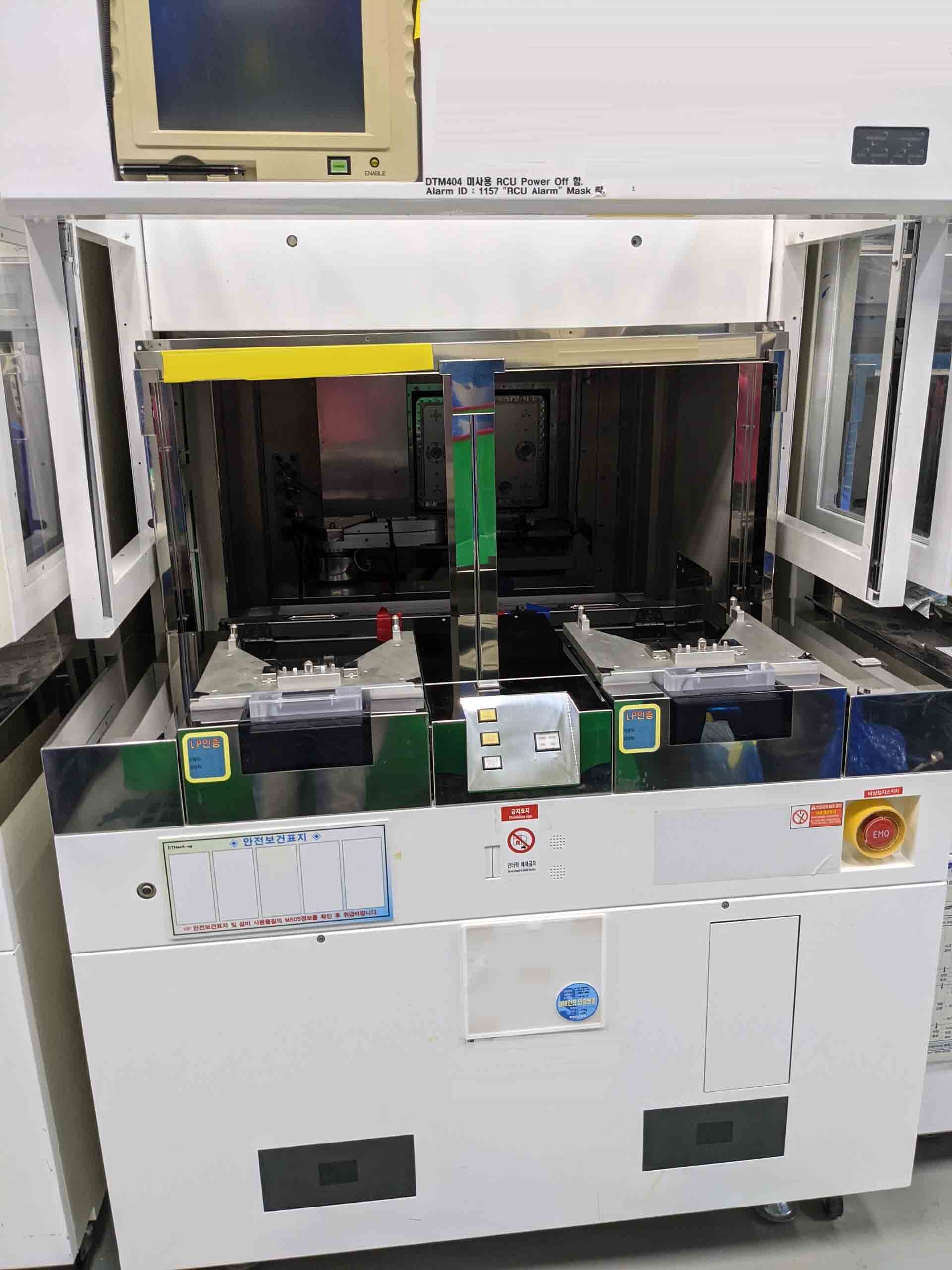

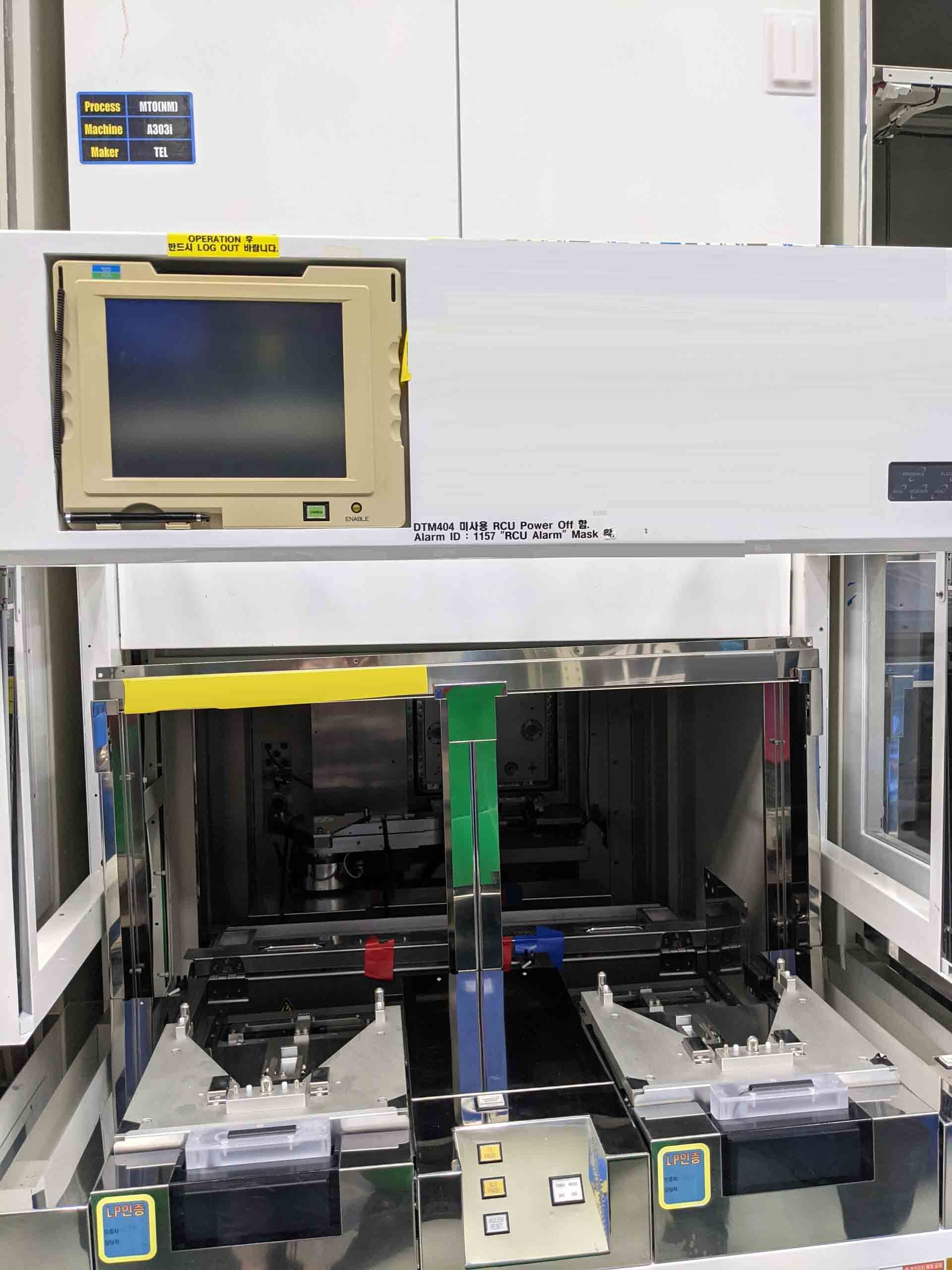

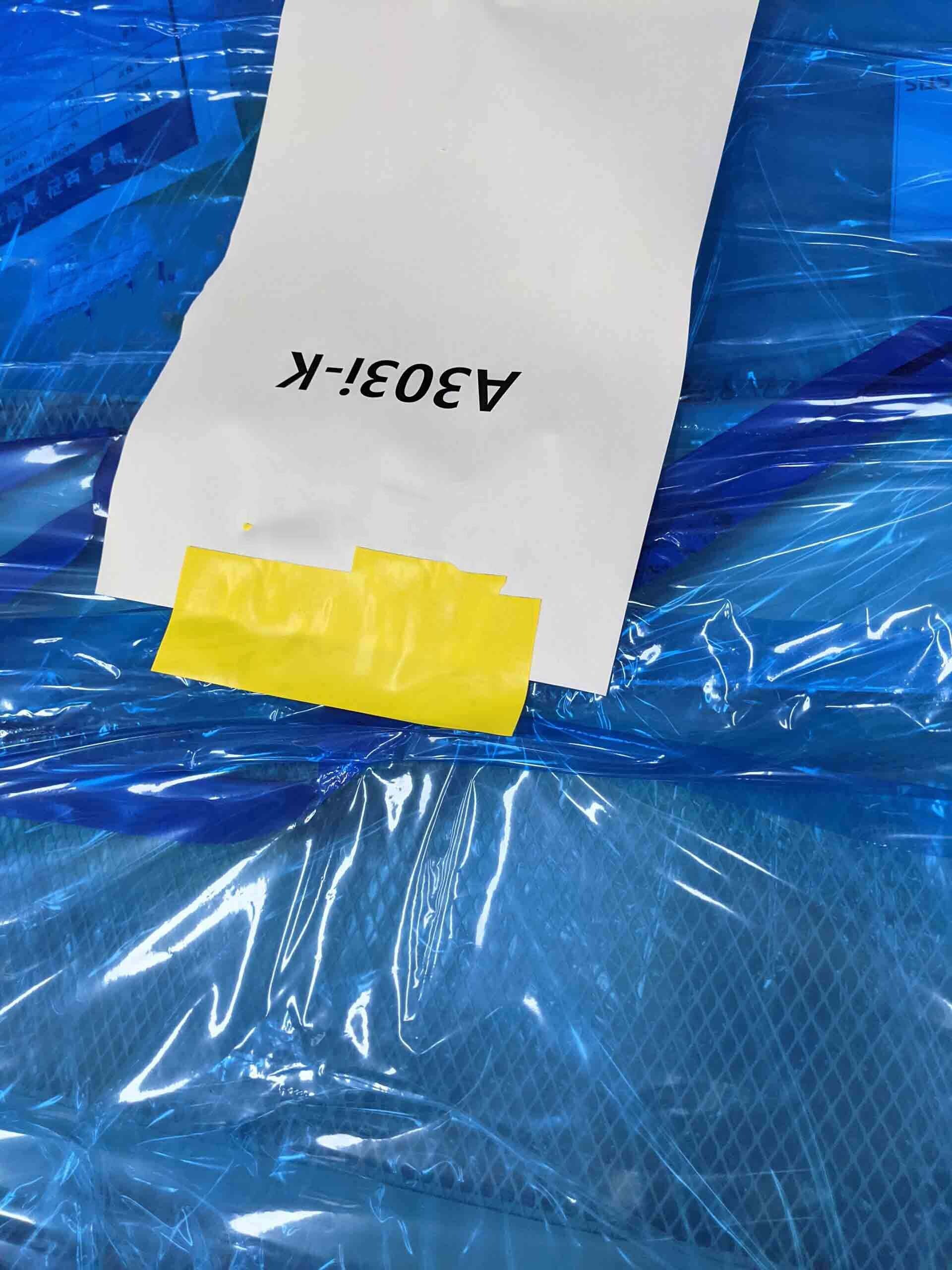

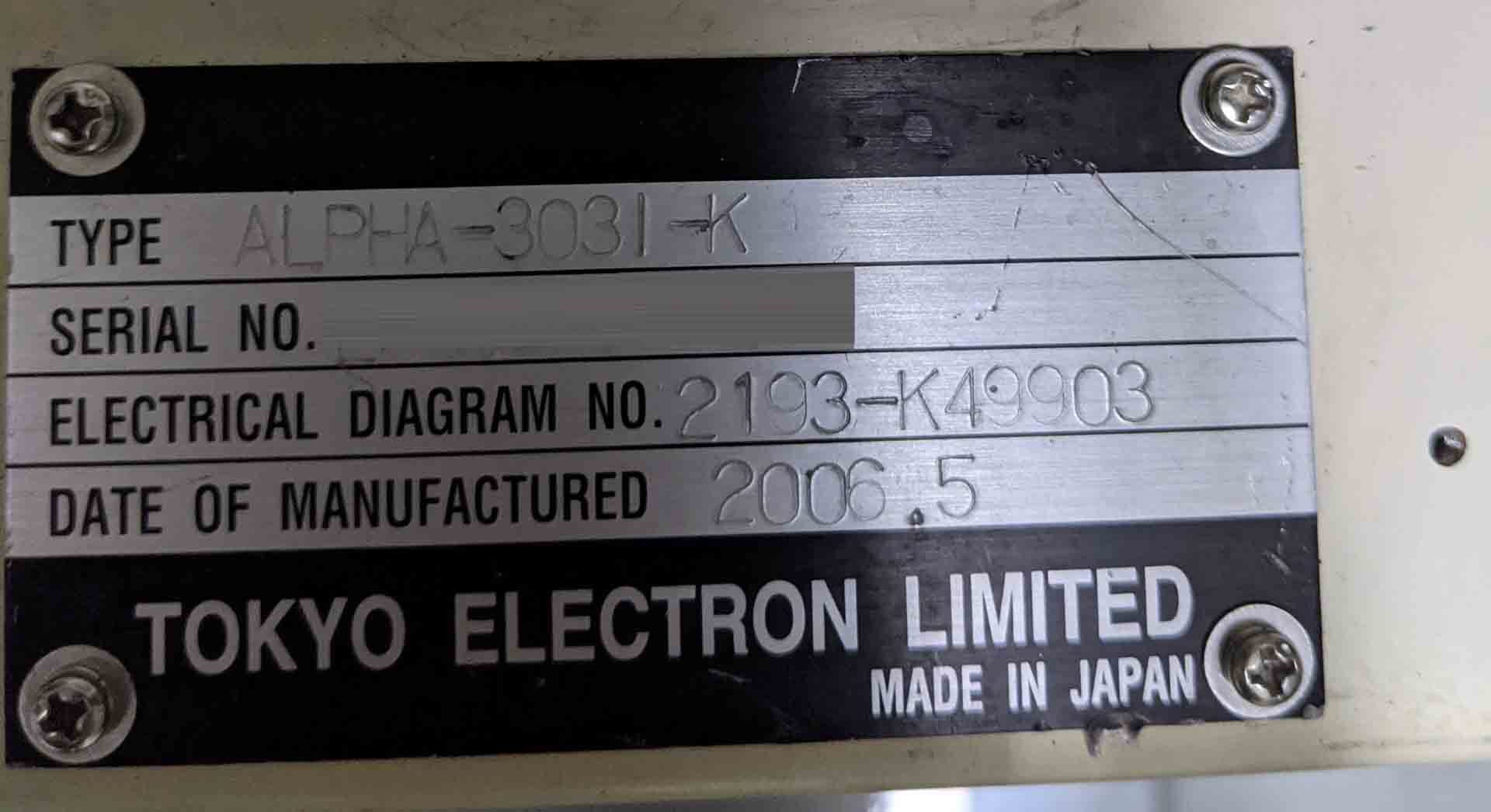

Used TEL / TOKYO ELECTRON Alpha 303i-K #9381826 for sale

URL successfully copied!

Tap to zoom

ID: 9381826

Wafer Size: 12"

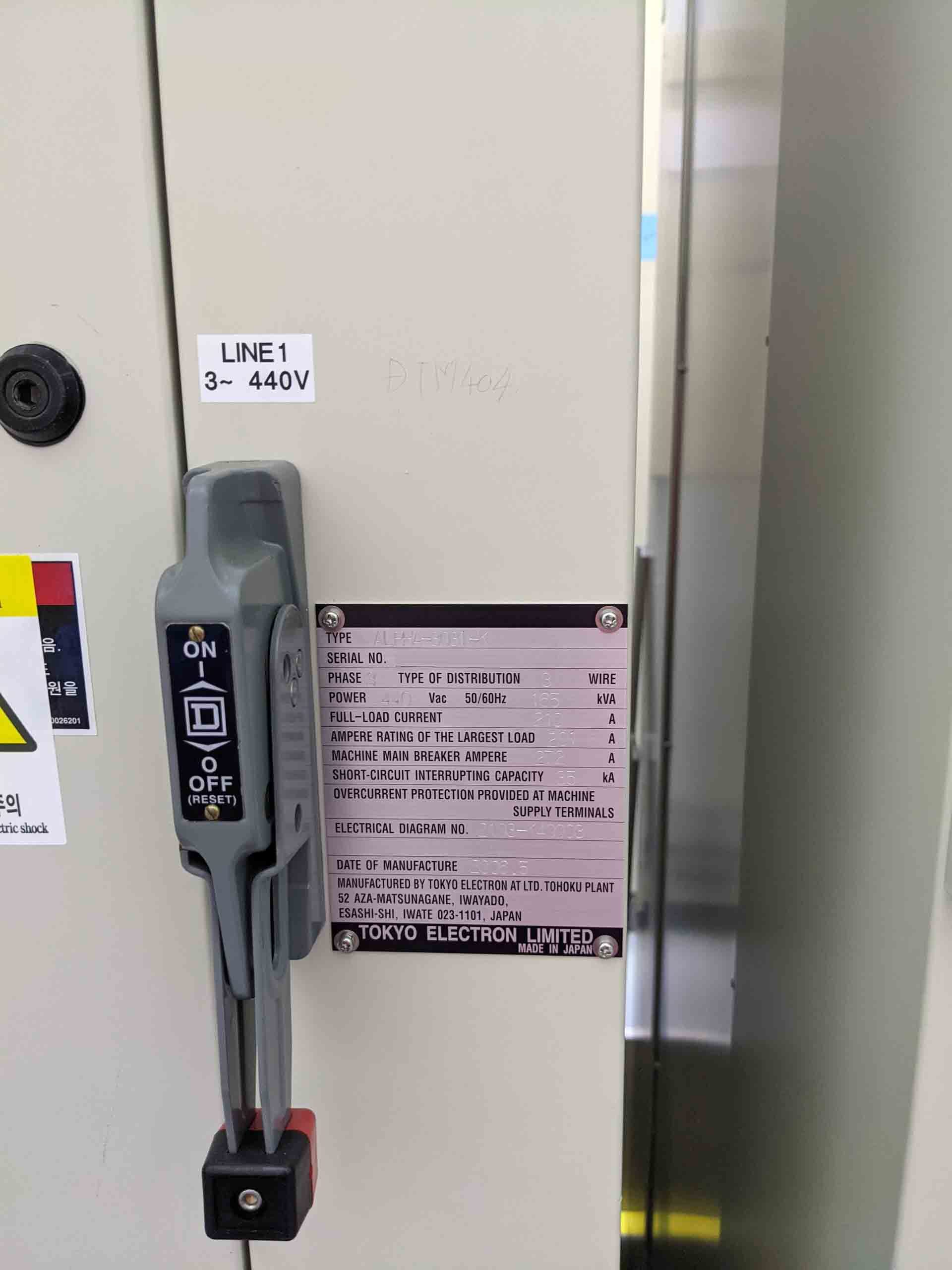

Vintage: 2006

Furnace, 12"

MTO

Heater type: VMM-56-002

Gas: SiH4 / N2O

2006 vintage.

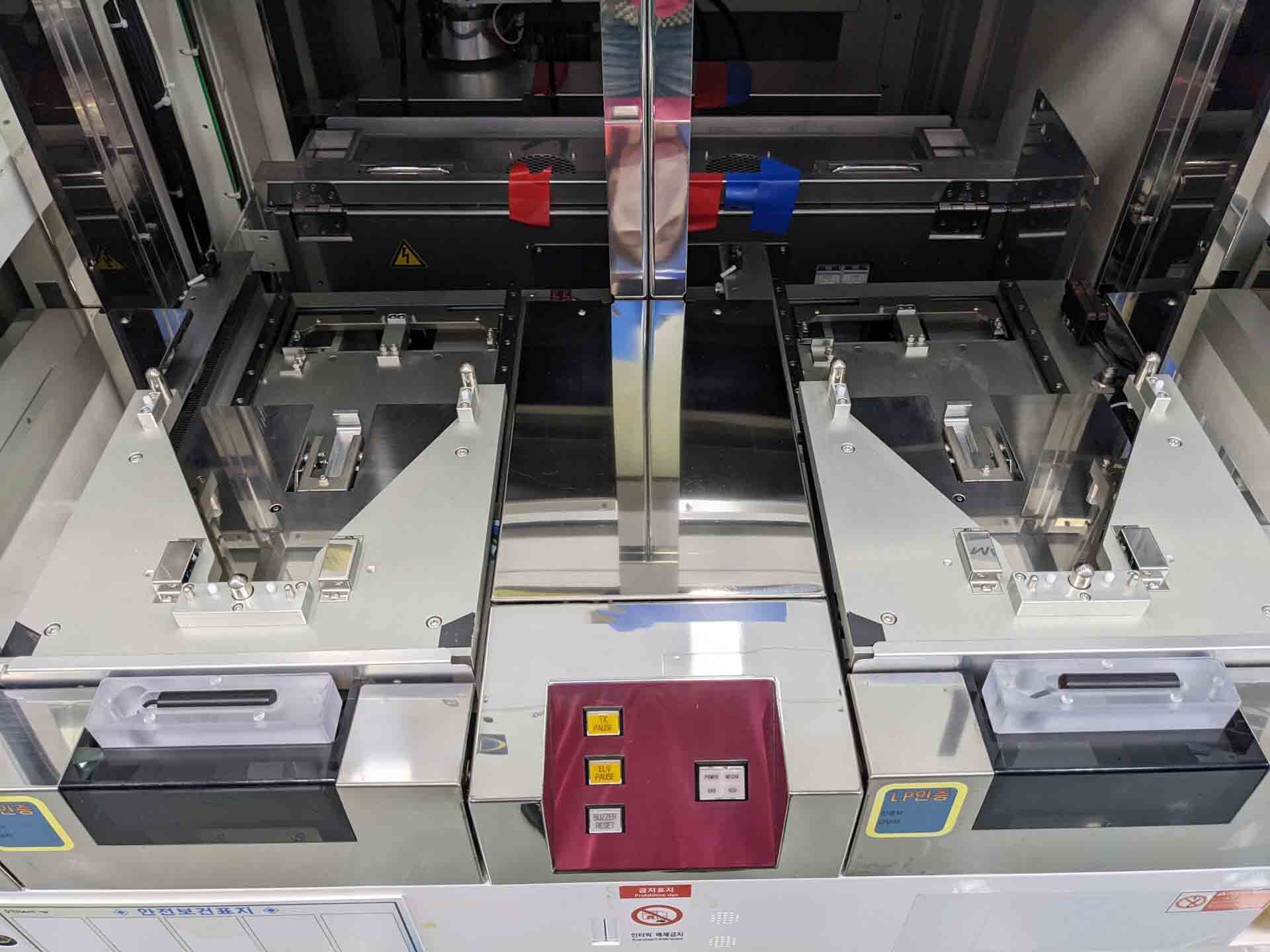

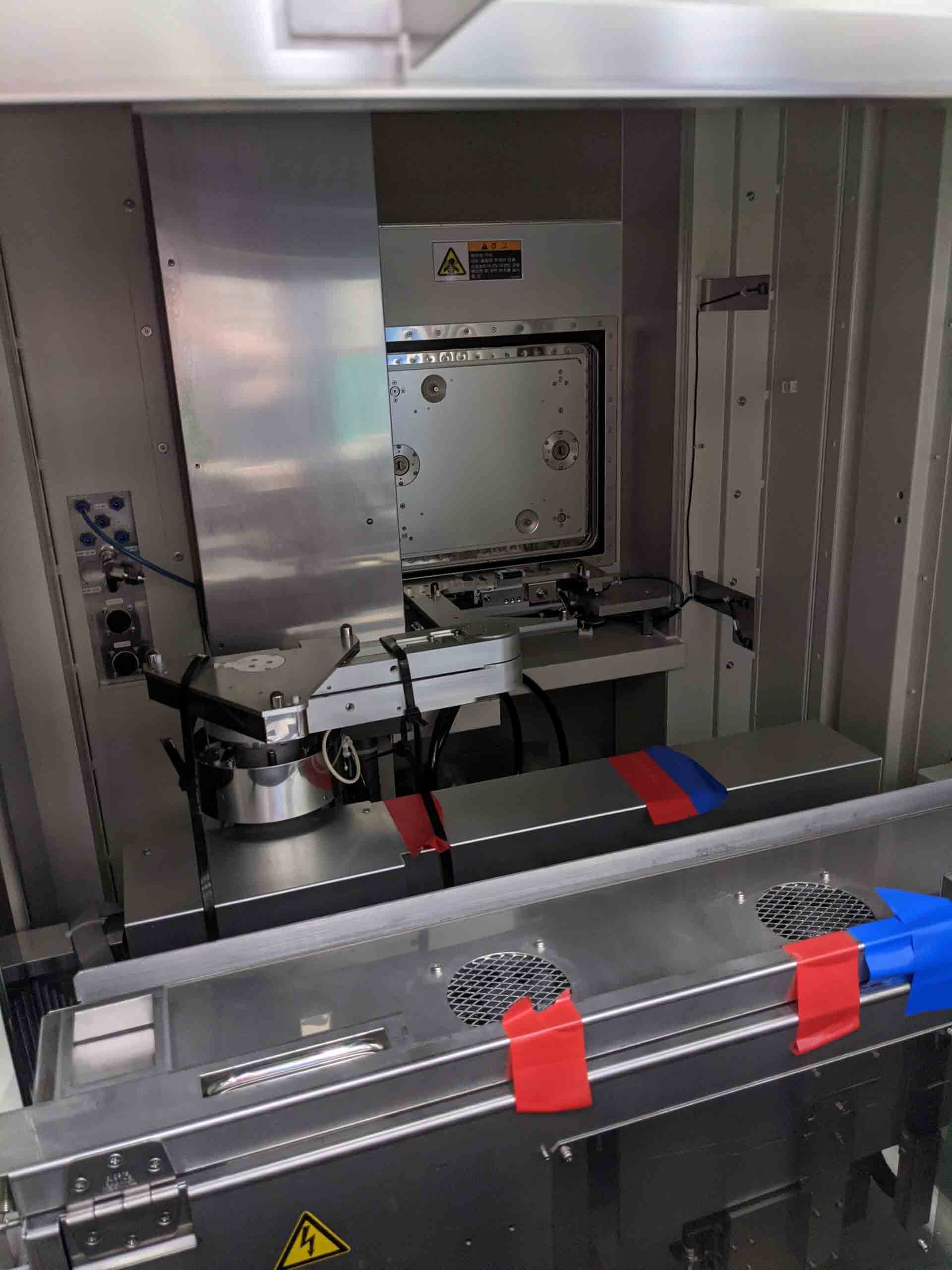

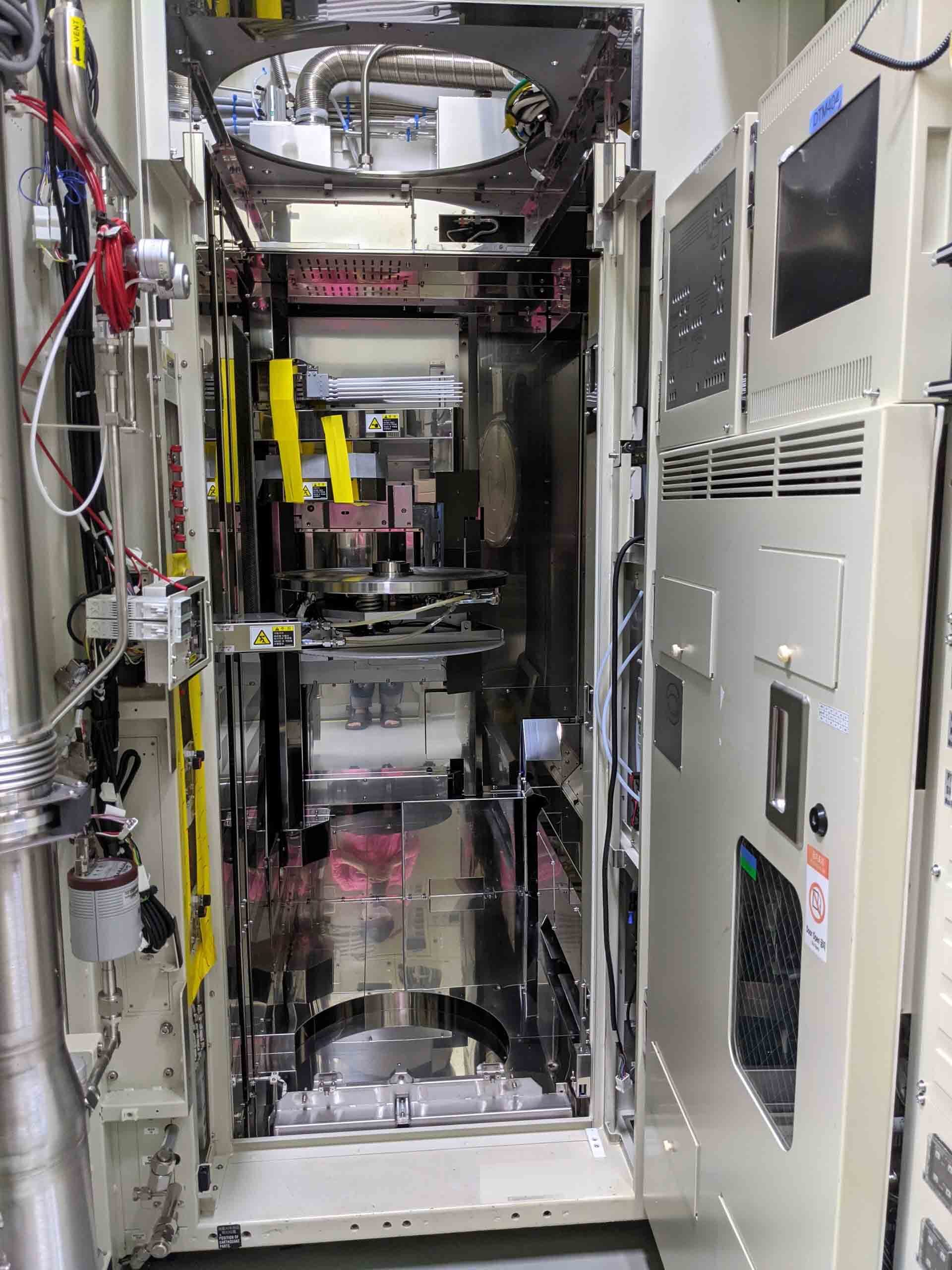

TEL / TOKYO ELECTRON Alpha 303i-K diffusion furnace is a tool used for high-quality, precise wafer fabrication. It is a multi-zone furnace with an advanced wafer transfer and coating equipment. It consists of two chambers: the heat zone and the cooling zone. The heating zone is where sublimation and etching processes are carried out; and the cooling zone is where the wafer is cooled and an oxide layer is formed. The advanced wafer transfer system allows for precise and repeatable control of the diffusion parameters for each process. TEL ALPHA 303IK has a highly efficient heating unit, with the heat zone achieved by an IR lamp. This lamp is situated inside a quartz tube, which allows for controlled temperature range set by the user. The lamp emits visible light and IR radiation that is efficiently absorbed by the silicon wafer in the process chamber. The machine also provides precise control of the thermal profile by controlling the heating rate and cooling rate for each zone separately. Moreover, the advanced Two-Zone Temperature Control (TZTC) feature allows for precise control of the temperature in the heat zone and cooling zone, providing uniform and precise diffusion rates within the chamber. TOKYO ELECTRON ALPHA 303 I K is also capable of highly precise etching and sublimation processes. Its advanced coating tool allows for precise deposition of thin films and layers, as well as nitridation and etching processes. The integrated deposition head can handle a variety of wafer sizes, ranging from 200 mm to 300 mm, as well as varying thicknesses. The integrated quartz chamber enables a clean environment during processing. The asset is also equipped with several safety features to protect both the user and the model. These include an LCD display that allows the user to monitor all the diffusion parameters from the outside, as well as an emergency stop button that can quickly shut off the equipment in case of an emergency. TEL Alpha 303i-K diffusion furnace is a highly advanced and precise tool for wafer processing. It features advanced technologies such as an efficient heating system, two-zone temperature control, and an integrated quartz chamber, among others. This allows for precise deposition and etching processes, as well as nitridation and sublimation processes. With its advanced features, TOKYO ELECTRON ALPHA 303IK is capable of providing high-quality, precise wafer fabrication, making it an excellent choice for any development and production lab.

There are no reviews yet