Used TEL / TOKYO ELECTRON Alpha 303i-K #293608018 for sale

URL successfully copied!

Tap to zoom

ID: 293608018

Wafer Size: 12"

Vintage: 2005

LPCVD Furnace, 12"

Process: PIQ

(100) Process wafers

I/O Port / SMIF: FOUP

No load lock

25-Carrier slots

Boat type: Single

WAVES System controller

Operation screen: Touch screen

Gas flow chart: Front and rear

M560 Temperature controller

Vacuum pressure control: CKD VEC

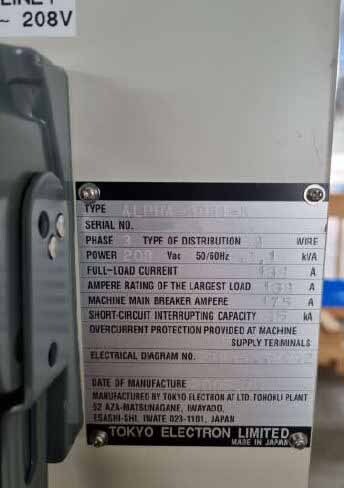

Controller transformer: 208 V, Single phase

Heater transformer: 208 V, 3 Phase

Oxygen analyzer

RCU

Process gasses:

N2

O2

Gas distribution:

Basic style: Conventional

Tubing material: SUS-316L

Tubing finish: VCR

Air operated valve: FUJIKIN

MFC: STEC

Exhaust distribution:

Air operated valve type: IGS Connect

Wafer / Cassette handling:

(16) Cassette storage

Cassette In/Out port

Cassette handling robot

Wafer transfer type: 1 + 4

(5) Forks

Fork material: AL2O3

Fork variable pitch

Fork wafer presence sensor

Elevator handling:

Boat elevator

Auto shutter

Boat rotation

Spare parts

Heating chamber:

Heater type: VMM-56-201

(5) T/C Type

(5) Spike T/C

2005 vintage.

TEL / TOKYO ELECTRON Alpha 303i-K is an advanced diffusion furnace and an essential tool for research, production, and quality-control work in semiconductor industry. It is designed to create accurate and uniform dopant profiles and prevent electrical leakage during processing. This furnace is specifically designed for the deposition of silicon-on-insulator (SOI) layers and is highly suitable for strain engineering, multi-layer deposition, and for the production of high-performance semiconductor devices. TEL ALPHA 303IK features a temperature range of 200-1200 °C with advanced heating equipment, which ensures uniform and accurate temperature distributions. It is also equipped with a closed-loop thermoelectric cooler (TEC) for precisely controlling substrate temperatures during processing. The advanced heater controller features low power consumption, enabling improved heating system performance. Additionally, the unique wafer-level dopant verification unit provides accurate process monitoring, even when wafer-level variations are present. TOKYO ELECTRON ALPHA 303 I K contains an advanced forced-flow gas dispersion machine, which provides uniform and precise gas distribution. This tool helps in maintaining the uniformity of chemical vapor deposition (CVD) and other processes by minimizing fluctuations in gas concentrations along the substrate. Along with the diffusion furnace, there are also various accessories, such as quartz heating elements, manual and automatic conveyor motors and wafer chuck. These accessories enable efficient processing and low contamination. ALPHA 303IK also features a flexible cooling asset for rapid cooling and stabilization of semiconductor materials. Its autofluid model efficiently manages temperatures and ensures wafer-level thermal uniformity throughout the cooling process. Furthermore, its award-winning intelligent vacuum venting equipment promotes efficient operation and prevents pressure build-up in the process chamber. ALPHA 303 I K is built for safe and reliable operation; it includes a number of safety features such as emergency shutoff and interlocks. In addition, the furnace is equipped with an intuitive GUI, which enables easy programming and operation. Overall, Alpha 303i-K is an advanced and highly reliable diffusion furnace designed to meet the demands of semiconductor research and production.

There are no reviews yet