Used TEL / TOKYO ELECTRON Alpha 303i #293658609 for sale

URL successfully copied!

Tap to zoom

ID: 293658609

Wafer Size: 12"

Vintage: 2001

Diffusion furnace, 12"

Type: Automation

Heater

Process chamber

Temperature

Controller

Scavenger cooling water unit

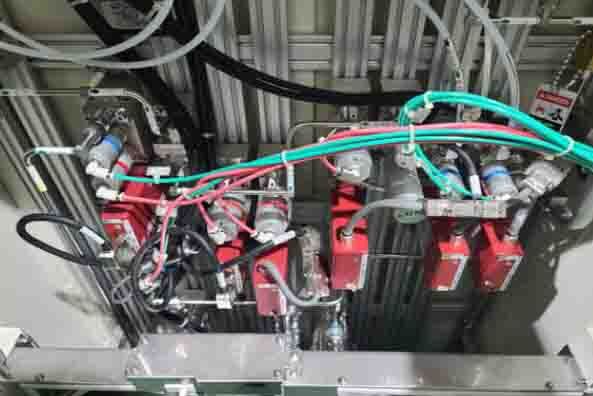

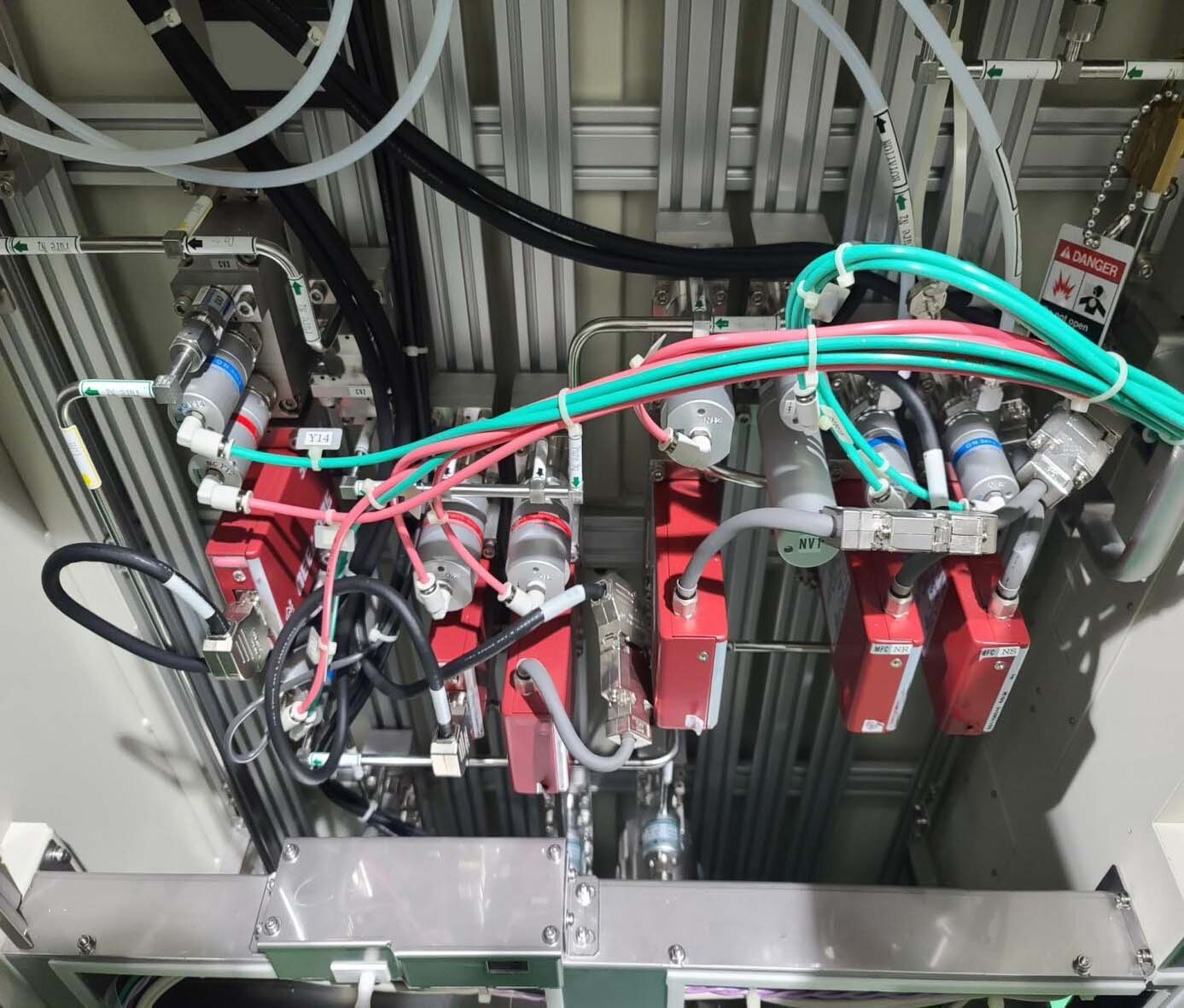

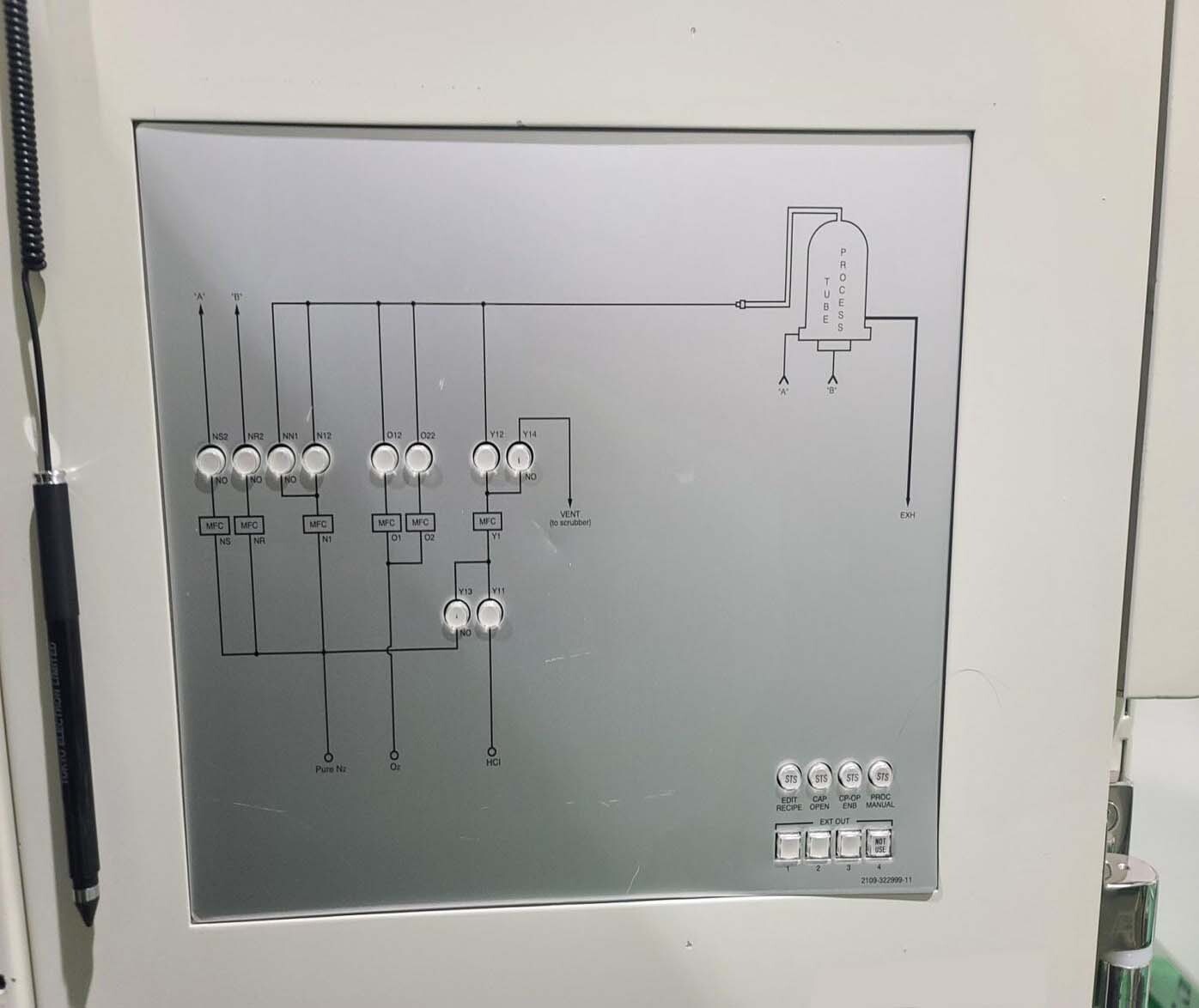

Gas supply unit

Exhaust vacuum line

Power box

Pump box

Rapid cooling unit

Missing parts:

Quartz wares

Process tube

APC: CKD

Gas: PN2, O2, HC

KAWASAKI MECHA

FUIIKIN EC Air valve

Power supply:

AC 440V, 3 Phase

AC 100V, Single Phase

2001 vintage.

TEL / TOKYO ELECTRON Alpha 303i is an advanced diffusion furnace and accessory equipment designed for high-precision heat treatment of silicon wafers. This system utilizes an ultra-fast three-zone furnace with a single-stage, low wattage, RF-based resistance-heating technology. TEL ALPHA-303I unit is modular which allows for simple and efficient expansion to suit the needs of customers. In addition, the furnace is designed with a heated-shield planar magnetron sputtering source, multiple height adjustable loading and unloading racks, and a gas inlet manifold. The temperature uniformity of TOKYO ELECTRON ALPHA-303 I is second-to-none due to the unique three-zone furnace setup which utilizes advanced P.I.D. Control. This ensures that the desired process temperature is maintained accurately and quickly throughout the entire chamber interior. A patented, novel catalyst material also ensures repeatability and improved process stability. The furnace is also designed for high-accuracy uniformity and repeatability, such as a temperature uniformity of up to ±2 °C across the entire chamber. ALPHA 303 I is also designed for ease of maintenance and operation. The furnace setup is designed for quick and easy access to all elements in the chamber and machine via stainless steel access covers located at the back and bottom of the furnace. In addition, the tool is equipped with a high-performance suction asset which provides effective removal of exhaust gas generated during the processing cycle. This ensures that no hazardous fumes are produced during the process. Other features of TEL / TOKYO ELECTRON ALPHA-303 I include a powerful micro-processor control model to monitor and adjust the furnace's parameters such as heating times and temperatures. This ensures an accurate and reliable process in every cycle, and the ability to store the parameters for future use. The equipment is also equipped with an automatic wafer loading system which helps to reduce downtime and improve the unit's productivity. Alpha 303i is a reliable and advanced diffusion furnace machine which provides high-precision heat treatment solutions for silicon wafers. The furnace's modular design allows for easy expansion and the powerful micro-processor control tool ensures accurate and repeatable operation every time. In addition, the low wattage RF-based heating technology ensures accurate heating and the gas inlet manifold ensures effective removal of exhaust gases. This diffusion furnace asset is ideal for those looking for a reliable and precise heat treatment solution for semiconductor devices.

There are no reviews yet