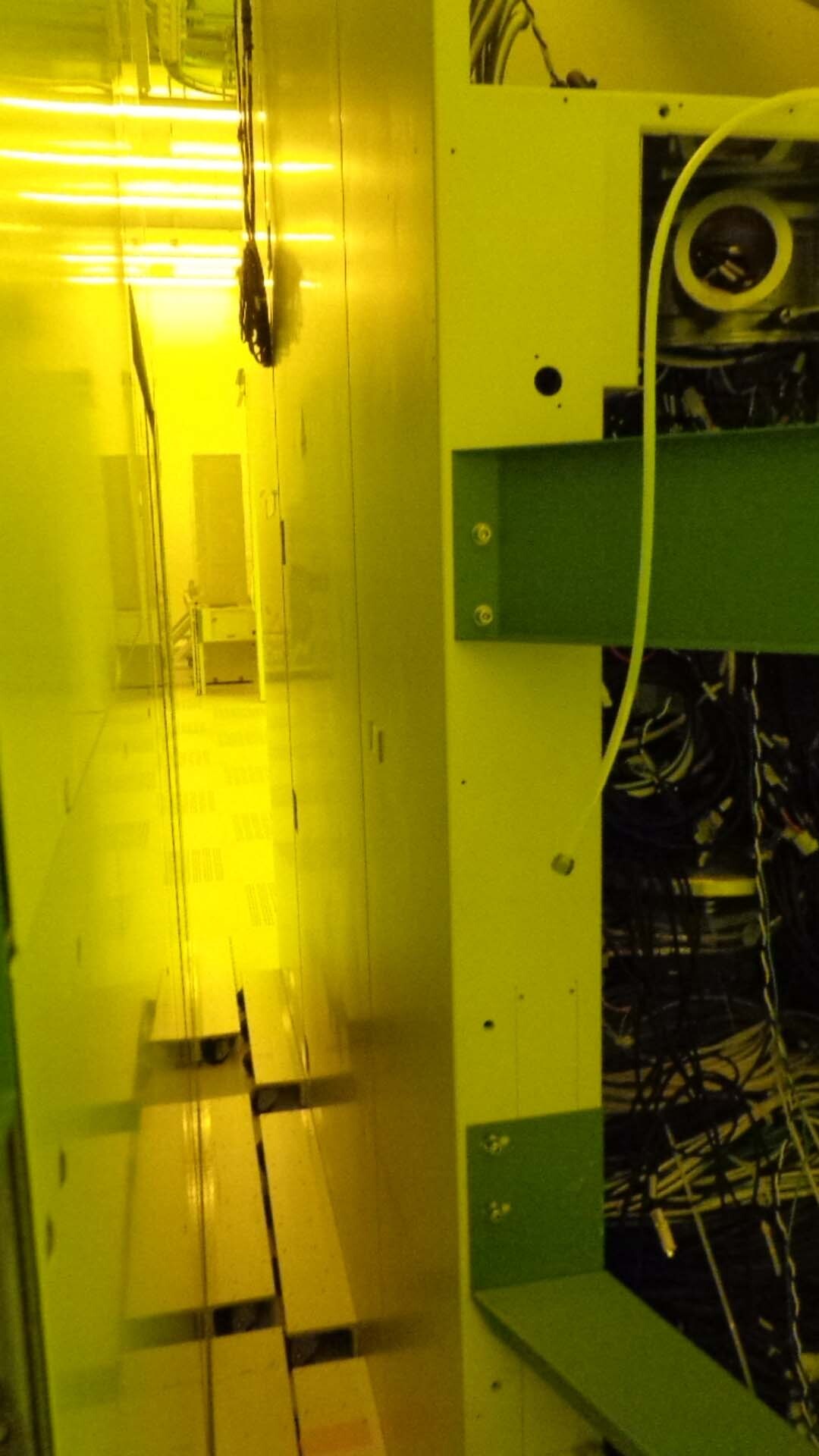

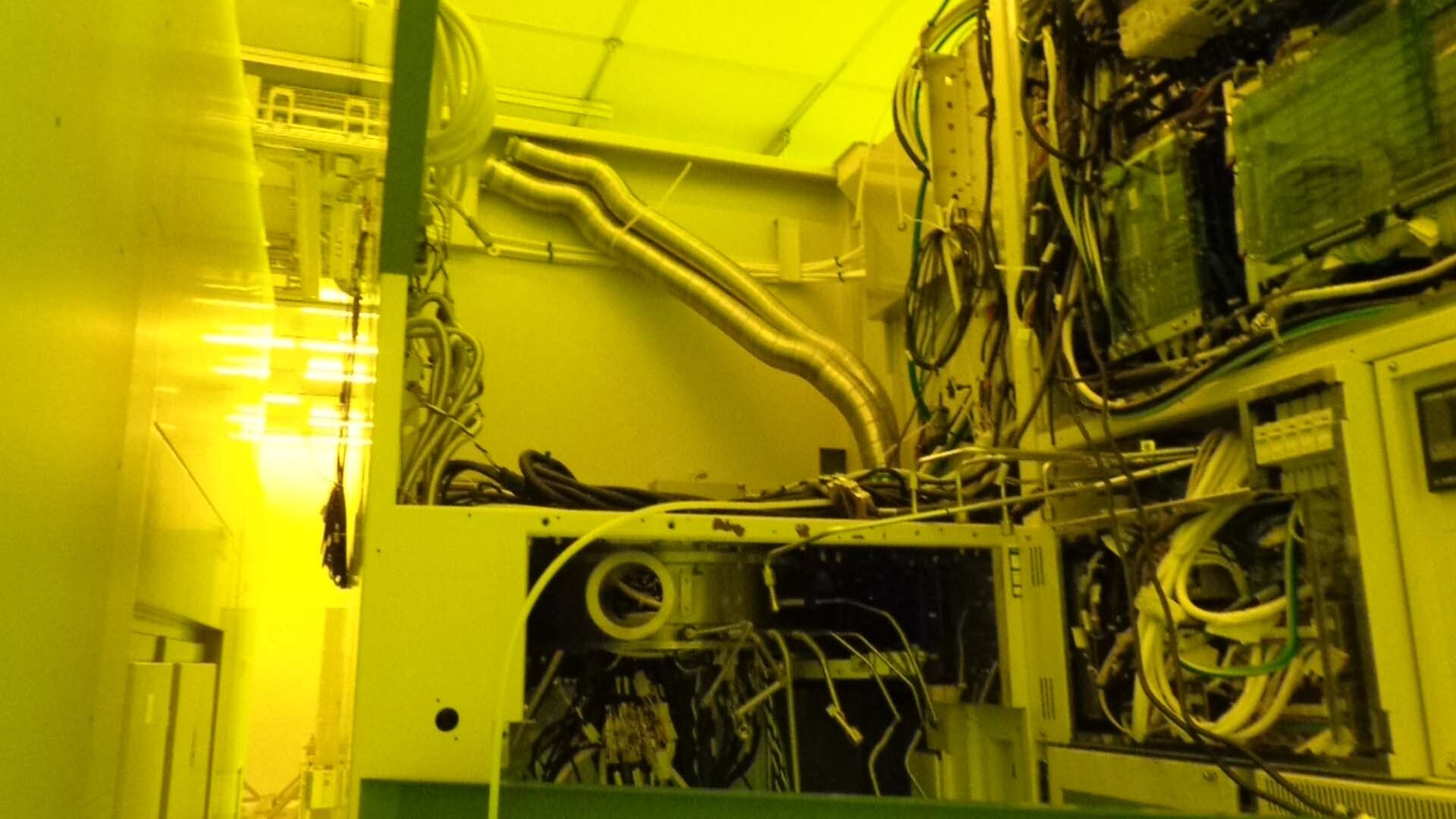

Used TEL / TOKYO ELECTRON Alpha 303i-K #293606627 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON Alpha 303i-K diffusion furnace and accessories is a comprehensive device that provides a cost-effective and reliable solution for semiconductor device production. With a wide range of options and configurations, TEL ALPHA 303IK diffusion furnace and accessories can meet specific process requirements. The full automated gas supply equipment and remote support capability makes it an efficient and reliable tool for device production. TOKYO ELECTRON ALPHA 303 I K diffusion furnace offers a wide range of operating temperature ranges with a maximum of 1250°C. It can be used with a variety of precursor gases, allowing for precise control over the diffused gas concentrations and atomization rate. It is equipped with a high-precision heating zone temperature control system which enables quick heating and cooling time response. Additionally, the furnace is designed for fast loading and unloading of the wafers. Its automated gas unit allows for precise control of the gaseous phases of a variety of precursors such as silicon and germanium. The gas machine is capable of precisely controlling the flow rates of up to 10 precursors and a residual gas monitor tool to ensure safety and accurate process results. Additionally, the automated gas asset is equipped with a combination of an internal calibration device, pressure control model, and complete equipment diagnostics for the automatic detection of errors and other malfunctions. TOKYO ELECTRON Alpha 303i-K diffusion furnace and accessories also provides additional functions such as remote support, temperature uniformity control, and automatic temperature profiling. The temperature uniformity control system provides a high level of temperature stability throughout the entire furnace area. In addition, the automated temperature profiling unit provides a uniform temperature across the wafer. These functions help maintain consistent results during the diffused gas concentration process. ALPHA 303IK diffusion furnace and accessories also includes extended process capabilities such as electron cyclotron resonance (ECR) oxidation, polysilicon electron-cyclotron resonance doping, and atomic layer deposition (ALD). The ECR oxidation machine uses a high frequency (L-Band) signal to produce oxygen radicals for oxidation and diffusion processes. The polysilicon electron-cyclotron resonance doping tool is a two-step process which consists of pattern definition followed by negative ion implantation. The ALD asset vaporizes precursors and deposits material on the wafer by a pulsed laser. Overall, TEL / TOKYO ELECTRON ALPHA 303 I K diffusion furnace and accessories is a comprehensive and safe device for cost efficient semiconductor production. It offers a wide range of temperature, gas, and process capabilities to meet specific process requirements. In addition, it is equipped with automated gas delivery, remote support, accurate temperature profiling, and extended process capabilities. This makes it an ideal choice for semiconductor device production and process support.

There are no reviews yet