Used HITACHI / KOKUSAI DJ-1206VN-CX5 #9233610 for sale

URL successfully copied!

Tap to zoom

ID: 9233610

Wafer Size: 12"

Vintage: 2006

System, 12"

Process: Zro

Front body

Main body

Front upper

Heater

Power box

Blower box

GMP Box

Source box

O3 Generator

Killer box

N2 Purifier

IGS Box

Vacuum line

N2 Purge box

Heater exhaust

Damper frame

Main upper

Heater upper

(5) Boxes

(120) Process wafers

I/O Port / SMIF: FOUP

Load Lock: L/L

(25) Carrier slots

Operation screen: Touch screen

Vacuum pressure control: VAT

Controller transformer: 208V, Single phase

Heater transformer: 440V, 3 Phase

Oxygen analyzer: NGK

Module name:

Process gas 1: N2

Process gas 2: He

Process gas 3: Zr

Process gas 4: O2

Gas distribution system:

Basic style: conventional

Tubing material: SUS-316L

Tubing finish: VCR

MFC: STEC

Ozone system: MKS

Manual & air-operated valve: FUJIKIN

Exhaust distribution system:

Air-operated valve type: VCR Connect

Main valve: VAT

Pump line

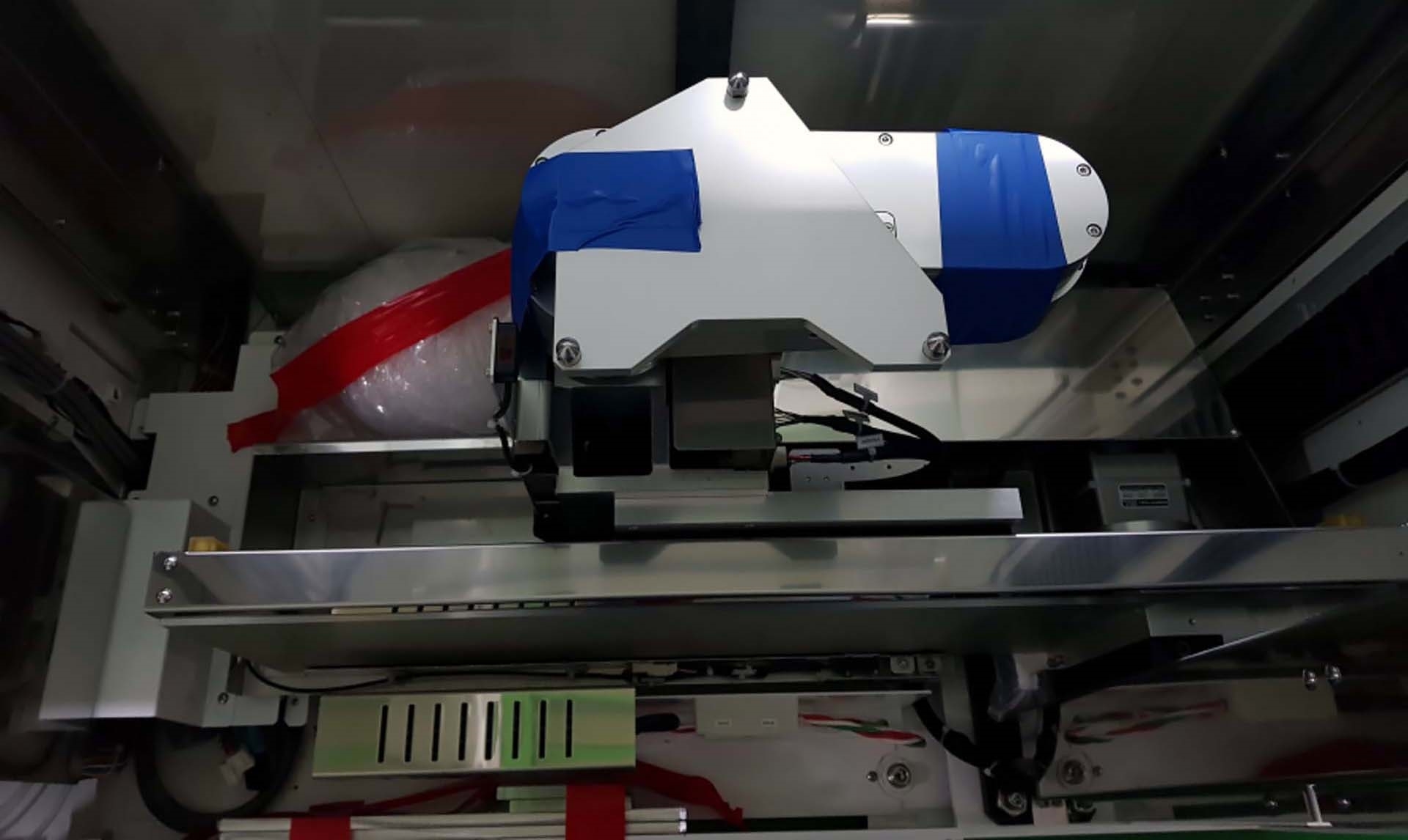

Cassette In/Out port

Cassette handling robot

(16) Cassette storages

Wafer transfer type: 1 + 4

Fork material: AL2O3

(5) Forks

Fork variable pitch

Fork wafer presence sensor

Elevator handling:

Boat elevator

Auto shutter

Boat rotation

Mechanical parts

Heating chamber:

Heater type: RHC

(5) T/C Types

(5) Spike T/C

Missing parts:

CX5000 System controller

CQ1700 Temperature controller

2006 vintage.

HITACHI / KOKUSAI DJ-1206VN-CX5 is a diffusion furnace and accessories package designed to provide superior quality diffusion processing. It features a computer-controlled touch panel increase/decrease equipment which allows for precise temperature adjustments. The furnace has a frequency of up to 400Hz and a maximum temperature of 1,300 °C. It is also equipped with an edge-coated graphite susceptor which minimizes heat dispersion and allows for a clean and even heating surface. The system comes with a set of two quartz boats for the diffusion process, which are designed for efficient and consistent operation. The boats have an inner diameter of 17.2mm, an outer diameter of 19mm and a maximum capacity of 1ml. It also comes with an electrostatic baffling unit, which minimizes eddy current losses and ensures a consistent temperature. The package includes a water-cooled microprocess control unit, which helps reduce operating temperature and minimize thermal drift. It is also equipped with an efficient cooling machine, which utilizes forced-air cooling agents to maintain a stable operating temperature. Additionally, the diffusion furnace has a maximum active working time of five hours, allowing it to complete the diffusion process quickly and effectively. In addition to the diffusion furnace, the package includes a set of accessories including a quartz tray, a balancing mount and a weight pan, which are all designed to assist the user in setting up and carrying out the diffusion process. An air compressor is also included to provide a steady flow of air to the furnace, improving the efficiency of the diffusion process. HITACHI DJ-1206VN-CX5 package is ideal for all diffusion processing needs. With its precise temperature controls, high-efficiency cooling tool, stable operating temperature and long active working time, it is the perfect choice for any diffusion application.

There are no reviews yet