Used SVG / THERMCO / AVIZA VTR 6000 #293597263 for sale

URL successfully copied!

Tap to zoom

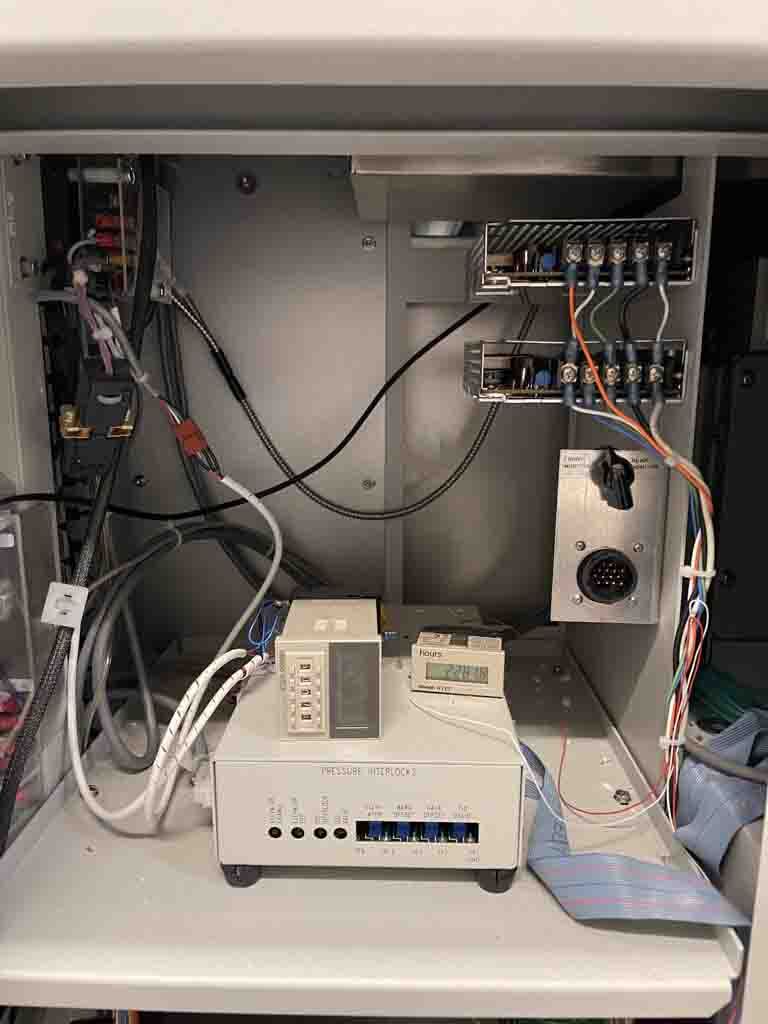

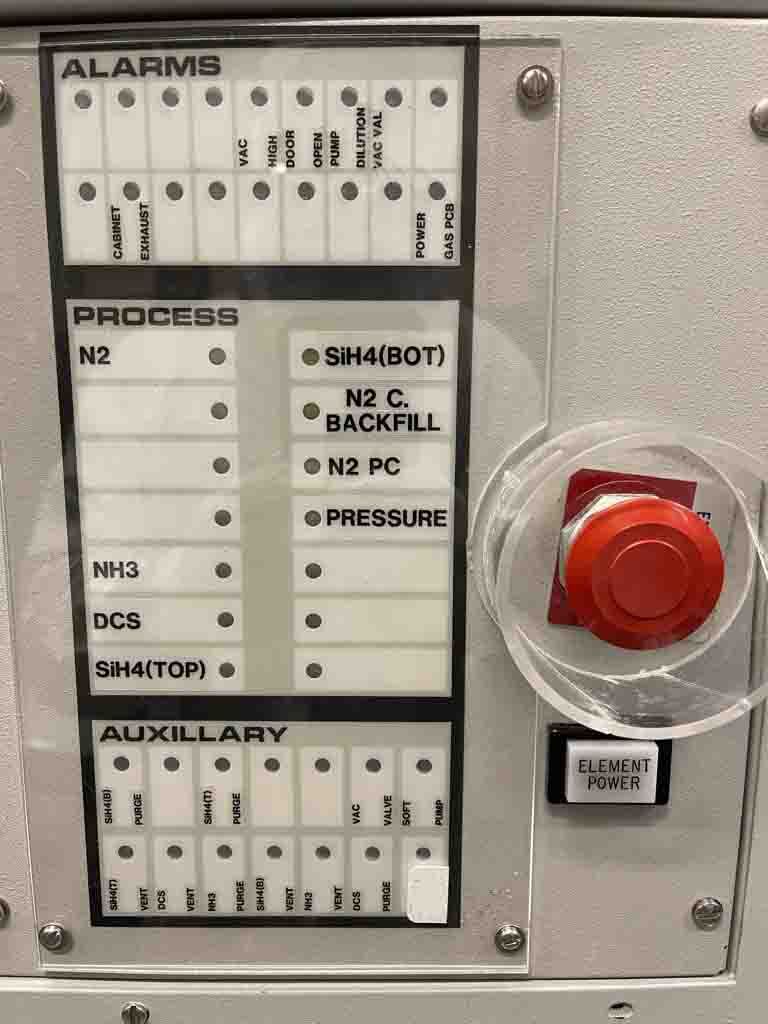

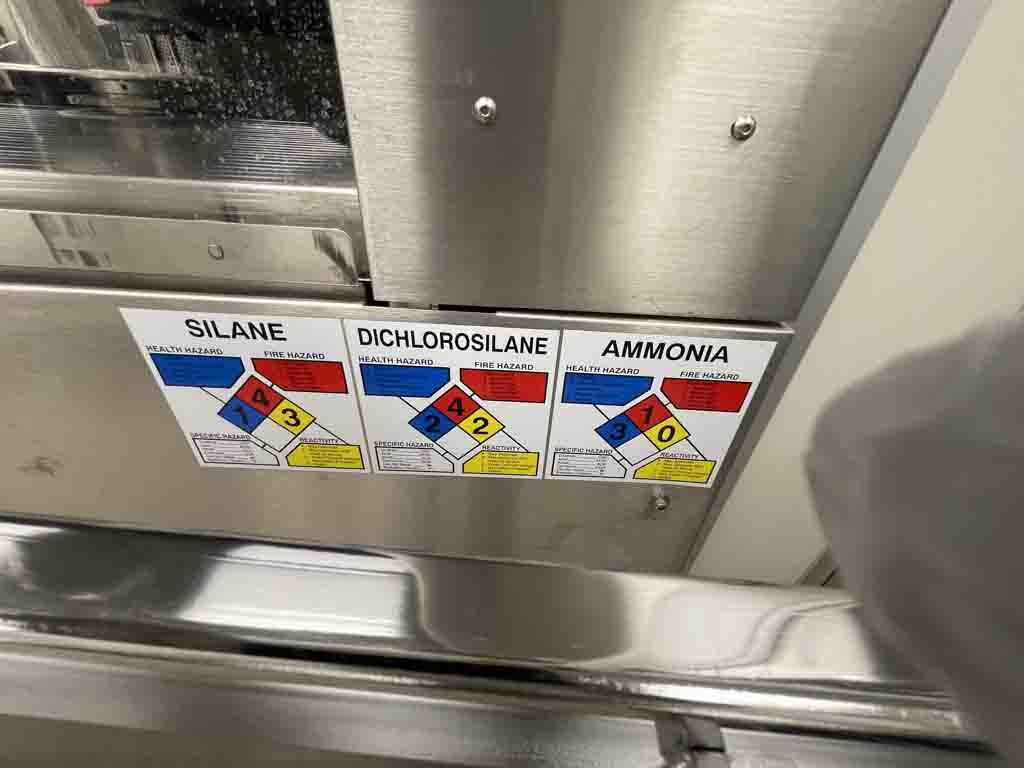

SVG / THERMCO / AVIZA VTR 6000 is a diffusion furnace used in the semiconductor industry that combines the capabilities of a standard diffusion furnace with advanced automation and customization options. This furnace can provide up to 25 watts of power, up to 3600 watts of applied heat and temperatures up to 1150 °C. Its advanced controller contains 16 advanced diffusion and implantation programs, enabling users to customize their processes to achieve the desired results. The chamber is also equipped with an automated glycol cooling equipment, ensuring uniform cooling during each step of the process. The chamber is composed of two sections: the base and the stack, which allows for more precise control. The base is powered electronically and displays real-time temperature and pressure readings, as well as a digital readout for the temperature and pressure settings. The chamber also features a quartz viewport for observing the interior, as well as a 0-5 volt output to connect to a programmable logic controller (PLC). SVG VTR 6000 is equipped with a diffusion pump that contains both a baffle thrower and a condenser, allowing for precise control of chamber pressure. This advanced pump is designed to reduce environmental noise and vibration for more precise concentration of materials and faster cycle times. The pump is also programmable, enabling users to customize the rate at which materials move through the chamber to achieve their desired levels of diffusion. The furnace also includes an automated central process control system, which includes a series of timers and alarms that monitor temperatures, chamber pressures and process steps. This unit is designed to ensure that recipes are followed precisely and that processes are completed within their specified times. The machine also works to prevent any process conditions that could result in damage to the chamber or its components. Furthermore, the central process control tool helps to increase safety by monitoring the chamber's oxygen levels. In addition to its impressive array of features, AVIZA VTR 6000 offers numerous accessories for enhanced productivity and convenience. These include a carrier wafer transfer asset that supports automated and manual wafer handling, as well as a radial furnace hub and pinning set for loading and unloading applications. The model also features a variety of high-quality quartz accessories, including curtains, grading buckets, collimators and special quartz liners. Finally, VTR 6000 offers an additional set of graphite and RP-CVD parts for coating applications. Overall, THERMCO VTR 6000 is a powerful, reliable and versatile diffusion furnace that offers tremendous opportunities for customization and increased productivity. By combining a standard diffusion furnace with advanced automation options, users can achieve the desired results while remaining safe and efficient.

There are no reviews yet