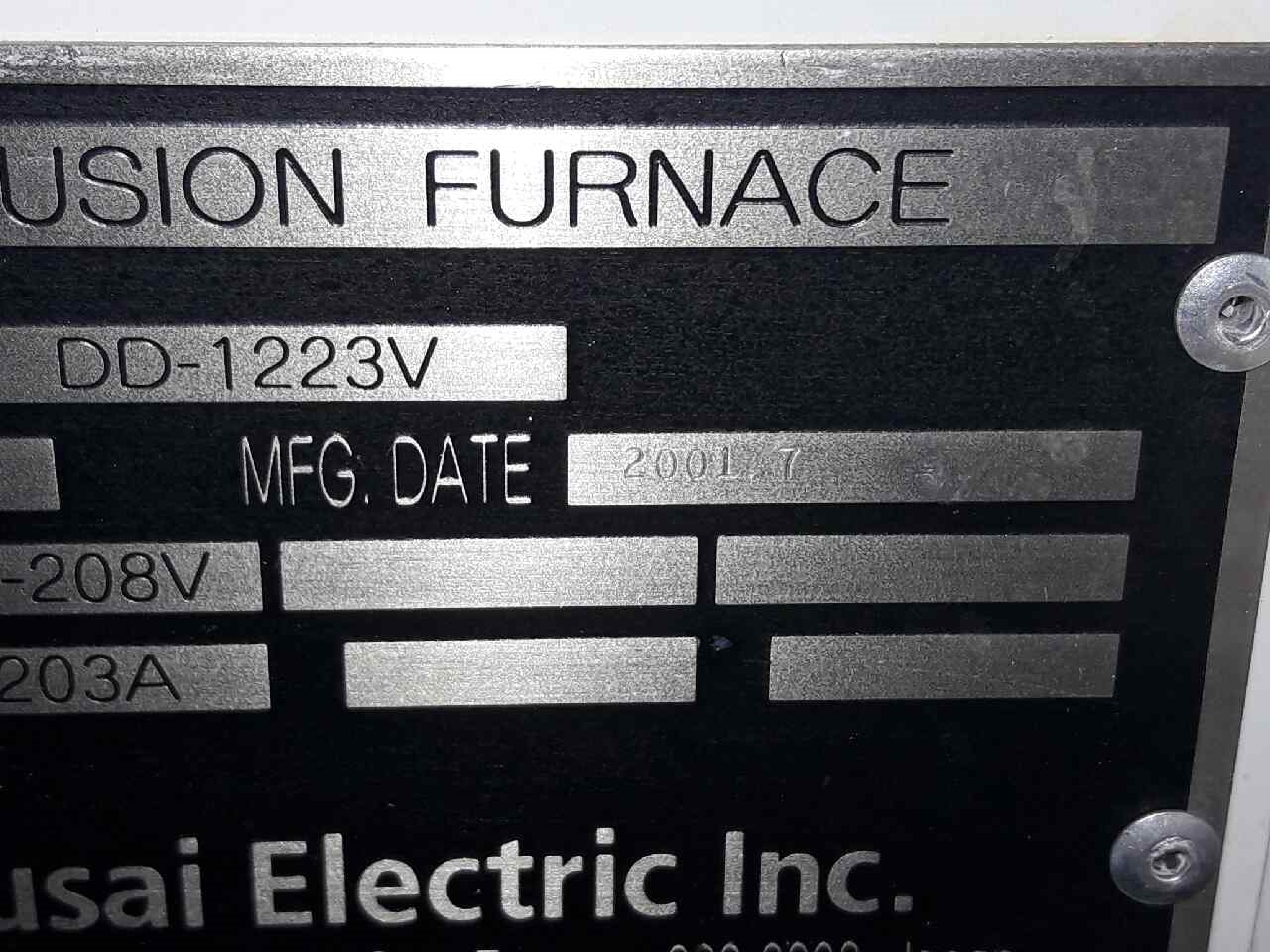

Used HITACHI / KOKUSAI DD-1223V #9190226 for sale

URL successfully copied!

Tap to zoom

ID: 9190226

Wafer Size: 12"

Vintage: 2001

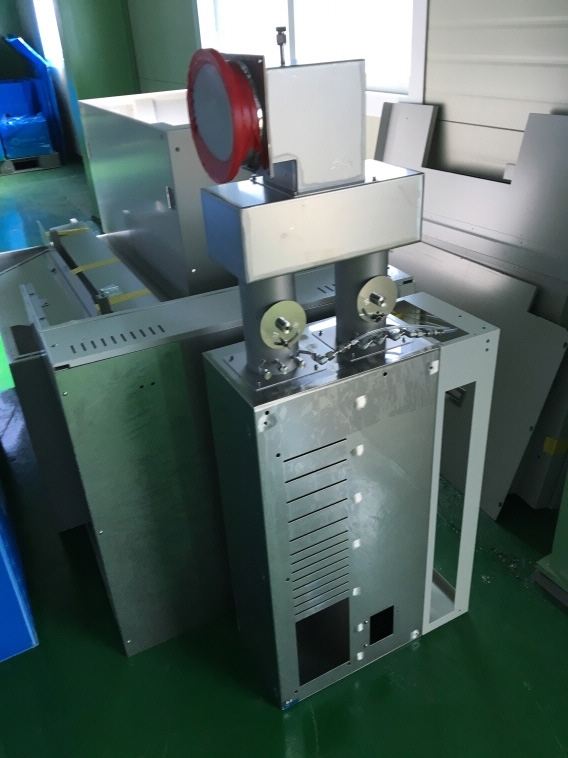

Furnace, 12"

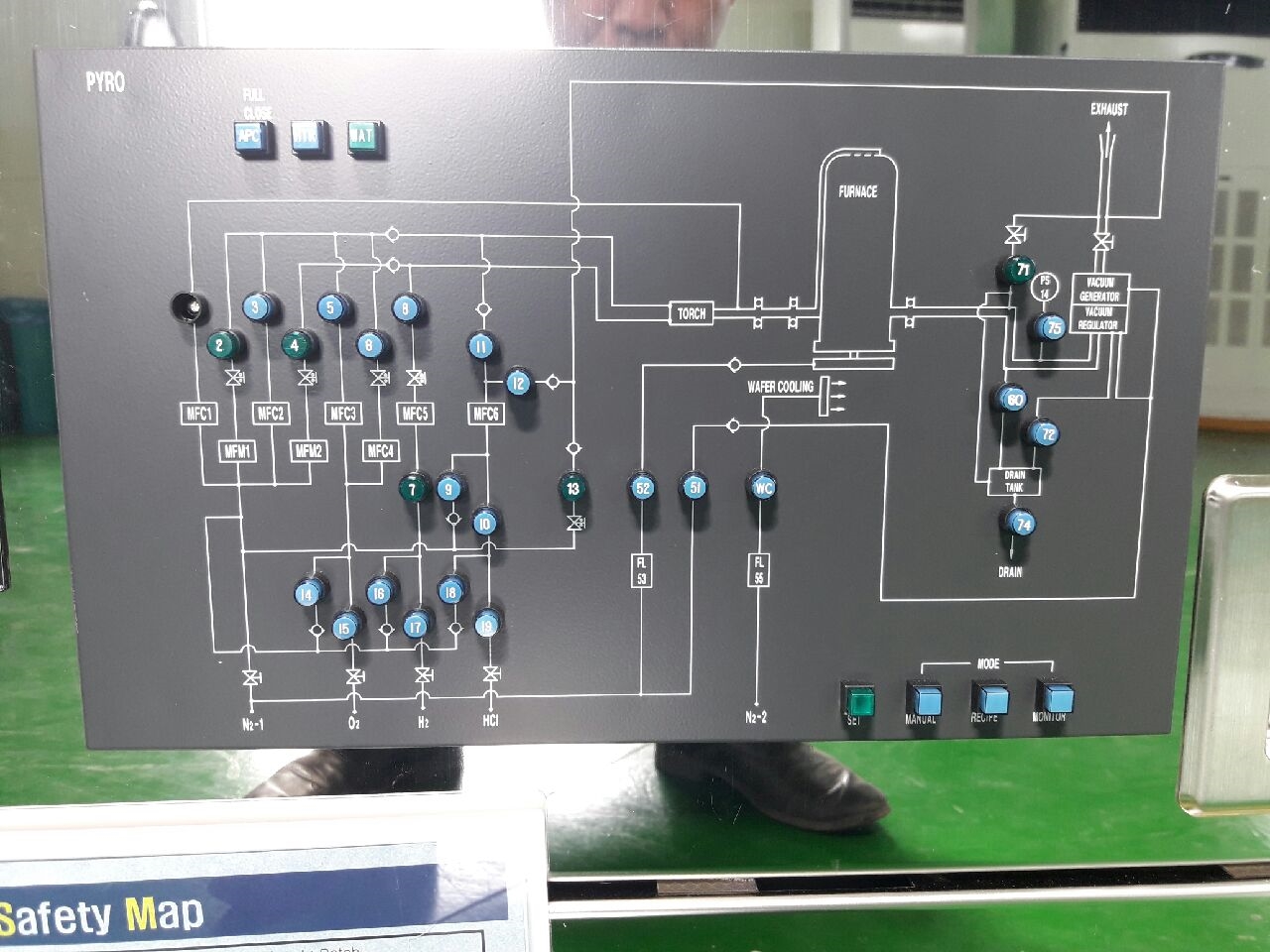

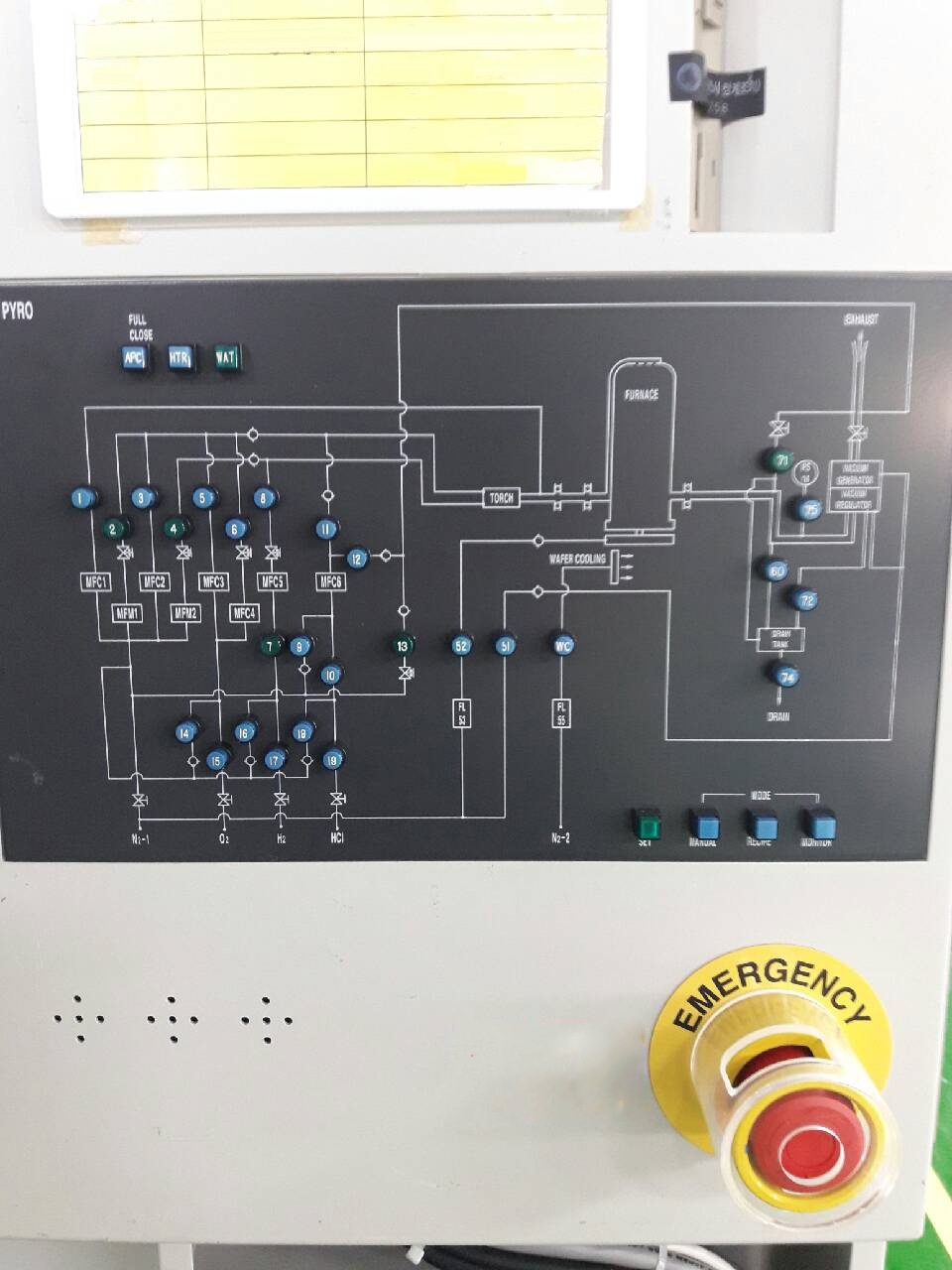

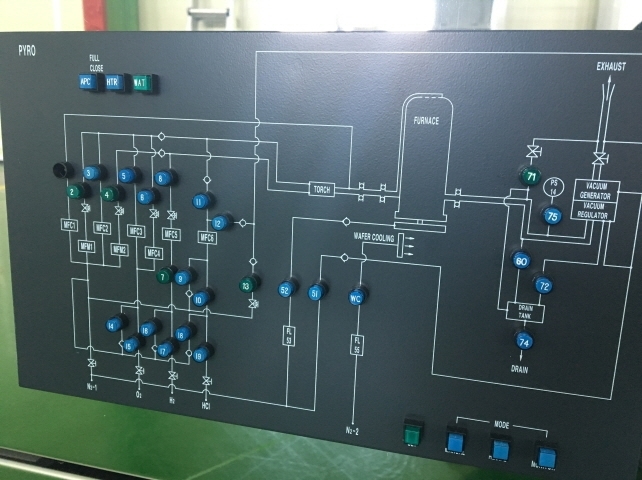

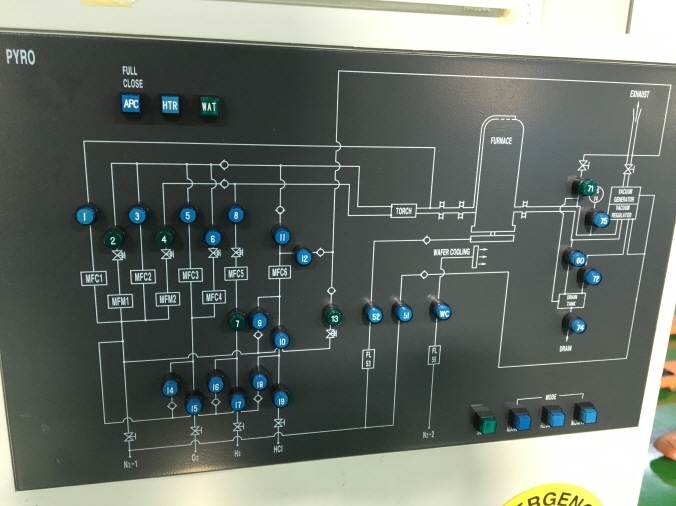

Process: Pyro

(100) Process wafers

Process type: Oxide

Gas supply: Bottom

PCW Supply: Bottom

Boat operation: 1Boat

Load lock: No

(25) Carrier slots

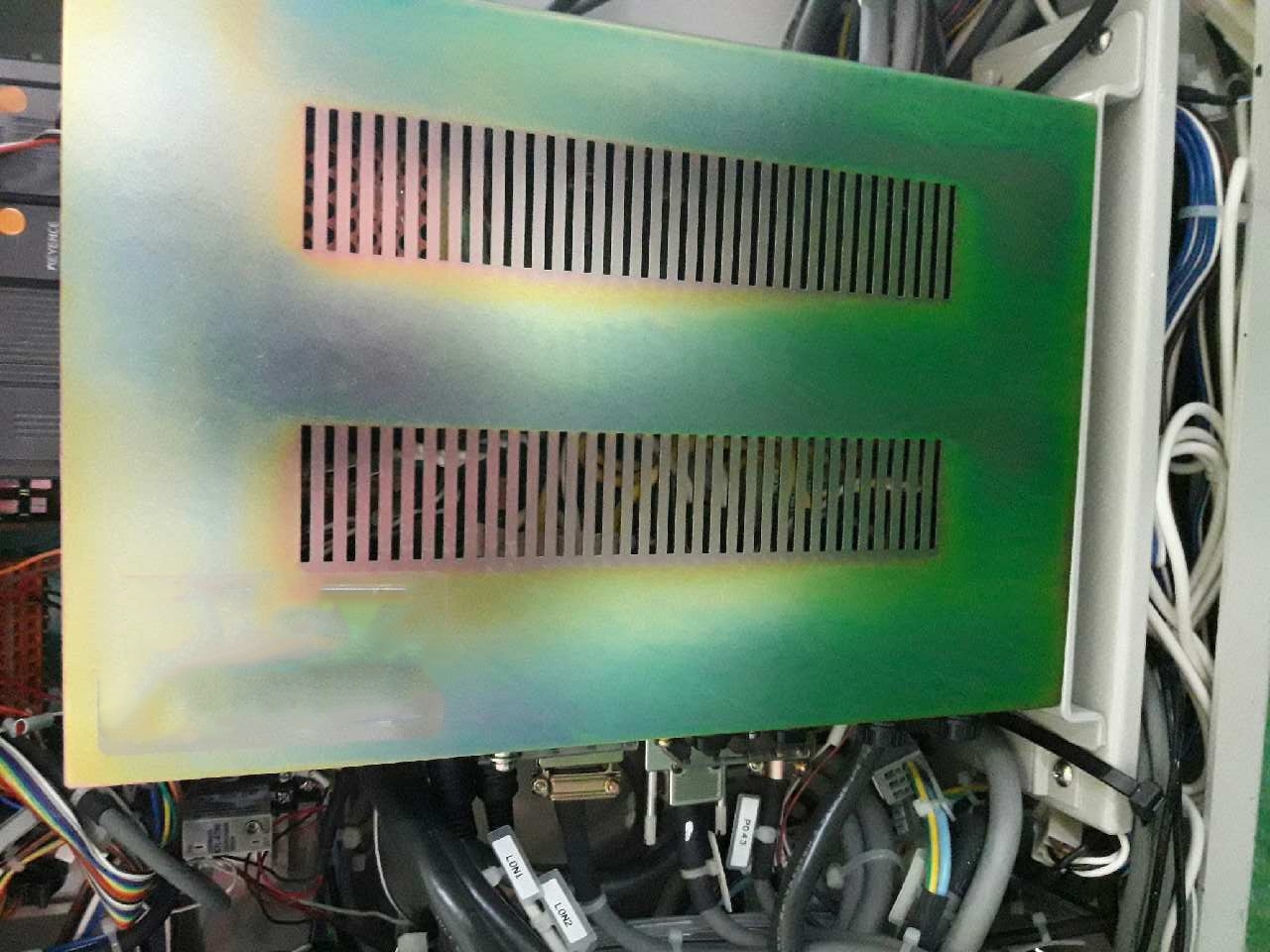

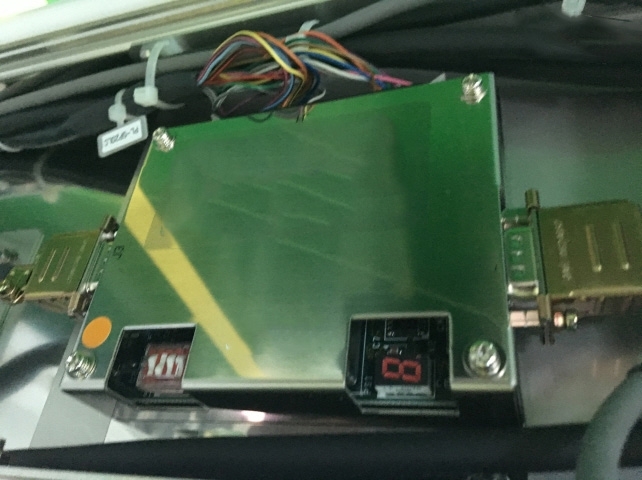

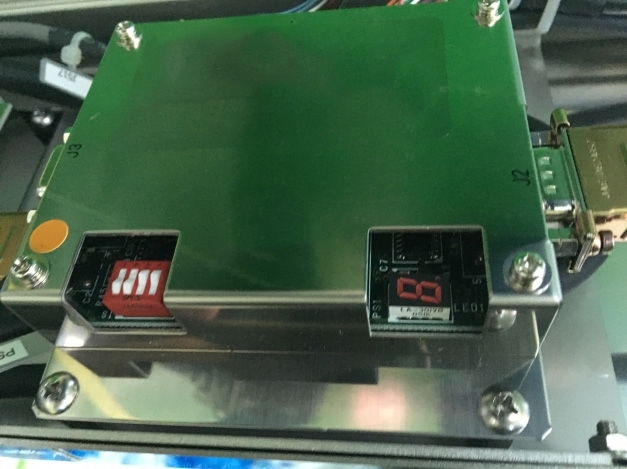

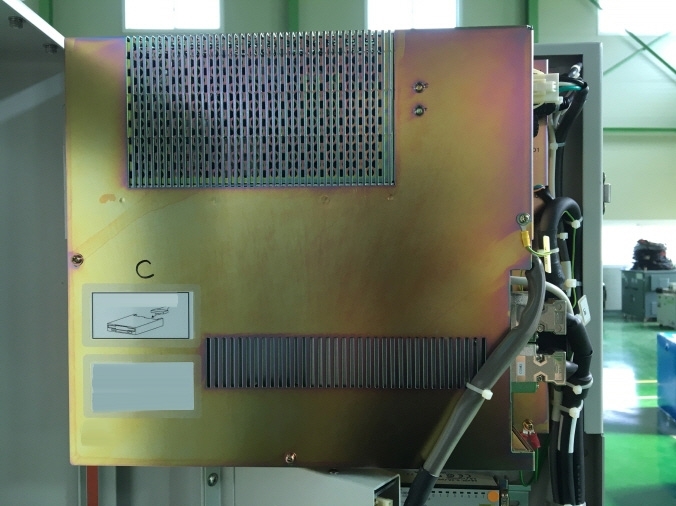

System control:

Main controller: CX3002C

Touch screen operation

Gas flow chart (Front, Rear)

Temperature controller: CQ1600

Pressure control: EPV100-AW

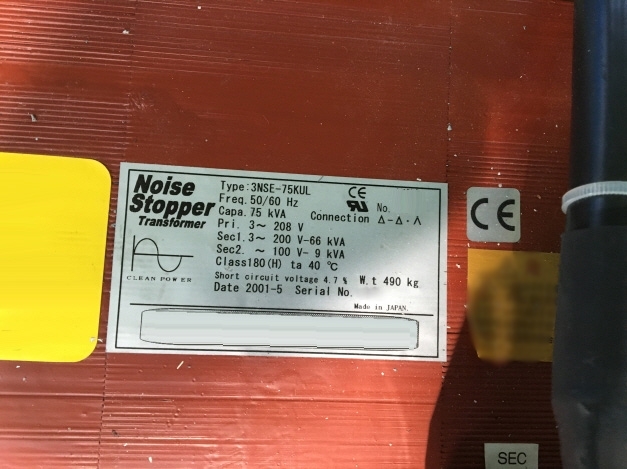

Controller power: Ø1 208V 150A

Heater power: Ø3 208V 350A

Oxygen analyzer: No

Tape heater controller: SR Mini

Torch

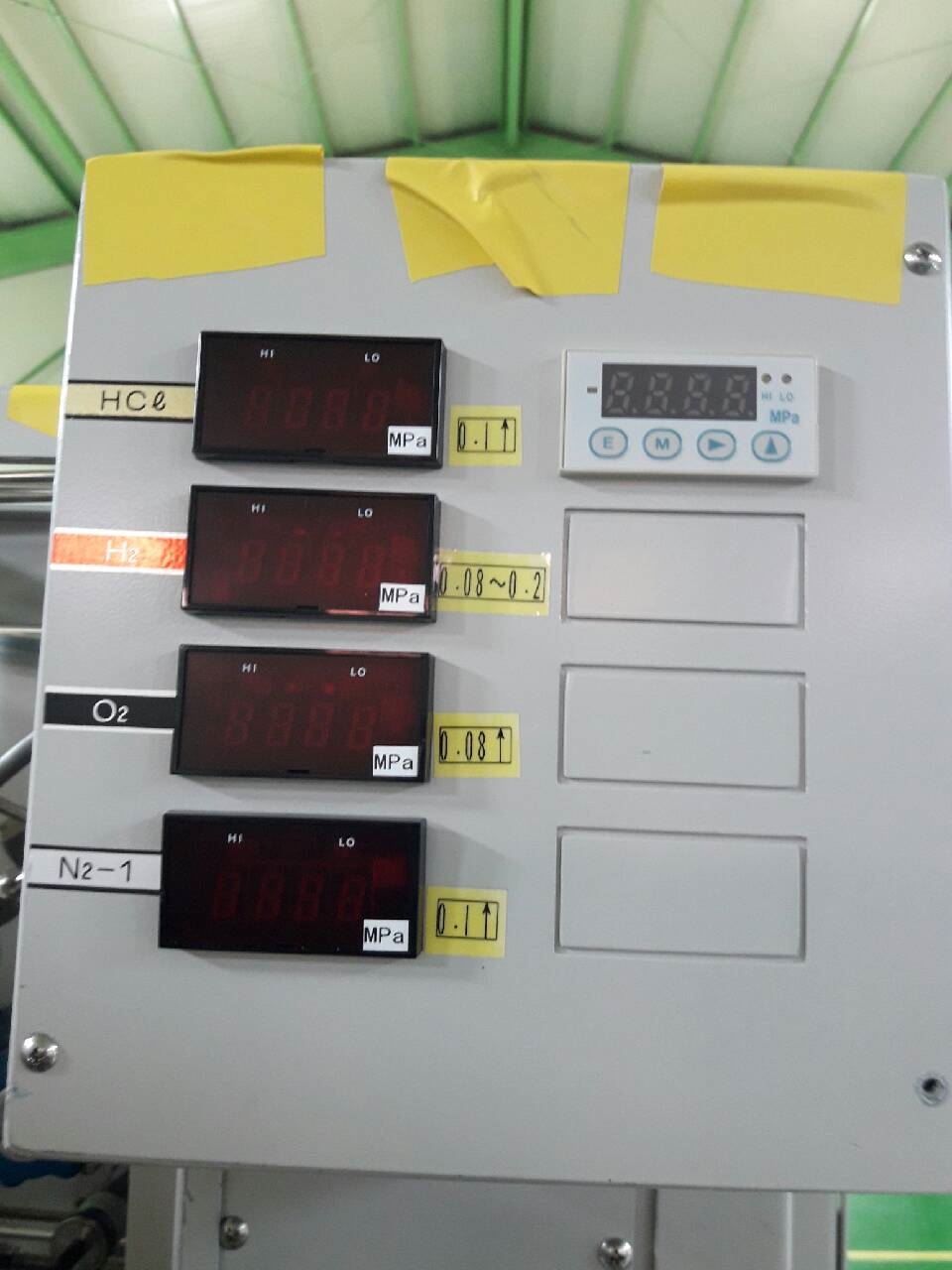

Process gases:

Process gas 1: N2

Process gas 2: N2

Process gas 3: O2

Process gas 4: O2

Process gas 5: H2

Process gas 6: Hcl

Process gas 7: N2

Process gas 8: N2

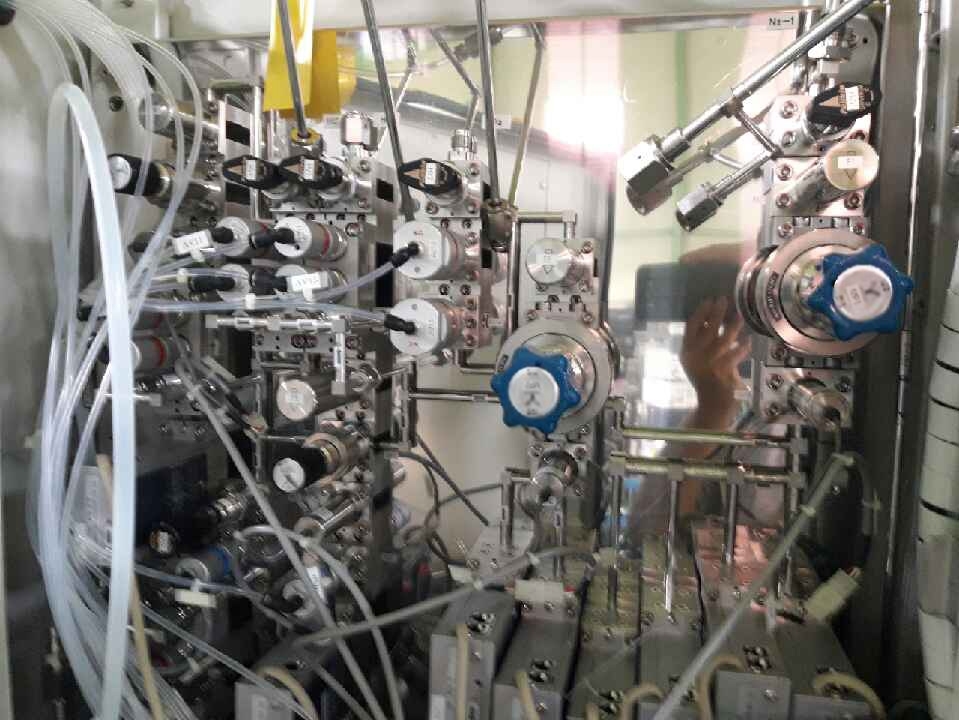

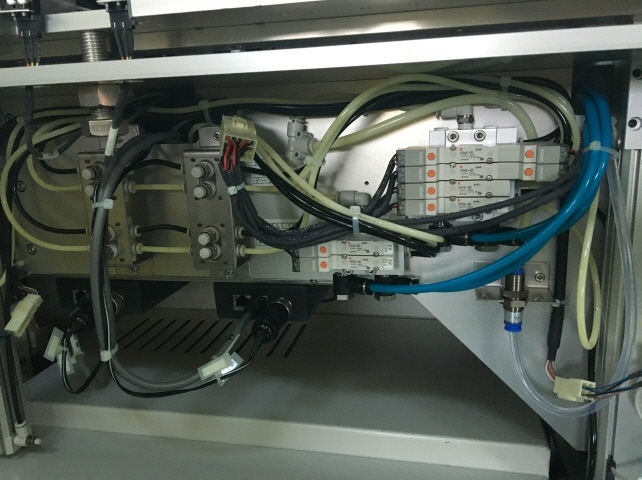

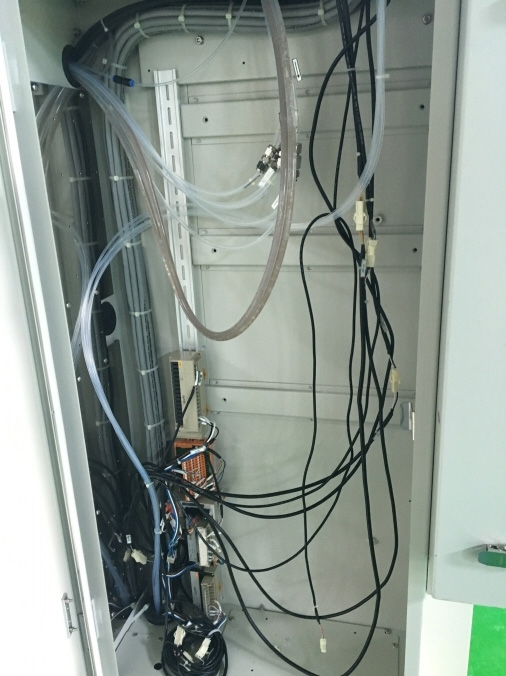

Gas distribution system:

Basic style: FUJIKIN IGS

Tubing material: SUS-316L

Tubing finish: VCR

Manual valve: FUJIKIN

Air operated valve: FUJIKIN

Regulator: AP Tech

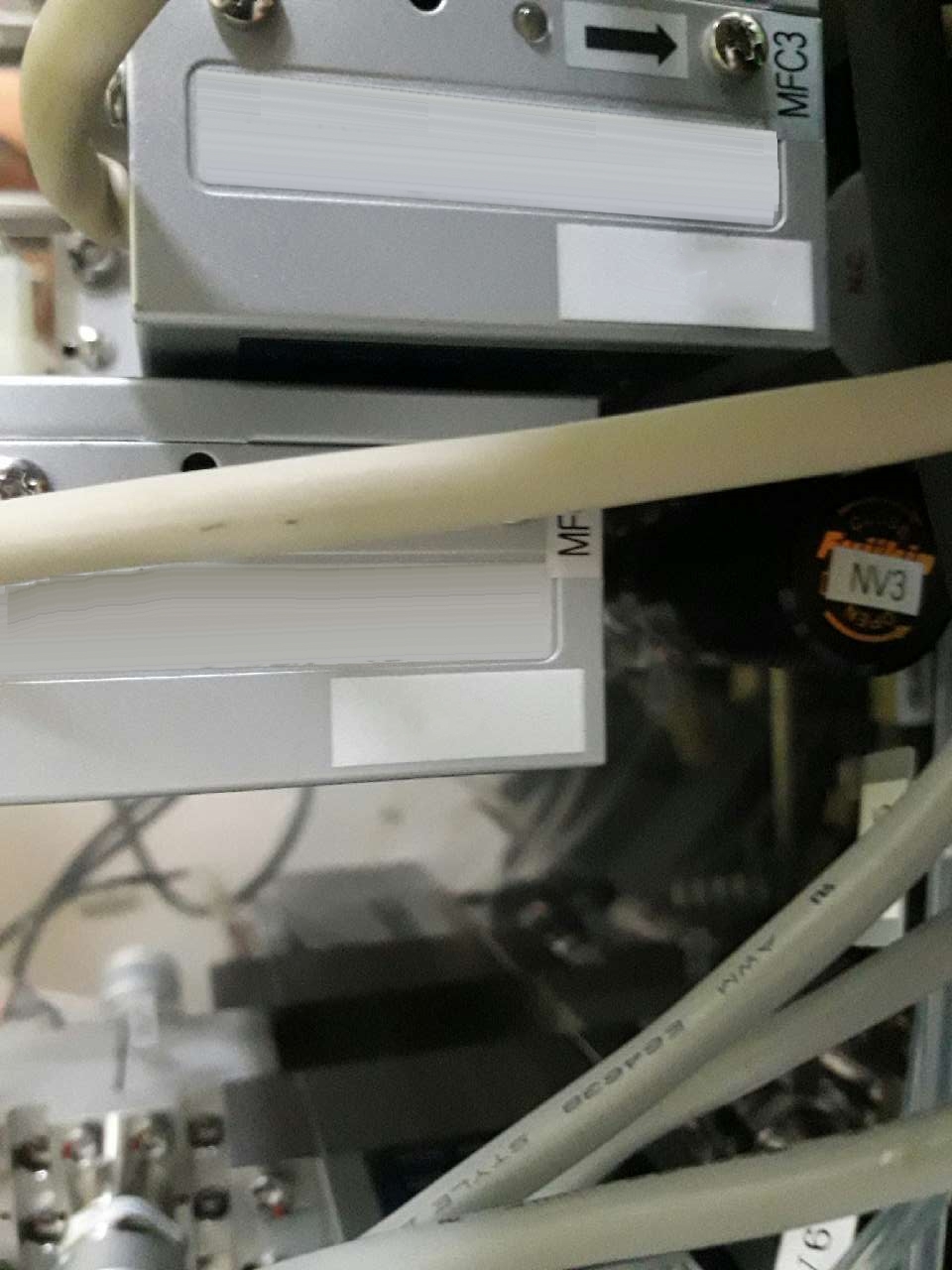

MFC (Maker. Model): AERA

GAS Detector

Exhaust distribution system:

Air operated valve type

APC EPV-100

Baratron gauge

Main valve

Cold trap

Pump line

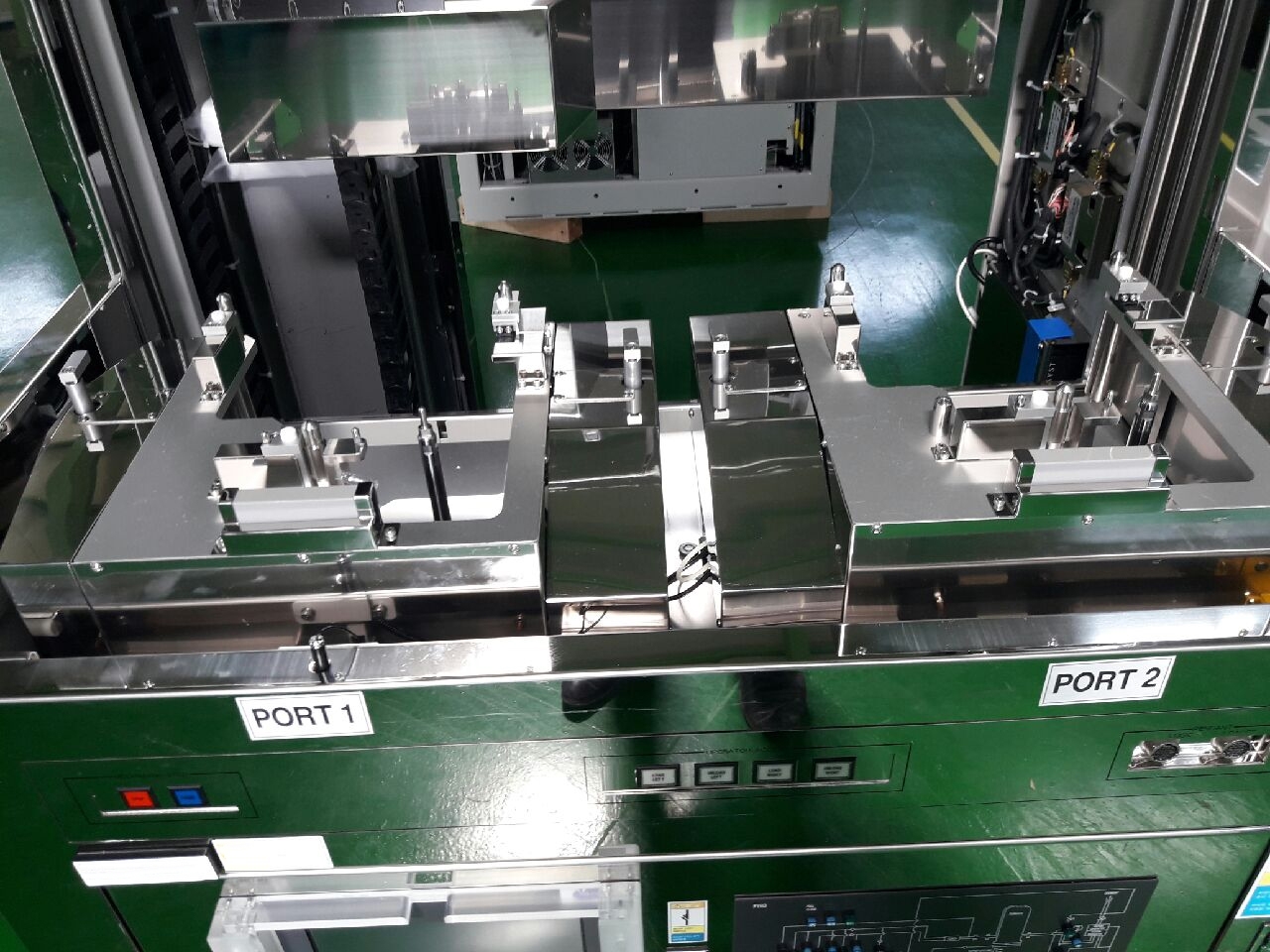

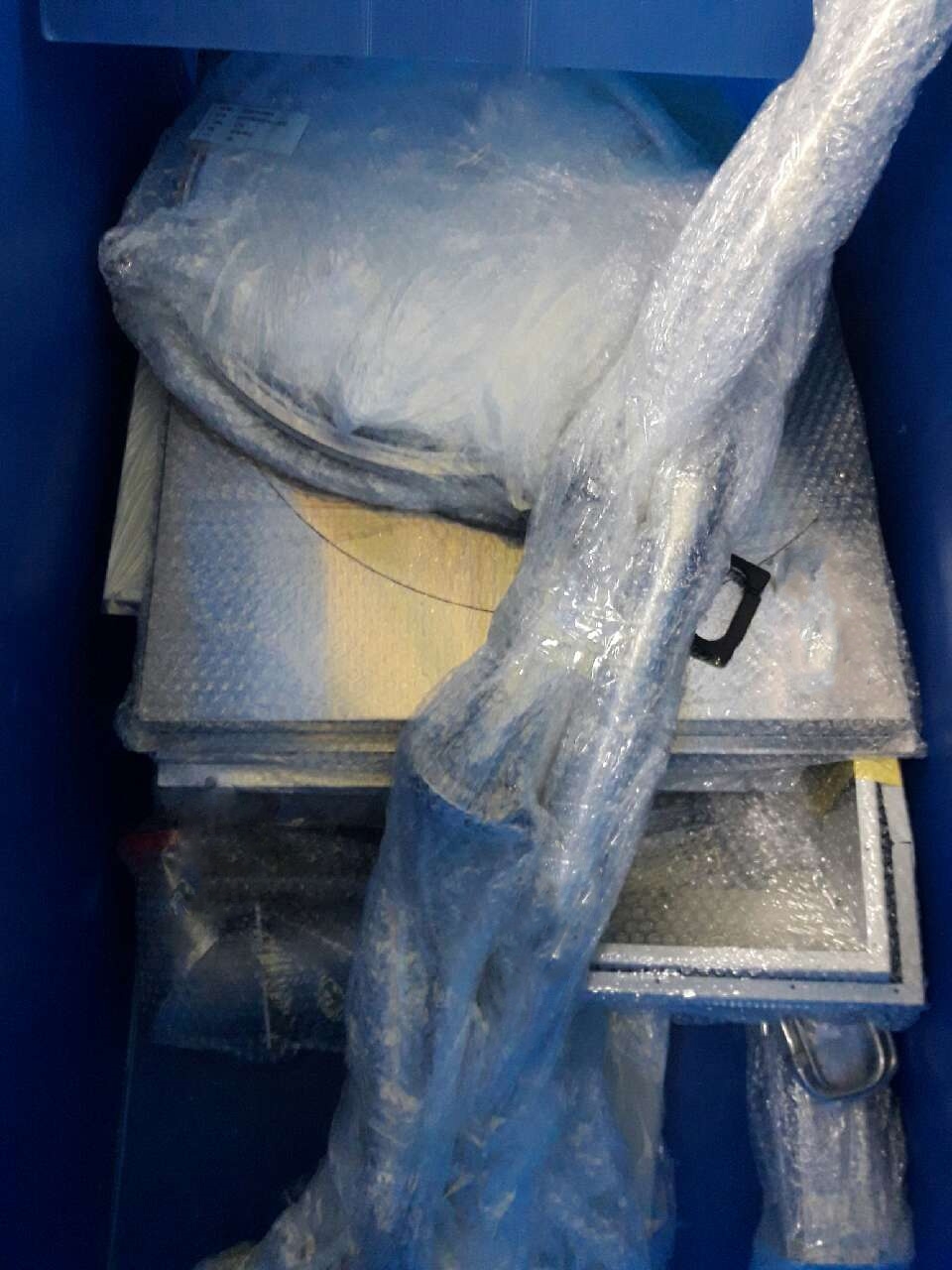

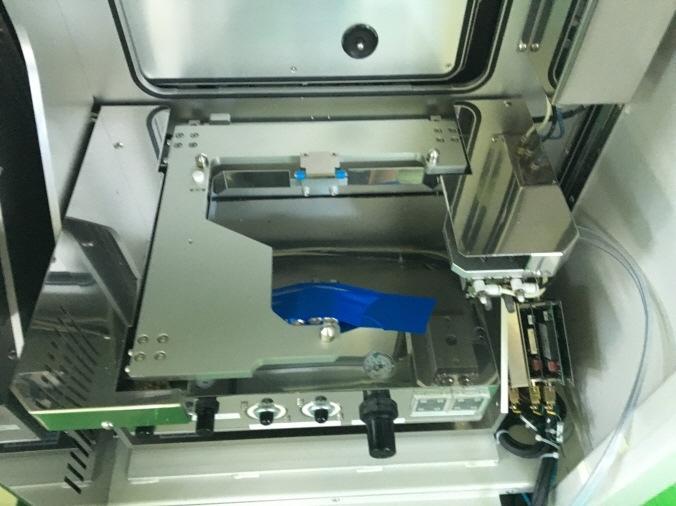

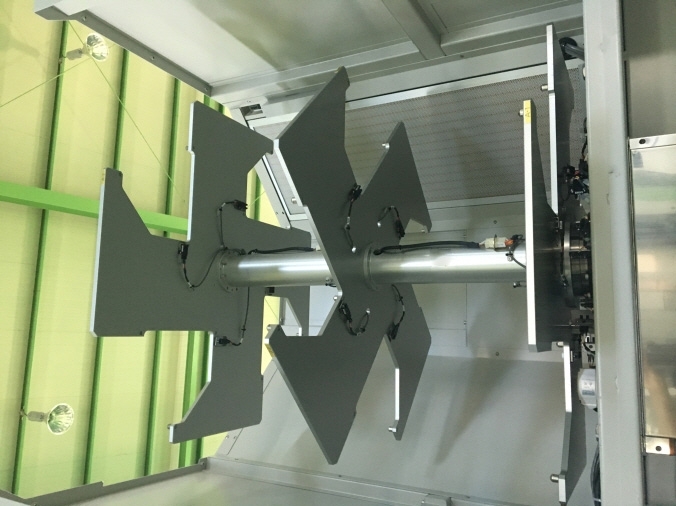

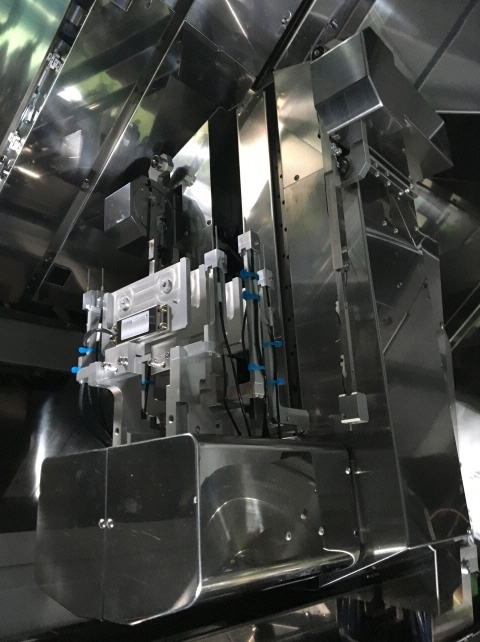

Wafer / Cassette handling:

Wafer alignment: No

(16) Cassette storage

Cassette in/out port

Cassette handling robot

Wafer transfer type: 1+4

Fork material: Ceramic

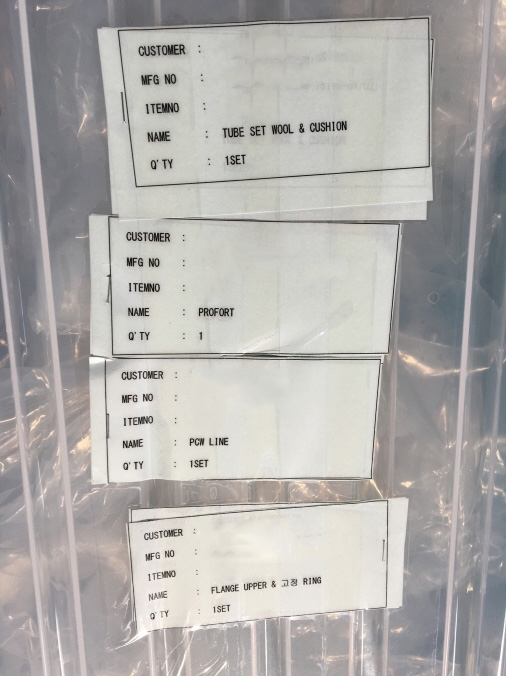

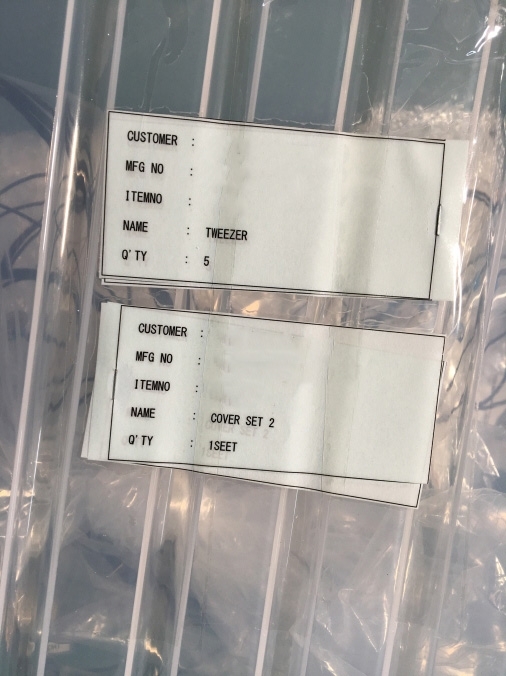

(5) Forks

Fork variable pitch

Fork wafer presence sensor

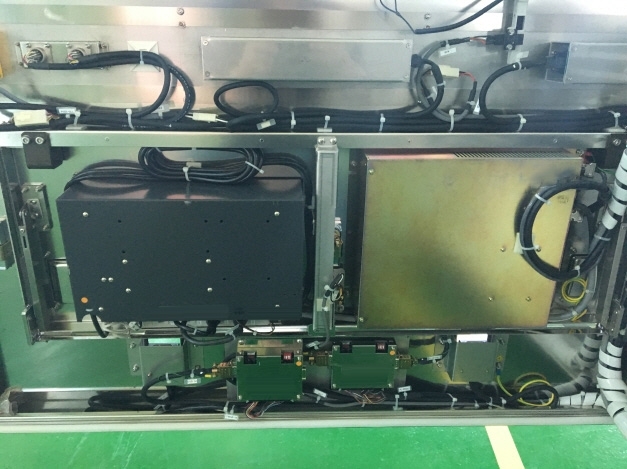

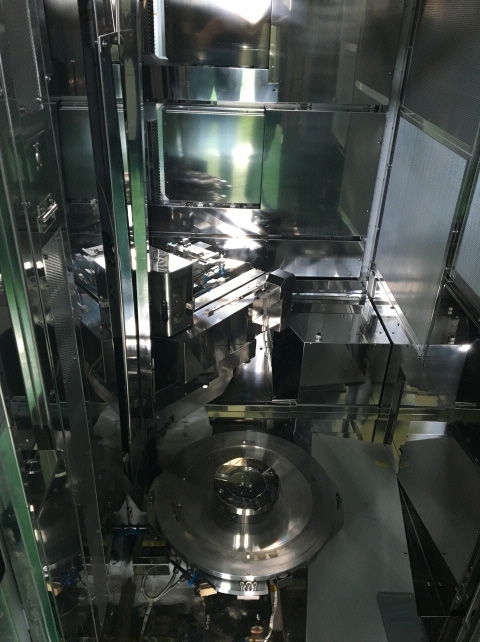

Elevator handling:

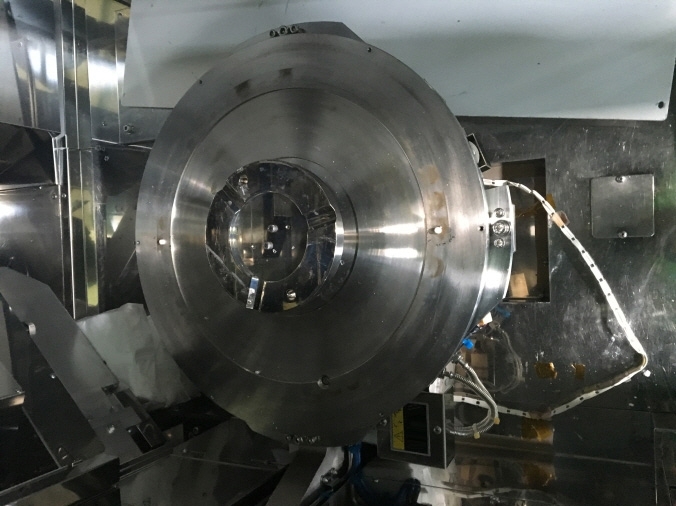

Boat elevator

Auto shutter

Boat rotation

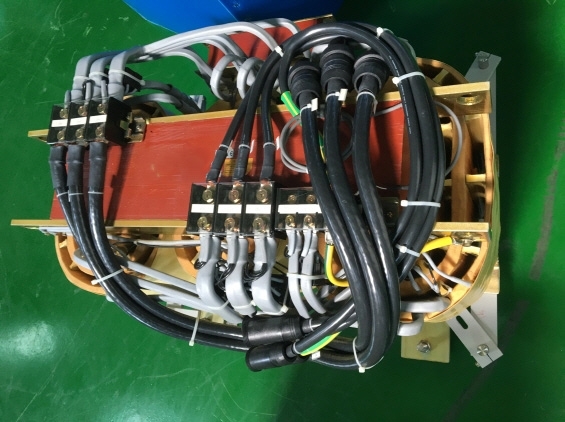

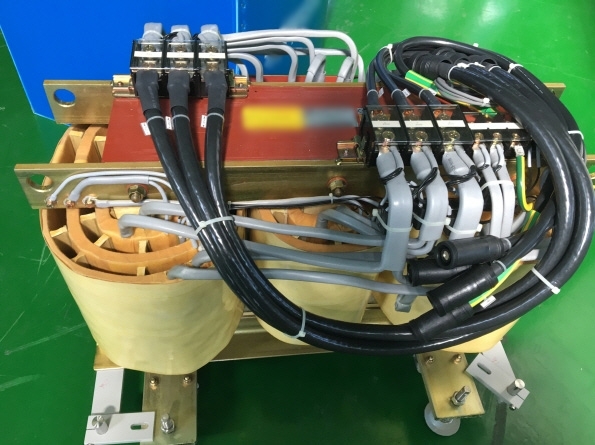

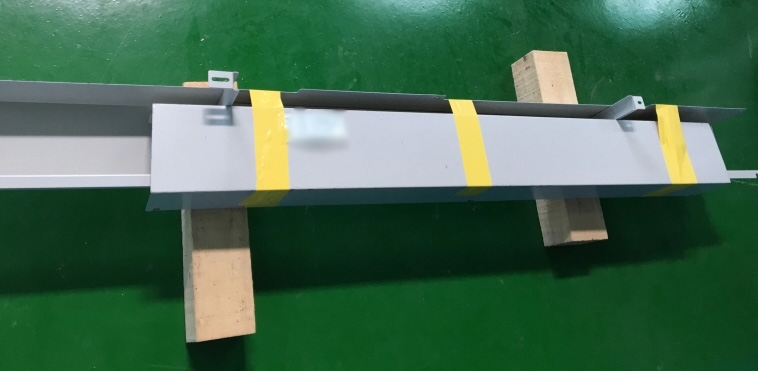

Mechanical parts

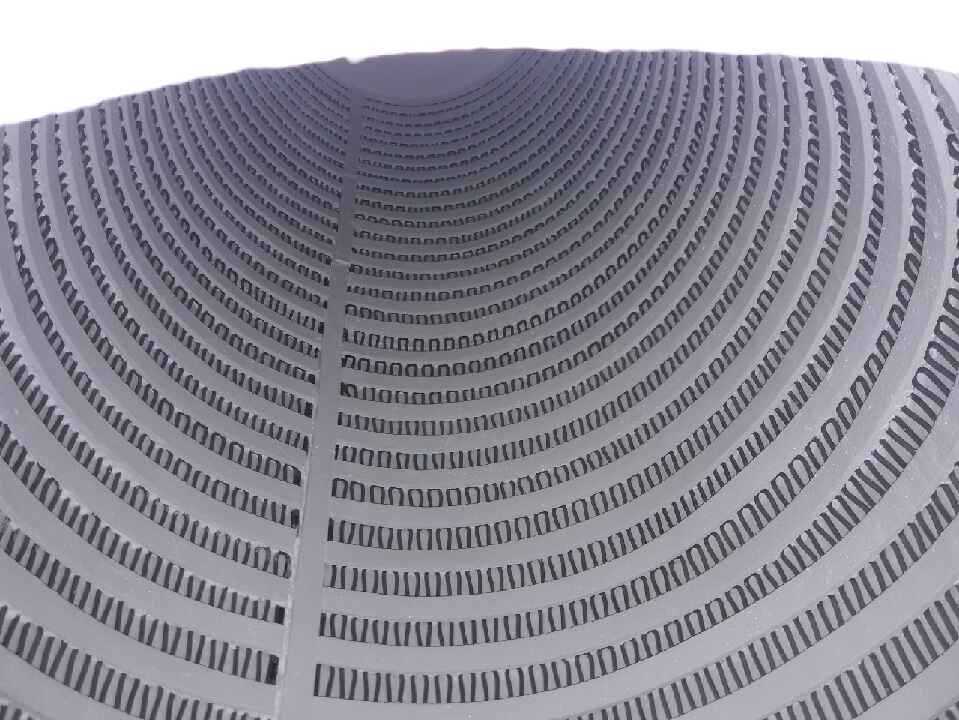

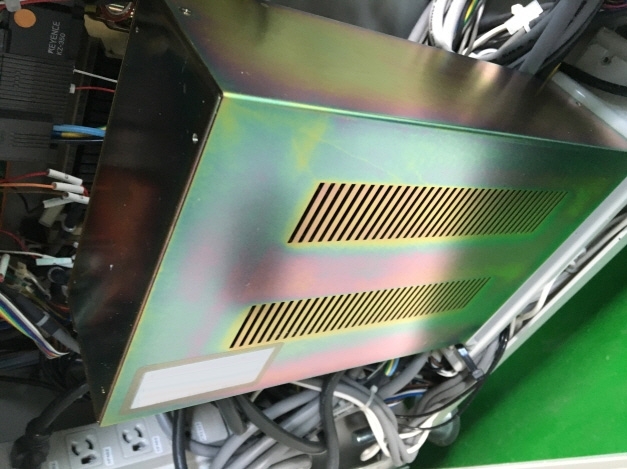

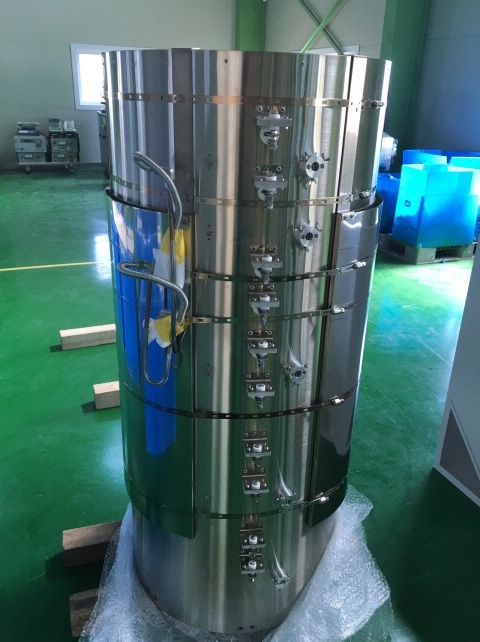

Heating chamber:

D4EX16975-1 Heater

TC Type: No

Spike T/C

Overtemp protect T/C

Door interlock

Exhaust System:

Heater exhaust

Gas box exhaust

Process exhaust

ETC:

Handy terminal

Maintenance zig: No

Operation manual: No

Electrical manual: No

Mechanical manual: No

Boat cap ass'y: No

Manifold ass'y

Cap base ass'y

Tube setting part ass'y

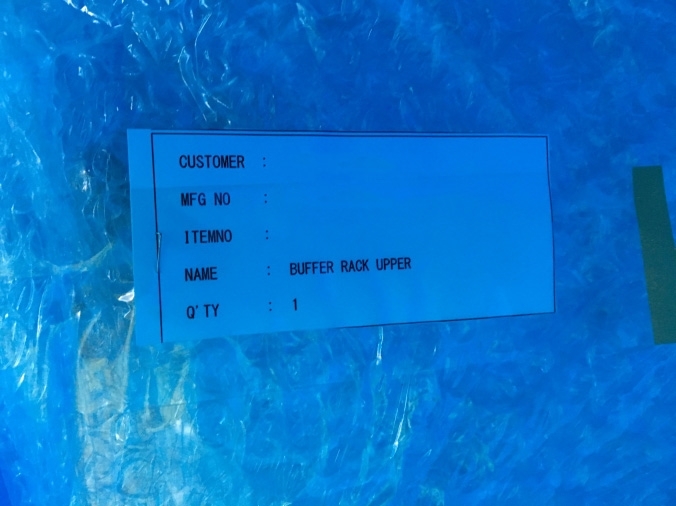

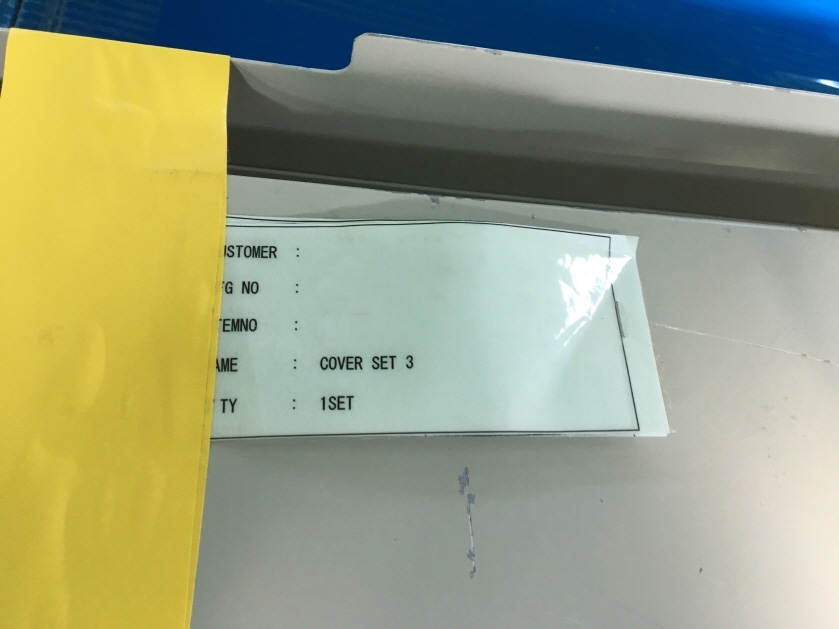

Missing parts:

Scavenser EXH MS3 Sensor

Torch TC

Currently warehoused

2001 vintage.

HITACHI / KOKUSAI DD-1223V is a versatile diffusion furnace equipment that can be used for a range of applications, including semiconductor and solar cell manufacturing, thin film deposition, and other process furnace applications. HITACHI DD-1223V features an insulated quartz tube and a maximum furnace temperature of 1,200°C. The furnace can be installed in both vertical and horizontal configurations and includes an in-chamber gas system for adjusting oxygen and nitrogen balance levels. KOKUSAI DD-1223V comes with a set of accessories designed to support various process requirements. These accessories include a quartz liner tube for reducing contamination, a collection plate for collecting exhausts, an anode ring for preventing arcing, and a crucible heater for controlling the temperature of the substrate. Additionally, the furnace includes a variety of safety features such as a gas monitoring unit, combustible gas filters, safety shut-offs, and an automatic shut-off when the temperature exceeds pre-set limits. DD-1223V features an easy to use touchscreen interface and a wide range of pre-programmed recipes for different processes. The furnace is programmed via a Windows-compatible PC and can be remotely operated via a network connection. Additionally, the furnace includes an RS232 interface for connecting to external systems to allow users to access additional control and monitoring functions. HITACHI / KOKUSAI DD-1223V is designed to be durable and reliable, as well as energy efficient. The furnace is constructed from sturdy aluminum and includes a dual-insulated quartz tube to reduce heat loss whileproducing consistent temperatures throughout. The furnace also includes a water-cooled machine that circulates coolant through the power and control circuits to ensure safe operation and cooling efficiency. HITACHI DD-1223V diffusion furnace & accessories is an easy to use, versatile tool which is compact, space-saving and suitable for a range of cleanroom and industrial applications. It offers reliable operation, extensive process control features, advanced safety features, and easy maintenance. With its intuitive touchscreen interface, comprehensive accessories package, and wide selection of pre-programmed recipes, KOKUSAI DD-1223V is a great choice for any user.

There are no reviews yet