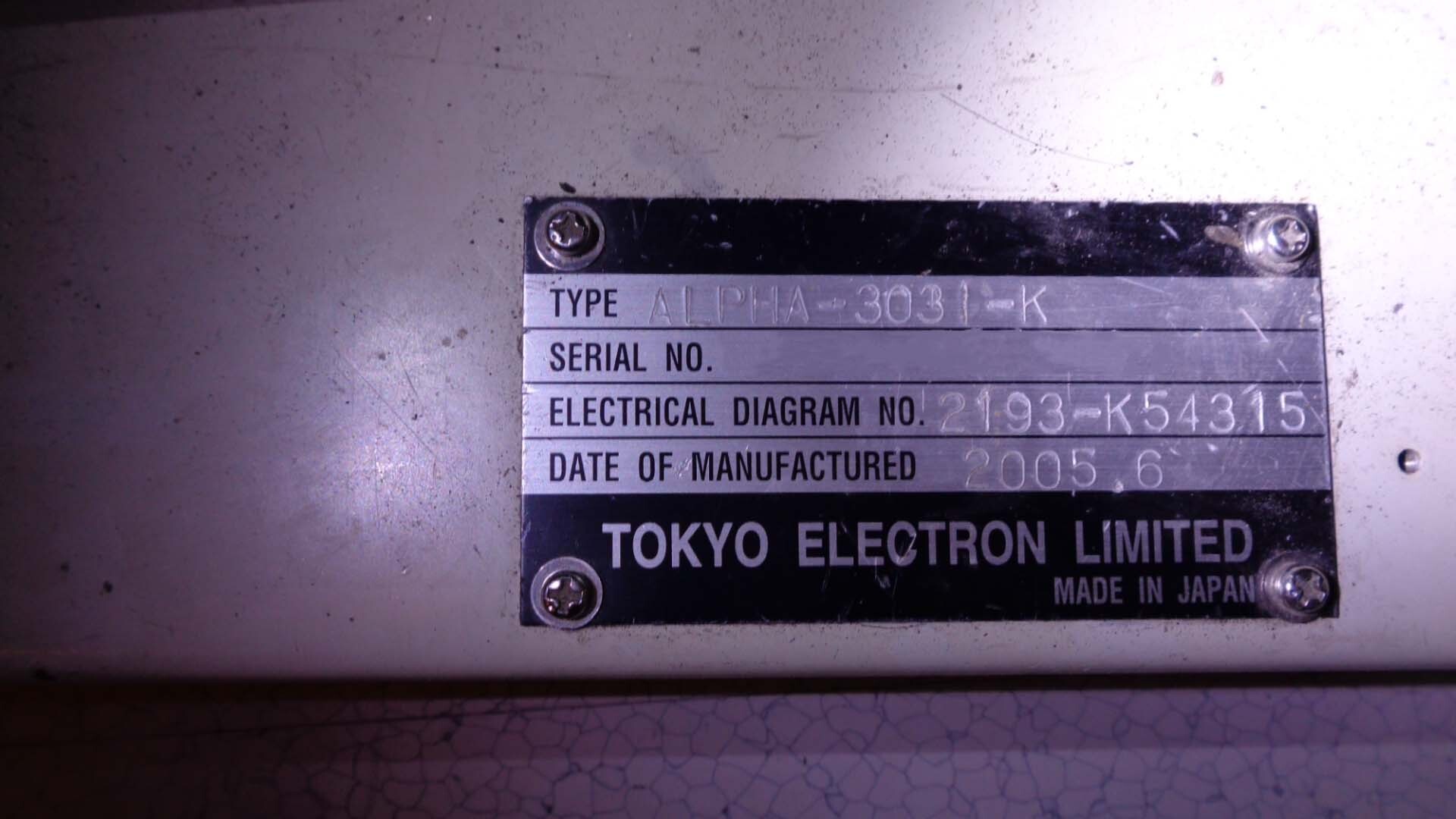

Used TEL / TOKYO ELECTRON Alpha 303i-K #293606613 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON Alpha 303i-K is a diffusion furnace and accessory developed by TEL (TOKYO ELECTRON Limited), a leading global company that produces semiconductor production equipment. This equipment was specifically designed for vacuum furnace CVD (Chemical Vapour Deposition) processes, offering high productivity and superior performance in a low-cost, compact design. TEL ALPHA 303IK diffusion furnace is equipped with a 3-zone Programmable Logic Controller (PLC) for controlling the automatic functions. The furnace has a working temperature range from 800°C to 1400°C (1472°F to 2552°F), with a substrate temperature accuracy of ±2°C at 1100°C (2012°F) and a uniformity of ±10°C within a single zone. The diffusion furnace provides vertical susceptor movement, large working volume, and uniformity making it ideal for large wafer processes. TOKYO ELECTRON ALPHA 303 I K is also equipped with additional hardware accessories to improve its functionality. These accessories include an angled susceptor tray, flow controllers, an ion gauge, a mass flow controller, a purge system, and an independent cooling unit. The angled susceptor tray ensures process uniformity while the flow controllers ensure a continuous flow of up to four gases. The ion gauge is used to accurately measure the level of gas particles within the furnace chamber. The mass flow controller is used to precisely control the gas flow rate and pressure, while the purge machine boosts the cleanliness of the chamber. The independent cooling tool helps cool the heater and halt the process once the desired temperature is reached. Besides providing enhanced diffusion capabilities, TEL / TOKYO ELECTRON ALPHA 303IK also offers superior safety features. The furnace is designed with an interlocked lid, an emergency switch, and an inert gas supply asset, which ensures the safety of operators during usage. ALPHA 303IK diffusion furnace combines convenience, safety and precision in a small and cost-efficient design. It is an ideal choice for many semiconductor applications, ranging from diffusion of compounds for IC fabrication to deposition of films and polymers for nanotechnology.

There are no reviews yet