Used TEL / TOKYO ELECTRON Alpha 303i-K #9373155 for sale

URL successfully copied!

Tap to zoom

ID: 9373155

Wafer Size: 12"

Vintage: 2006

Vertical LPCVD furnace, 12"

Process: TEOS

(100) Process wafers

I/O Port / SMIF: FOUP

No load lock

25-Carrier slots

Boat type: Single

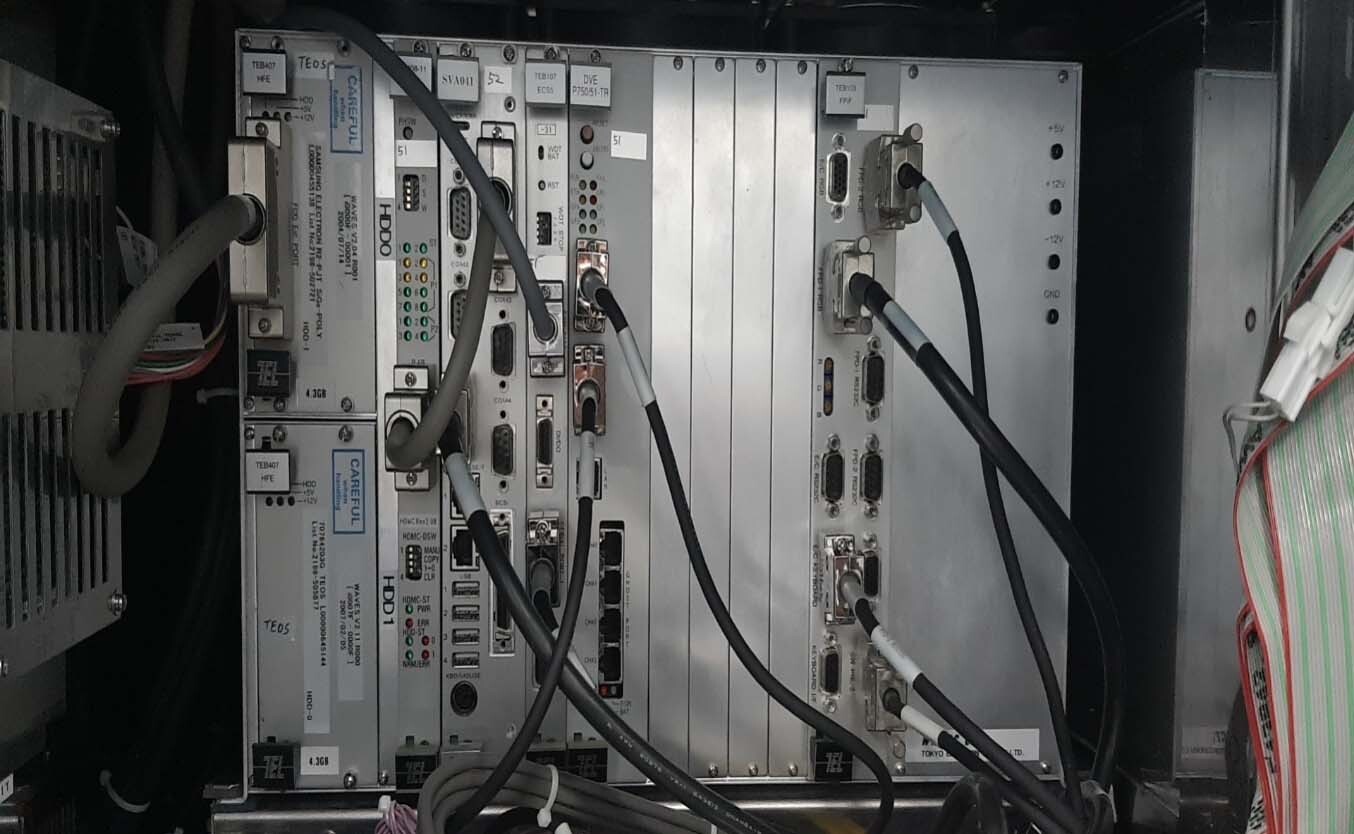

Main controller (WAVES)

Operation screen: Touch screen

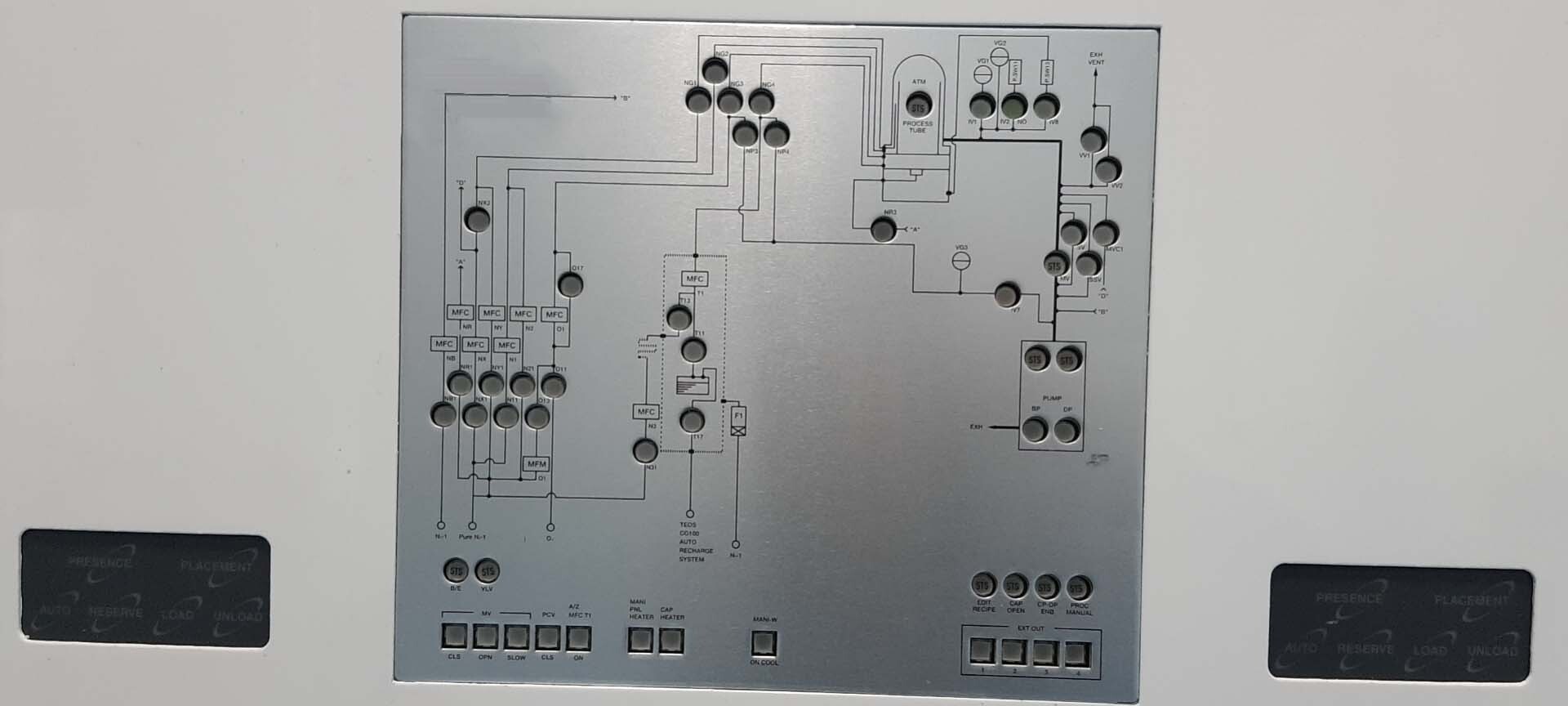

Gas flow chart: Front and rear

M560 Temperature controller

Vacuum pressure control: CKD VEC

Controller transformer: 208 V, Single phase

Heater transformer: 208 V, 3 Phase

Gases:

Gas 1: N2

Gas 2: N2

Gas 3: O2

Gas 4: TEOS

Gas 5: N2

Gas distribution:

Basic style: Conventional

Tubing material: SUS-316L

Tubing finish: VCR

Manual valve: CKD

Air operated valve: CKD

MFC: HORIBA STEC

Exhaust distribution:

Air operated valve type: IGS Connect

Main valve: CKD VEC

Cold trap

No pump line

Wafer / Cassette handling:

(16) Cassette storage

Cassette In/Out port

Cassette handling robot

Wafer transfer type: 1 + 4

Fork material: AL2O3

Fork variable pitch

Fork wafer presence sensor

Elevator handling:

Boat elevator

Auto shutter

Boat rotation

Mechanical parts

Heating chamber:

Heater type: VMM-56-002, 100 wfs

(5) T/C Type

(5) Spike T/C

Furnace cabinets includes clean air flow system

Scavenger and water cooling unit

Power supply unit (U/P Box):

Control unit

Transformers

SCR

Breaker unit

FOUP and wafer handling automation:

(2) FOUP Load ports

FOUP Transfer

Stocker: (18) FOUPs

FIMS Port

KHI Wafer load automation

Variable pitch change mechanism with (5) forks

Auto tube shutter

Boat elevator with boat rotation mechanism

Integrated gas system in gas cabinet and TEOS LSC baking system:

O2 Gas line

TEOS Gas line

Purge N2

Vacuum vent

Exhaust vent

Piping tape heater

Main valve type: CKD Hot, P/N: VEC-VH8G-X0101

Vacuum gage

Pressure switch

Piping: 100 A VAC

Does not include:

Outer/Inner T/C

N2 Load lock

N2 Boat cooling shower

Dual boat operation

B.S Sensor: 0-10 Torr, 0-1000 Torr

Cable length: 12 m (Power box)

AC Power box: 208V,3 Phase, 4 Wires

2006 vintage.

TEL / TOKYO ELECTRON Alpha 303i-K is an advanced diffusion furnace and accessories equipment enabling customers to perform high-quality, low-cost, high-throughput semiconductor fabrication processing. The system features a single-zone furnace, a gas delivery unit, an on-board wafer loader, an automated wafer transfer arm and a controller. The single-zone furnace utilizes low-velocity, low-expansion quartz tubes to meet component diffusion requirements and provide improved thermal uniformity and wafer temperature stability. With a maximum working temperature of 1,100°C (2,012°F), TEL ALPHA 303IK is well suited for dielectric and metallization layers and related processes. Additionally, the machine features an innovative protective atmosphere gas stagnation tool, which helps ensure consistent flow and response, allowing for optimal performance with a wide range of gases. The on-board wafer loader provides an efficient and automated way to feed wafers into the asset quickly and reliably. With its large capacity and multiple load options, TOKYO ELECTRON ALPHA 303 I K is well equipped to handle a variety of wafer sizes and substrates. Combined with the automated wafer transfer arm, ALPHA 303IK eliminates the need for manual wafer handling and improves throughput times. The model is easy to operate and maintain, featuring a controller with intuitively designed menus and windows for enhanced usability. The controller offers control parameters such as ramp and soak settings, furnace operation parameters and gas delivery settings. Additionally, the controller can be interfaced with an external PC to allow for the remote monitoring and evaluation of process data, ensuring process performance and reliability. TOKYO ELECTRON Alpha 303i-K is the ultimate solution for customers requiring an efficient and cost effective diffusion furnace and accessories equipment. The system features a single-zone furnace, an automated wafer transfer arm, an on-board wafer loader, a protective atmosphere gas stagnation unit, and an intuitive controller. Fully automated, user-friendly and with reliable performance, TEL ALPHA 303 I K is the ideal choice for demanding semiconductor fabrication processes.

There are no reviews yet