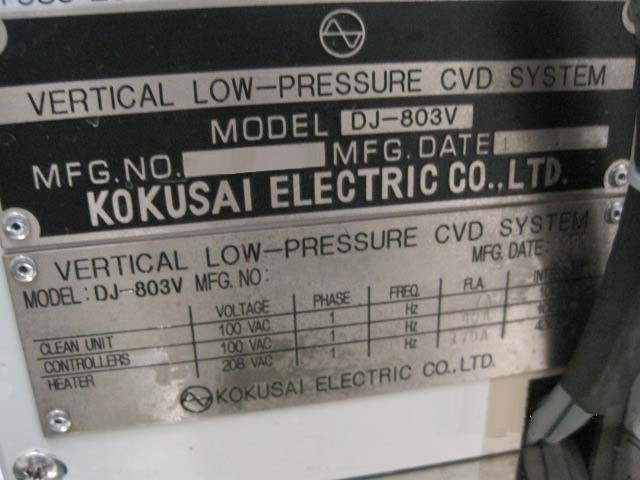

Used KOKUSAI Vertron III / DJ-803V #9272701 for sale

URL successfully copied!

Tap to zoom

ID: 9272701

Wafer Size: 8"

Vintage: 1999

Vertical diffusion furnace, 8"

Process: LPCVD Nitride

CX2001 System controller

SECS/GEM Communication: Load station

Load station:

BROOKS SMIF Loader

WIP Carrier storage capacity: 8"

MIDAS Gas detector: Process Gas detection module

Wafer spacing: 6.5 mm

Load size: 125 Slots

Boat rotation

No N2 purged loadlock

Furnace:

CQ1501A Temperature controller

(4) Zones

D4EX02626 Heater: Mid temperature

Process temperature: 650°C-780°C

Flat zone length: 1200 mm

QUARTZ Process tube material

QUARTZ Wafer boat material

Tube seal: O-Ring seal (Viton)

Temperature control methodology: Closed loop (PID)

Thermocouple type: R Type

Process gas control system:

Process gases (LPCVD):

HORIBA STEC Z500 MFC

Process gases: DCS, NH3

Other gases: N2

Process pressure control system:

Vacuum pump: EDWARDS QDP80

Dry pump capacity: QMB 1200

Fore line size: 80

Pressure controller: CX1204

Pressure control methodology: Close loop (PID)

Process manometer

Pressure differential manometer

Pump manometer

Inline cold trap

Exhaust controller

BROOKS SMIF Loader (Left/Right):

Integrated and base mounted with cassette optical light sensor detection

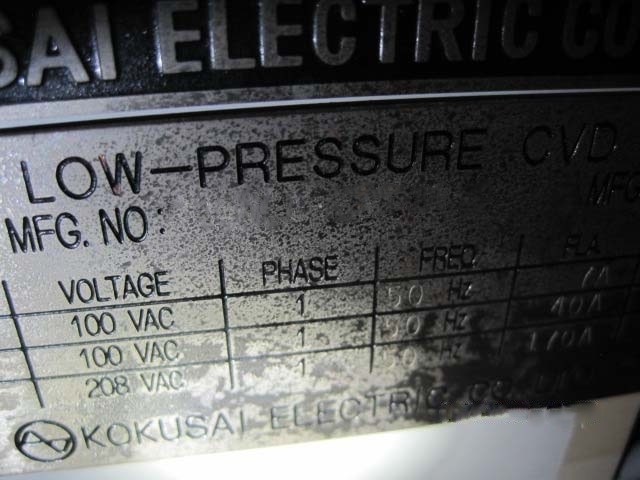

Heater voltage: 280 VAC, Single phase, 42 K A/C

Controllers: 100 VAC, Single phase, 10 K A/C

Clean unit: 100 VAC, Single phase, 10 K A/C

1999 vintage.

KOKUSAI Vertron III / DJ-803V is an advanced diffusion furnace and accessorie equipment, designed for the accurate and precise control of temperatures in a wide range of industries. It features a high-temperature chamber with an advanced closed-loop temperature control for precise control of temperatures, as well as a high-accuracy, high-speed thermal response measurement system. KOKUSAI VERTRON III DJ-803V is designed with a highly efficient forced air circulation design, which provides stable and fast thermal diffusion even with different temperatures produced by the heating unit. This advanced technology also allows efficient operation in the range of 5 ~ 1400°C and a wide range of heating mode settings, such as the continuous and accumulative pulse modes. It also features several additional thermal control modes, such as the constant temperature and a programmable time-controlled temperature adjustment, to give users greater control over the thermal processes. Vertron III / DJ-803V comes with a variety of accessories to enhance the user experience. It includes two quartz quartz plates and an alumina quartz boat for reliable sample heating. The furnace also comes with an LCD display to allow users to monitor the temperature and the process, as well as data logging equipment to store data and program settings. Additionally, this diffusion furnace also has an alarm unit to alert users in case of unexpected or dangerous temperature shifts. This advanced diffusion furnace and accessorie machine is designed with a powerful, yet compact footprint, making it easy to install and maintain. The high grade materials used in its construction provide enhanced durability and reliability. It is also highly energy efficient, thanks to its efficient forced-air circulation design, with the four-sided furnace body helping to keep temperature consistent, even in extreme temperatures. VERTRON III DJ-803V is an ideal choice for industries and applications requiring precise temperature control. It is highly reliable, accurate, and energy efficient, and comes with a wide variety of accessories to make the process easier and faster. The highly efficient forced-air circulation design, with its four-sided furnace body and advanced closed-loop temperature control, make this diffusion furnace tool a great choice for high-precision industries.

There are no reviews yet