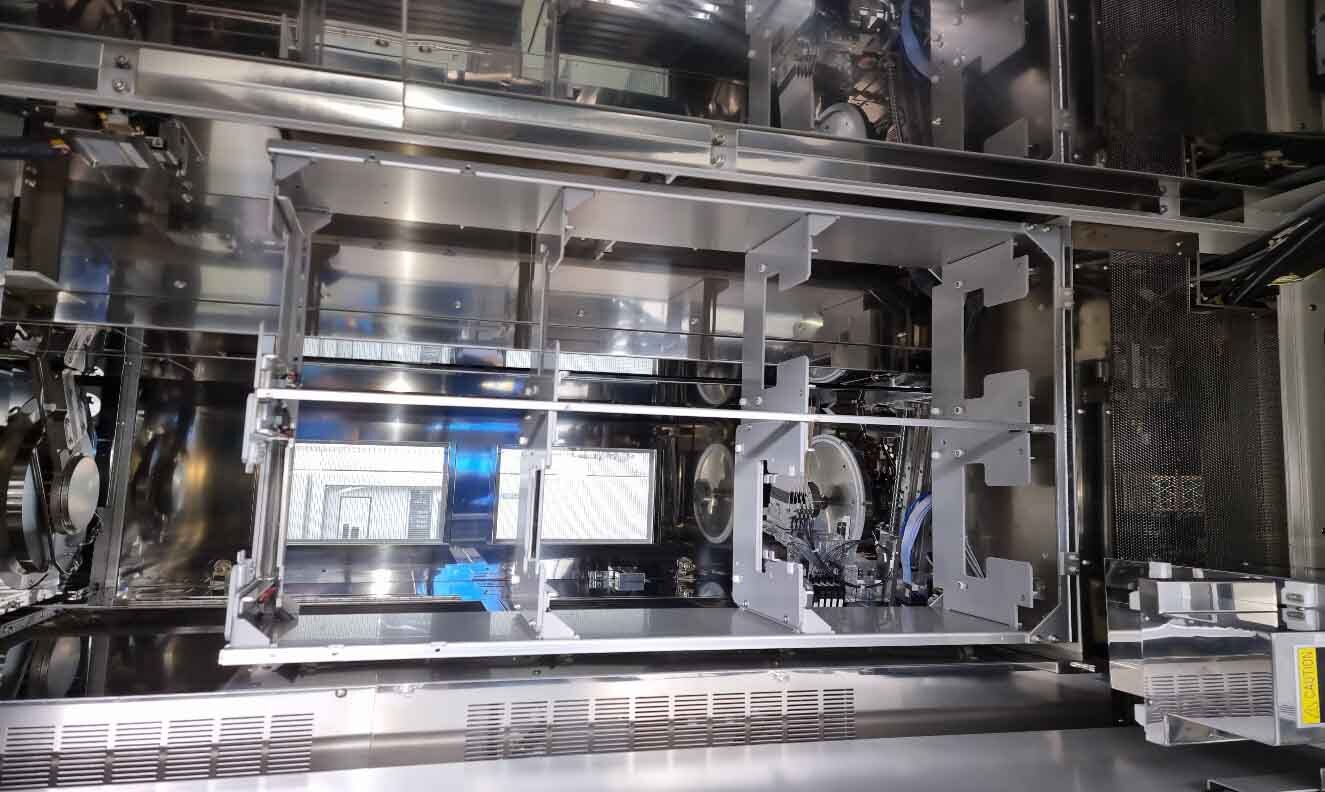

Used HITACHI / KOKUSAI DD-853 #293643214 for sale

URL successfully copied!

Tap to zoom

ID: 293643214

Wafer Size: 8"

System, 8"

Process: J2 Pyro

Gas supply: Bottom

PCW Supply: Bottom

Controller power: 120 VAC, Single phase

Heater power: 208 VAC, Single phase

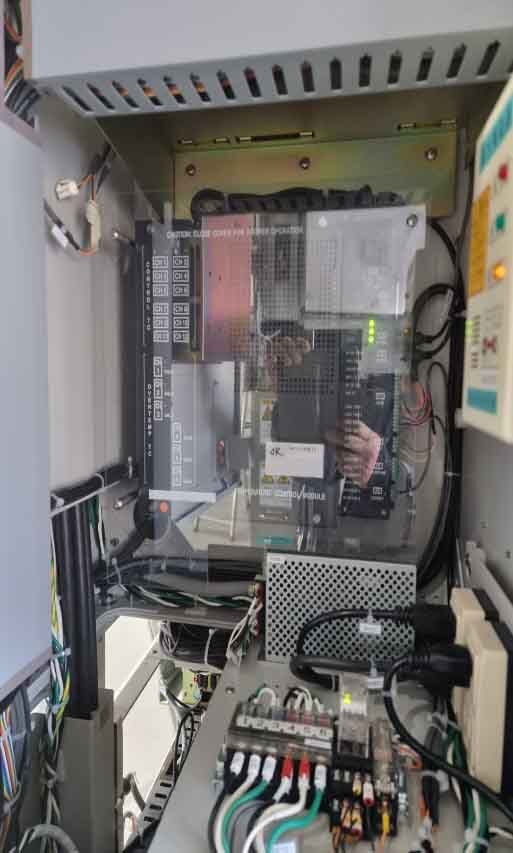

Hard Disk Drive (HDD)

Power box

Heater upper cover

Gases: N2, H2, O2, TLC (DCE)

Torch heater

CX1317 Torch controller

ATCS-15 SCHUMACHER

CQ1600 Temp controller

PLC OMRON

CX3202 Gas controller

Gas box

Gas box DCE Line

CX3002/B Main controller

D4EX05486 transformer

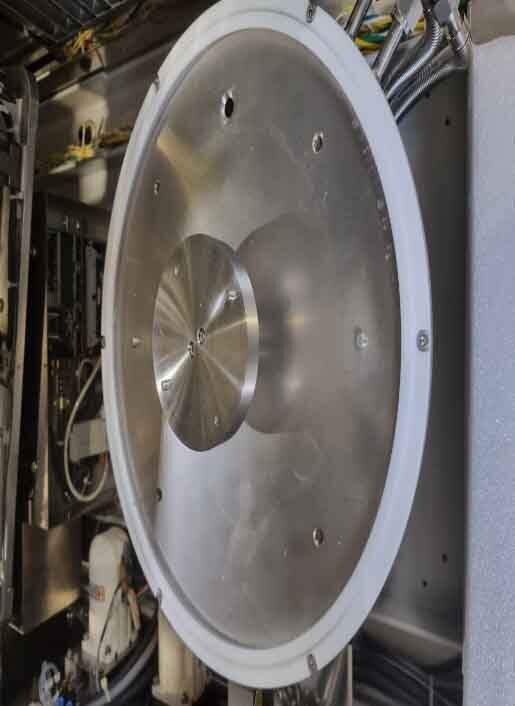

SIC Liner tube

SIC Boat

SIC Boat cap

SIC Boat Pin

SIC Torch liner tube

Temperature controller:

Heater controller

Heater over

Driver mechanisms:

I/O Shutter

I/O Stage

FOUP Loader ARM

Wafer detection: 25 Uin

Wafer transfer

1+4 Ceramic fork

Boat elevator

Sealcap

Turntable

Pendent

No heater

Racks:

(4) Lower 2

(5) Upper 2

(2) Sub 2

Gas supply:

MFC

Valve

Torch unit

ATCS-15 Absolute temperature control system

Drivers:

E-Axis motor

R-Axis motor

Z-Axis motor

X-Axis motor

Y-Axis motor

V-Axis motor

CS-Axis motor

CZ-Axis motor

CX-Axis motor

CY-Axis motor

OR-Axis motor

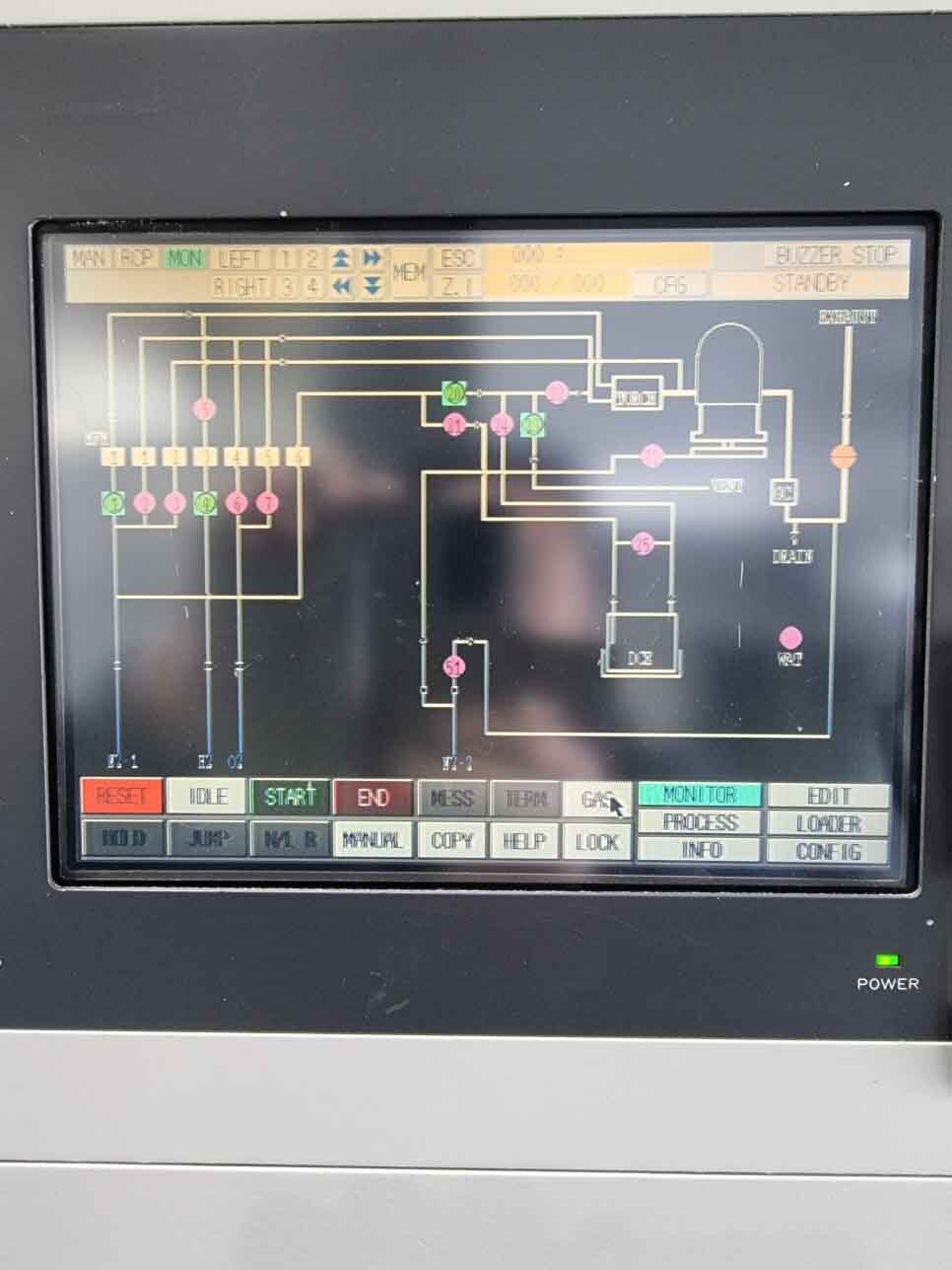

Exhaust system:

HORIBA STEC EC-5000 / PVU-3000 Exhaust APC Valve

Pressure sensor.

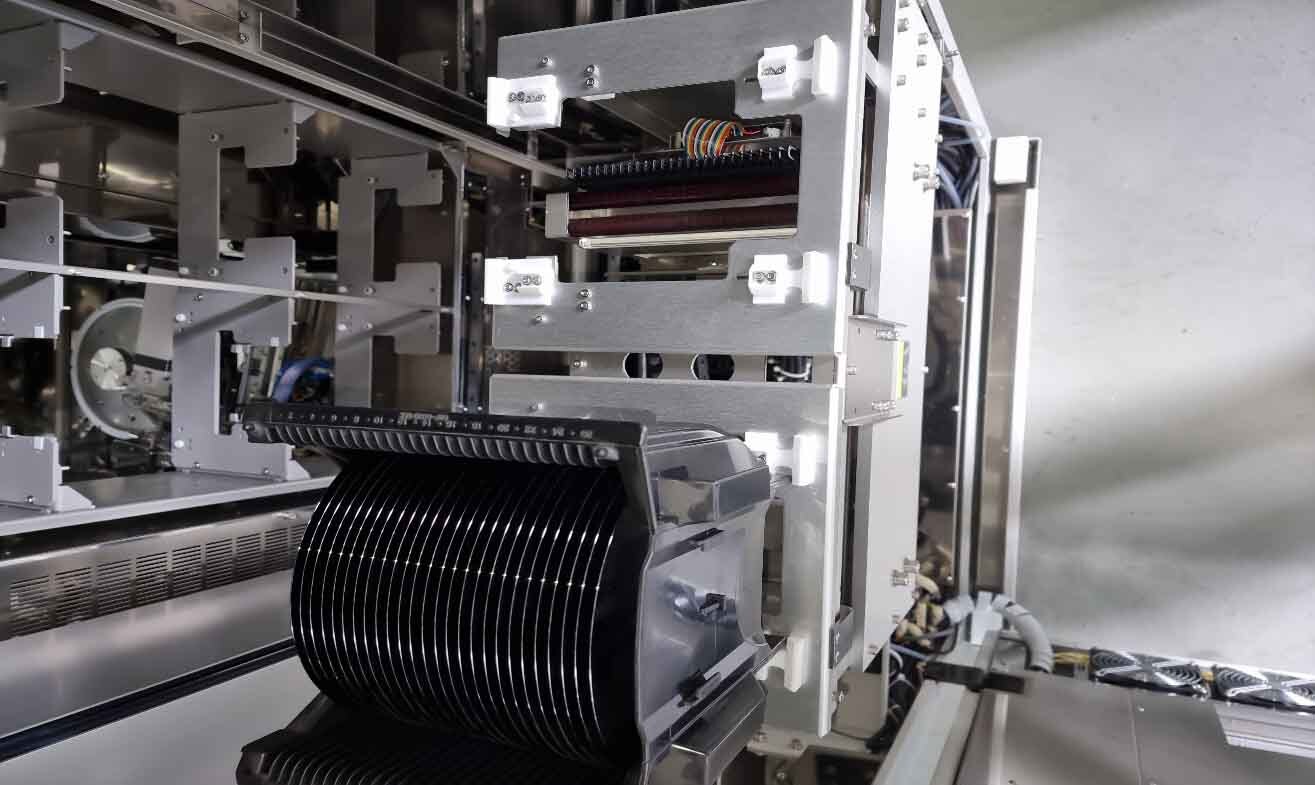

HITACHI / KOKUSAI DD-853 is a diffusion furnace and accessories that provides users with a high level of user control and performance when using it for diffusion and annealing processes. HITACHI DD-853 is equipped with a unique, high-precision control equipment that allows for close control of temperature, timing, and gas purity. The furnace body is constructed of durable, high-end materials and is designed to protect the process and environment from excessive wear and tear. At the heart of KOKUSAI DD-853 is a vertically-mounted, single-cell, coil-type quartz reactor. This vertical positioning enables superior performance of diffusion and annealing processes. The furnace can reach temperatures up to 1450° C and is capable of delivering a maximum power of 3.2kW. Temperature uniformity is maintained within +/- 5°C up and down the length of the furniture body. The diffusion process monitoring system is designed to be easy to use, allowing users to carefully adjust their processes for optimal performance. The furnace is also equipped with an air scrubbing unit to ensure clean air is used throughout the diffusion and annealing process. This machine includes filters and cooling systems and operates in a closed-loop tool. A pressure vessel is integrated into the asset and filled with the approved gases required for diffusion or annealing processes. The furnace is also equipped with a series of pressure and displacement sensors to ensure optimal control of the process. DD-853 also includes a series of accessories and imaging tools, including a pyrometer, microscope, and imaging model. This combination enables users to precisely monitor their diffusion and annealing processes. The pyrometer is designed to measure the temperature of the sample during annealing or diffusion and provide detailed readings. The microscope and imaging equipment are designed to provide a high level of detail and accuracy, while providing images of the sample material as it is diffused or annealed. Finally, HITACHI / KOKUSAI DD-853 comes with a variety of safety features designed to protect the user and the environment. The furnace is designed with ground fault interrupters and pressure control valves to automatically shut off power when necessary. The exhaust hood is designed to provide a clean exhaust path, while a multi-stage filtration system catches and controls fumes. The furnace also includes an emergency stop button that immediately shuts off power when it is pressed. In summary, HITACHI DD-853 is a diffusion furnace and accessories that provides users with a high degree of control and performance for diffusion and annealing processes. The unit includes a variety of features and accessories that enable users to carefully control their processes and monitor the results. Additionally, the safety features ensure that users and the environment are protected during diffusion and annealing processes.

There are no reviews yet