Used HITACHI / KOKUSAI DD-833V #9238012 for sale

URL successfully copied!

Tap to zoom

ID: 9238012

Wafer Size: 6"

Diffusion furnace, 6"

Process: PYRO (HCL)

Process gas: N2, H2, O2, HCL

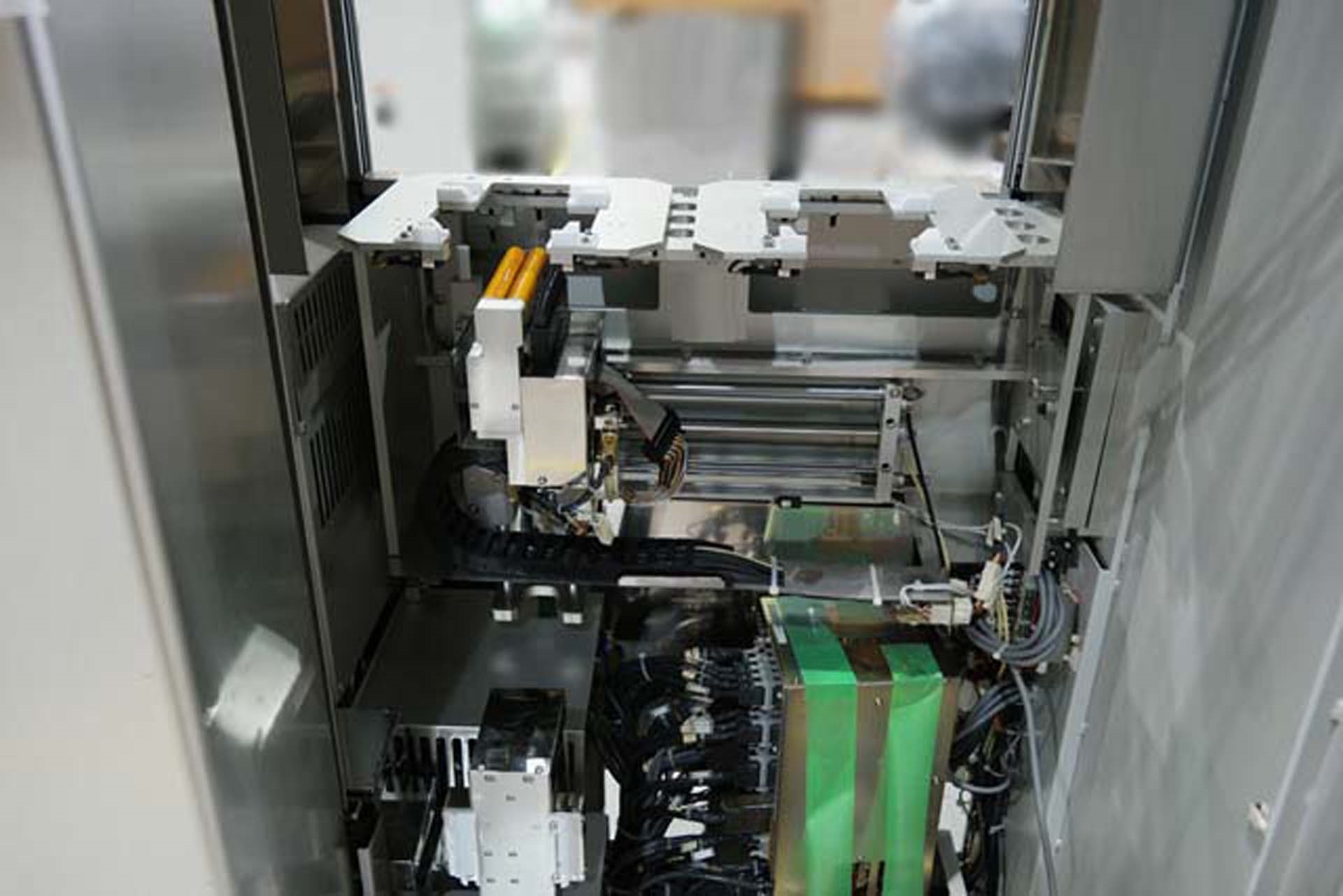

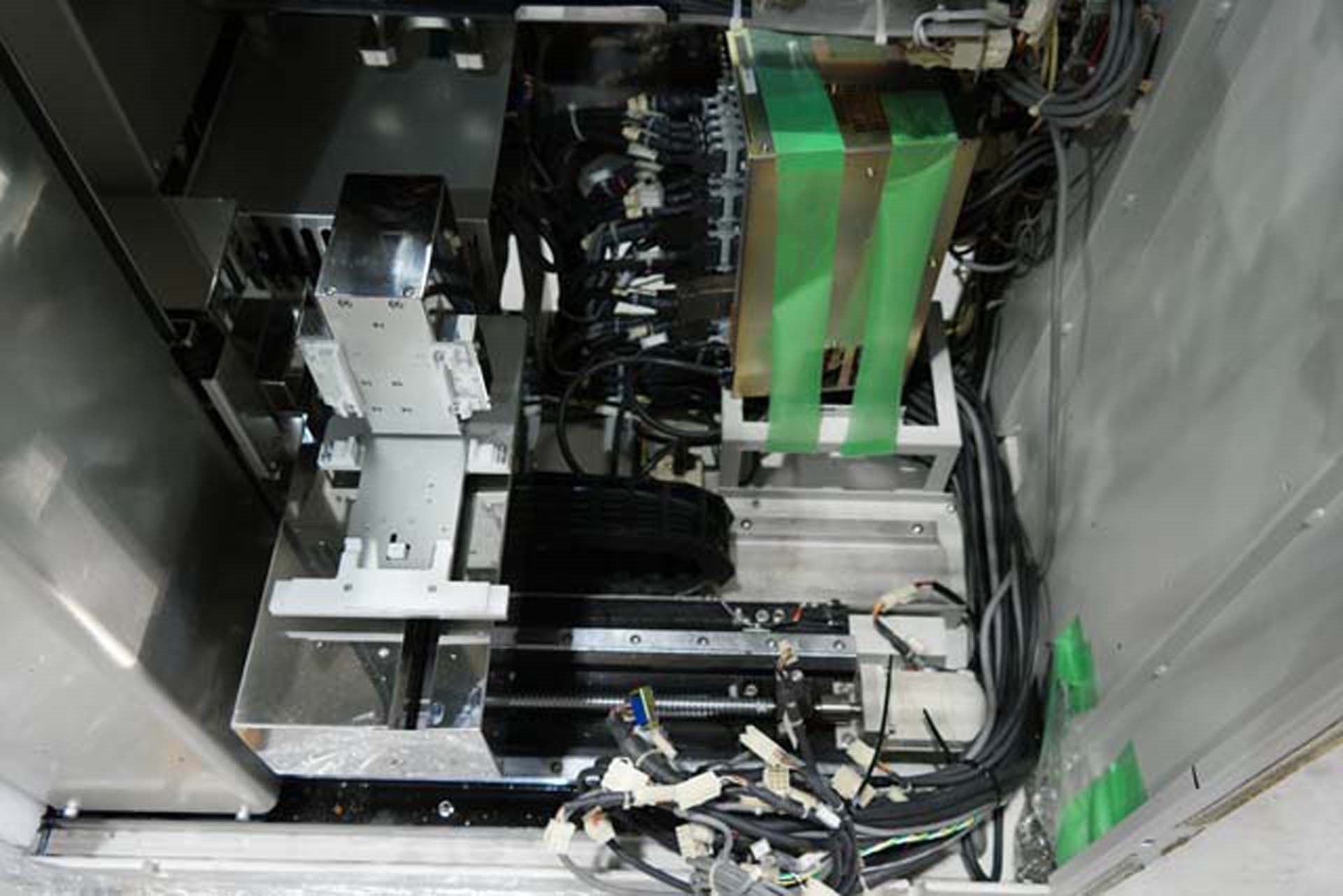

Loading system:

Front operation panel: R-Axis

Pass box (Load lock): Cassette loader

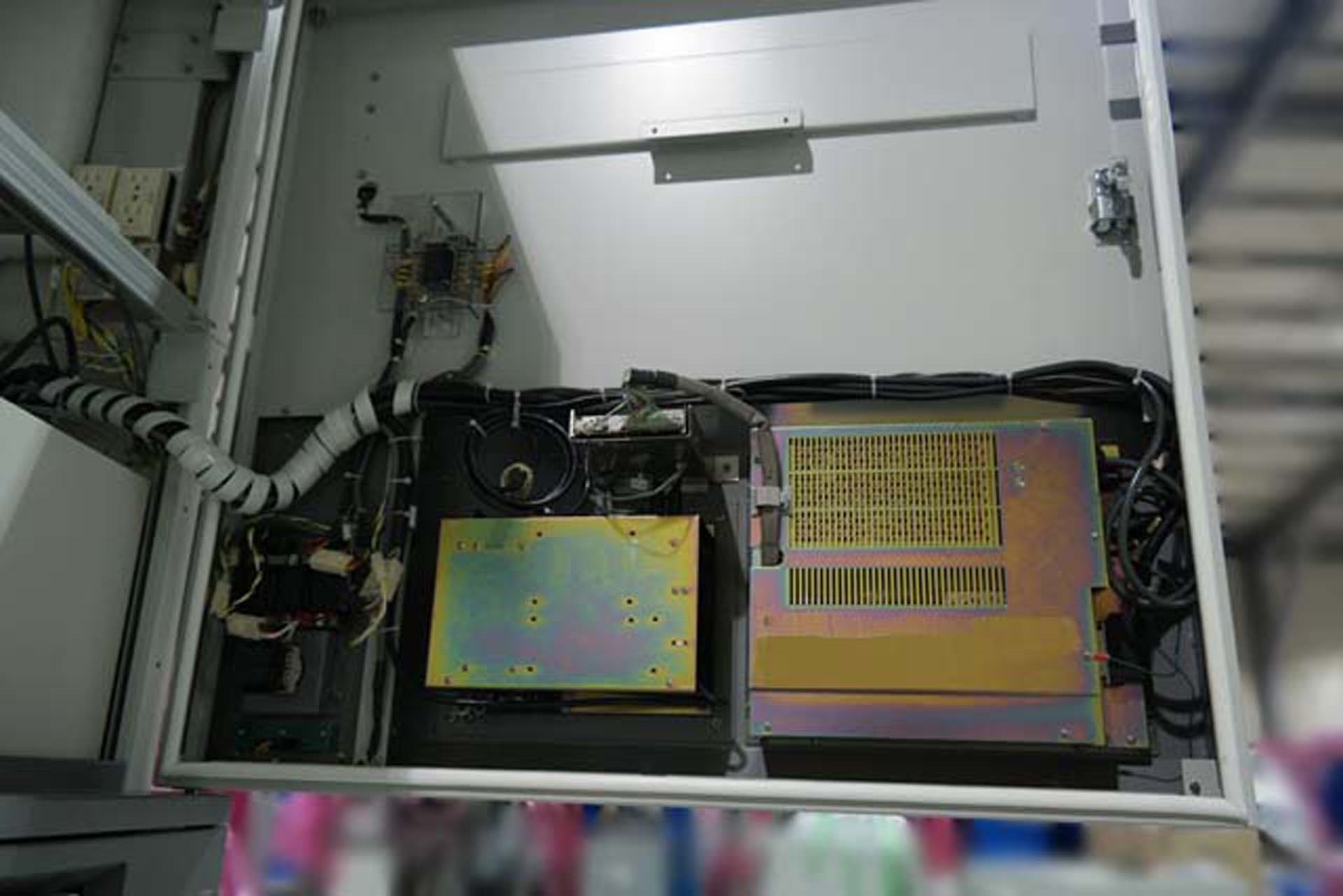

CX 3002 Main controller

CX 1220 Mecha controller

Wafer counter, 6" (every 25)

I/O Stage check: Air off

CX 3002 Cassette loader

Wafer transfer: Air Off ((5) vacuum tweezer, 6")

Furnace system:

CQ 1500 (DN-150) Temperature controller

D4EX 05414 Heater

SIC Profile

(4) Controllers

(4) Monitors

Gas system:

CX 1311 MFC Controller

MFC (STEC):

MFC1: 30SLM

MFC2: H2 20SLM

MFC3: O2 20SLM

Model / Gas:

MFC4: O2 2SLM

MFC5: HCl 1SLM

MFM: N2 10SLM

(2) Filters

Pressure control system:

AERA RC-100F Pressure controller

Valve open / Close check: APC Valve area RV-100

Burning system:

CX 1310 Burn controller

Power:

Heater: 3Φ, AC 200 V, 42 kVA

Control: 1Φ, AC 100 V, 30 A

Clean unit: 1Φ, AC 100 V, 40 A.

HITACHI / KOKUSAI DD-833V is an advanced diffusion furnace and accessories package designed to provide precise temperature control and uniformity for a variety of materials. The furnace features a molybdenum sixth-wall heating chamber, a high power quartz tube-type heating element, a two-stage diaphragm pump, and a high-precision temperature controller. With these features, HITACHI DD-833V is capable of closely controlling temperatures up to 1,400°C during a variety of diffusion processes. The furnace can be used in applications requiring rapid thermal diffusion, such as thinfilm deposition of metals and glass, CVD processes, and thermal processing. The molybdenum heating chamber of KOKUSAI DD 833V is designed to rapidly heat materials with minimal thermal losses. The quartz tube-type heating element provides an exact response to temperature changes for precise and consistent thermal diffusion. The two-stage diaphragm pump located next to the furnace helps reduce the risk of surface contamination. High-precision temperature controllers provide precise temperature control and uniformity, allowing for quick and accurate operation of the diffusion furnace. The package also includes additional accessories designed to enhance the operation of DD 833V. A height-adjustable holder is included to assist in positioning samples in the furnace. A lid lift mechanism allows for easy access to samples during thermal processing. A separate power supply module is included to provide additional sources of power, such as dry gas, for the diffusion furnace. In addition, a variety of furnace control panels, electrical components, and other accessories are included with DD-833V to enable precise control of the diffusion process. The control panels are easy to use, offering intuitive commands and an array of indicators to monitor temperature and diffusion progress. All necessary electrical components are included for a safe and reliable connection to the power source. KOKUSAI DD-833V is an advanced and reliable diffusion furnace and accessories package, offering precise temperature control and uniformity for a variety of materials. Through its superior heating system, included accessories, and easy-to-use control panels, HITACHI DD 833V makes thermal diffusion a simple and complex process.

There are no reviews yet