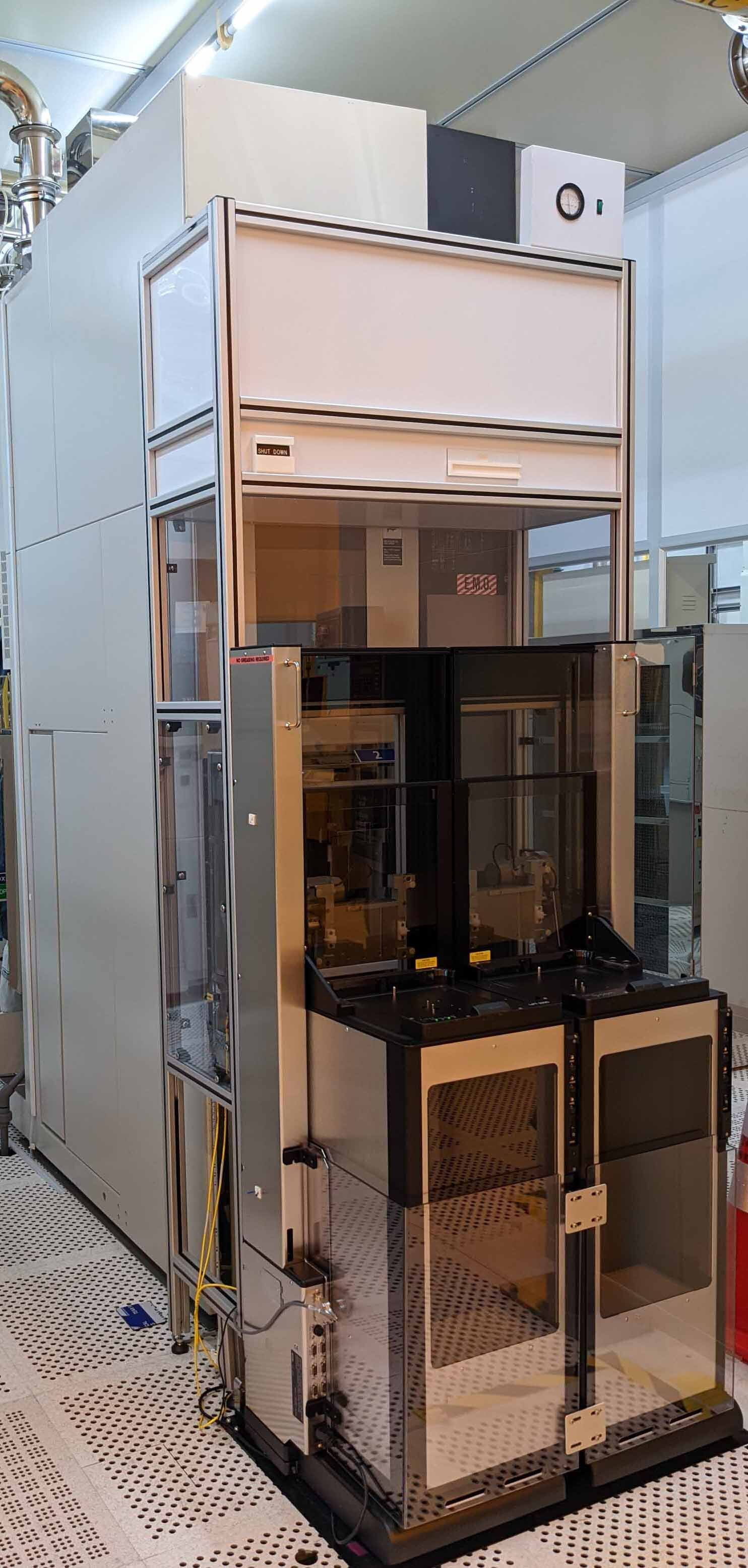

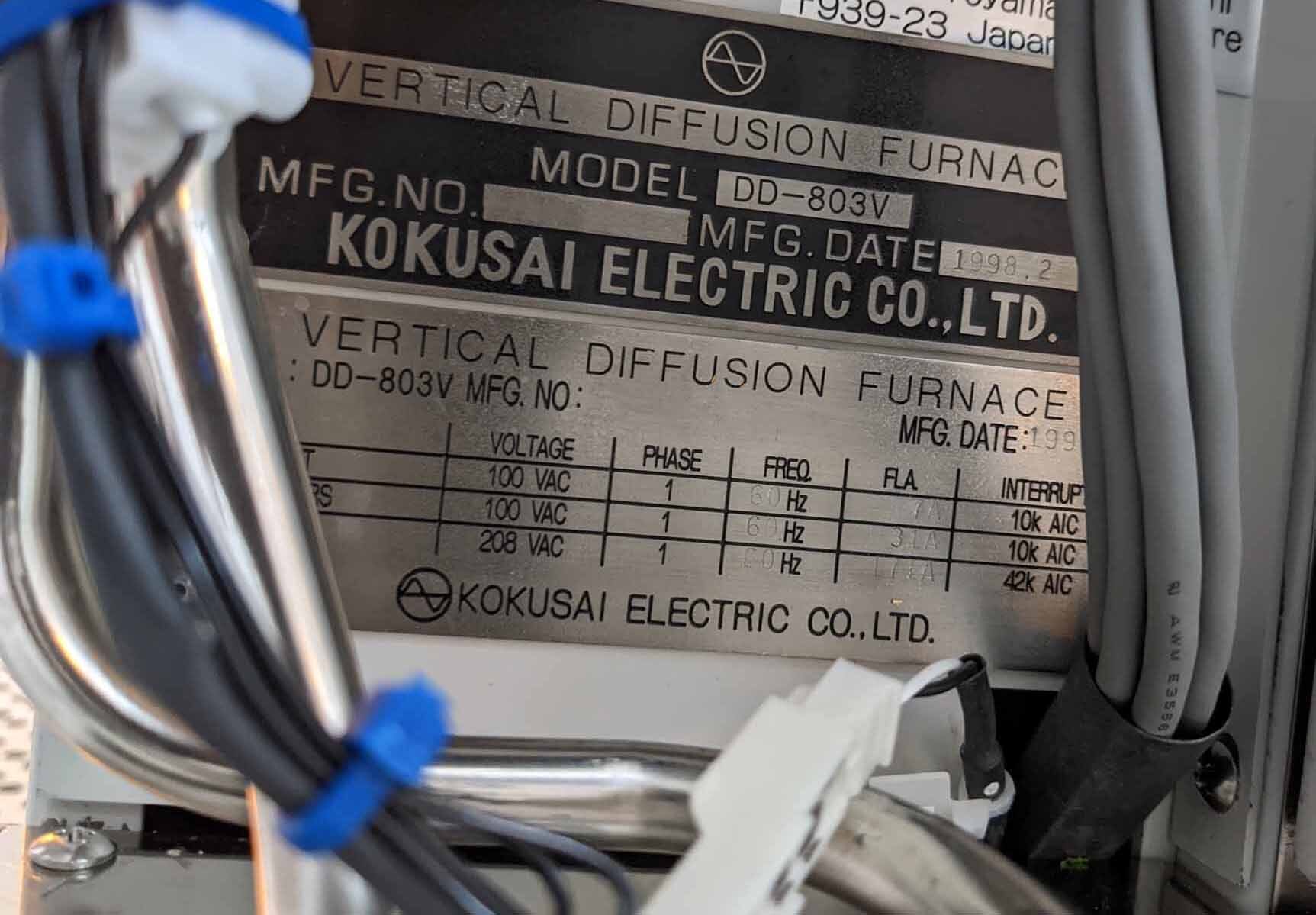

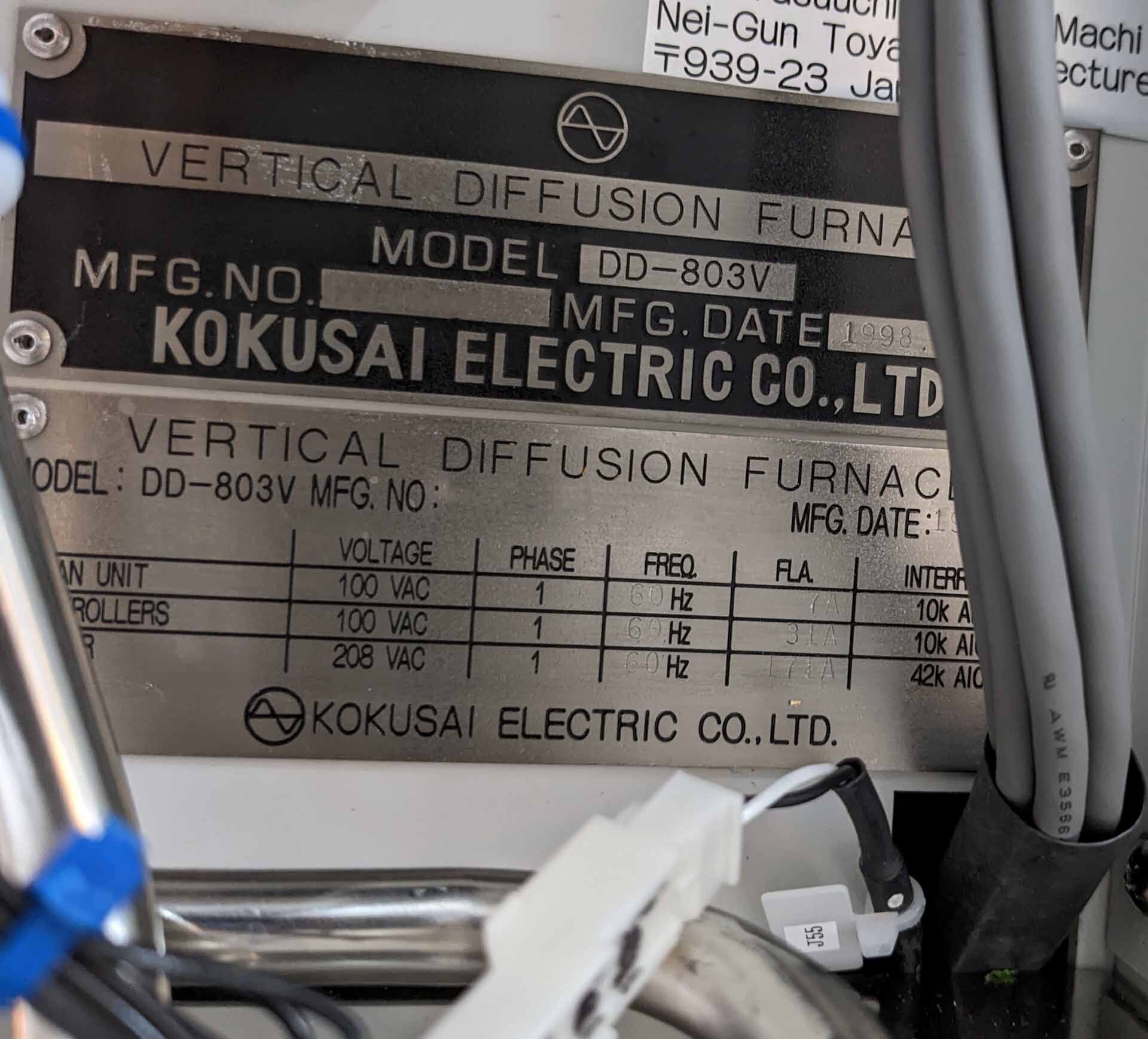

Used HITACHI / KOKUSAI DD-803V #293633553 for sale

URL successfully copied!

Tap to zoom

ID: 293633553

Wafer Size: 8"

Vintage: 1998

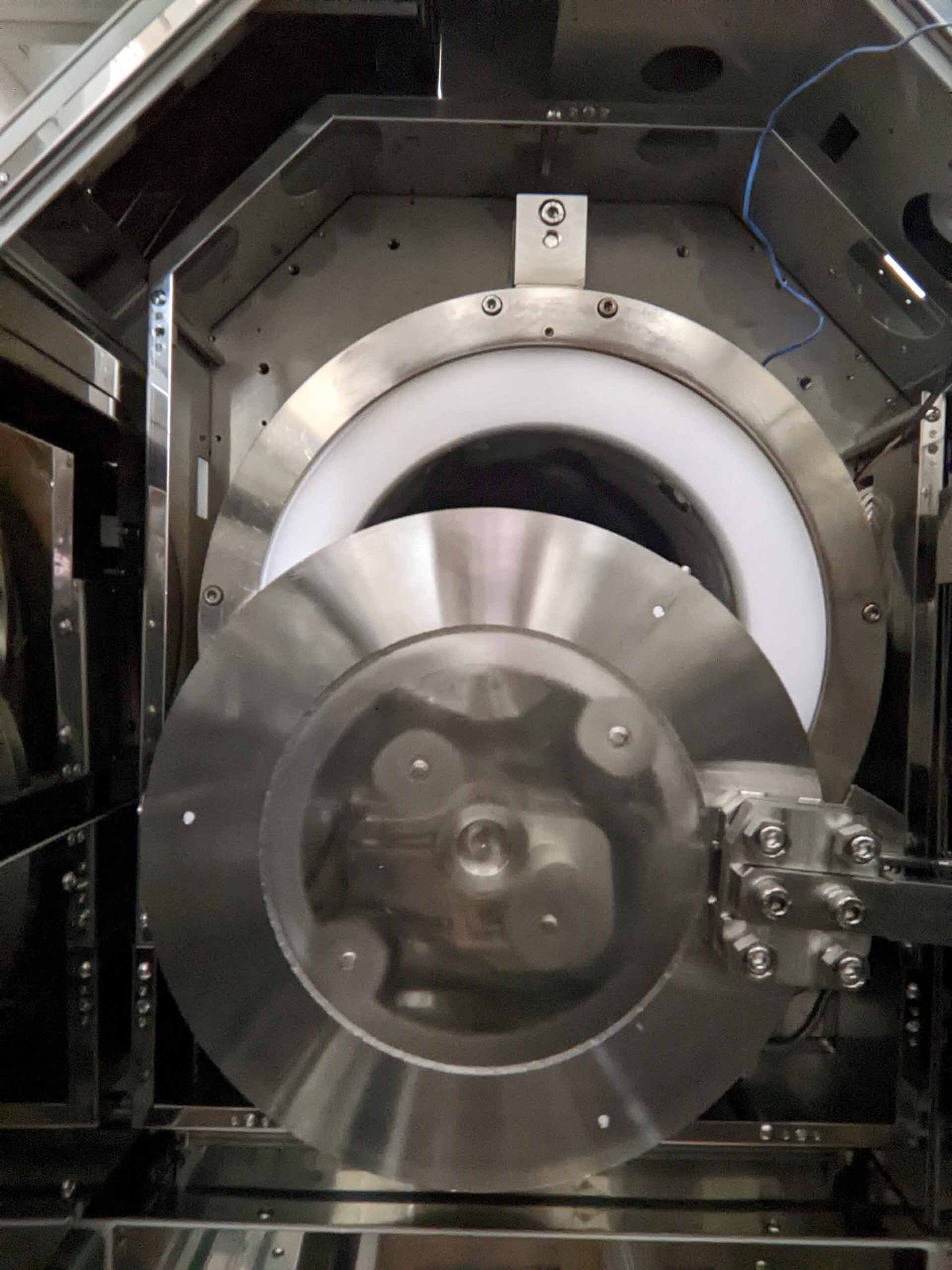

Vertical furnace, 8"

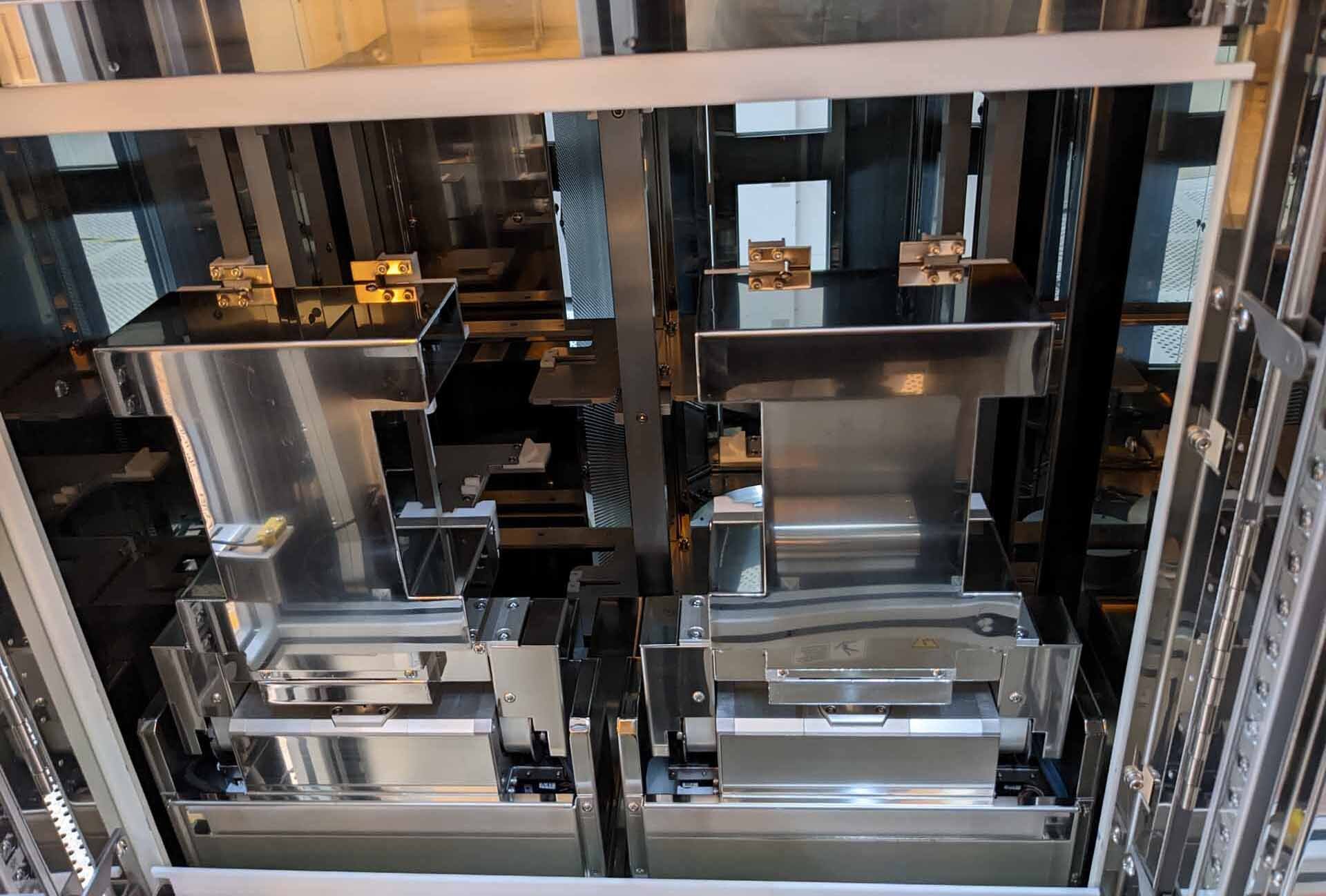

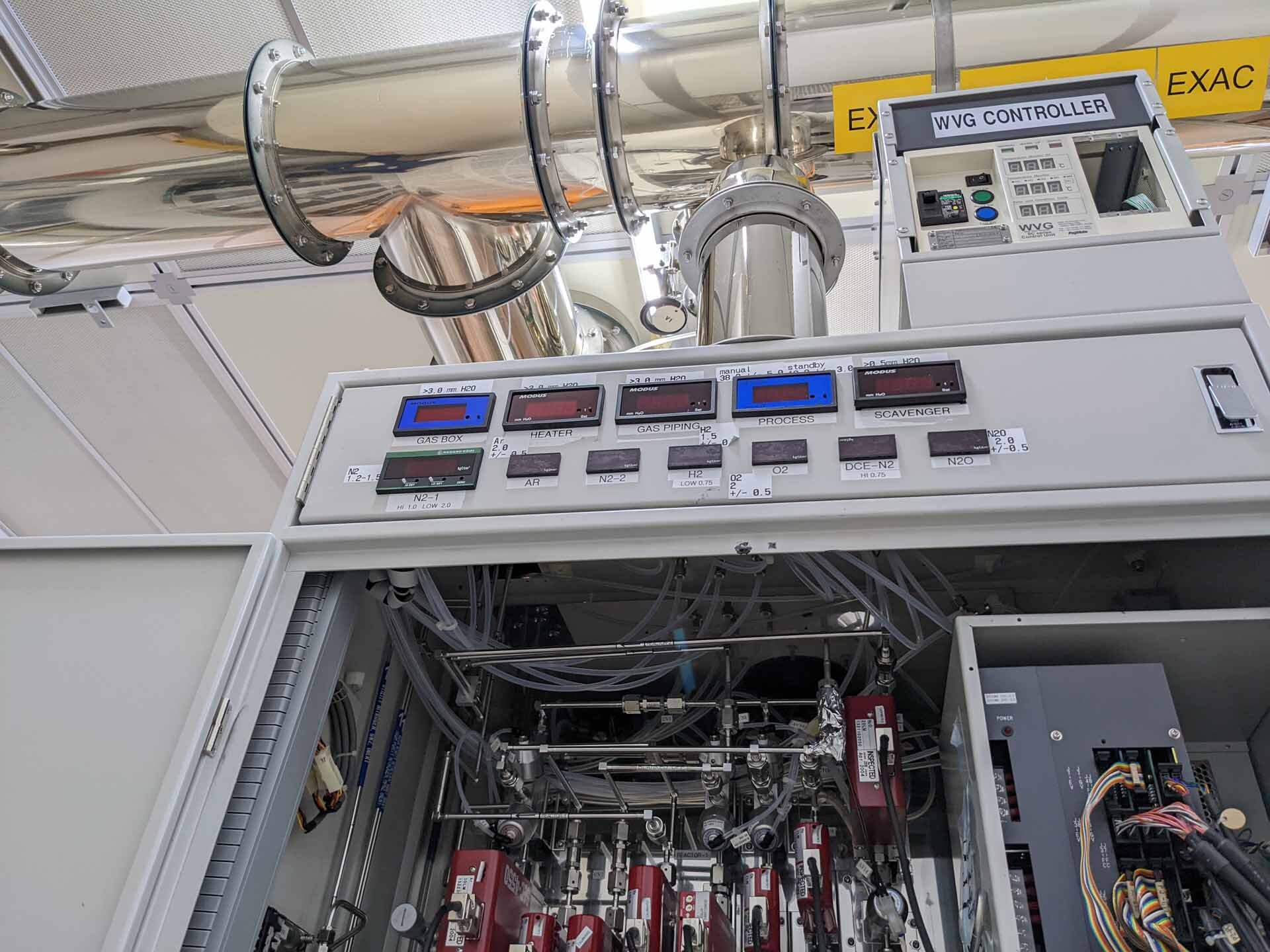

Atmospheric controller

Hand controller

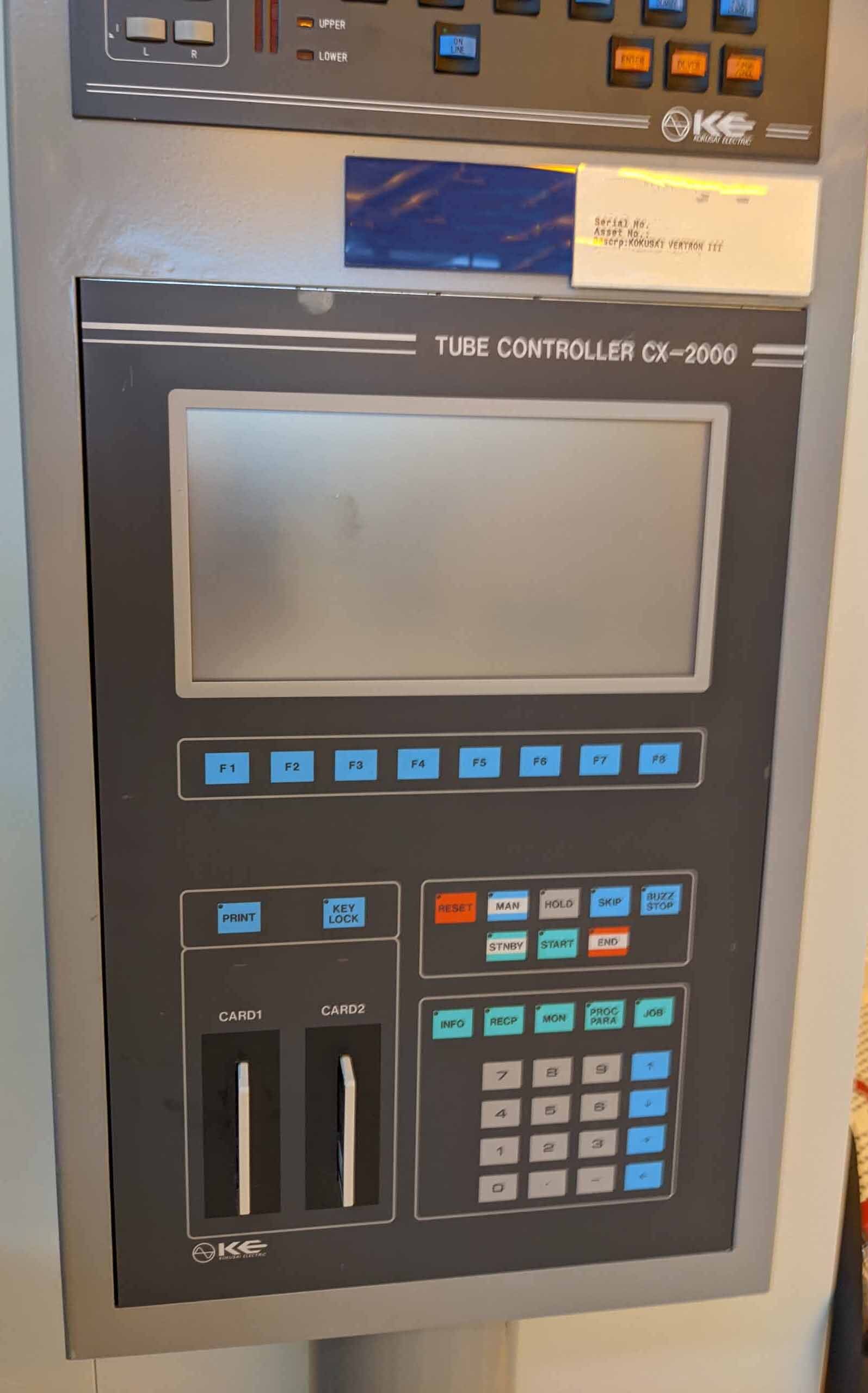

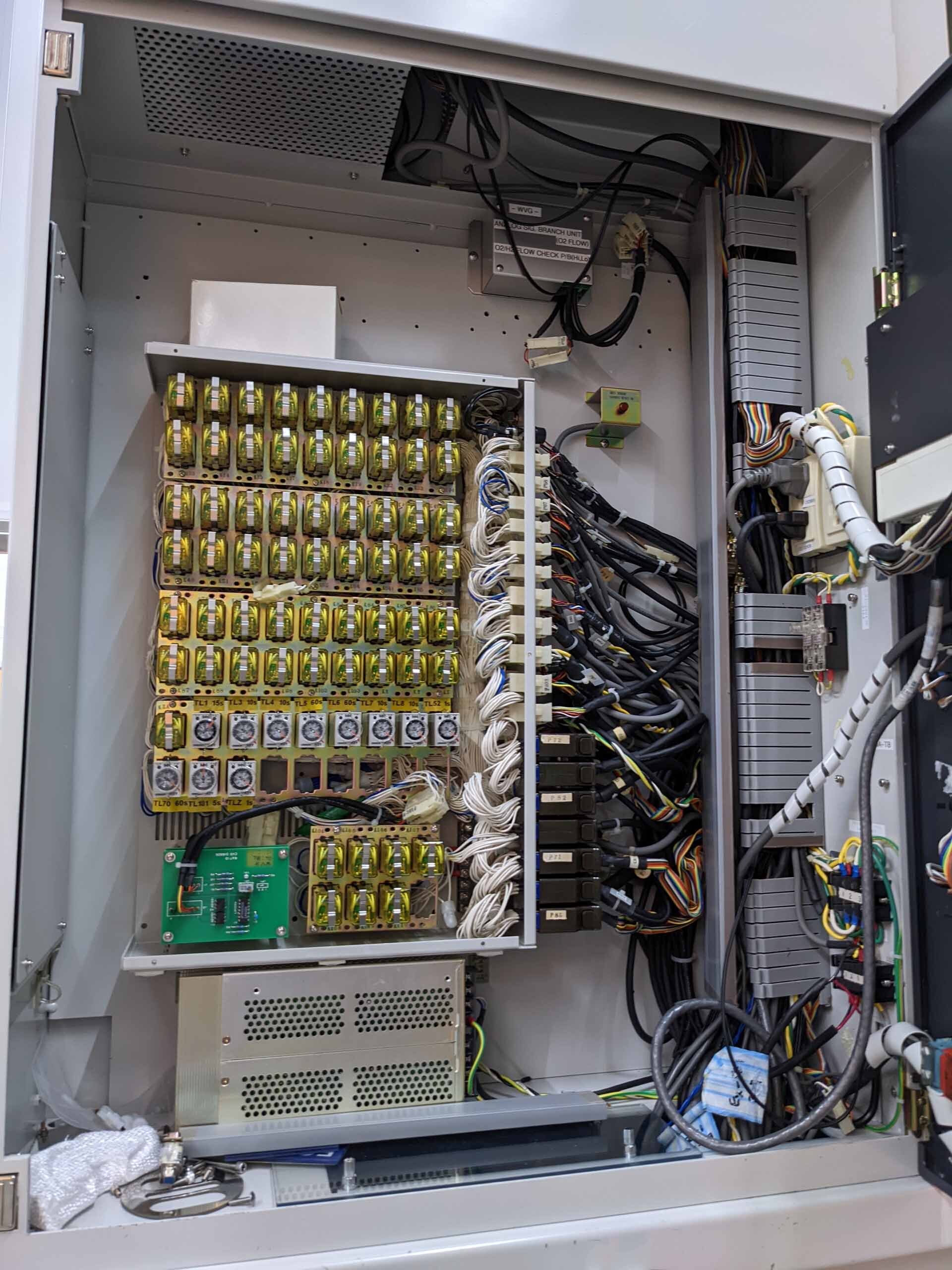

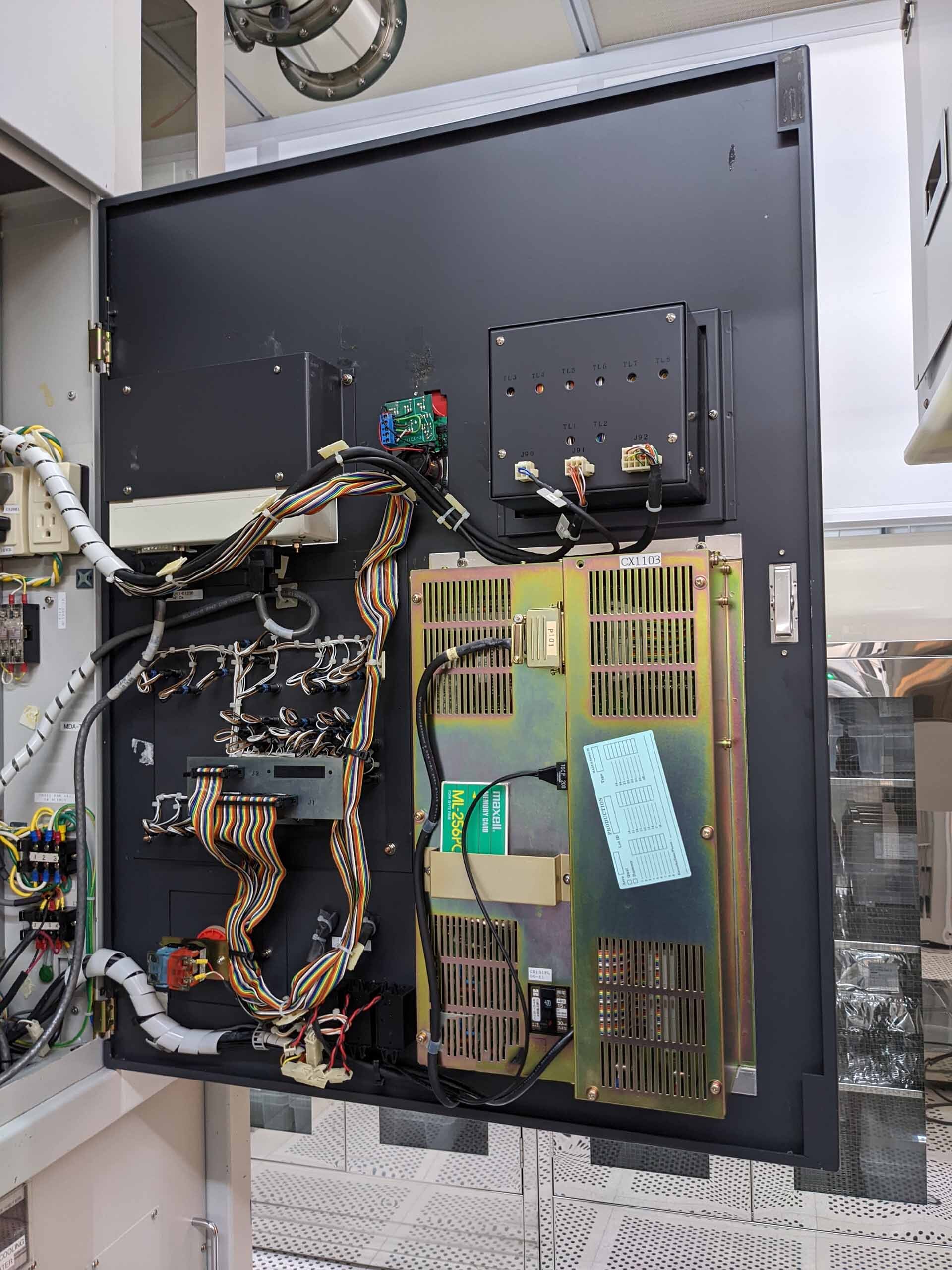

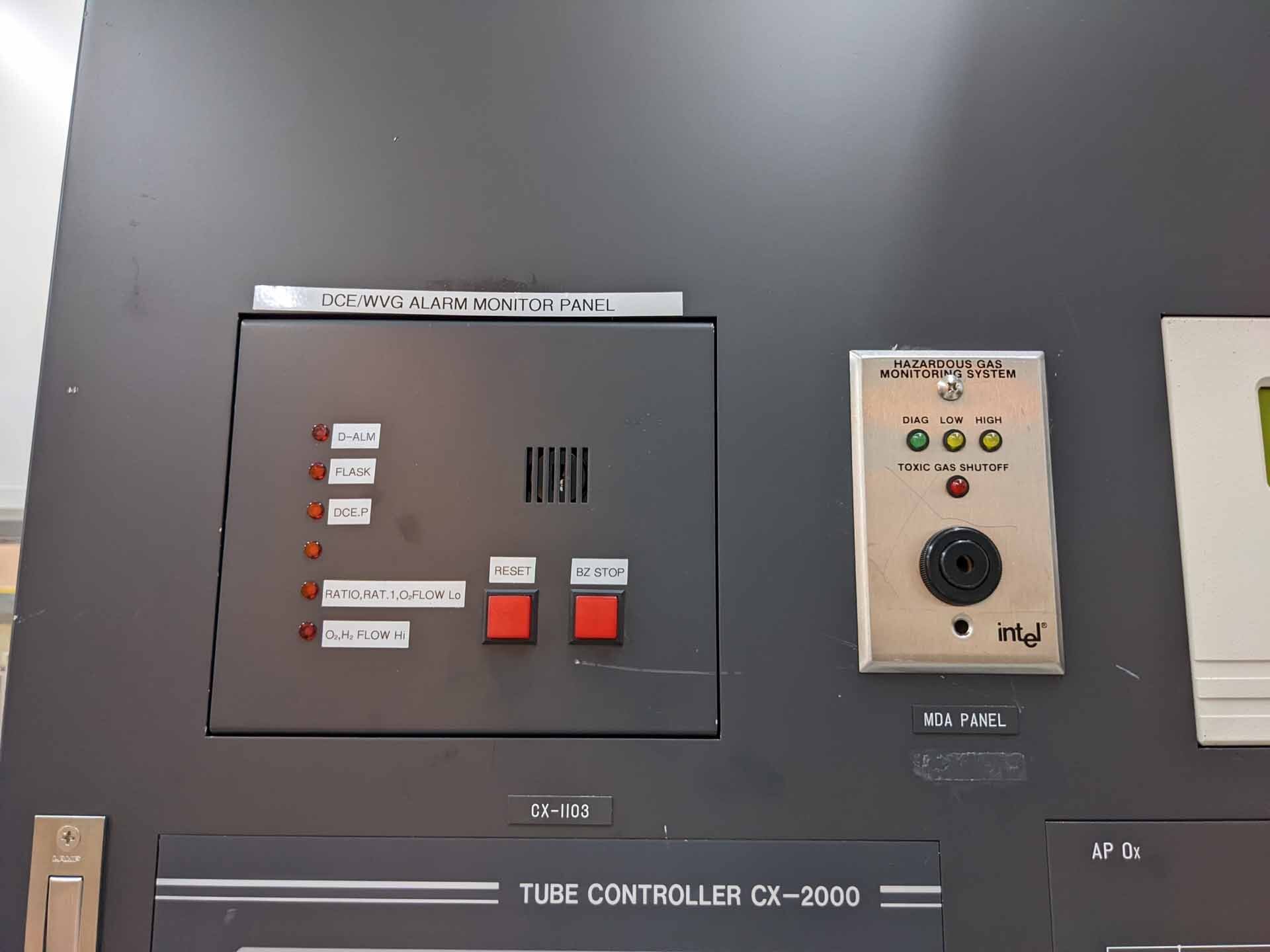

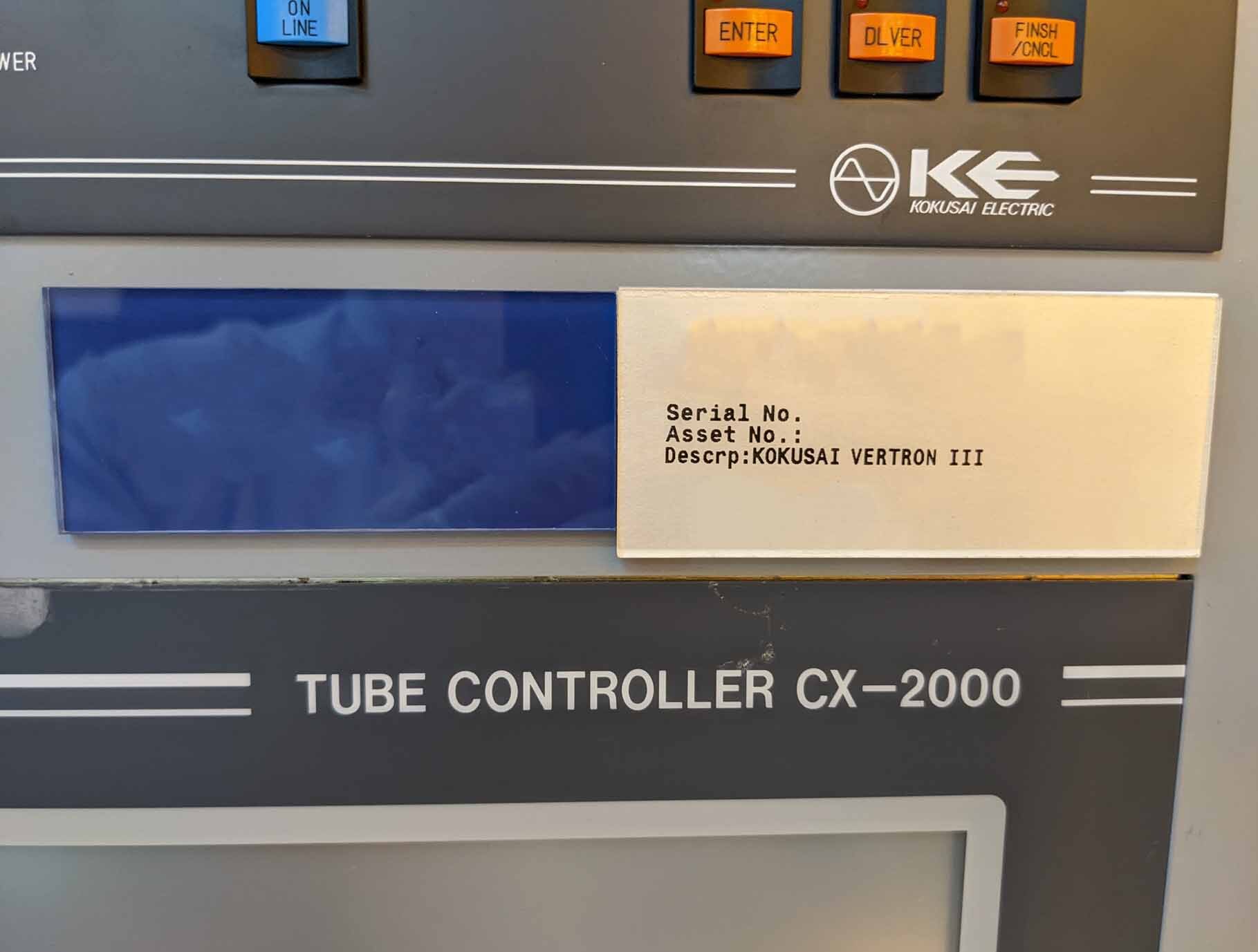

CX2000 Controller

SECM / GEM Communication: Serial

Utility cabinet

CQ1501 Temperature controller

(4) Zones

D4EX02728 Heater

Process temperature: 700°C-1000°C

Flatzone length: 952.50 mm

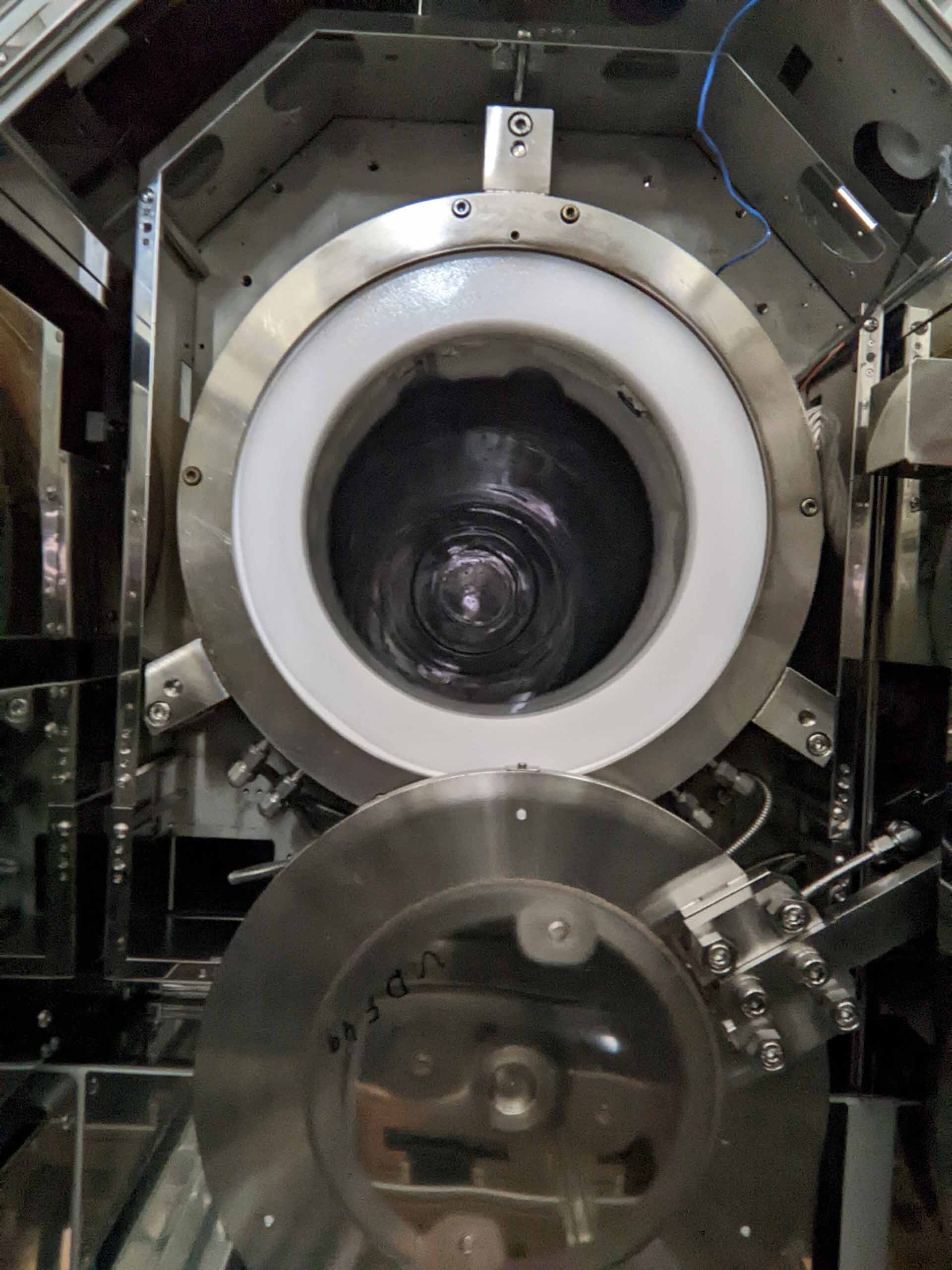

Process tube material: Quartz

Wafer boat material: Quartz

Tube seal configuration: N2 Flow

R-Type thermocouple

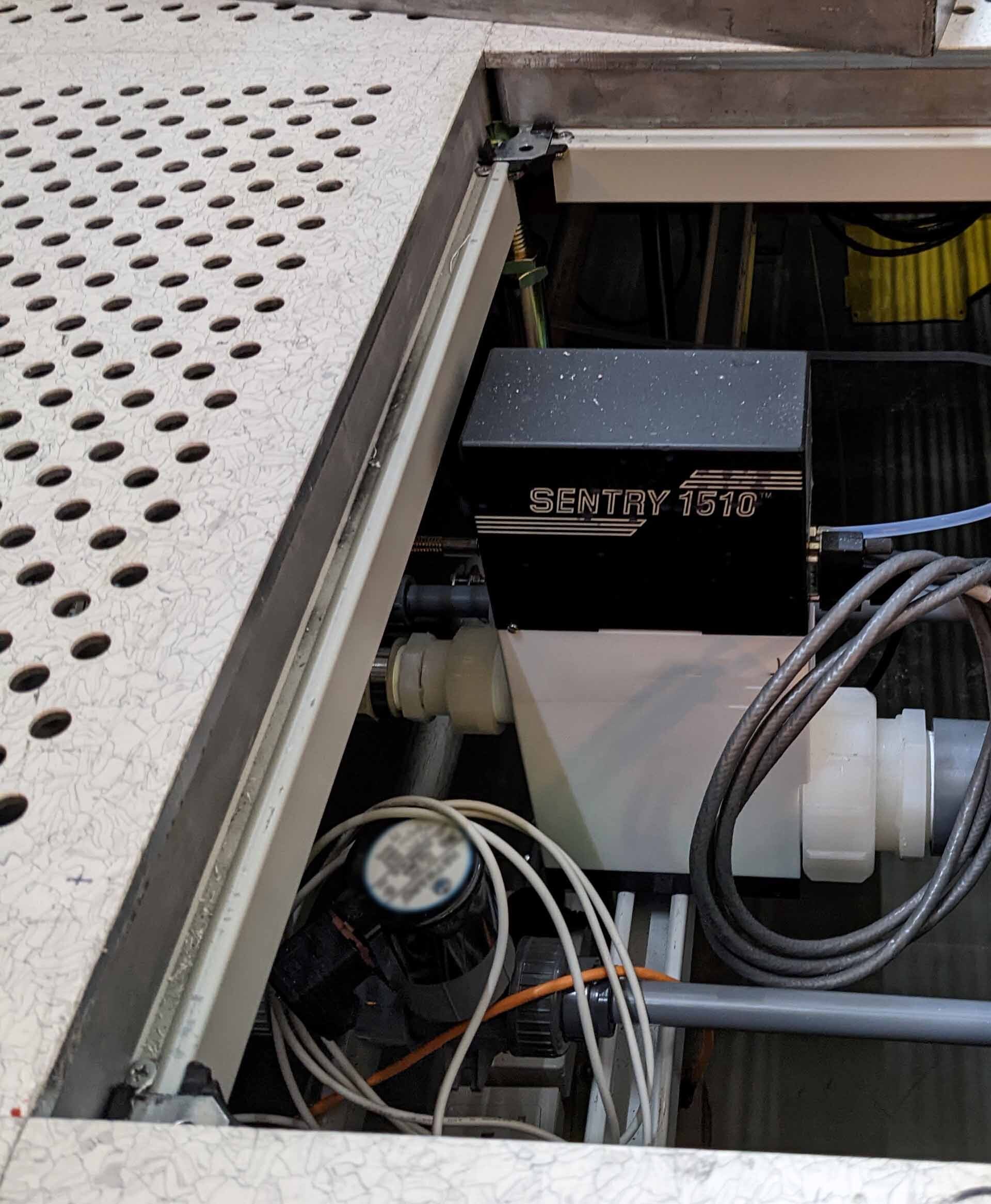

Exhaust controller

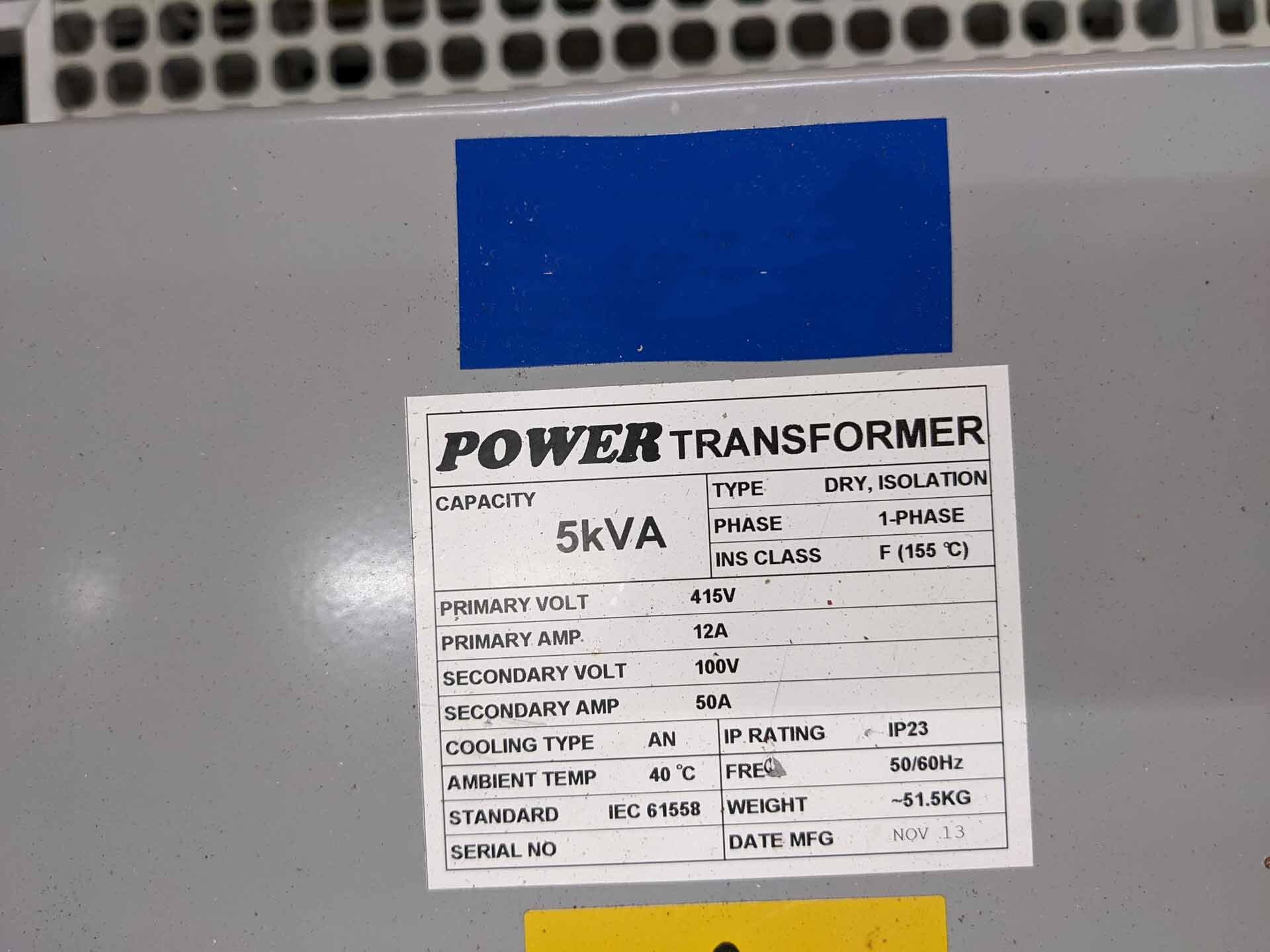

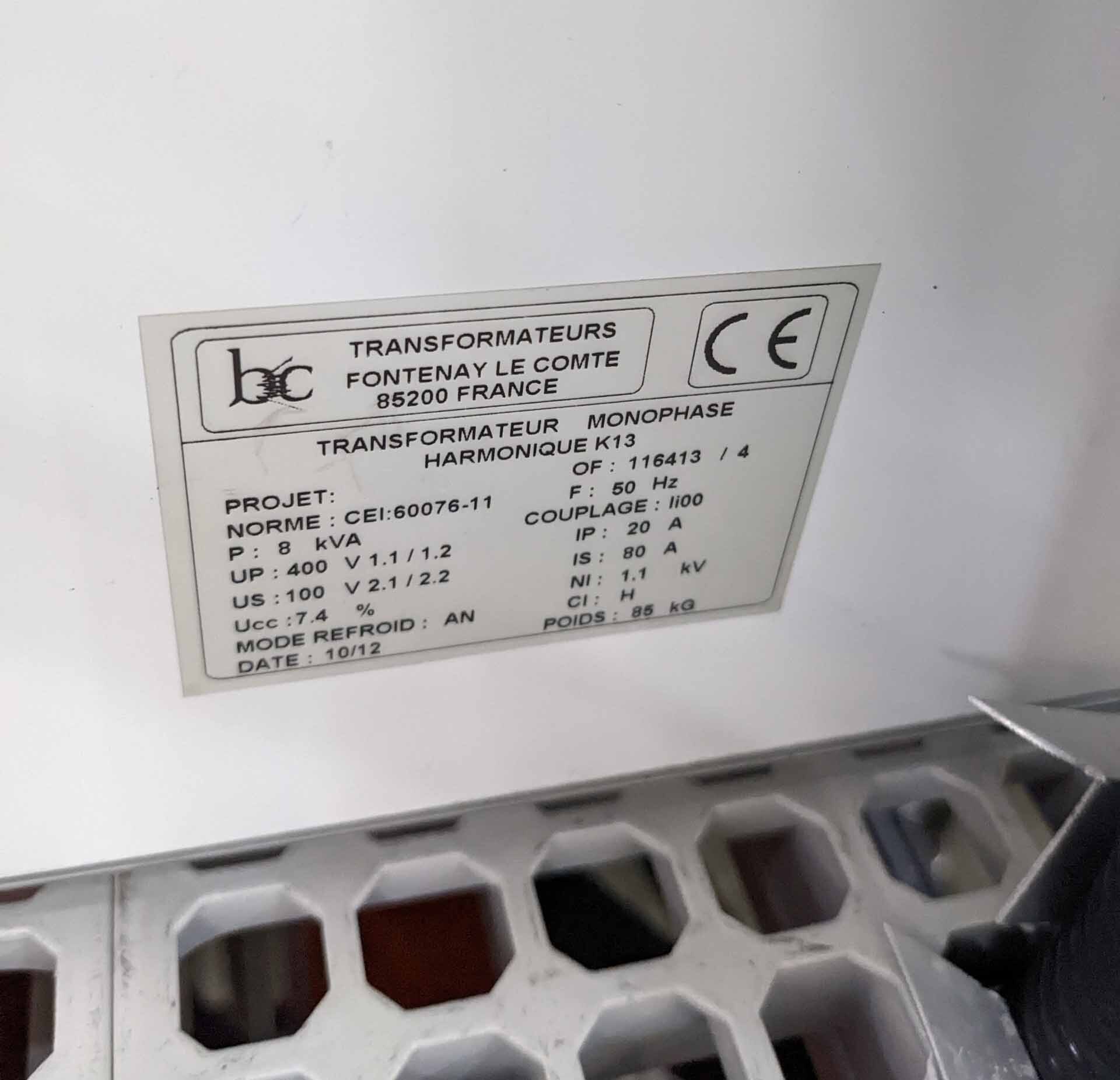

Transformer

Temperature control:

P: 0.1~200%

I: 0.01-100.00 min

D: 0.00-10.00 min

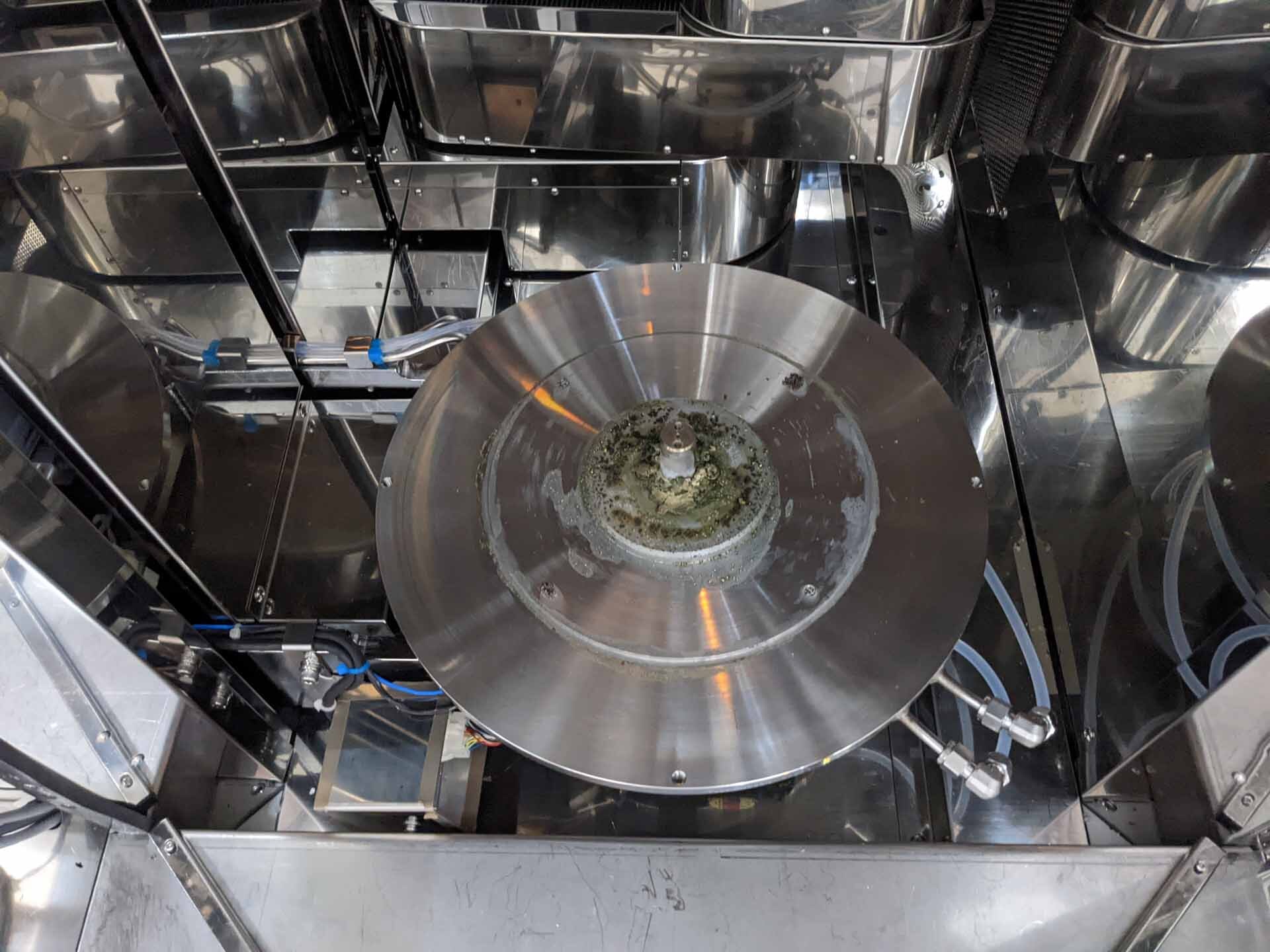

Load station:

WIP Carrier capacity: 16

Wafer spacing: 5.20 ±0.05 mm

Load size: 150-Slots

Boat rotation

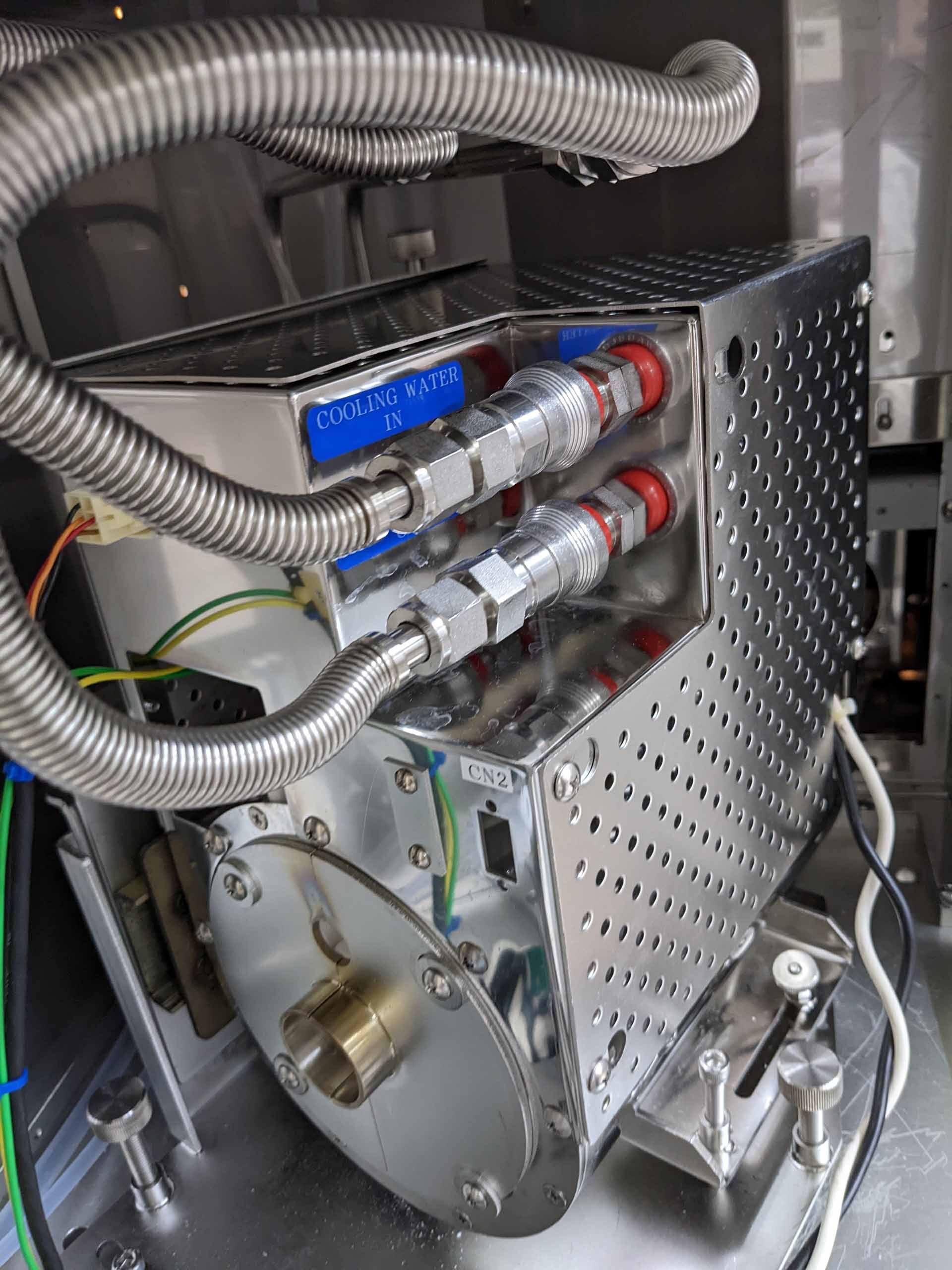

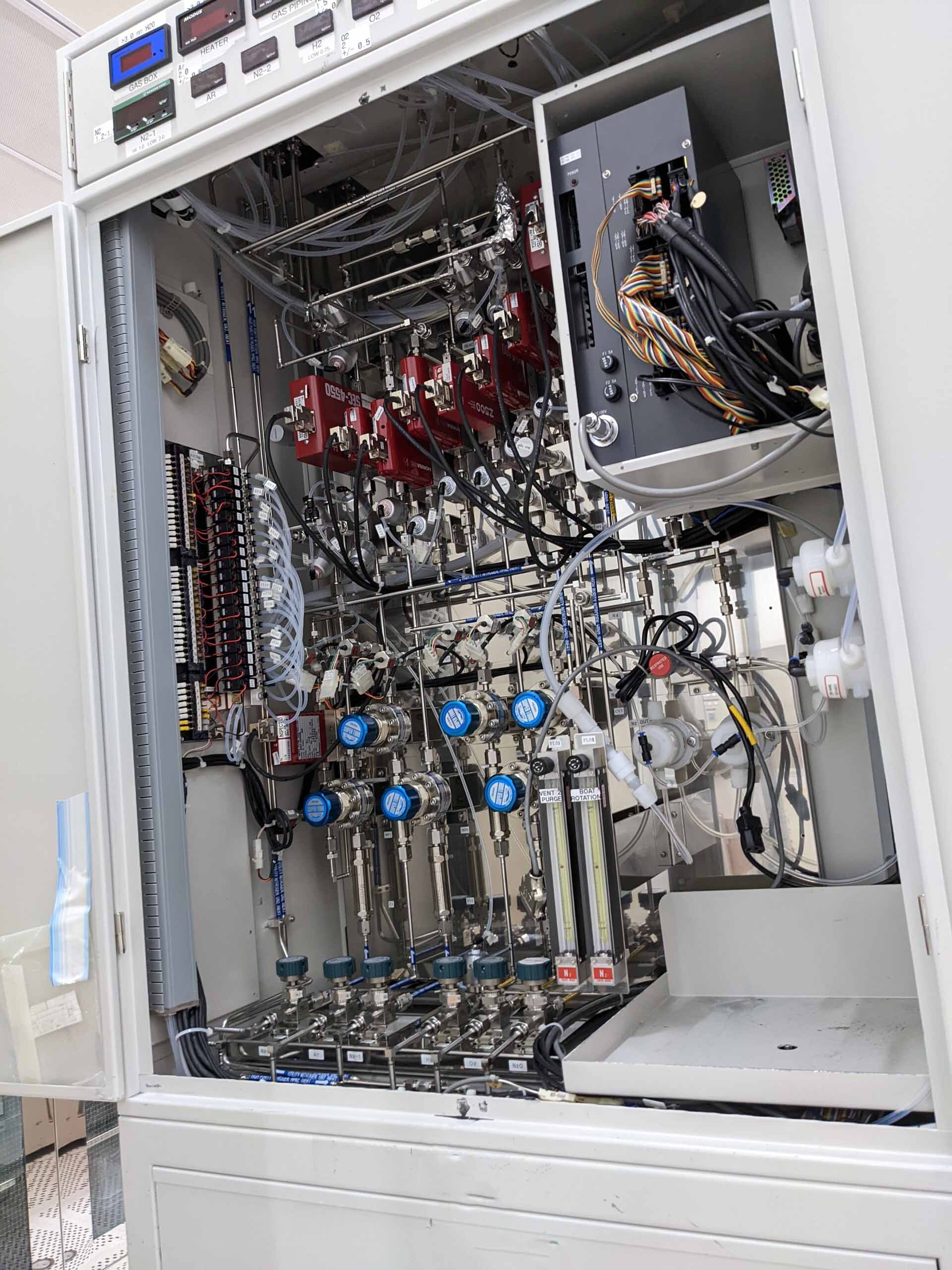

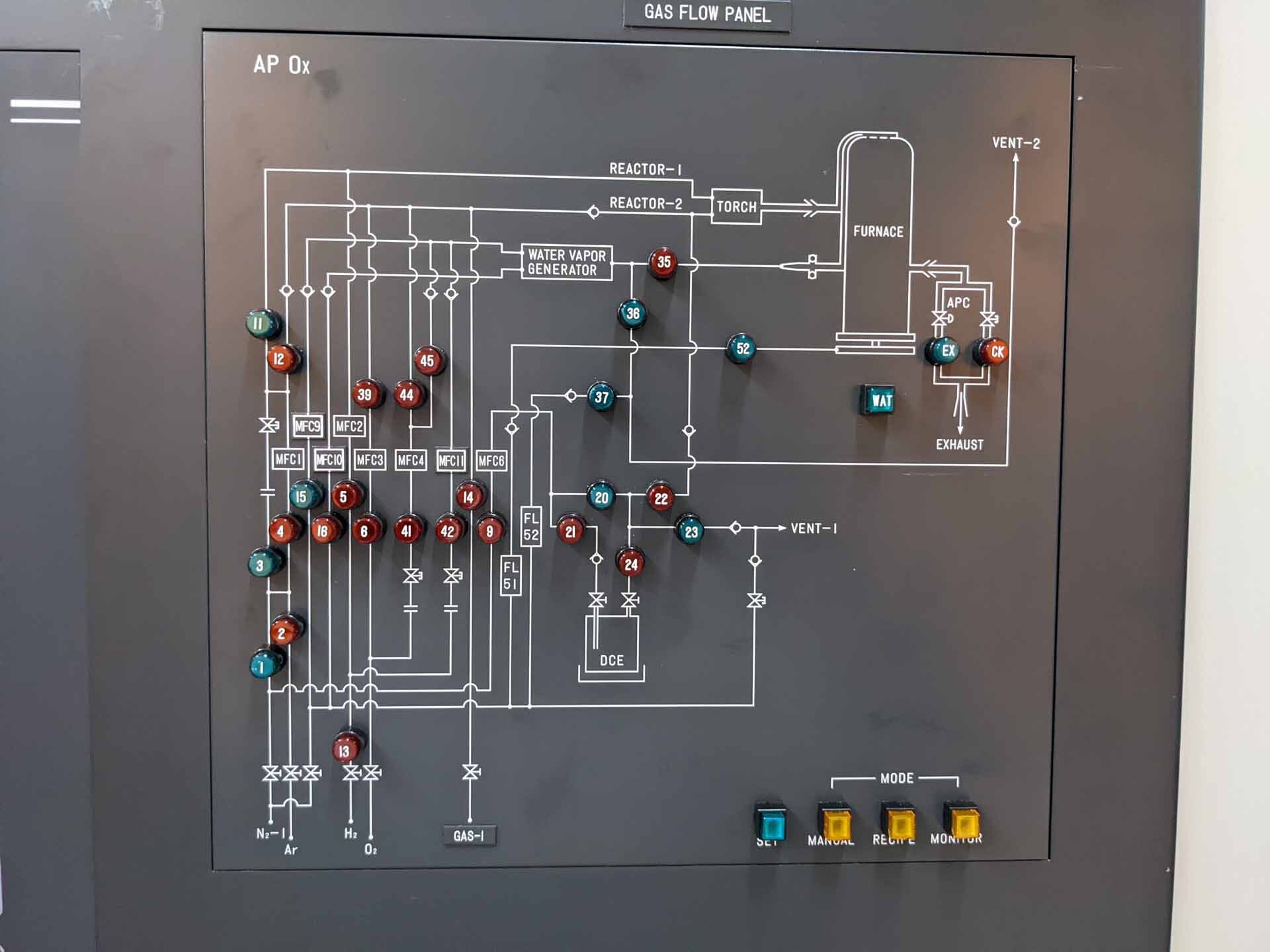

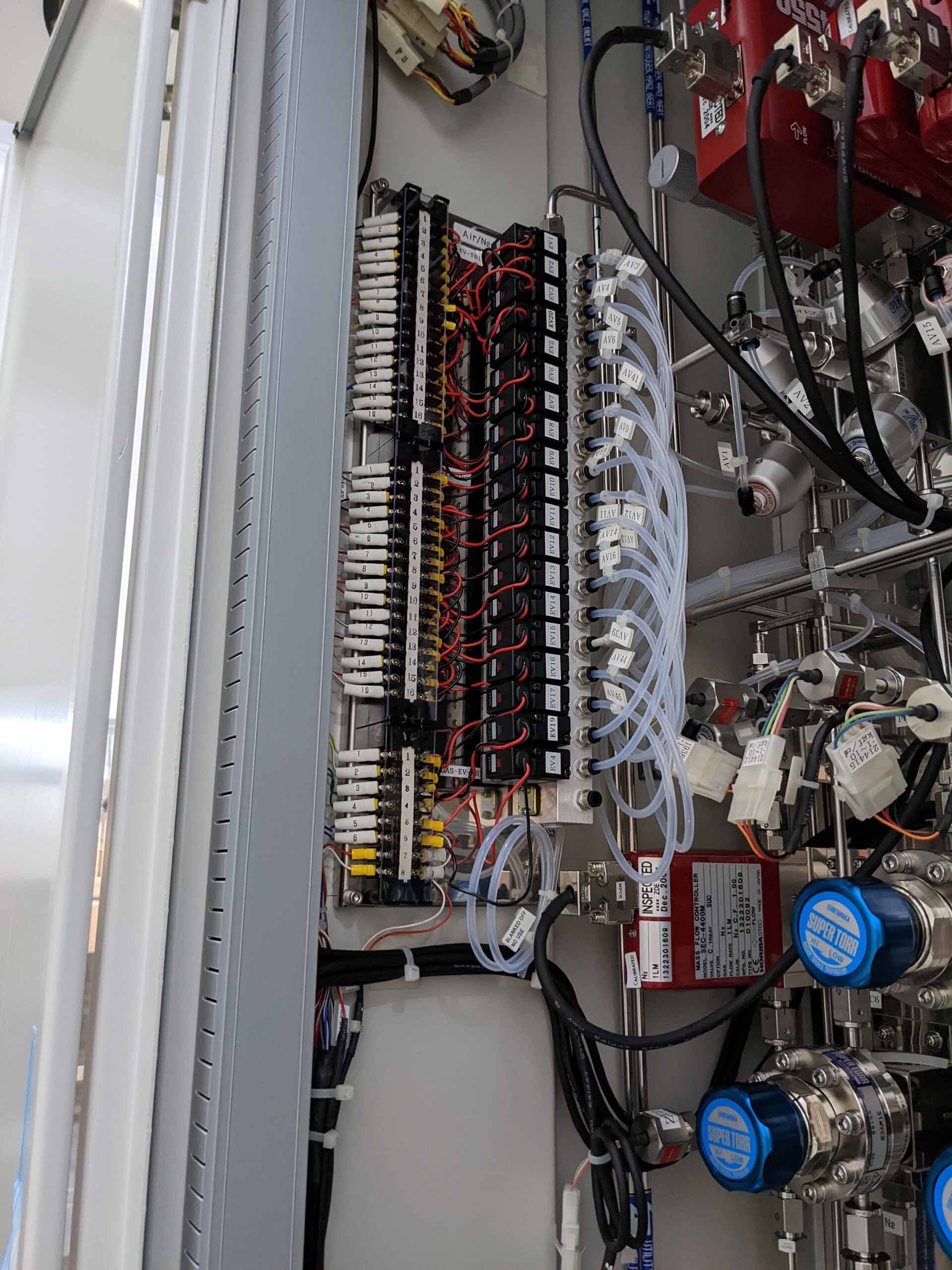

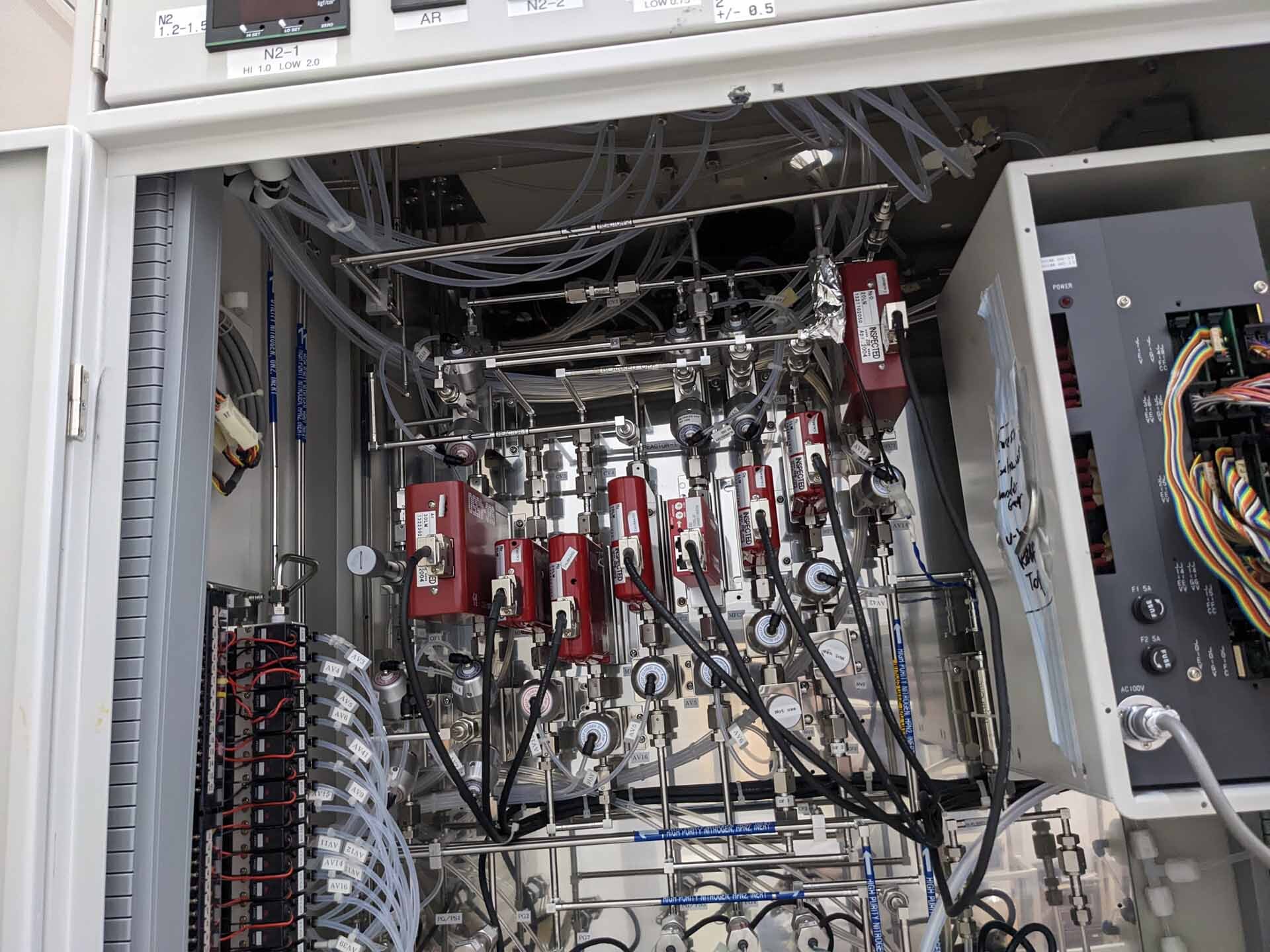

Process gas control system:

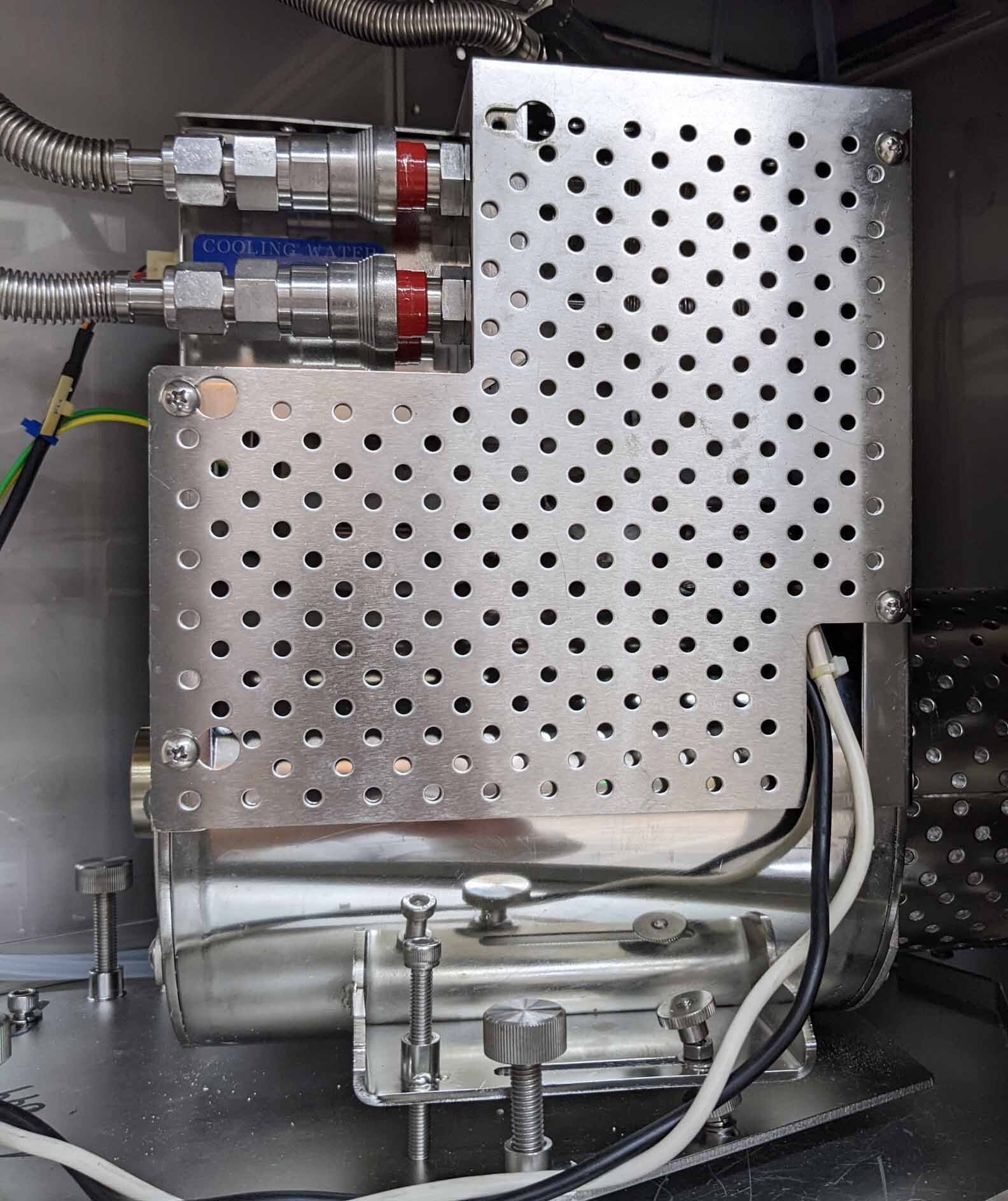

External torch

H2 Burn off

Bubbler

Process gas (Atmosperic):

MFC Model: SEC-Z500, SEC-4500, SEC-4400 / Analog

Process gas: N2, H2, Ar, O2, N2O

SCHUMACHER ATCS 15 Bubbler system

Other gases: UN2 (Air/N2)

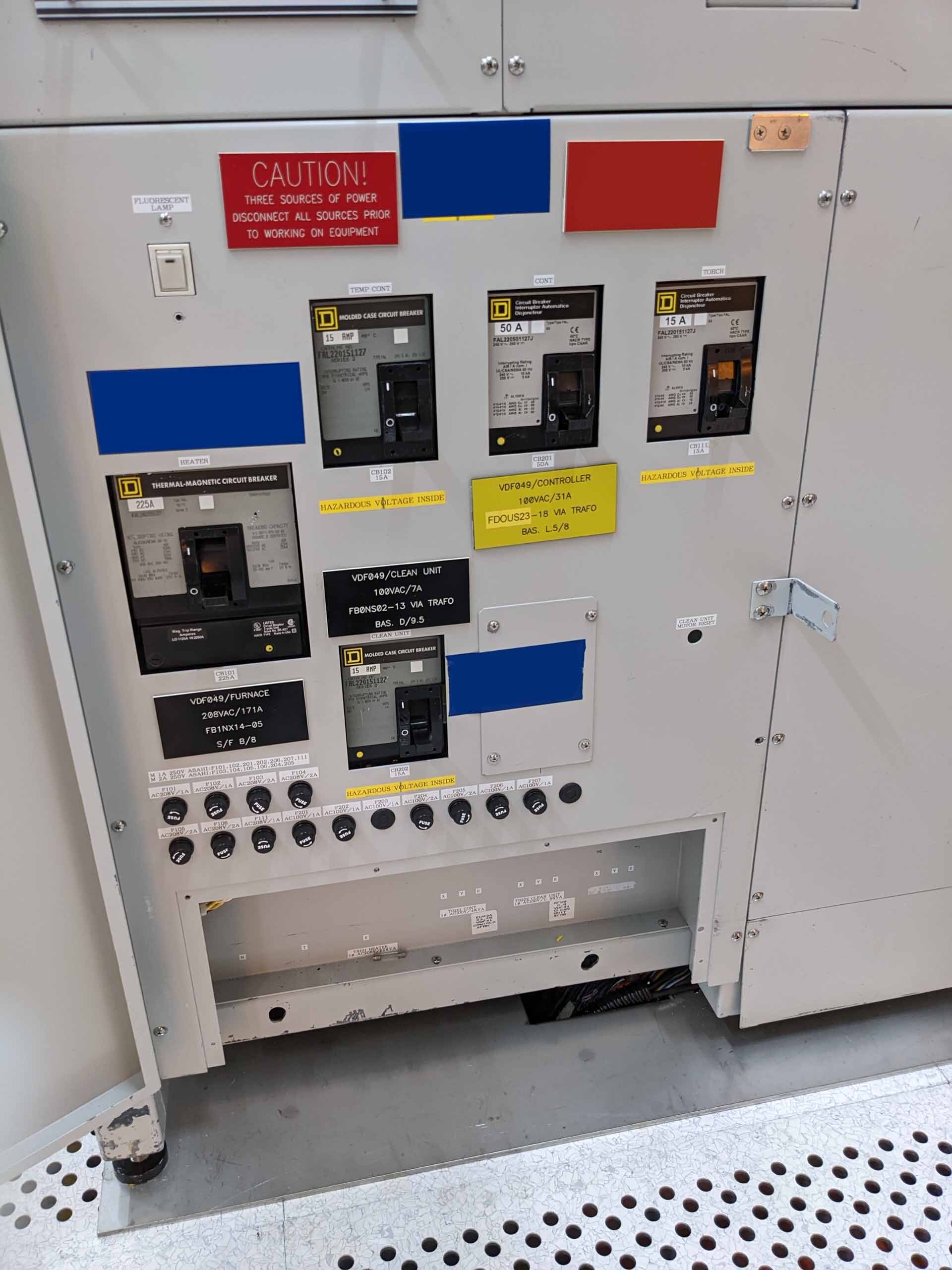

Input power supply:

Heater: 208VAC, 50KVA, Single phase

Controller: 100VAC, 4KVA, Single phase

Clean Unit: 100VAC, 1.5KVA, Single phase

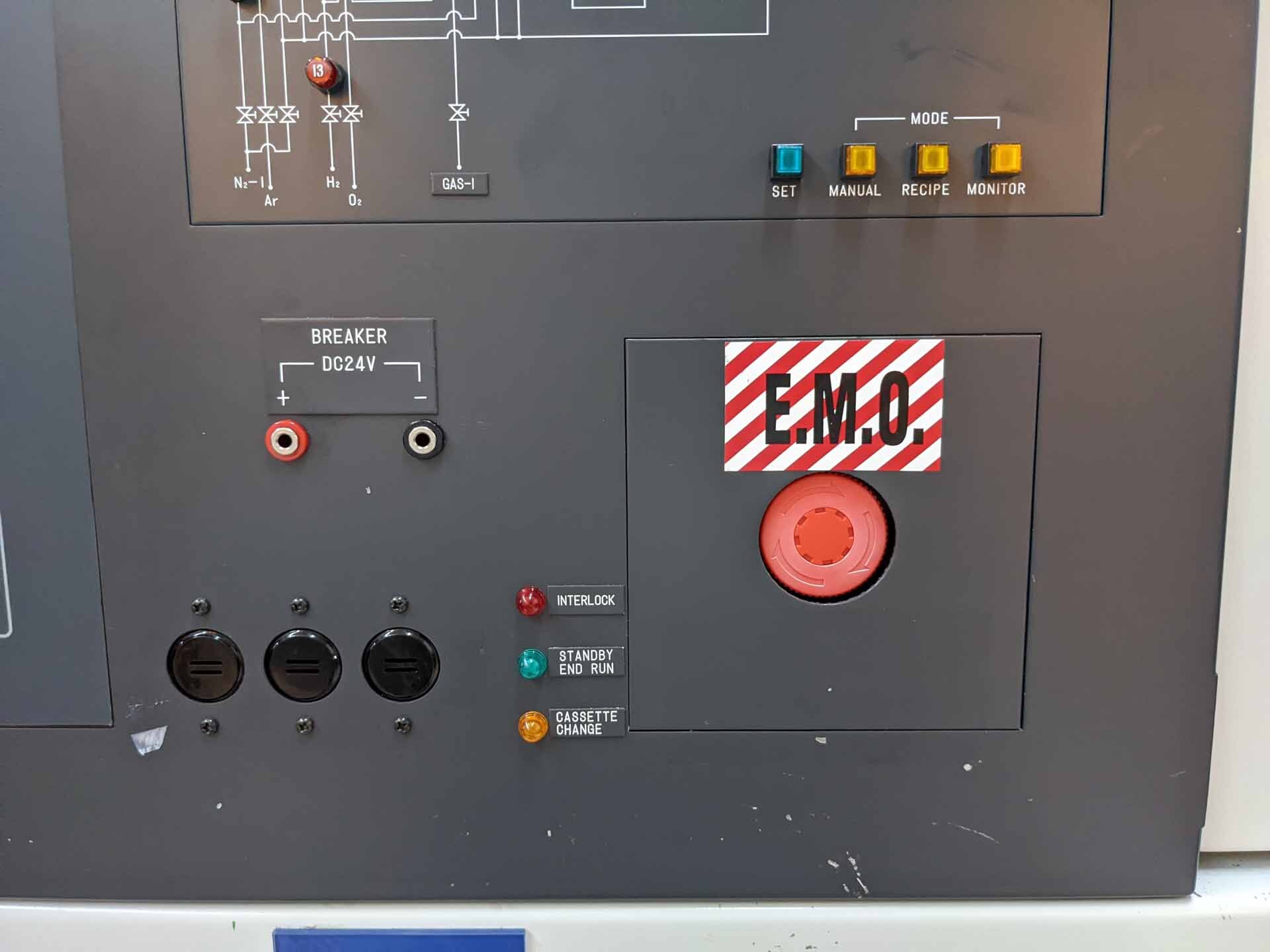

Start-up PSU: 24VDC

1998 vintage.

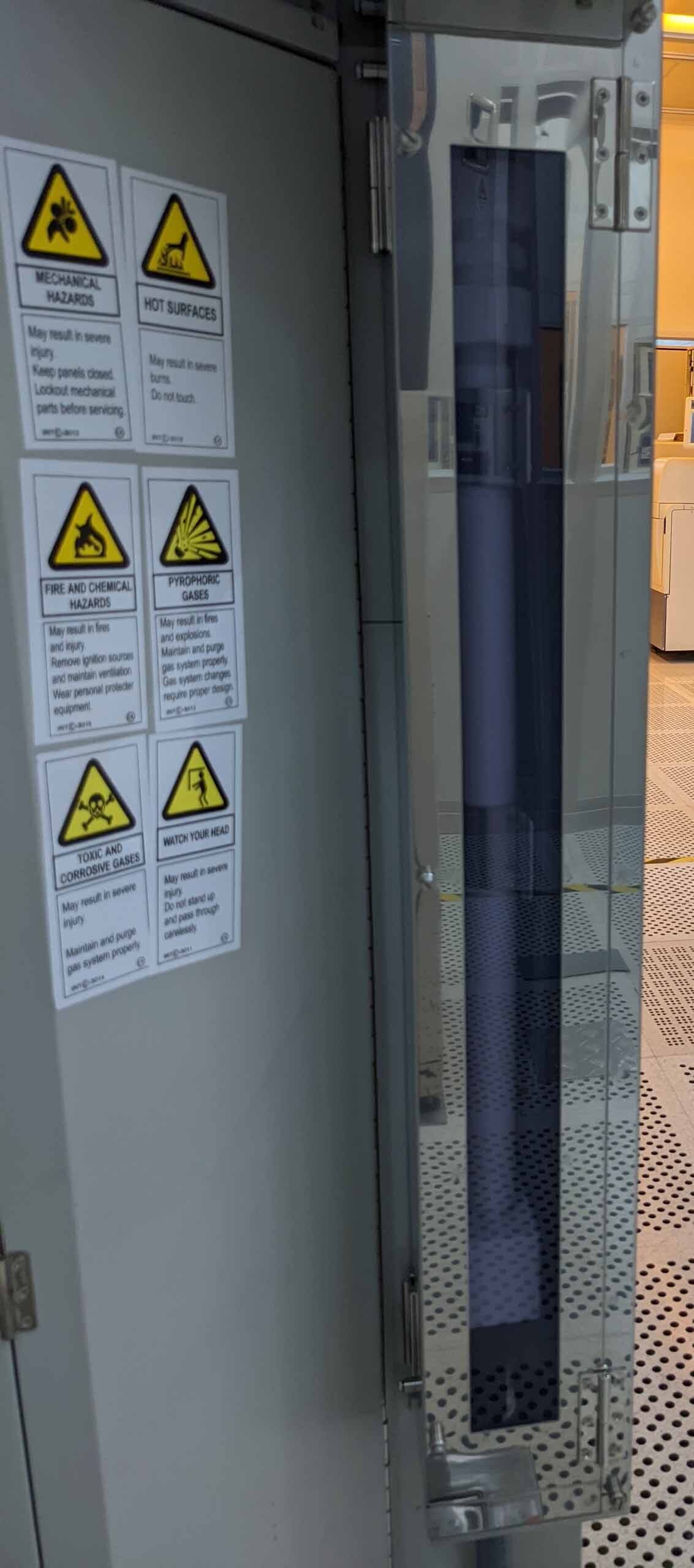

HITACHI / KOKUSAI DD-803V diffusion furnace is an advanced, reliable, and efficient tool for semiconductor manufacturers. This furnace features a gas-flow type design and can perform a variety of high temperature diffusion processes. It offers high speed, high reproducibility, and cooling capabilities. The furnace includes a gas-flow type design, which allows for a safe and even heating and cooling of the material. It also includes multiple controllers, including a temperature controller, flow controller, and pressure controller. The furnace has a wide temperature range and is capable of operating at up to 1500°C. It features advanced stirring and mixing techniques, allowing for a uniform distribution of heat in the material. The furnace also has a protective quartz tube, allowing it to operate in a vacuum environment. The furnace is equipped with an overhead mechanical system, which is designed to facilitate easy movement and loading of the furnace elements. The furnace also includes several safety features, such as a built-in thermal insulation system and an over-temperature alarm. The furnace also includes a number of extra features, such as a timer, a low temperature alarm, a high temperature alarm, and a purge timer. The furnace also features an automated control system, allowing for fine-tuned control of the process. HITACHI DD-803V diffusion furnace is also available with a variety of accessories, such as a cooling package, an alleid chuck, and an isolator. The cooling package allows for the furnace to be cooled down quickly and efficiently, while the alleid chuck helps to securely hold the substrate in the furnace. The isolator is used to protect the substrate against contamination. Overall, KOKUSAI DD-803V diffusion furnace is a reliable, efficient, and safe tool for semiconductor manufacturing. It offers a wide temperature range, advanced stirring and mixing techniques, multiple controllers, and a variety of accessories to ensure uniform diffusion processes.

There are no reviews yet