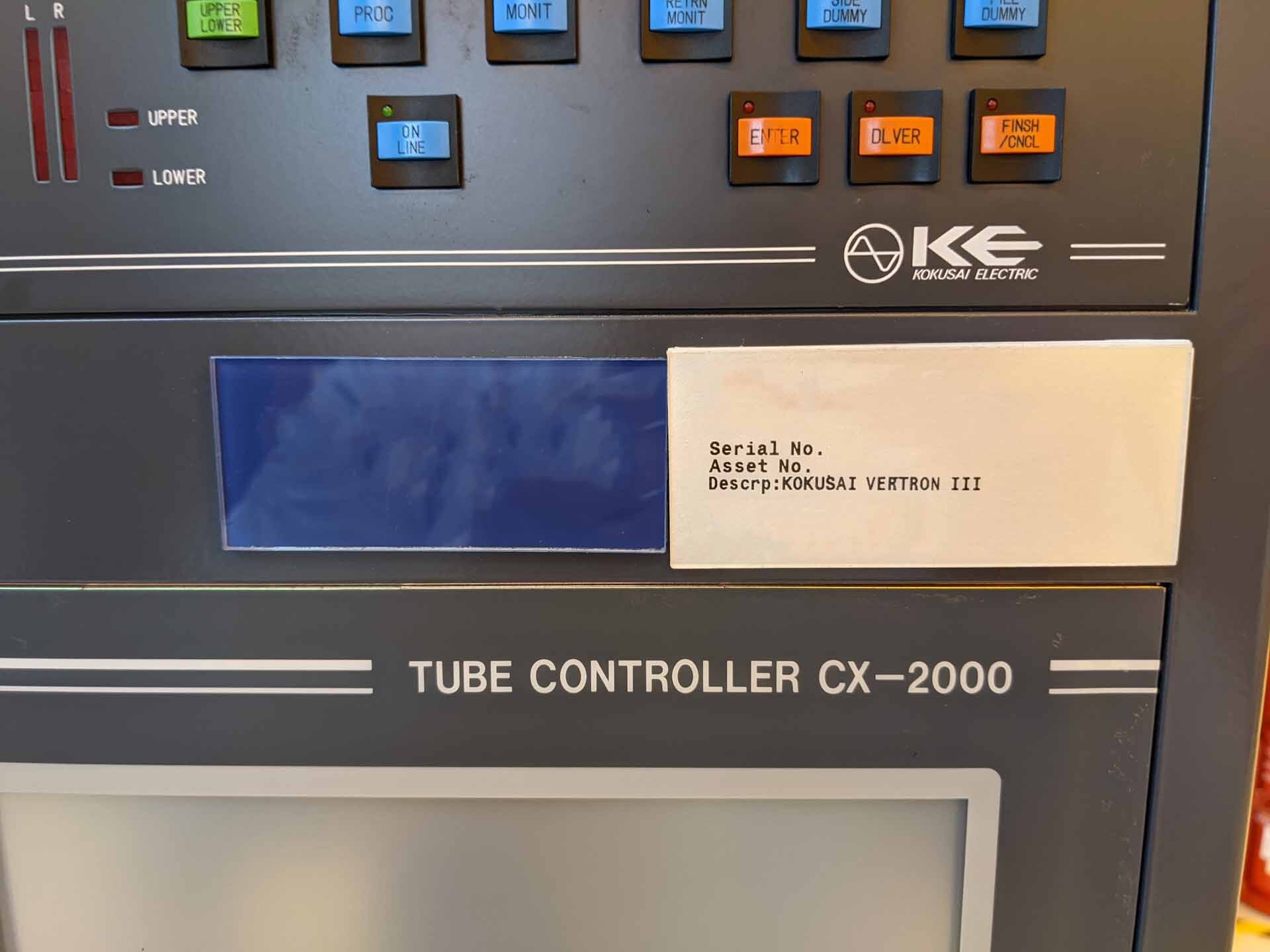

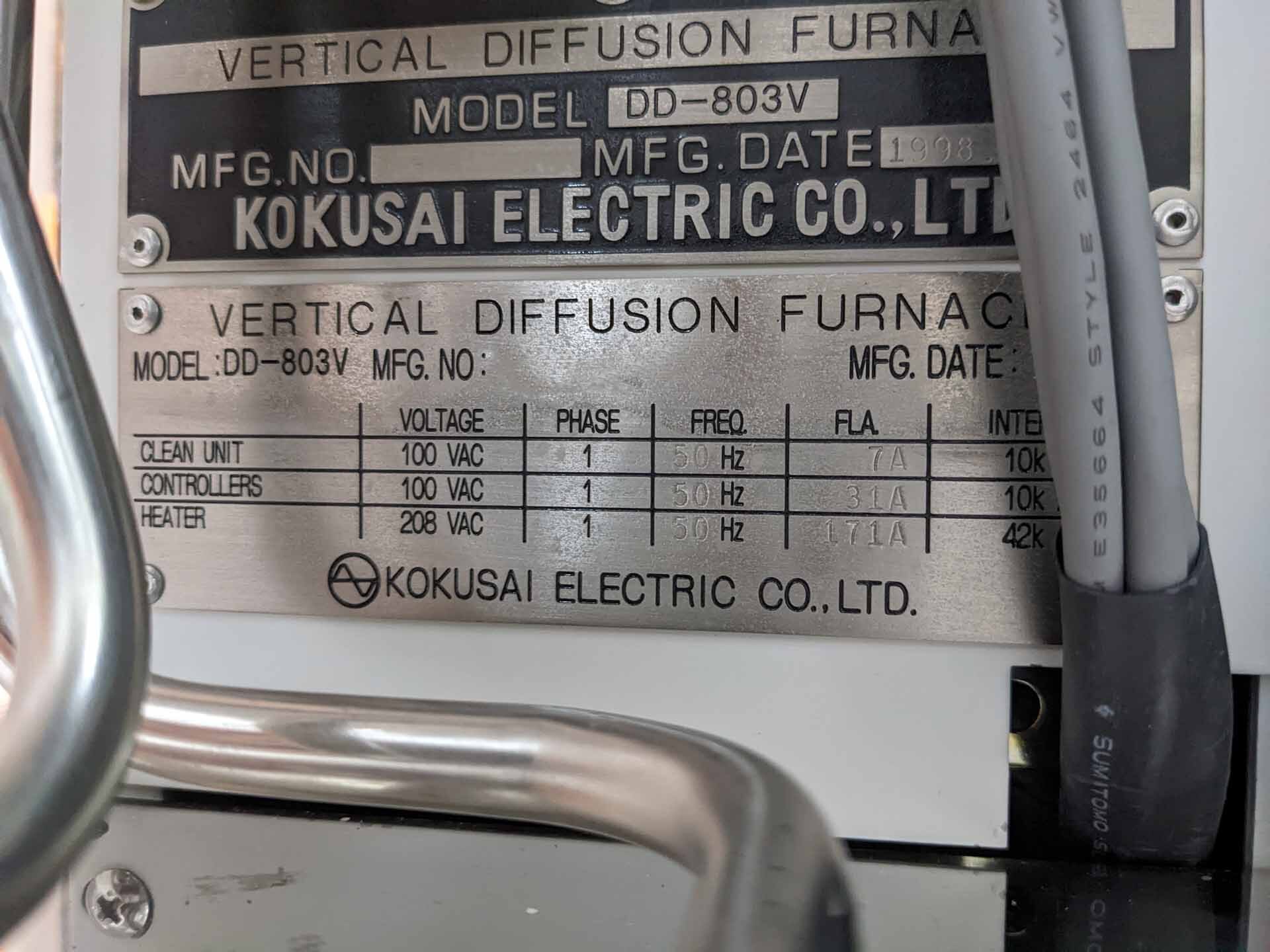

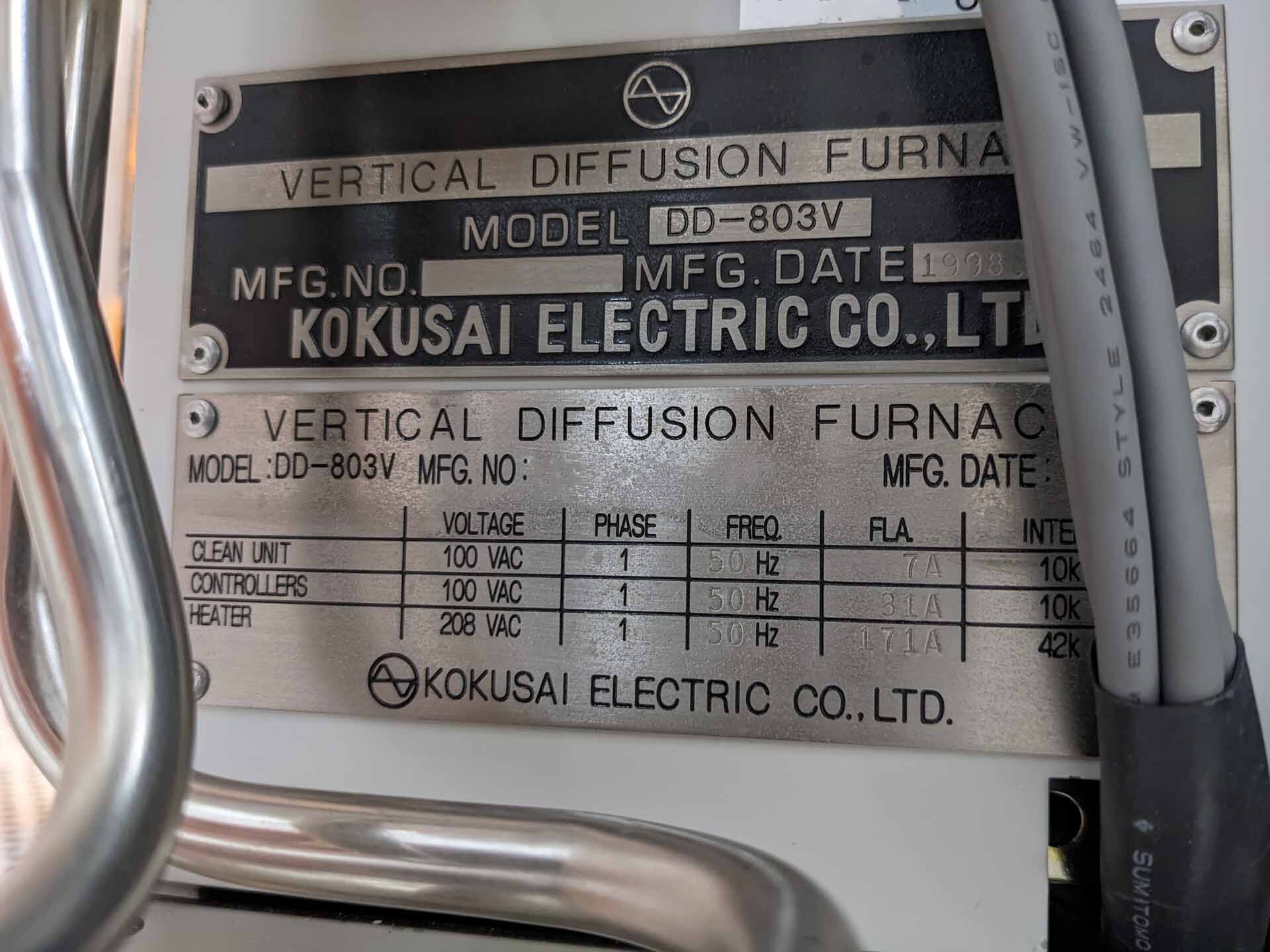

Used HITACHI / KOKUSAI DD-803V #293633554 for sale

URL successfully copied!

Tap to zoom

ID: 293633554

Wafer Size: 8"

Vintage: 1998

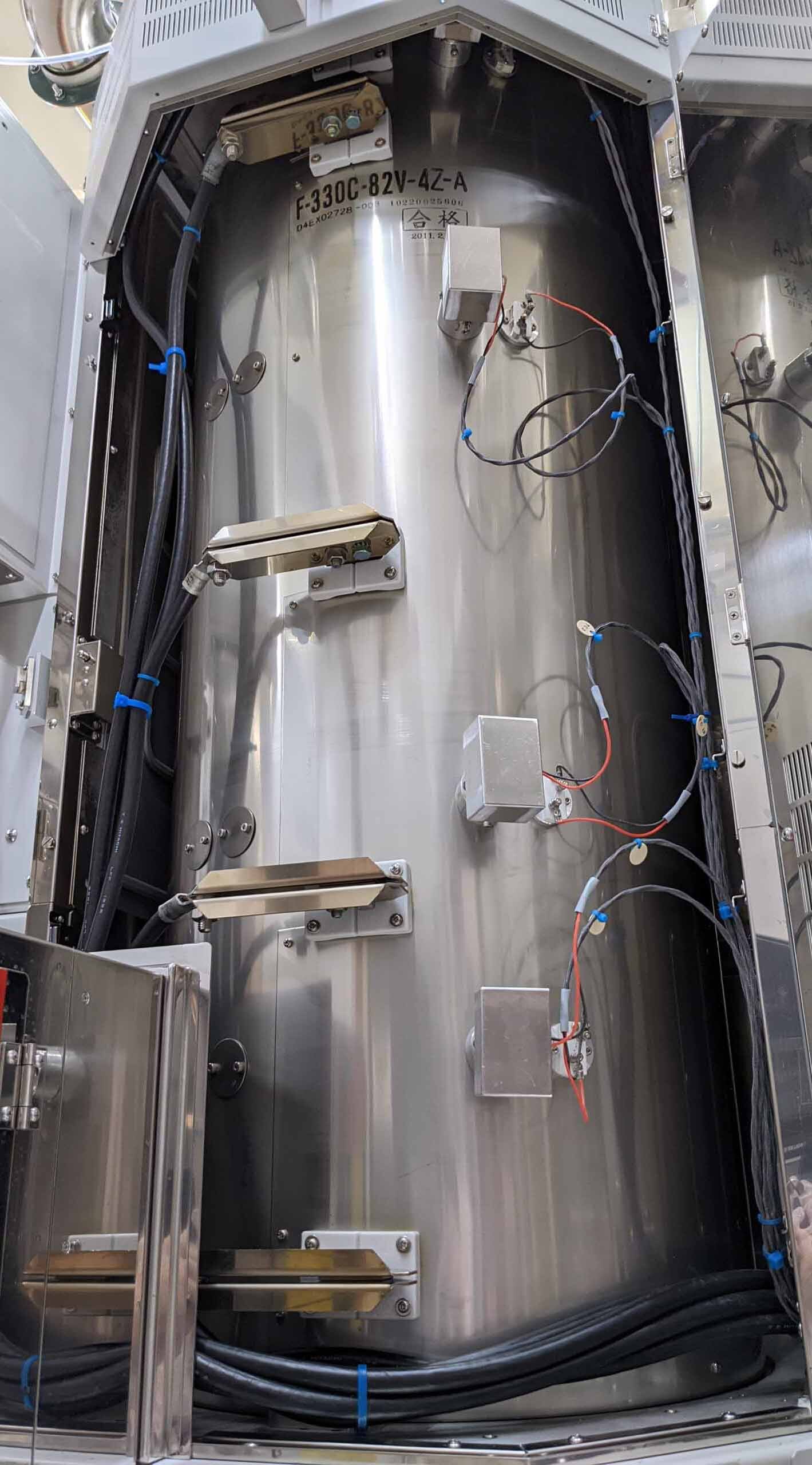

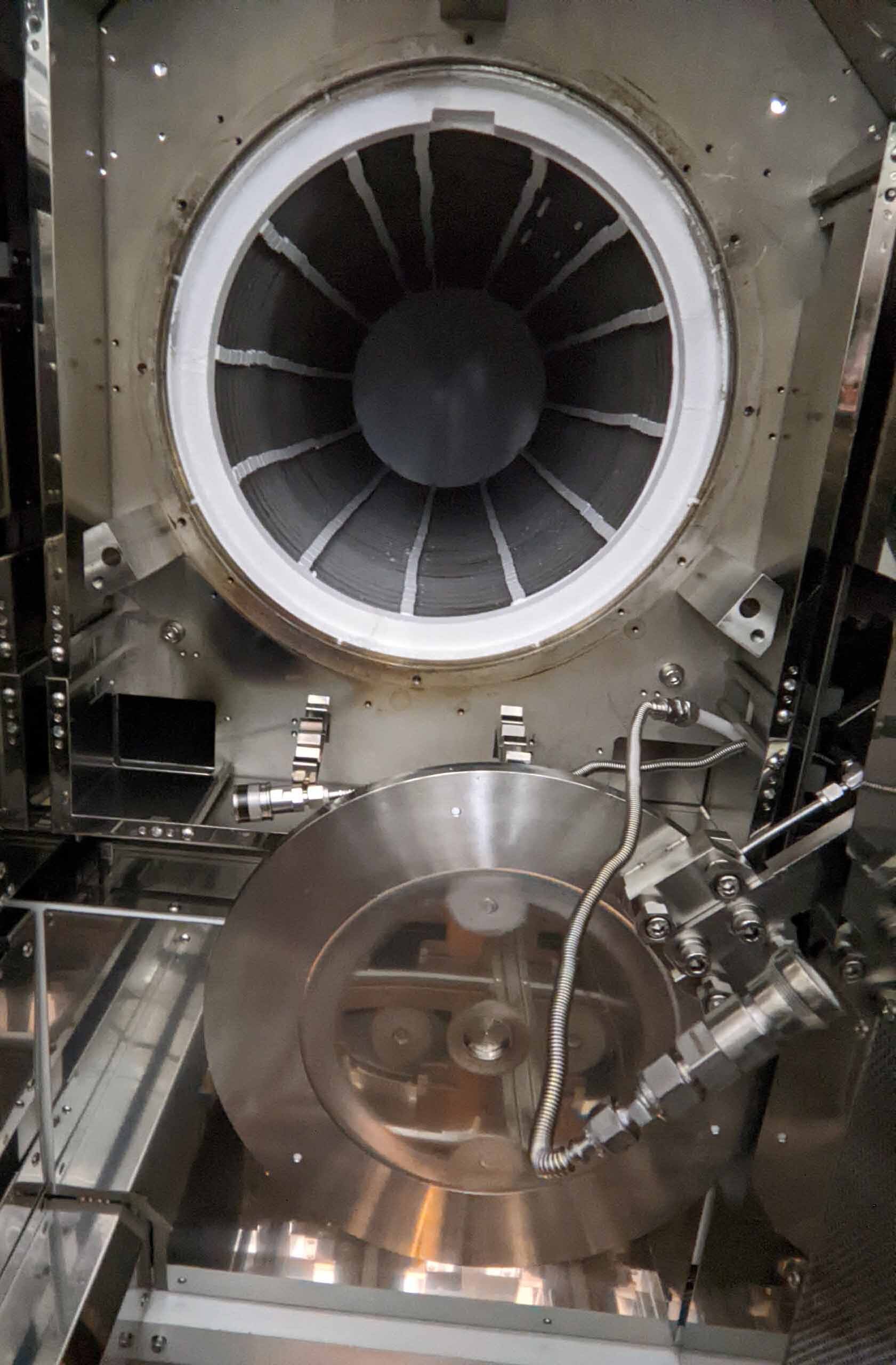

Vertical furnace, 8"

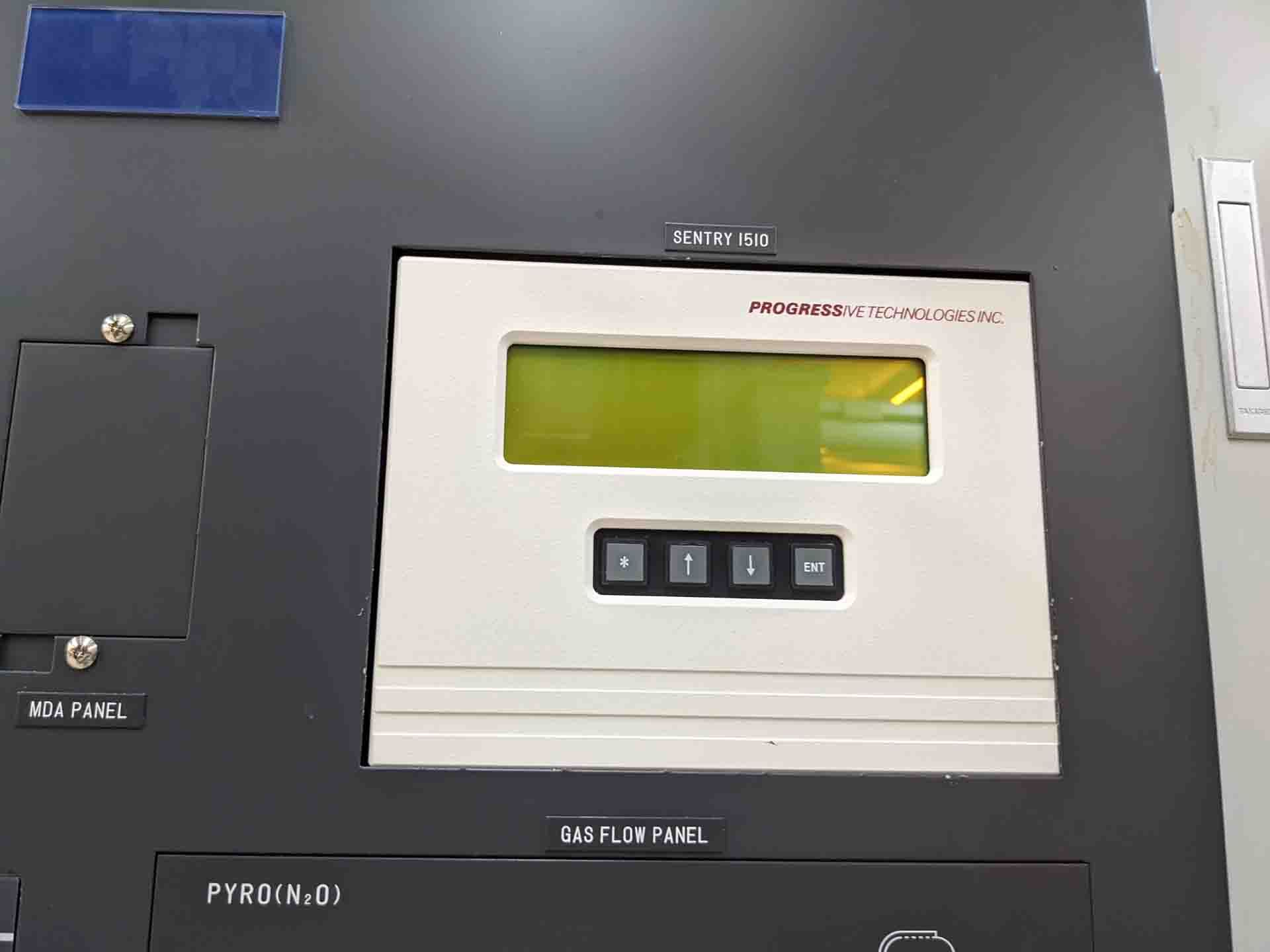

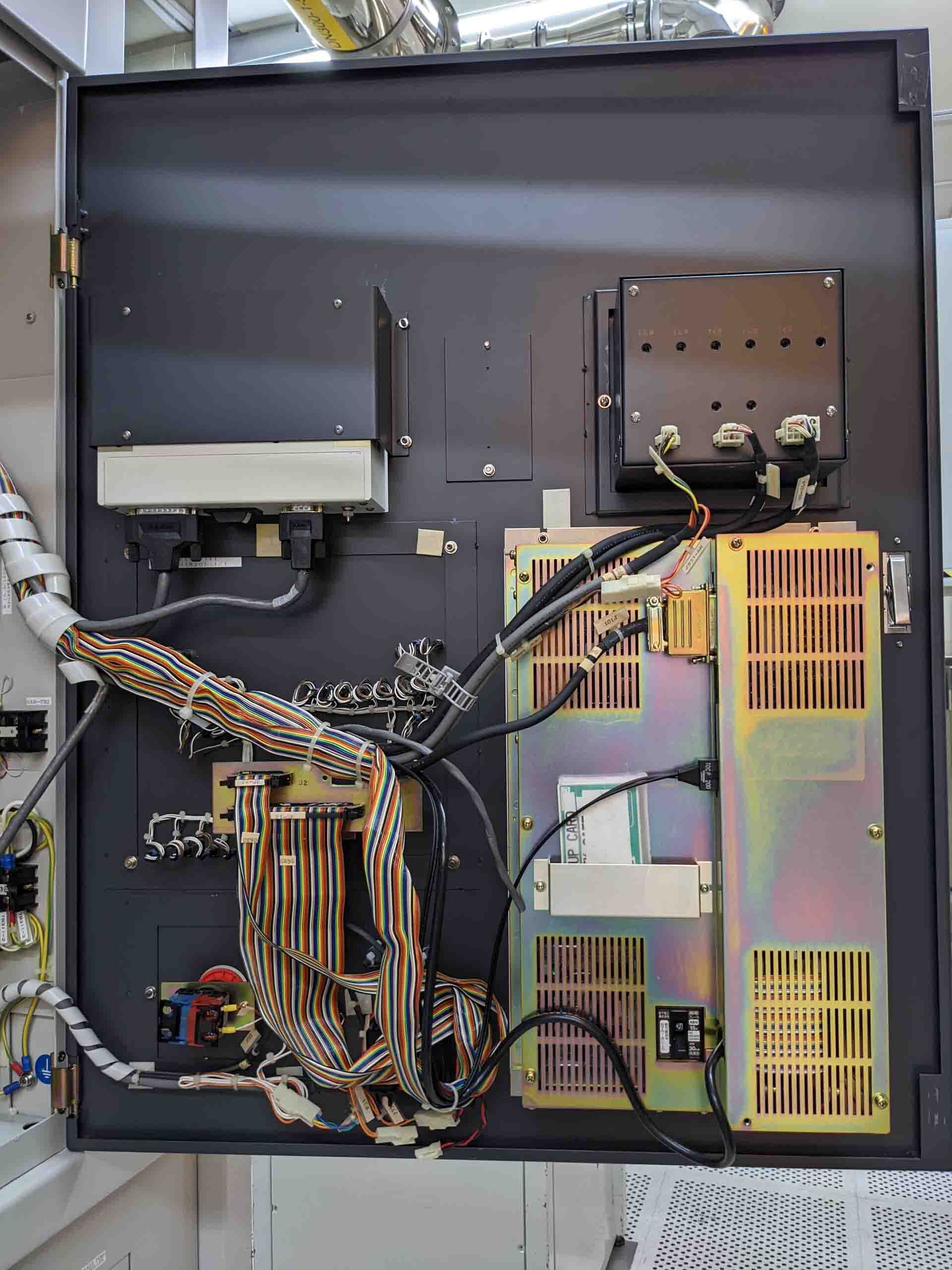

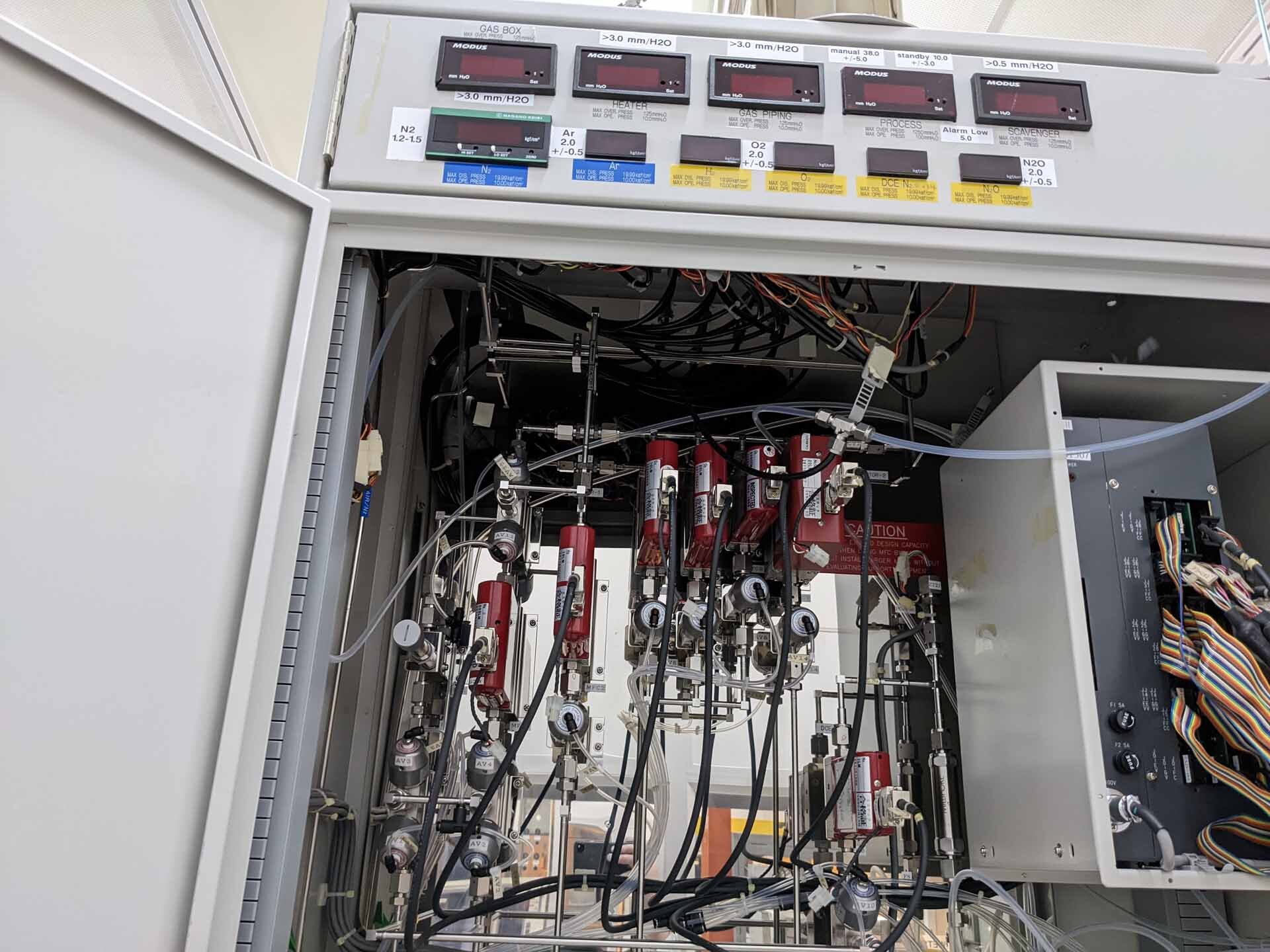

Atmospheric controller

Clean unit controller

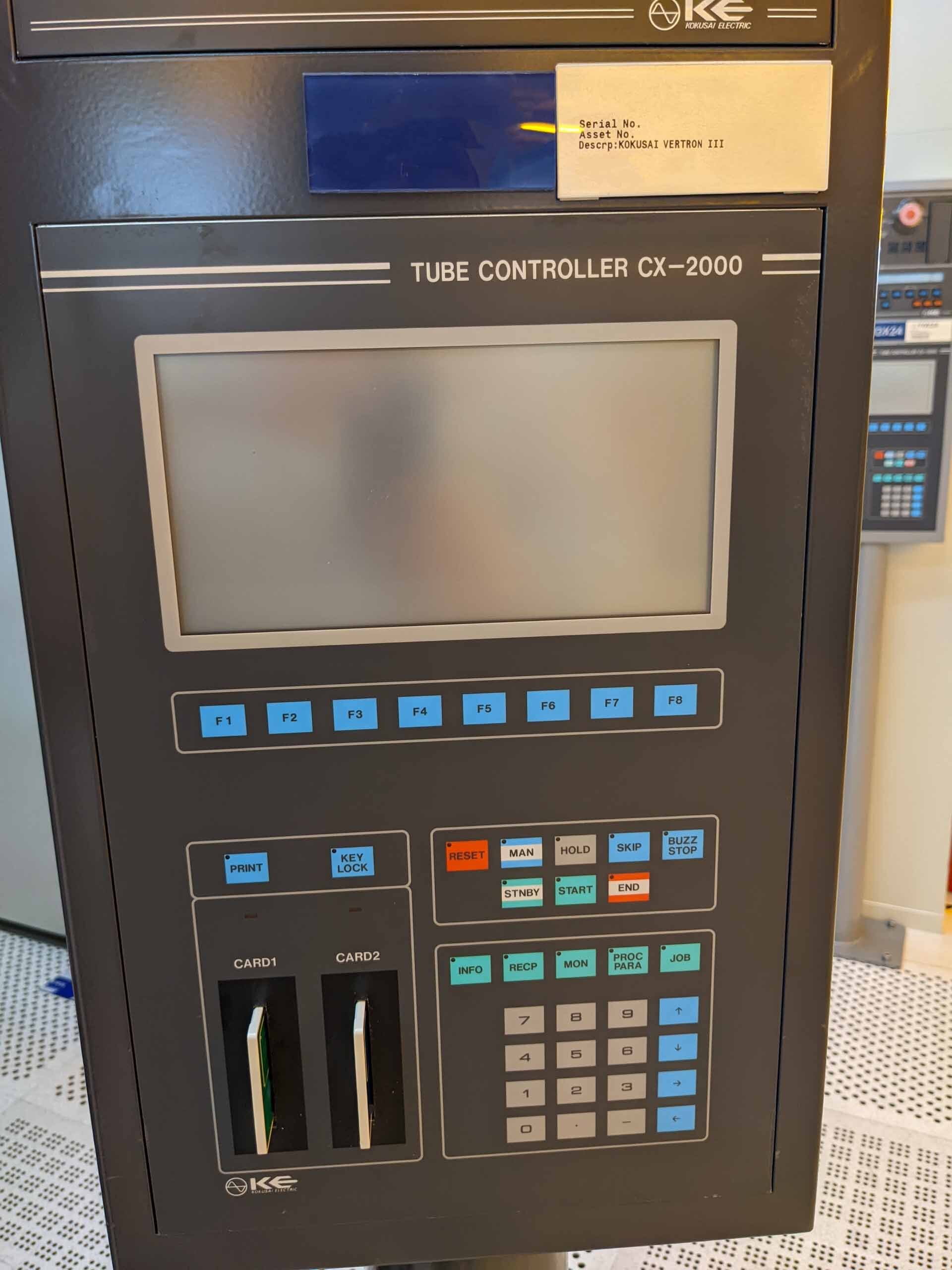

CX2000 Controller

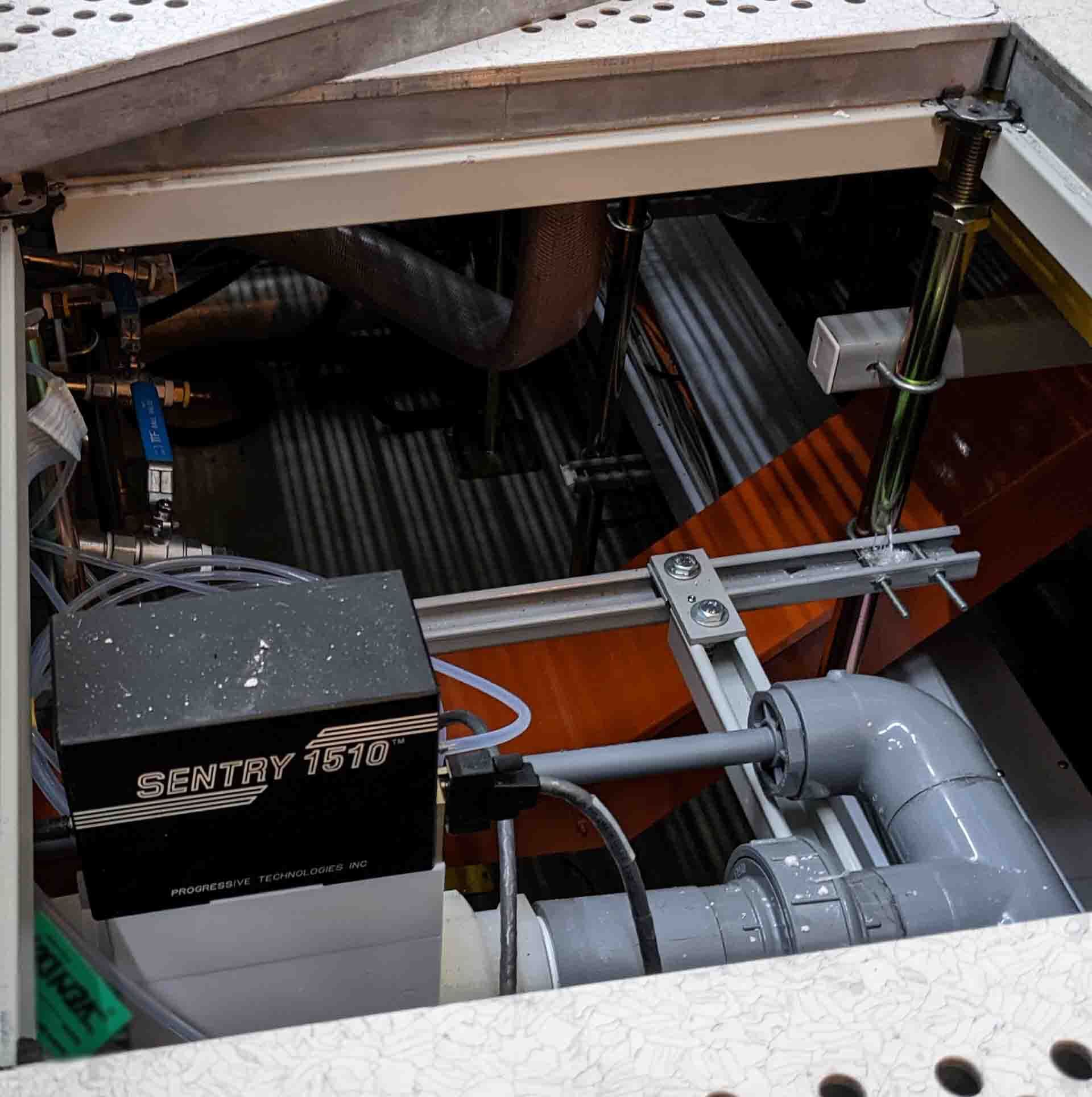

Utility cabinet

CQ1501 Temperature controller

(4) Zones

D4EX02728 Heater

Process temperature: 700°C-1000°C

Flatzone length: 952.50 mm

Process tube material: Quartz

Wafer boat material: Quartz

Tube seal configuration: N2 Flow

R-Type thermocouple

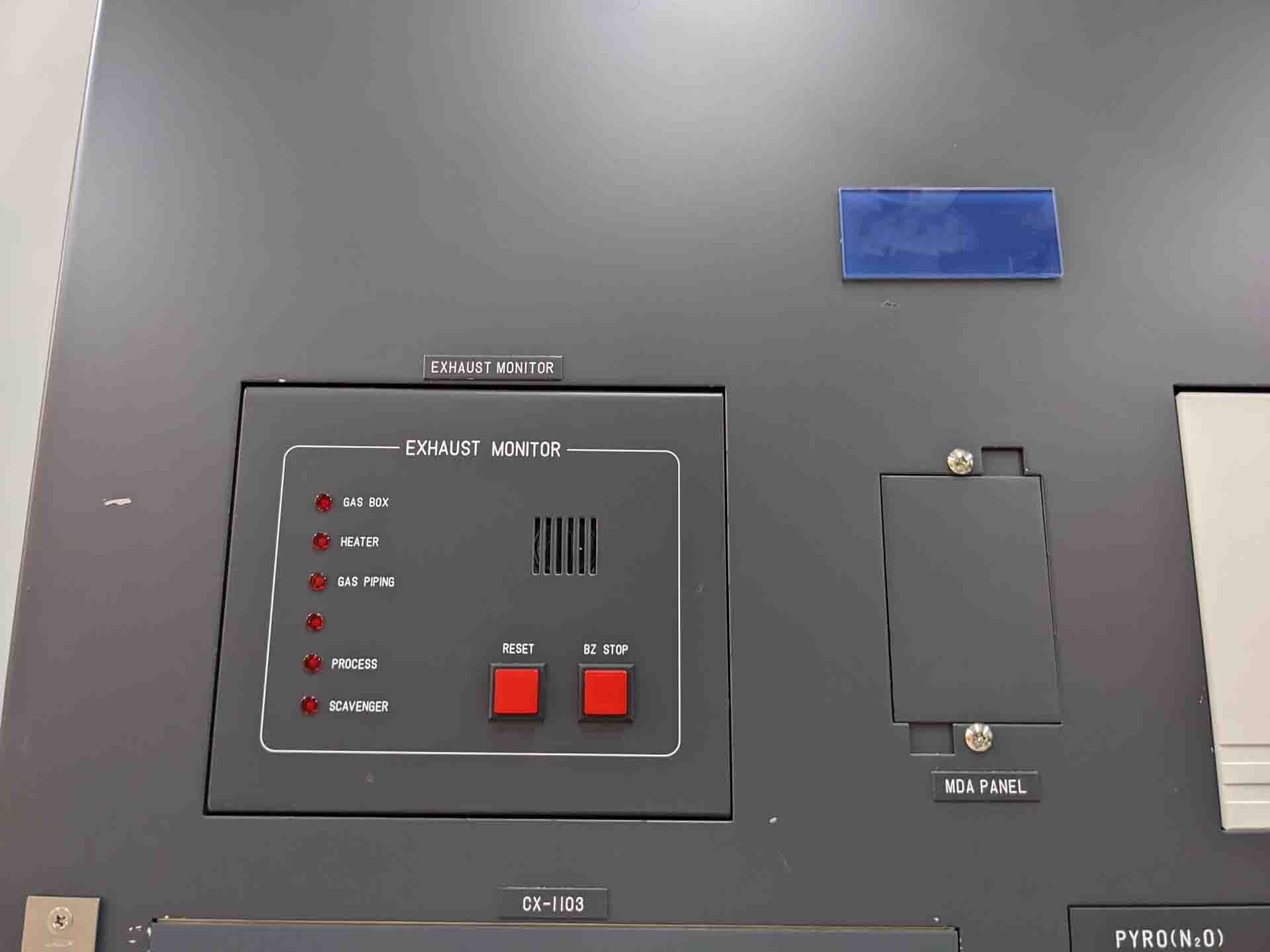

Exhaust controller

SECM / GEM Communication: Serial

Temperature control:

P: 0.1~200%

I: 0.01-100.00 min

D: 0.00-10.00 min

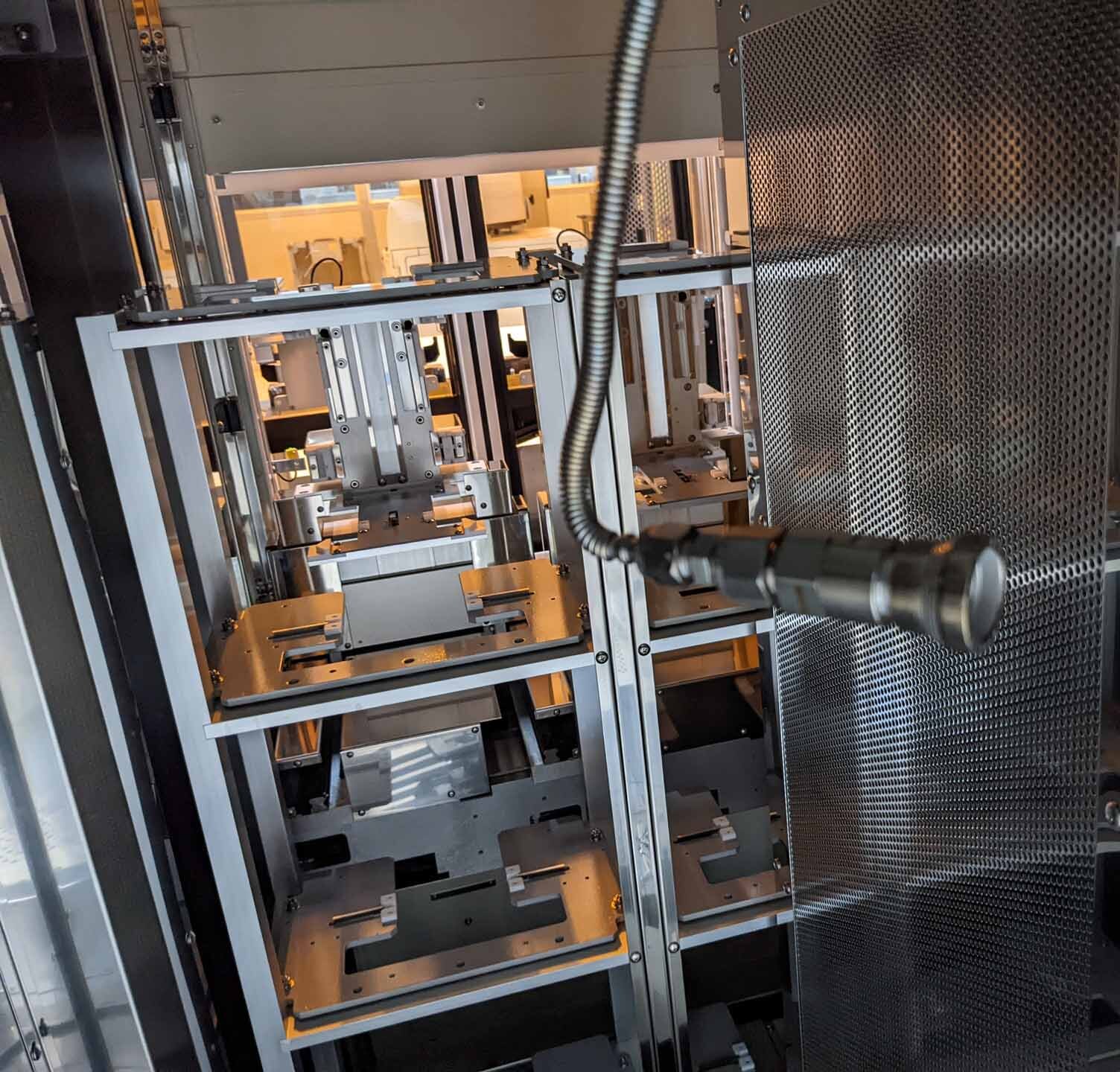

Load station:

WIP Carrier capacity: 16

Wafer spacing: 5.20 ±0.05 mm

Load size: 150-Slots

Boat rotation

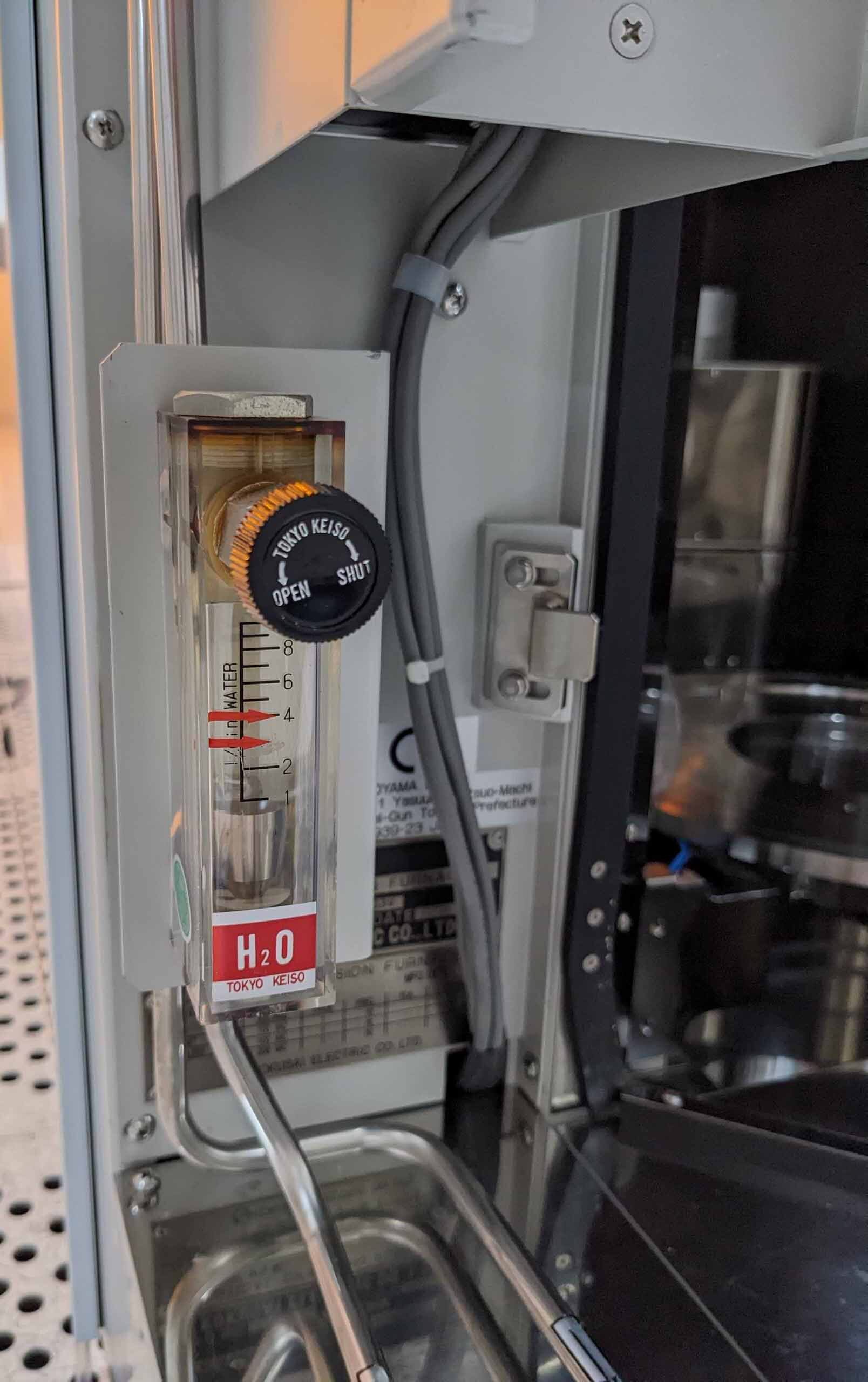

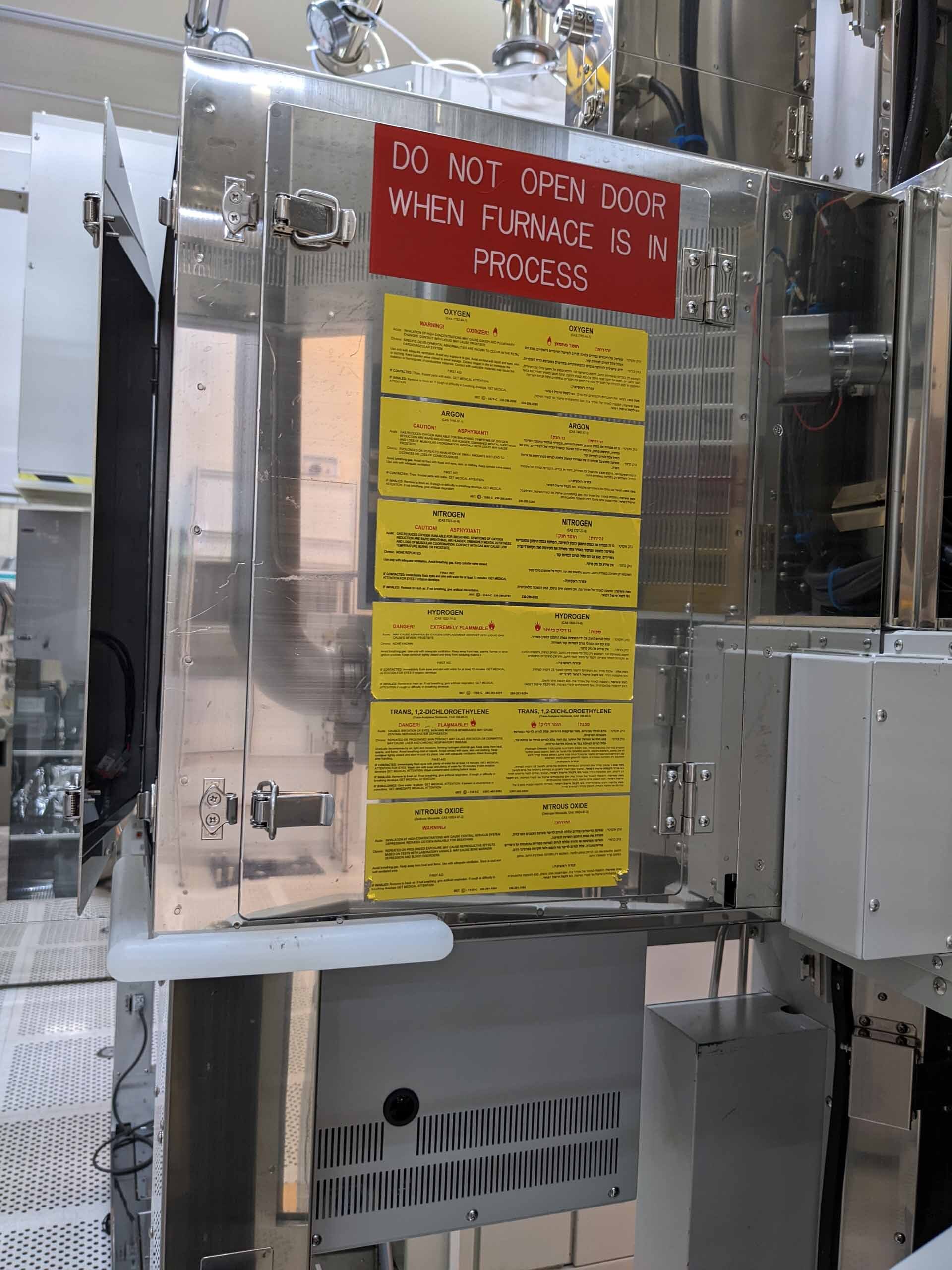

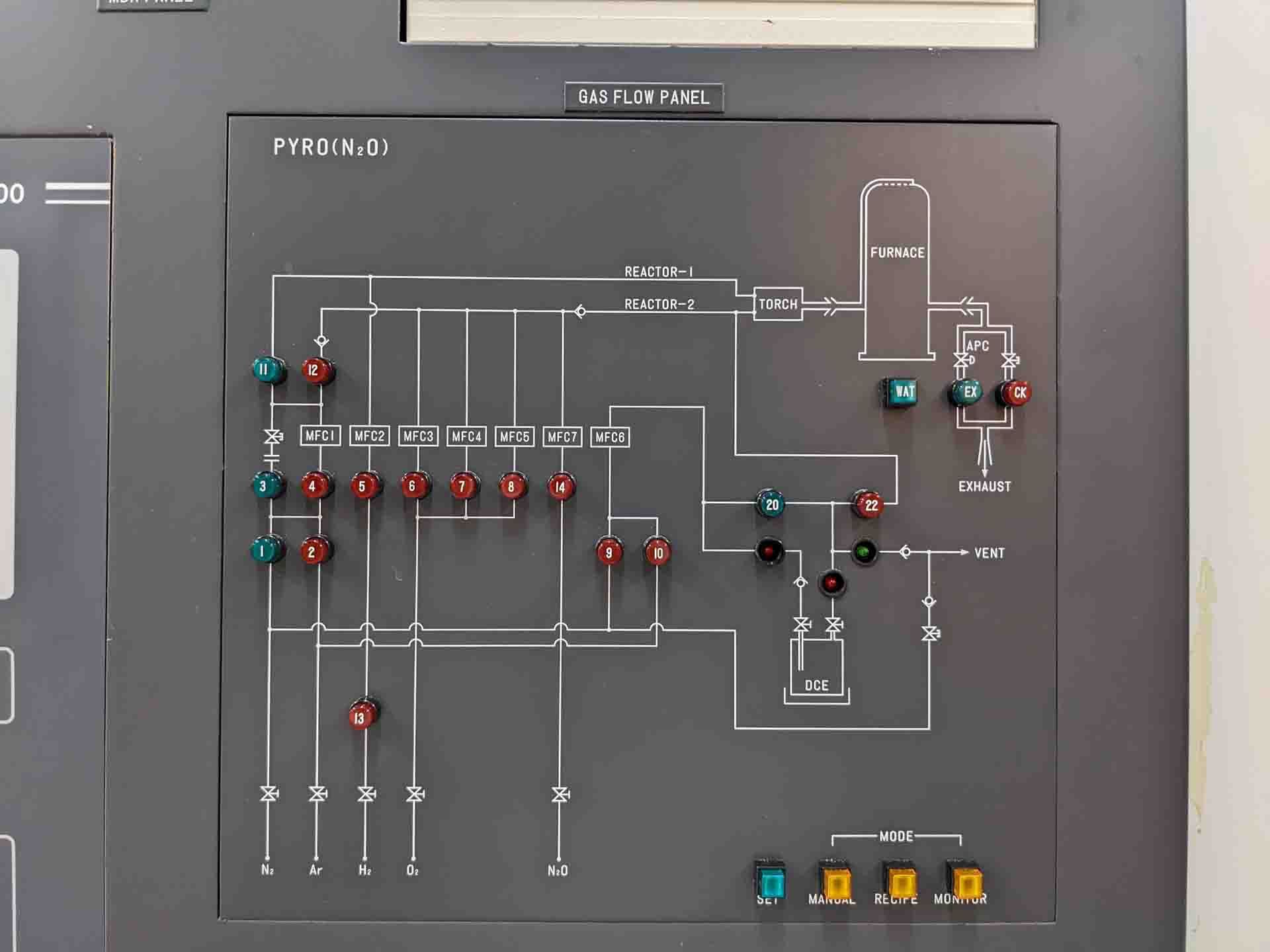

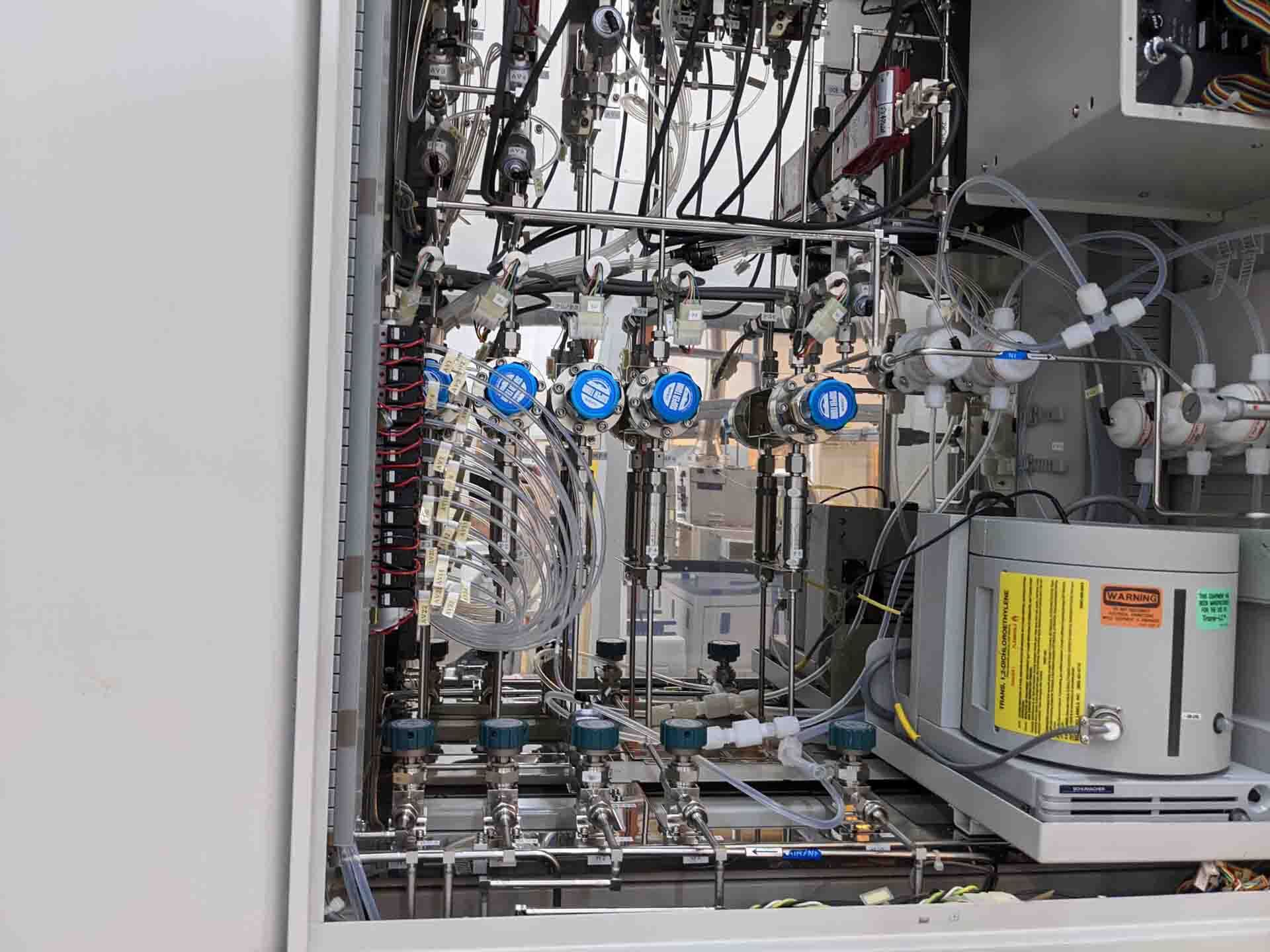

Process gas control system:

External torch

H2 Burn off

Bubbler

Process gas (Atmosperic):

MFC Model: SEC-Z500, SEC-4500, SEC-4400 / Analog

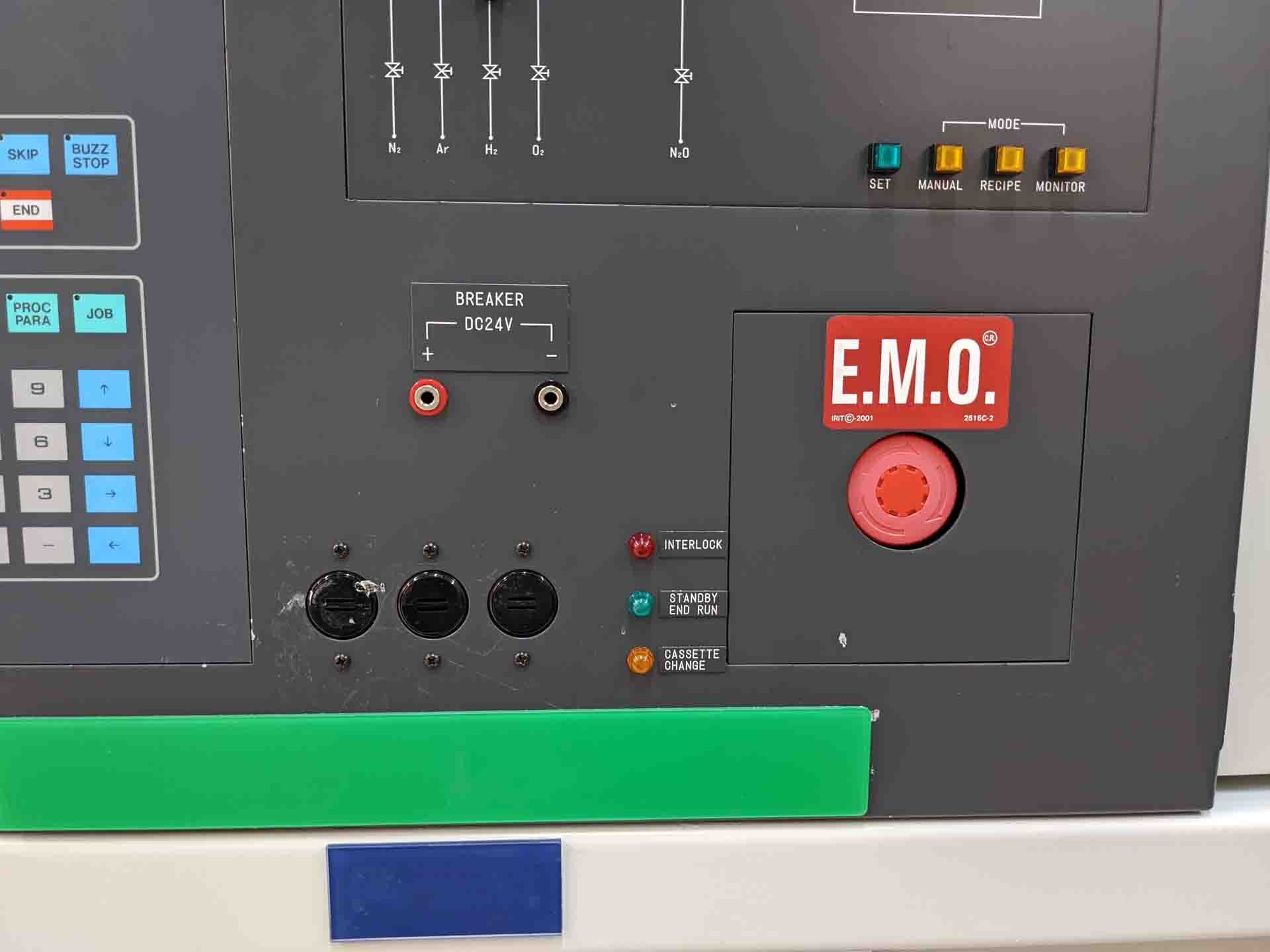

Process gas: N2, H2, Ar, O2, NO

SCHUMACHER ATCS 15 Bubbler system

Other gases: UN2 (Air/N2)

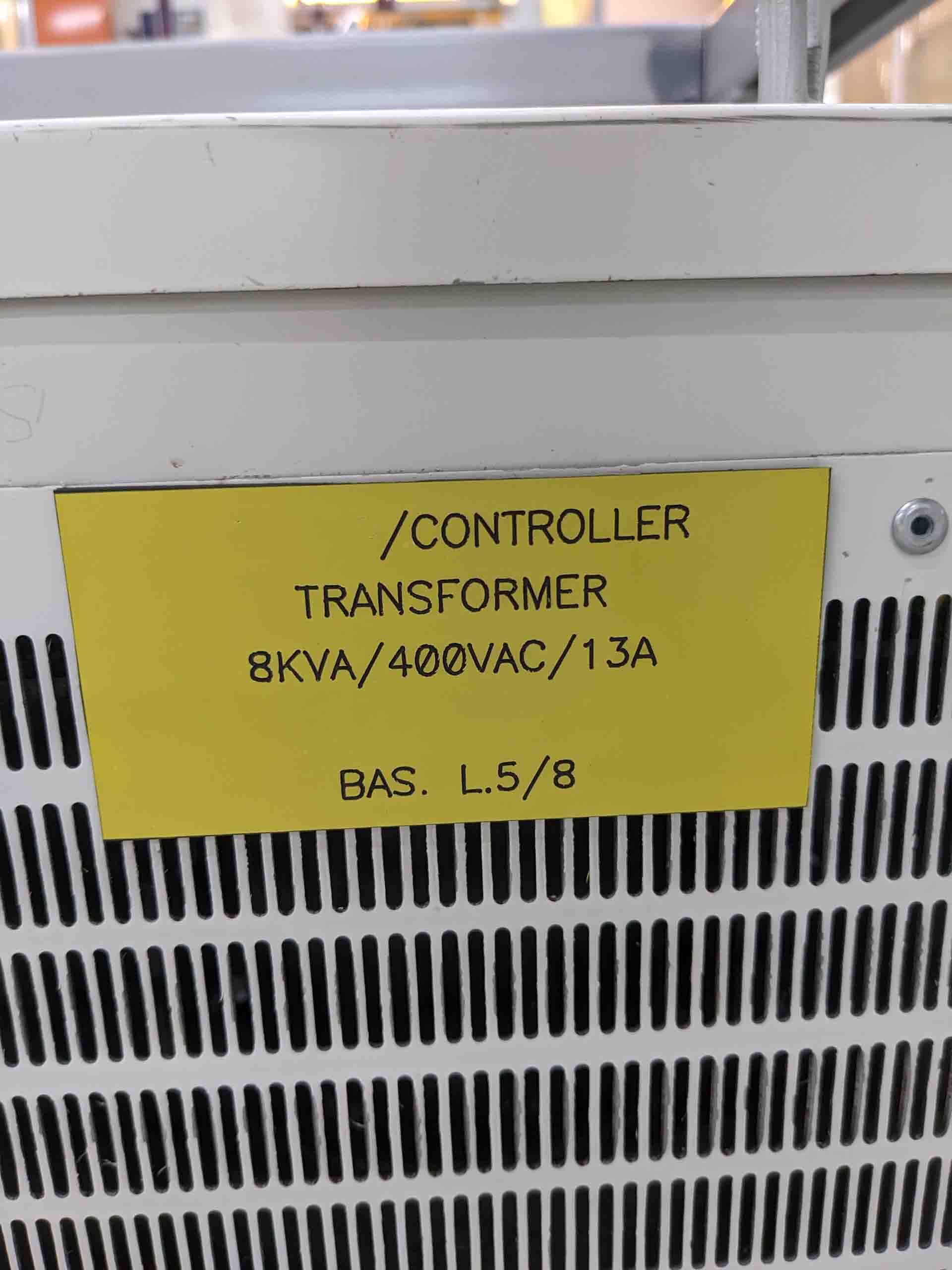

Input power supply:

Heater: 208VAC, 50KVA, Single phase

Controller: 100VAC, 4KVA, Single phase

Clean Unit: 100VAC, 1.5KVA, Single phase

Start-up PSU: 24VDC

Handler missing

1998 vintage.

HITACHI / KOKUSAI DD-803V diffusion furnace and accessories provide a comprehensive solution for annealing, sintering, and diffusion applications. This diffusion furnace equipment is made of a fully automated accurate Heating and Cooling Platform (HCP) and reliable action performance, which is suitable for a variety of materials and processes. HITACHI DD-803V is a versatile machine with a wide range of applications. It features four chambers, including a furnace chamber, a cooling chamber, and two auxiliaries. The furnace chamber boasts a number of features, such as digital temperature controllers, forced-air circulation, and an integral cooling chamber. The cooling chamber enables an effective cooling method for a range of materials and processes. It works efficiently with or without the help of inert gas, such as Argon. KOKUSAI DD-803V is built around a strong metal frame that offers long-lasting durability, even in harsh working environments. It is equipped with powerful ceramic insulation that improves performance and minimizes maintenance and energy costs. The furnace is controlled by a user-friendly touch-based interface, allowing for easy set-up and operation. Additionally, thanks to its built-in safety mechanisms, the furnace remains safe for use in a wide range of environments. DD-803V diffusion furnace and accessories is designed to meet the needs and requirements of many materials and processes, including semiconductor and solar cell production, research and development, thin-film applications, and medical device manufacturing. The Multi-Zone Processing System (MPS) offers advanced control of process temperatures and ambient conditions, ensuring precise and consistent results. The uniformity of the furnace chamber is maintained by the high-performance heating control unit, with adjustable zone control and an optional automated regenerative machine. In addition to the furnace, HITACHI / KOKUSAI DD-803V diffusion furnace and accessories includes a number of useful accessories. Examples include a power distribution unit, a load cell platform, fixturing systems, inert gas enclosures, and a programmable logic controller for advanced control and monitoring. HITACHI DD-803V is ideal for precise processes and sensitive components due to its precise temperature control, exceptional uniformity and reliability, and comprehensive safety features.

There are no reviews yet