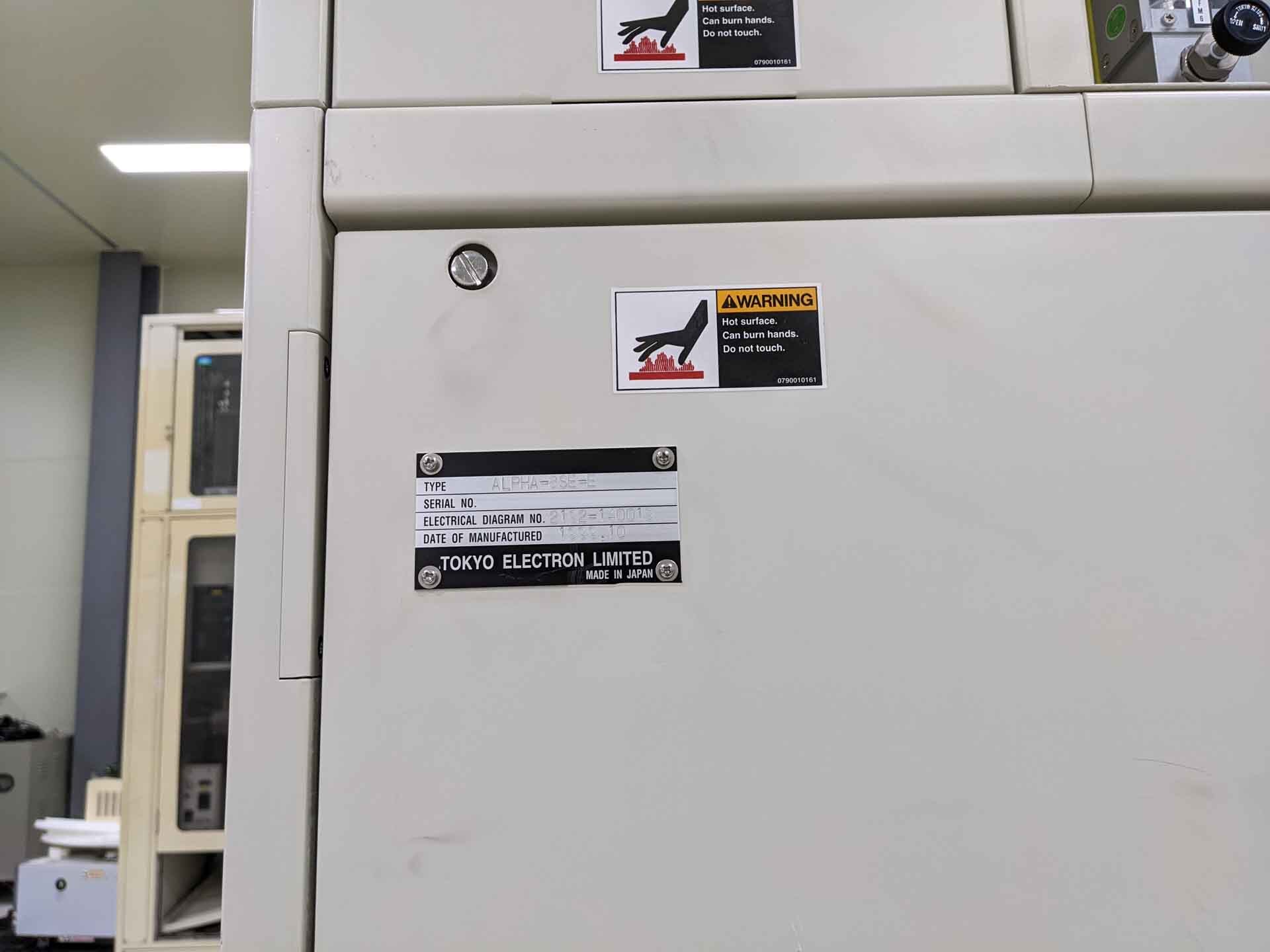

Used TEL / TOKYO ELECTRON Alpha 8SE-E #293652593 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON Alpha 8SE-E is a revolutionary diffusion furnace with a wide array of accompanying accessories. This diffusion furnace is capable of rapid, rapid thermal heating and processing which is vital for an efficient and effective depositing process. TEL Alpha 8SE-E is a versatile wafer heater and deposition platform with a rotary motion, allowing for tight and uniform processing temperatures. With an energy efficient motor and accurate temperature control, TOKYO ELECTRON Alpha 8SE-E can deliver higher precision results with faster throughputs. Alpha 8SE-E reaches temperatures up to 500°C in only a few seconds, and can maintain temperatures with a high degree of accuracy throughout the entire process. By using an energy efficient motor, TEL / TOKYO ELECTRON Alpha 8SE-E is able to warm-up and cool-down quickly, allowing for greater productivity and throughputs. TEL Alpha 8SE-E is designed to allow for a wide variety of deposition options while still providing precision and accuracy. This is achieved by using a combination of rotary and linear motion to create uniformity within the processing temperature. TOKYO ELECTRON Alpha 8SE-E is a well-integrated equipment, with a fully automated wafer-cleaning station, for greater finished wafer product quality. Additionally, this system includes a highly efficient post-processing solution, the B&H6000 cleaning unit. This machine is compatible with all wafer sizes, and is capable of reconditioning and polishing wafers with a high degree of precision and efficiency. Furthermore, the B&H6000 is designed to completely recondition the backside of a wafer, removing any potential stresses incurred during earlier stages of the deposition process. In order to monitor the process at all stages, Alpha 8SE-E is equipped with various sensors and temperature control features. During the deposition process, temperature sensors are located throughout the tool to detect both the general temperature and changes in the wafer temperature. By monitoring these changes, the asset is able to ensure a homogenous temperature for the entire wafer during deposition. Additionally, monitors are installed around the furnace to create an efficient temperature profile. This ensures that the temperature within the heater chamber is uniform, ensuring a greater uniformity on the finished wafer surface. Overall, TEL / TOKYO ELECTRON Alpha 8SE-E diffusion furnace is an invaluable asset in the semiconductor industry, providing precision and uniformity in an energy efficient platform. Through the use of rotary and linear motion, and a number of accompanying accessories, this model has revolutionized the way wafers are handled and processed.

There are no reviews yet