Used KOKUSAI Vertron III / DJ-803V #9242184 for sale

URL successfully copied!

Tap to zoom

ID: 9242184

Wafer Size: 8"

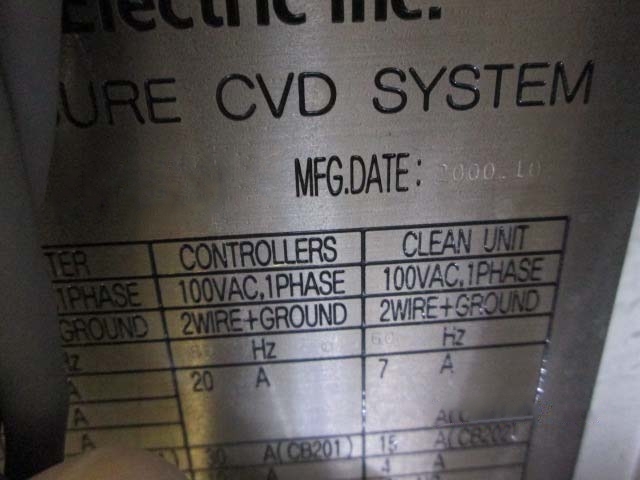

Vintage: 2000

Vertical diffusion furnace, 8"

Oxide

Process: LPCVD ONO HTO

System controller: CX2001

SECS/GEM Communication: Load station

WIP Carrier storage, 8"

Wafer spacing: 5.5

Load size: 150 Slots

Boat rotation

Furnace:

Temperature controller: CQ1501A

(4) Zones

Heater type: Mid temp D4EX1048

Process temperature range : 600-625°

Flat zone length: 1200mm

Process tube material: Quartz

Wafer boat material: SIC

Tube seal configuration: O-Ring Seal (Viton)

Temperature control methodology: Closed loop (PID)

Thermocouple type: R

Process gases (LPCVD)

MFC: Z4400 / HORIBA STEC

Process gases: SiH4, HCL

Other gases: N2

Process pressure control system:

Vacuum pump: EDWARDS QDP80

Dry pump capacity: QMB 1200

Fore line size: 80

Pressure controller: CX1204

Pressure control methodology: Close loop (PID)

Process manometer

Pressure differential manometer

Pump manometer

Inline cold trap

Exhaust controller

BROOKS SMIF Loader

MIDAS Gas detector

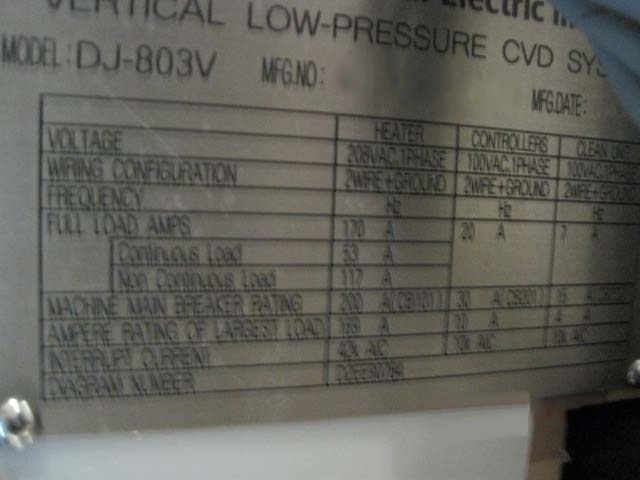

Power supply:

Heater voltage: Single phase, 280 VAC, 42 K A/C

Controllers: Single phase, 100 VAC, 10K A/C

Clean unit: Single phase, 100 VAC, 10K A/C

No N2 purged loadlock

2000 vintage.

KOKUSAI Vertron III / DJ-803V is a diffusion furnace and accessories equipped with a variety of features for precision engineering processes. It is a thermal processing tool designed to increase the efficiency and precision of processes such as soldering, heat treating, sintering, brazing, bonding, and others. The DJ-803V is designed and manufactured with the latest advancements in technology. Its mechanical movement and driving system have been designed to reduce user fatigue and correct the motion patterns to match the process required. The diffusion furnace is made of high quality and durable material, allowing it to be used in demanding applications. The furnace is equipped with advanced design components that maintain temperature consistency, with a consistent heating rate of 0.1 to 20C/min and a cooling rate of 10 to 150C/min. It is also equipped with advanced high-precision sensors, advanced heat monitoring, and an automatic temperature controller to ensure accurate temperature control. The DJ-803V also has an improved temperature measurement accuracy of up to 0.01C. The diffusion furnace is also equipped with a range of additional accessories to improve functionality, such as micromanipulators, ablation probes, chip lifts, and wiring mechanisms. The multipurpose chamber is also capable of a wide range of processes, from ultra-fine particle manipulation to plasma polymer film production. The micromanipulators allow for precise manipulation of micro assemblies and components, while the ablation probes can be used for effectively marking and etching of materials. The DJ-803V also provides safety features for users. It has multiple safety sensors that constantly monitor the safety of the process, and provide users with alarm signals should any temperature exceed the operating limits. It is further equipped with fire prevention measures, such as a high temperature monitoring sensor, automatic shut off, and heating loss prevention system. In addition to its advanced features, KOKUSAI VERTRON III DJ-803V is incredibly reliable due to its well-designed airflow system, which ensures uniform temperature distribution throughout the chamber and process chamber. This helps to maximize the lifetime of the diffusion furnace and maintain consistent and reliable performance with minimal downtime. With its combination of features, Vertron III / DJ-803V is the perfect diffusion furnace for applications requiring rigorous temperature control and accuracy.

There are no reviews yet