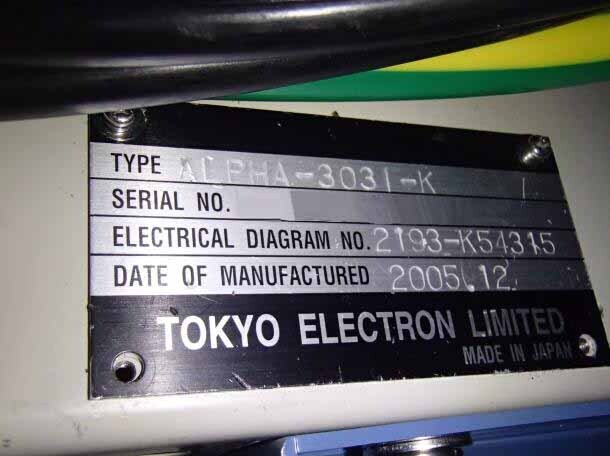

Used TEL / TOKYO ELECTRON Alpha 303i #9304085 for sale

URL successfully copied!

Tap to zoom

ID: 9304085

Wafer Size: 12"

Vintage: 2005

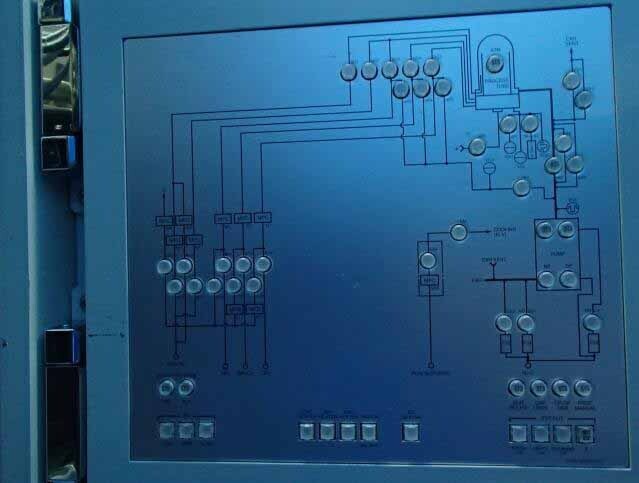

LPCVD System, 12"

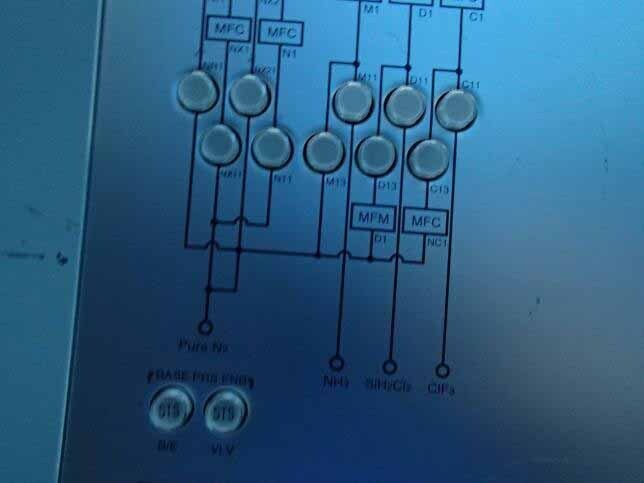

Gases: P-N2, NH3, SiH2CI2, CIF3

2005 vintage.

TEL / TOKYO ELECTRON Alpha 303i is a diffusion furnace and accessories that can be used to etch and process semiconductor wafers. It is ideal for the fabrication of advanced integrated circuits, thin films, and other semiconductor devices. It can be used to perform deposition, oxidation, annealing, ion implantation, and anneal-etch processes. TEL ALPHA-303I is a single-wafer tube-type furnace equipment that is equipped with dual process chambers. It has a main chamber and an auxiliaries chamber. The main chamber is used to perform oxidation, deposition, and other semiconductor device formation processes at a variety of temperatures and reacts gas mixtures with wafers. The auxiliary chamber is used to perform ion implantation, annealing, and etch processes. TOKYO ELECTRON ALPHA-303 I has a patented single stage wafer loading system that allows wafers to be quickly and easily placed into the furnace. It is also equipped with a programmable motor control that allows for precise control of the deposition rate and uniformity. TOKYO ELECTRON ALPHA 303 I is engineered with radial uniformity of process control, resulting in superior over-use performance. TEL / TOKYO ELECTRON ALPHA 303 I is designed with safety features such as a pressure control unit, which prevents the build-up of hazardous gases, and thermostatic valves, which regulate oxygen levels to ensure maximum safety. Additionally, the furnace is equipped with Embedded Intelligence and advanced diagnostics systems, such as TEL patent-pending Wymar Vision Machine, which detect a variety of process problems and alert operators. TOKYO ELECTRON Alpha 303i is capable of achieving temperature ranges of between 250°C and 1200°C and has an integrated process chamber capable of capable of processing up to seven wafers at a time. It is also compatible with many of the ancillary equipment used in semiconductor production processes, making it a truly versatile solution for both research and mass fabrication. Overall, TEL ALPHA 303 I is an advanced diffusion furnace and set of accessories that is trusted and used by many of the leading semiconductor manufacturers. It provides a cost-effective, reliable and uniform solution for the production of advanced integrated circuits, thin films, and other semiconductor devices.

There are no reviews yet