake

Gas detector

Gas box

Controller:

CX3010 Controller

CQ1700 Temperature controller

Power control unit

2004 vintage.

HITACHI / KOKUSAI DD-1206VN-DM is a diffusion furnace and accessories package that provides an automated, high-performance solution for rapid thermal processing of a variety of semiconductor substrates. The furnace consists of a quartz tube and graphite resistive heater connected to power supply control unit, a flow equipment for gas introduction, a temperature control unit for temperature set-point and monitoring, and a Vacuum Pump to run the entire system. The expansion box features multiple temperature zones, enabling it to process several substrates simultaneously with independent heating zones. The diffusion furnace is designed for a variety of semiconductor processes and wafer sizes, ranging from 150 to 300 mm, for both CVD and PECVD applications. It features a high-temperature range of up to 1,250°C, and tight temperature control with a variation of ± 0.1°C and a uniformity of ± 0.25°C, allowing for optimization of thermal processes. The unit also boasts a high-efficiency air flow, providing uniform thermal treatments and improved throughput. Its Degassing Kit is also available to reduce oxygen level for oxide etching and deposition. In addition to the furnace, HITACHI DD-1206VN-DM includes accessories such as a hotplate, susceptor carriers, high-temperature gas inlet tubing, and a loading manhole that allow for easy access to substrates that need to be processed. Its robust construction ensures reliable performance while its advanced microprocessor-based controller provides improved heating control compared to other diffusion furnaces on the market. KOKUSAI DD-1206VN-DM is ideal for processes like oxidation, annealing, diffusion, and film deposition, and can be utilized in various industries, including consumer electronics, solar cells, bio-sensors, and medical instruments. With its high-precision temperature control, efficient air flow machine, and wide selection of accessories, DD-1206VN-DM can meet the demanding requirements of modern thermal processing.

There are no reviews yet