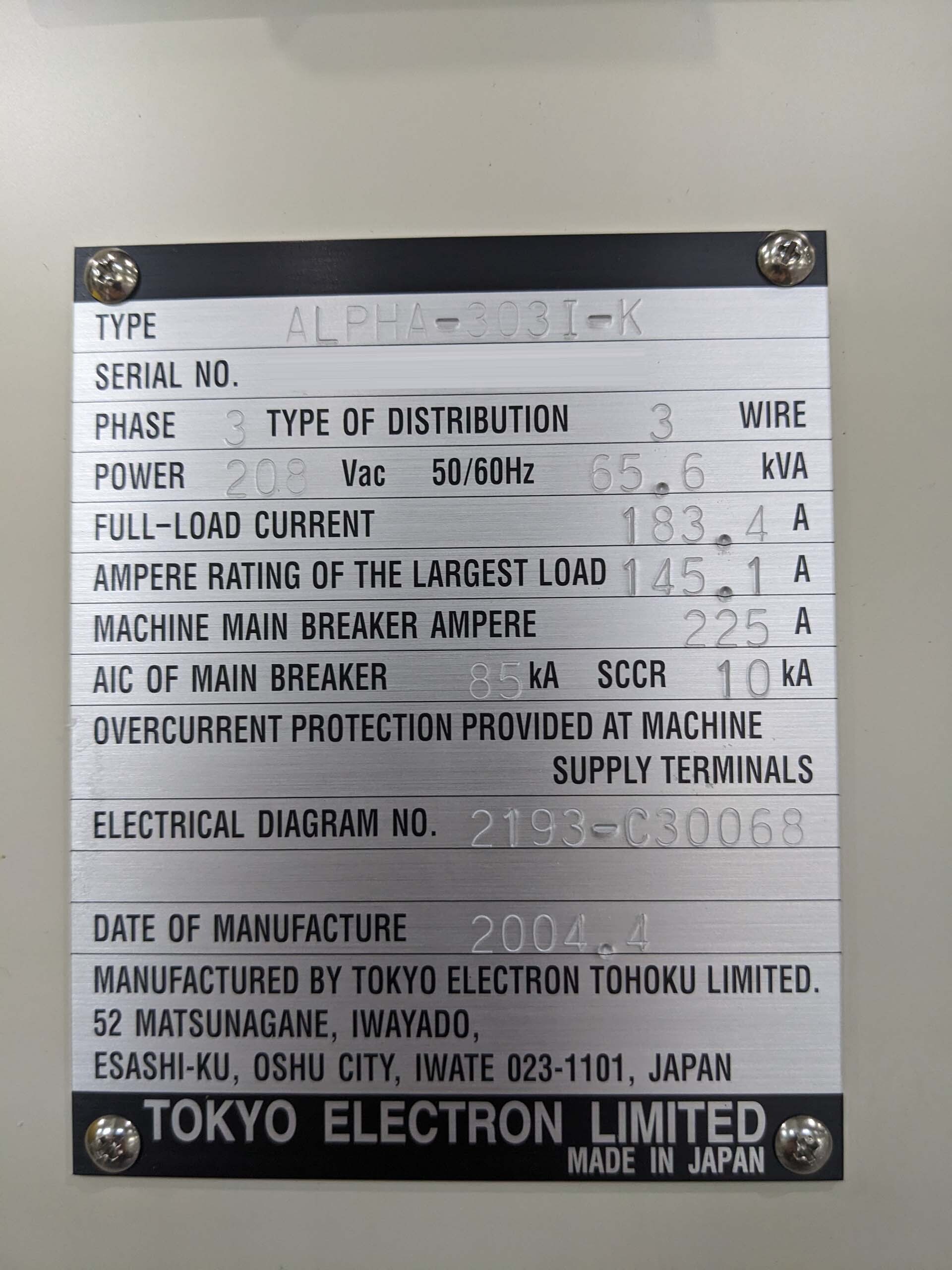

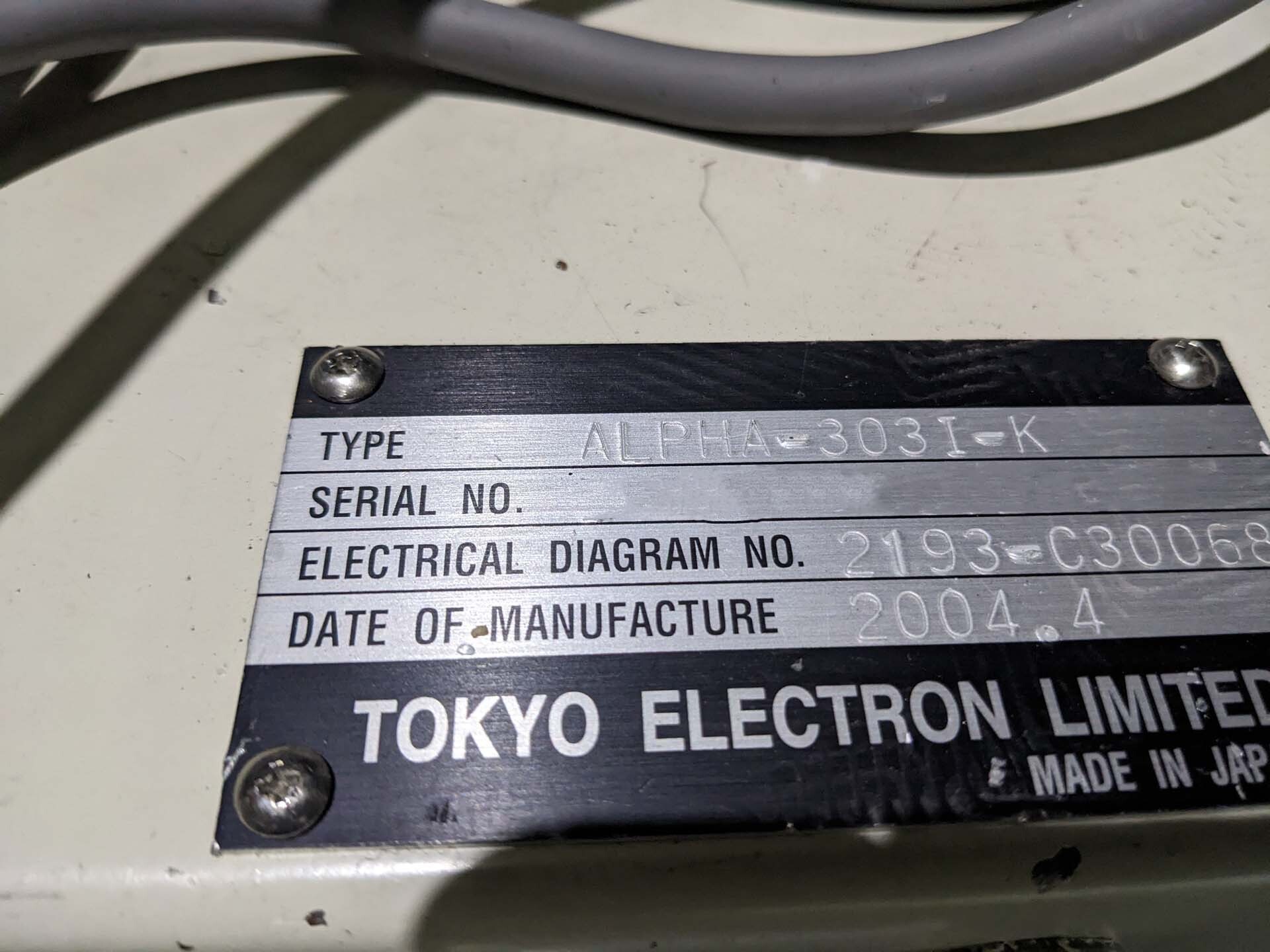

Used TEL / TOKYO ELECTRON A303i #293667428 for sale

URL successfully copied!

Tap to zoom

ID: 293667428

Wafer Size: 12"

Vintage: 2004

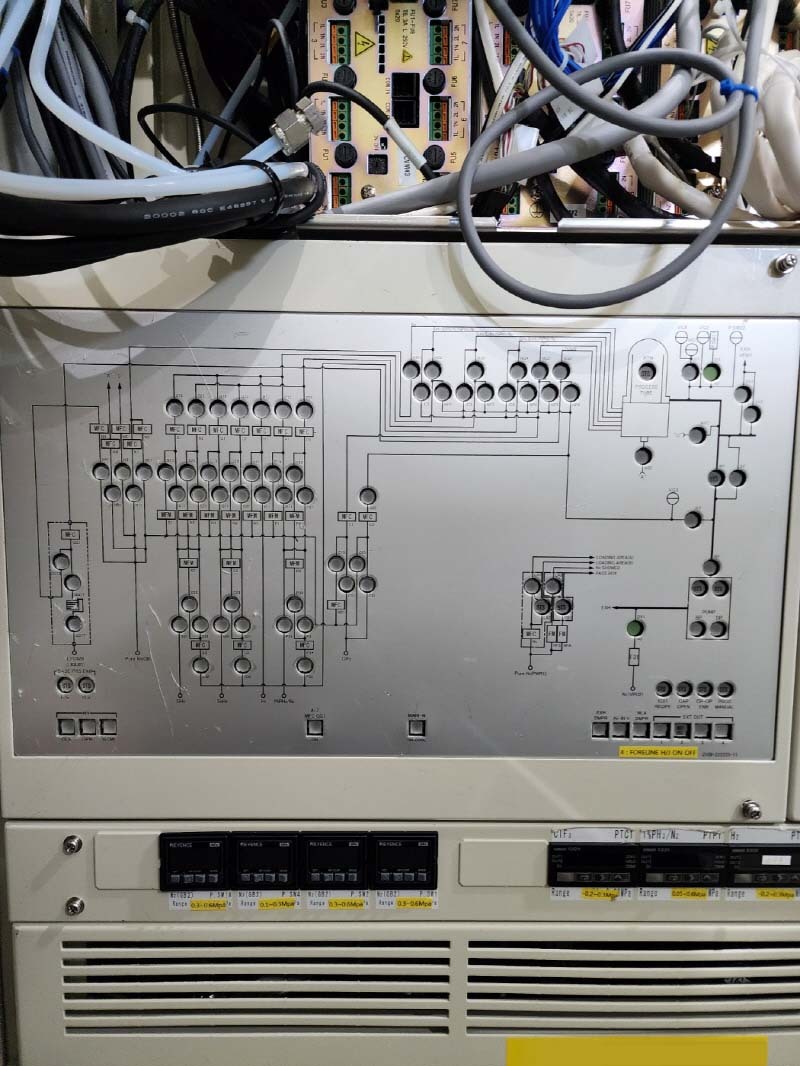

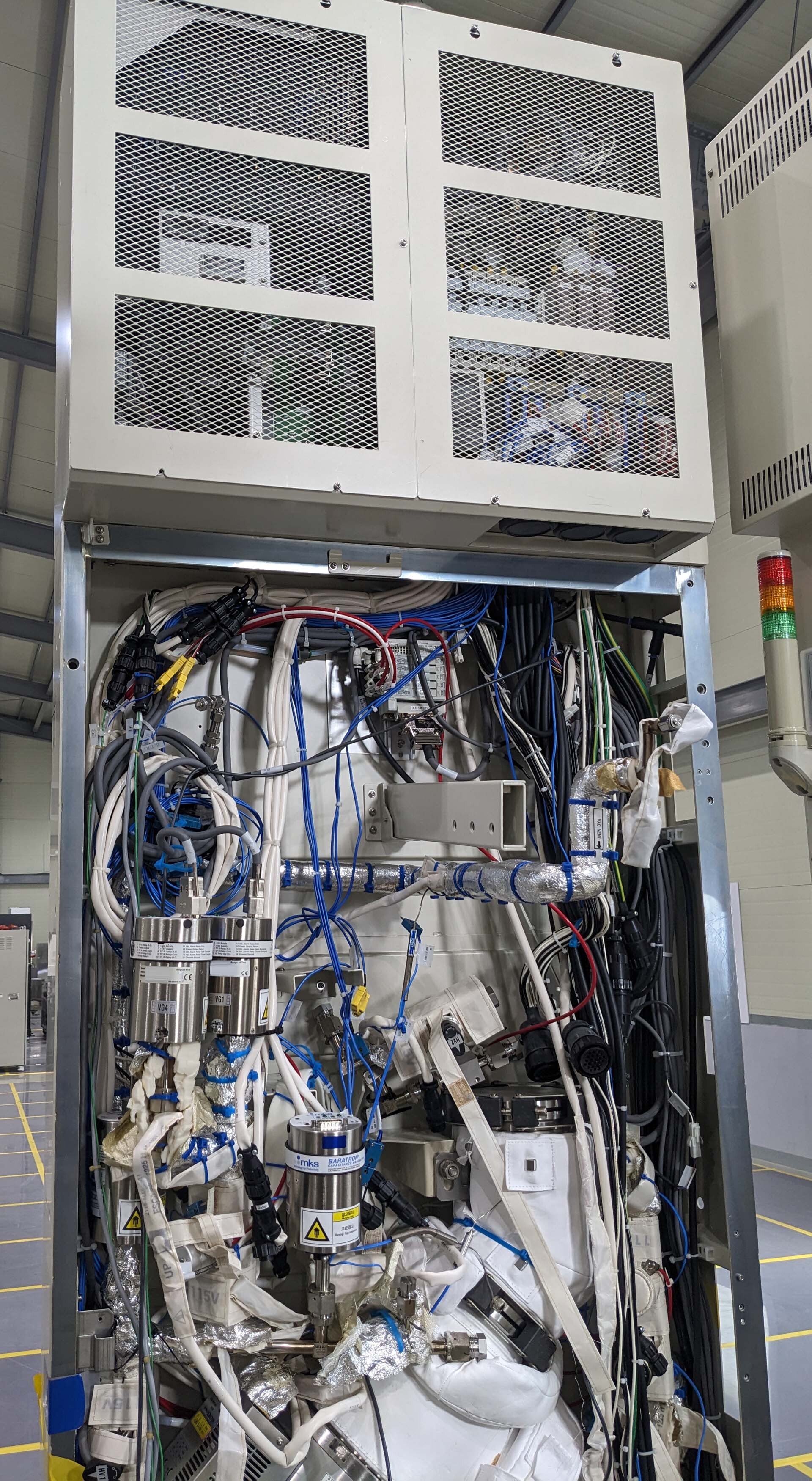

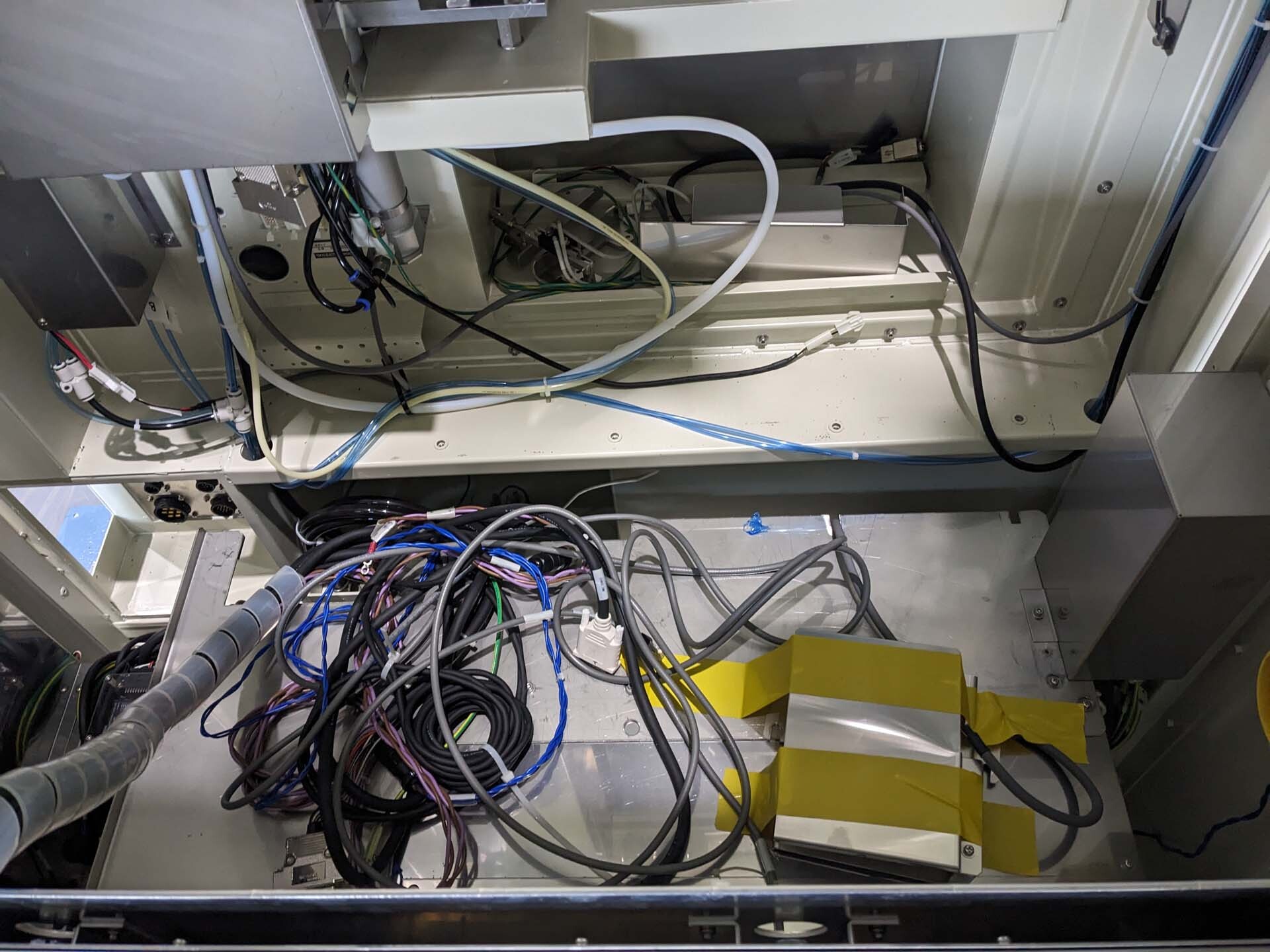

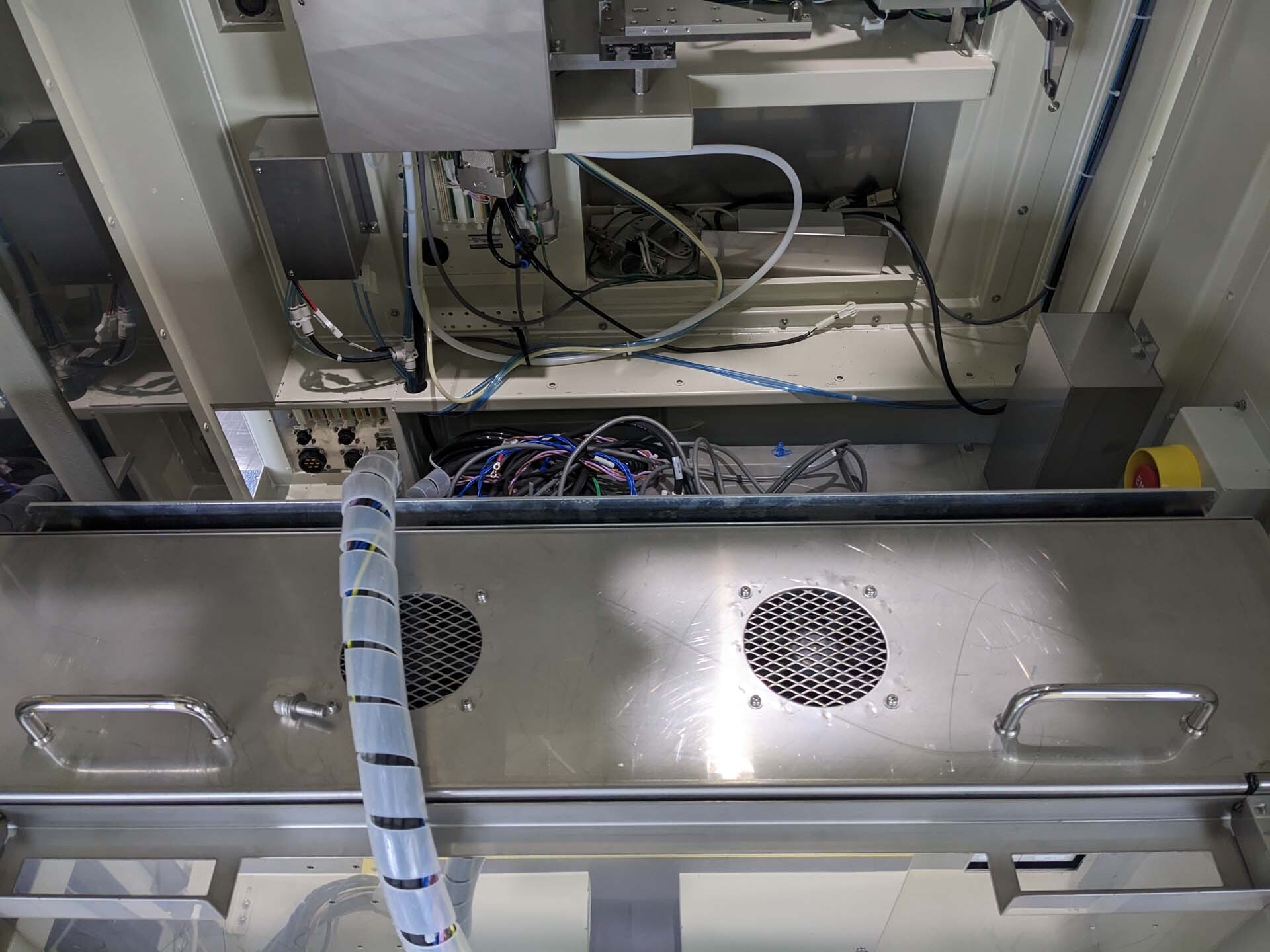

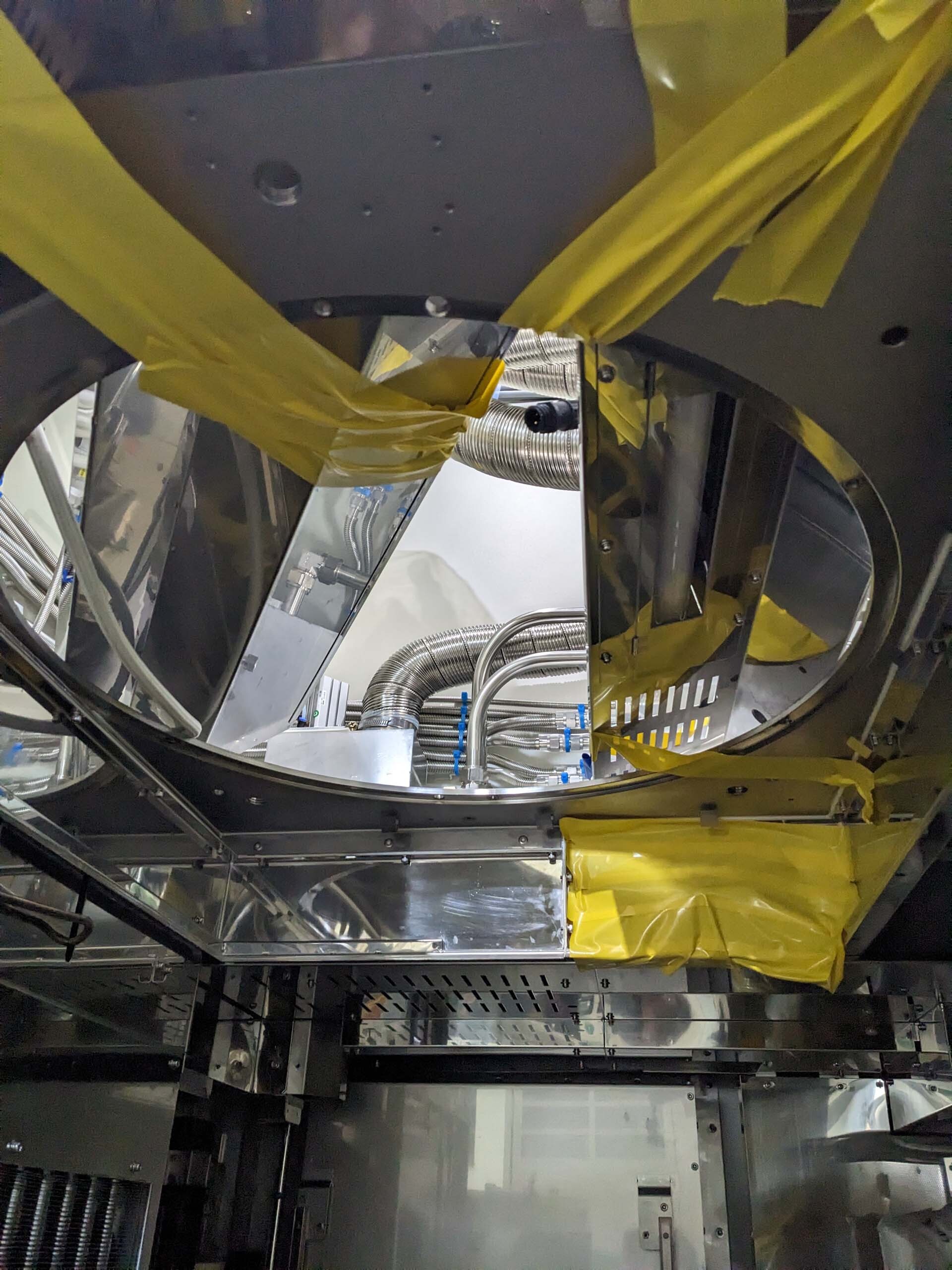

Vertical diffusion furnace, 12"

LTO Poly

Process: DIFF

Gasses: SIH4, SI2H6, 1% PH3/N2, LTO520, CLF3

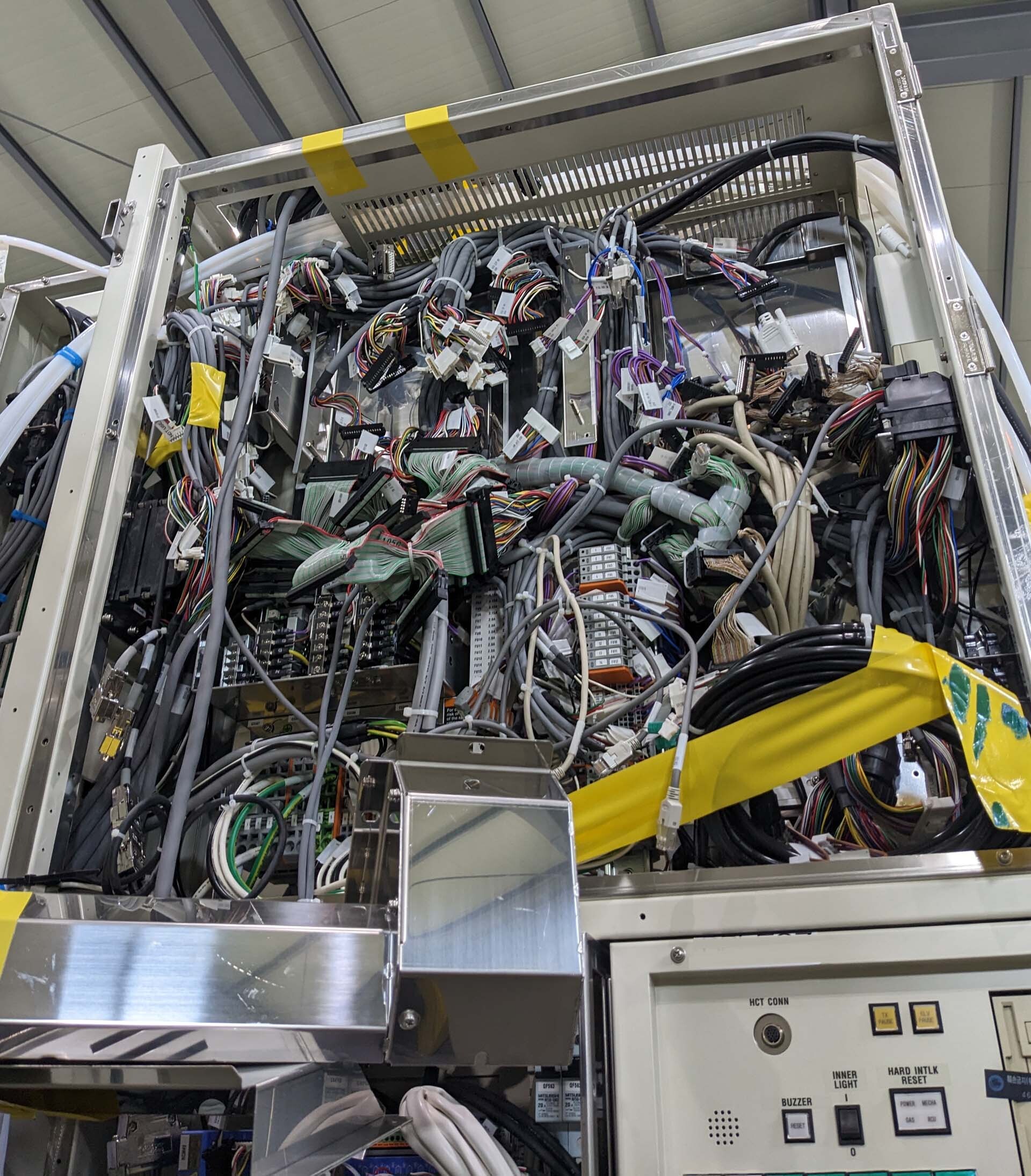

(2) Load ports

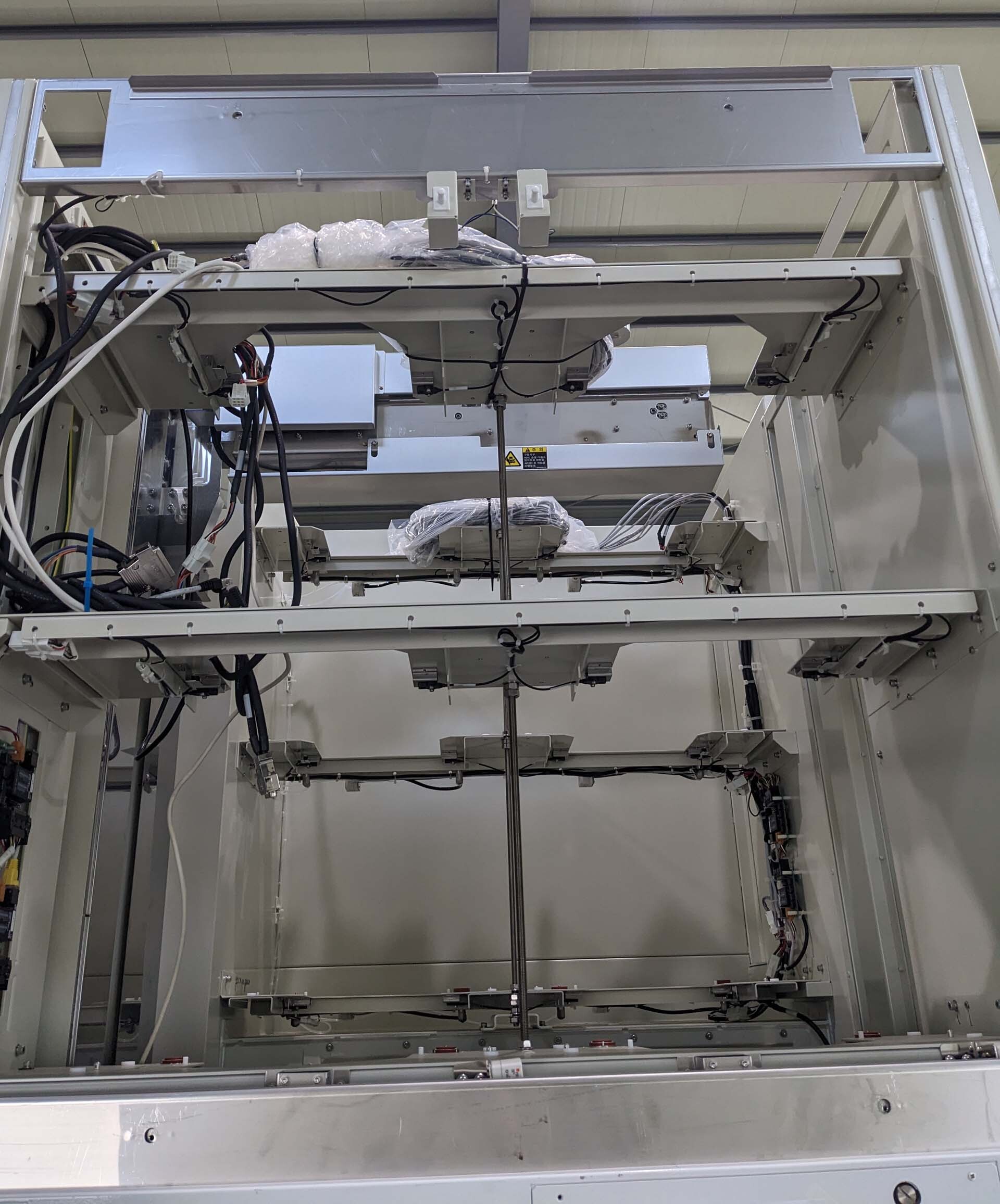

Loader arm

Transfer arm

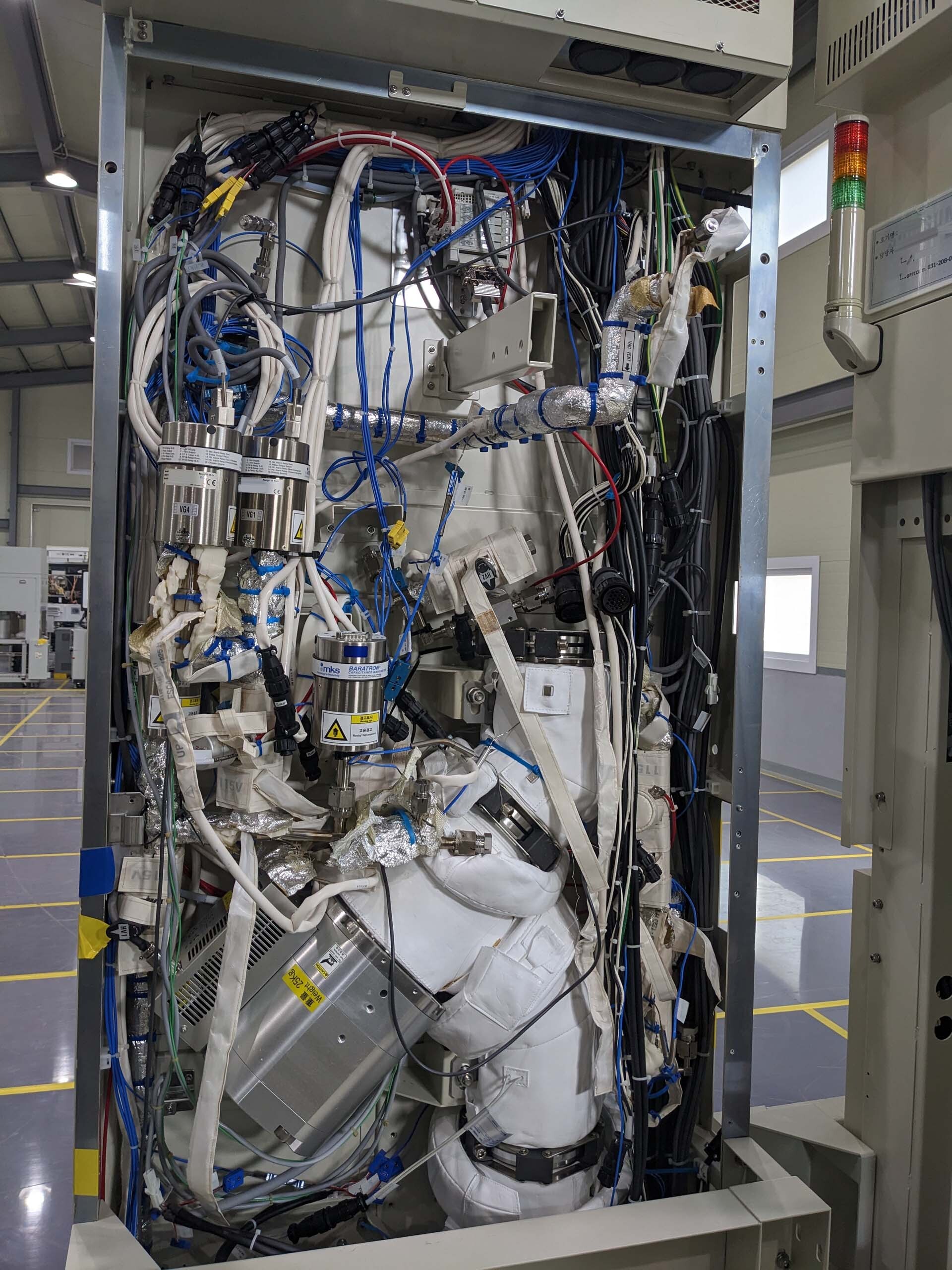

FUJIKIN Gas box

Does not include Hard Disk Drive (HDD)

Missing parts:

Part number / Description:

Q400-183245 / VAC Line 1

Q400-161162 / VAC Line 2

Q230-021126 / Turn table

Q400-252325 / Flange

Q310-260595 / Outer guide ring

Q460-006564 / Support in ring

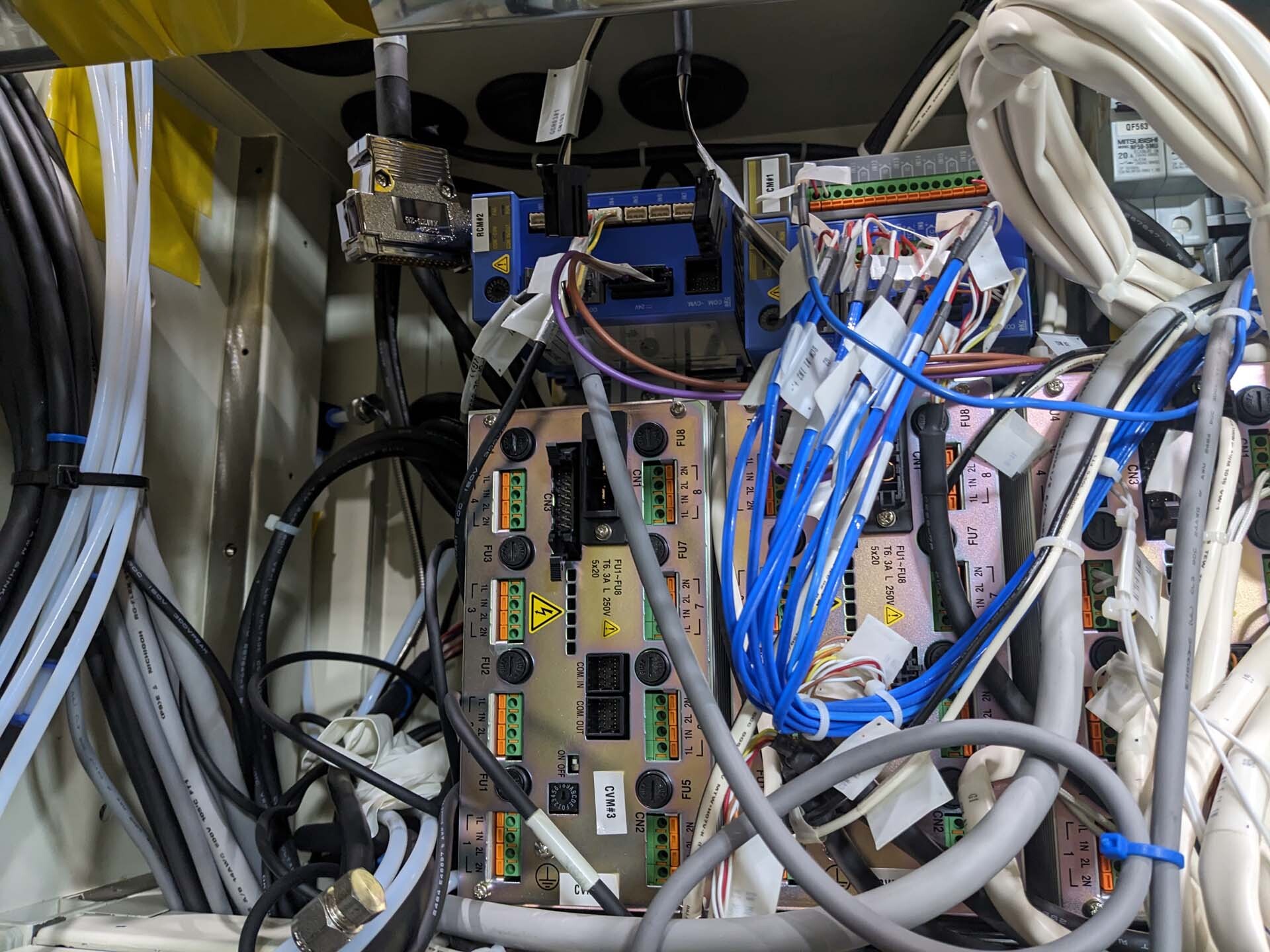

(3) Q320-082547 / MFC 16 Board

(4) Q320-060982 / DIO-I/F Board

Q320-083478 / DIO-ILK Board

Q320-072066 / GSR03 Board

Q320-162843 / MC-31255 Board

Q230-133460 / Wafer transfer

Q320-139834 / Board-control

Q400-236002 / Sol valve

Q310-230827 / Fork 1

Q310-230826 / Fork 2

Q310-125642 / Fork 3

Q310-230825 / Fork 4

Q310-230824 / Fork 5

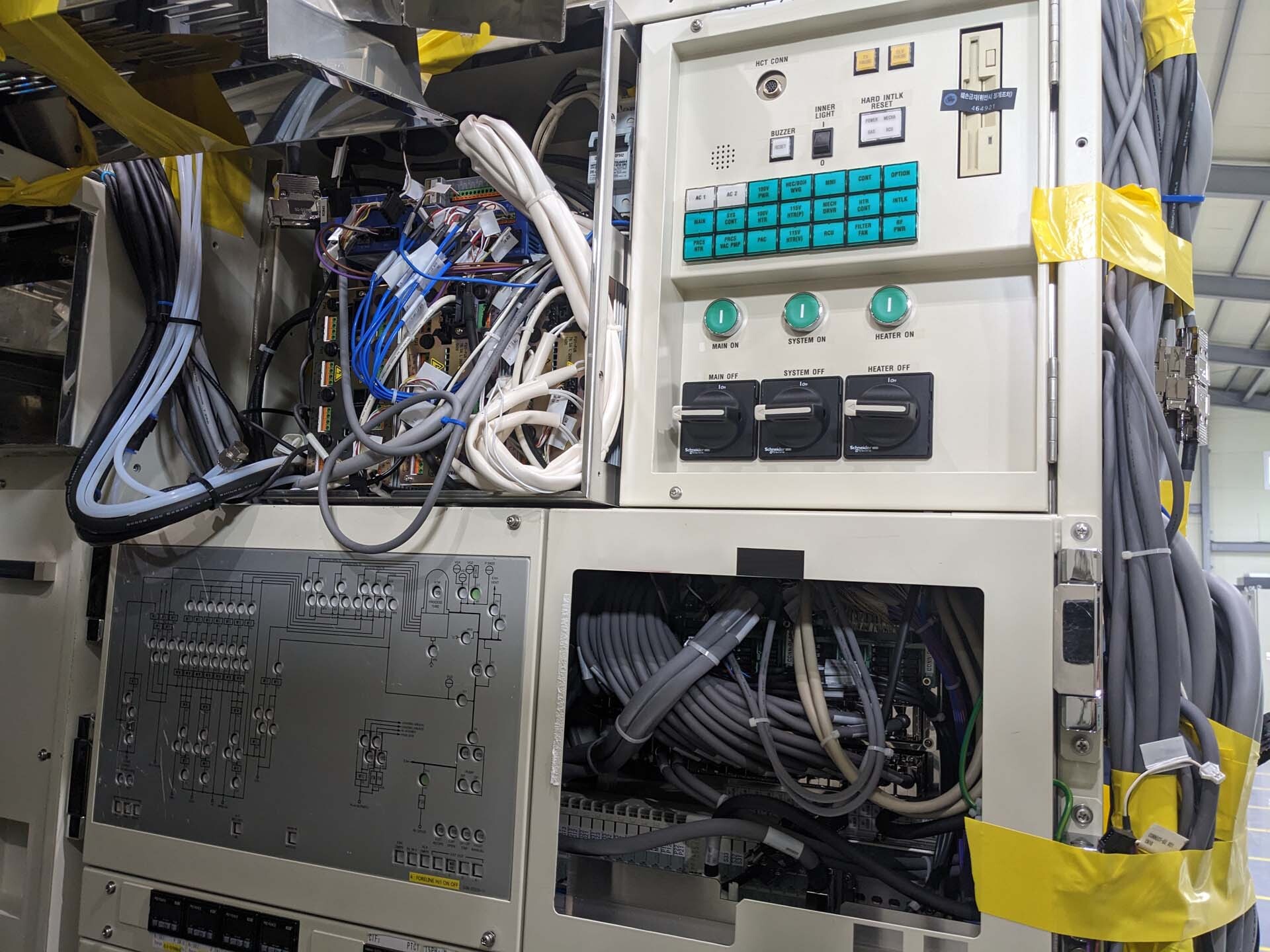

Operating system: Linux

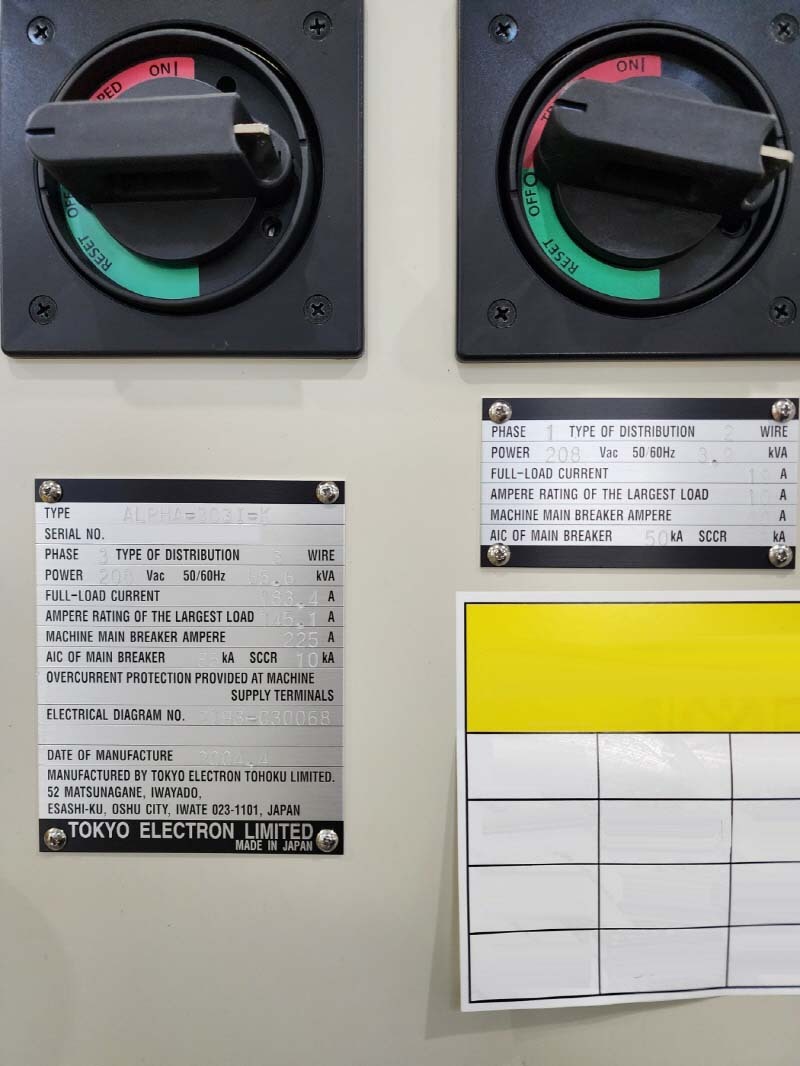

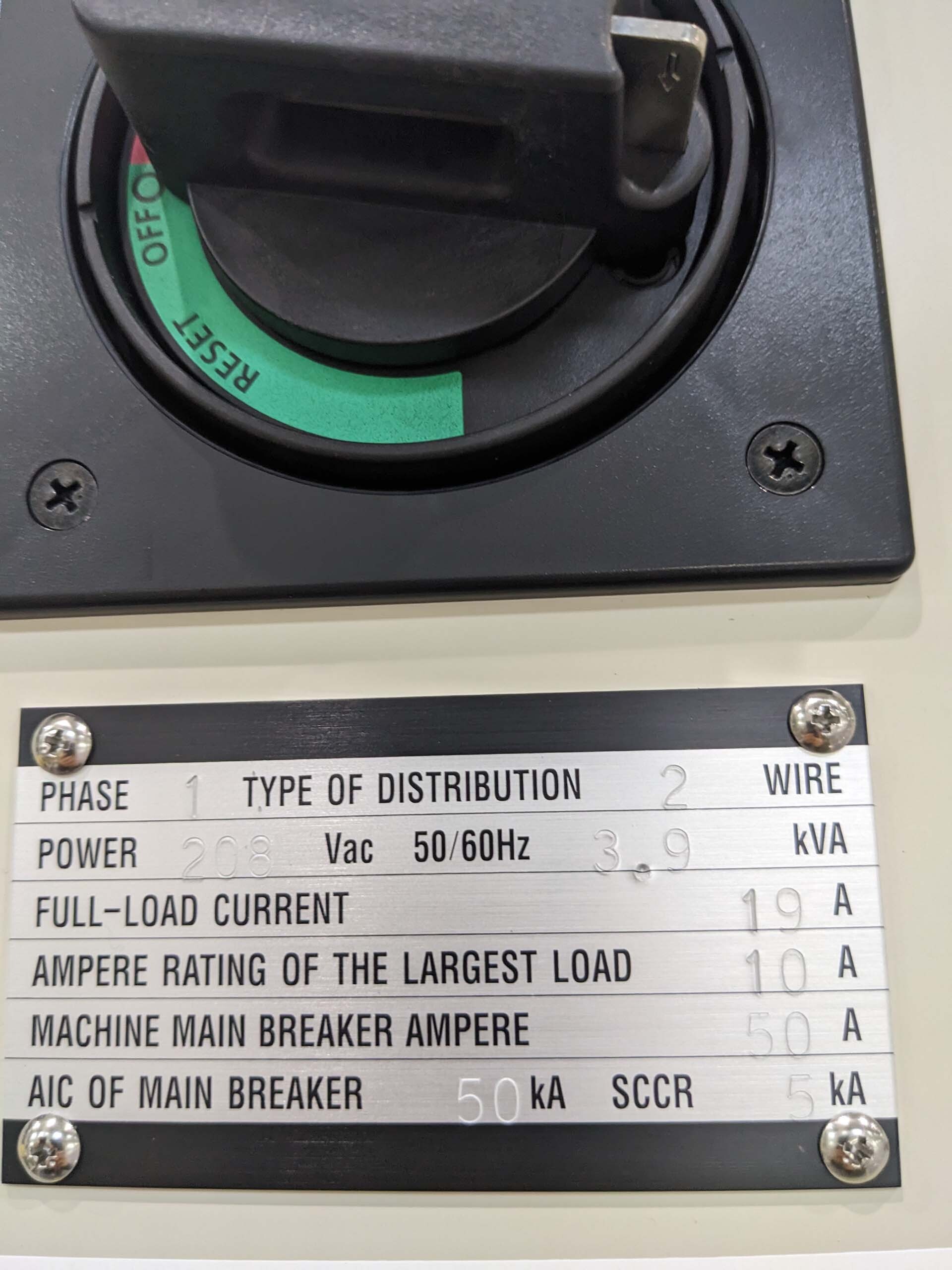

Power supply: 208 V

2004 vintage.

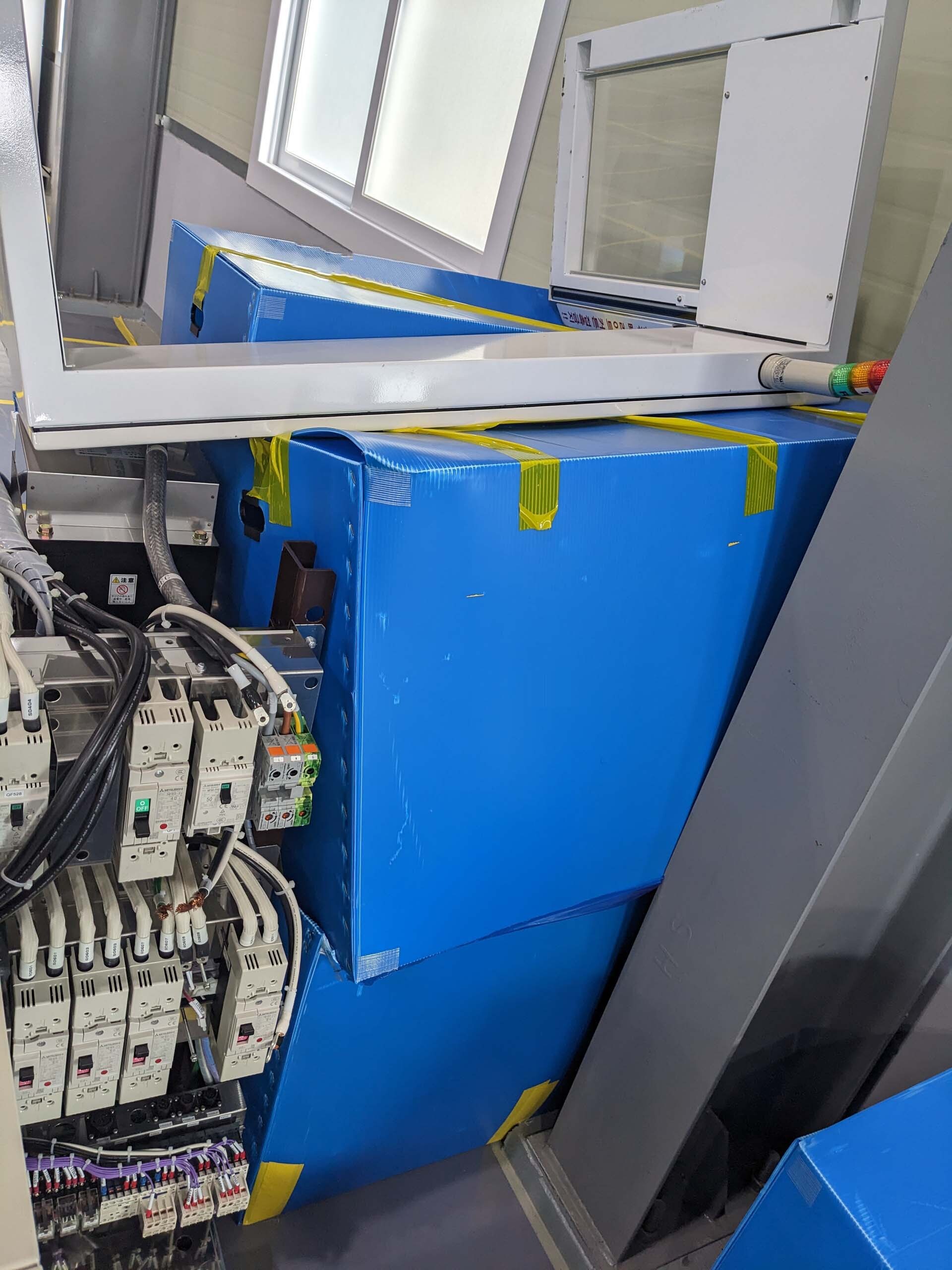

TEL / TOKYO ELECTRON A303i diffusion furnace is a fully automated thermal diffusion equipment with integrated accessories. It is designed to provide the highest quality and yields in semiconductor production processes. TEL A303i includes a powerful deposition chamber offering an efficient and reliable thermal diffusion process. It uses Rapid Thermal Processing (RTP) to rapidly heat the diffusion process gas to rise above a pre-set temperature, offering a uniform and highly repeatable thermal diffusion process. The outgassing rate is also adjustable, allowing precise doping concentrations and precise control of the diffusion process. The system includes automatic shutters for nitrogen and process gas input, as well as an in-situ degas and cool-down procedure. The entire process is continuously monitored by a computer control chamber, ensuring secure and safe operations. TOKYO ELECTRON A 303 I also features a built-in chemical vapor deposition (CVD) chamber. The CVD chamber consists of an induction unit for the introduction of silicon and germanium sources into the deposition zone. It also features multiple deposition sources to provide a uniform deposition over wide areas, as well as uniform doping profiles from the source to the destination. The induced magnetic fields provide uniformity and allow precise control over the deposition parameters for optimal performance. A303i is also equipped with a metrology platform for in-chamber non-destructive process characterization. It includes on-board features such as a pressure sensor, gas panel, temperature panel, and digital video camera, as well as an inspection plate for in-chamber analysis. This allows for accurate measurement and analysis of substrate parameters and process steps. TEL / TOKYO ELECTRON A 303 I machine also provides a variety of accessories and sample loading options. It can be configured to accept 100mm to 300mm wafers, as well as 200mm to 400mm flat panels. This configuration allows maximum flexibility for a wide range of production requirements and applications. A 303 I is an ideal solution for both high volume and prototyping production, offering an efficient and reliable tool for effective thermal diffusion. With its integrated features and accessories, TEL A 303 I is the perfect solution for semiconductor production processes.

There are no reviews yet