Used TEL / TOKYO ELECTRON Alpha 8SE #168532 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 168532

LPCVD furnace, 8"

Wafer size: 8"

Flat / notch type: Flat

Signal tower: 3 color (RYG)

SMIF or I/O type: I/O type

AGV compatibility: Not use

Rapid cooling unit: Not use

Load lock system: Use

Production wafer quantity: 150

Controller and software:

HD version: V3.11

HDD capacity: Waves V3.11 R0000

TEB 408-11 HDMC

SVA 011

TEB 107 ECS5

M/C TEB 205

TEB 103 FPIF

Power: (phase, voltage, frequency)

Heater power: 3 phase, 208V, 35.6 Kva

Controller power: 1 phase, 208V, 5.5 Kva

MFC flow:

MFC1: AREA TC FC D986Y-BF, N2 20 SLM

MFC1: AREA TC FC D986Y-BF, N2 10 SLM

MFC1: AREA TC FC D986Y-BF, N2 10 SLM

MFC1: AREA TC FC D985Y-BF, SiH4 100 SCCM

MFC1: AREA TC FC D986Y-BF, N2O 5 SLM

MFM1: AREA TC FM 865Y, SiH4 100 SCCM

Heater model: VMM 40-101

Vacuum controls:

APC (CKD) control: VEC-S8-X0201

Controller specifications:

Main controller: WAVES

Temperature controller: Alpha 8SE-C

Pressure controller: None

Mecha controller: None

Burn controller: None

MFC controller: None.

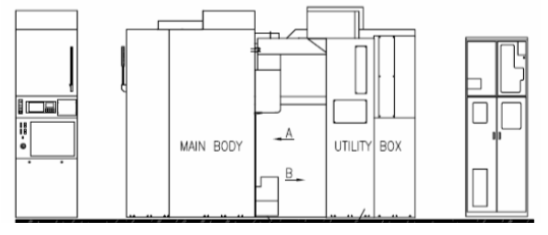

TEL / TOKYO ELECTRON Alpha 8SE is a multi-purpose high-frequency diffusion furnace used for semiconductor processing and other fabrication techniques. It features an internal quartz tube, with precise temperature control and uniform heating, that allows for precise control of the processing parameters. The quartz tube is surrounded by a nitrogen-filled gas shield, providing an inert atmosphere and superior thermal insulation. The furnace is equipped with a precise frequency-control equipment, specifically designed to provide precise temperature control. This system eliminates the need for frequent manual adjustments, allowing for repeatable heating times and steady-state conditions. The unit also features a power ratio control machine that delivers high speed and accurate temperature control for uniform heat distribution. TEL ALPHA-8SE is equipped with a sample loading tool and an integrated loading/unloading station. It allows up to eight wafers or substrates to be loaded in close proximity at any one time. Additionally, the design of the sample loading asset ensures the fabrication optomechanical alignment is maintained during loading, unloading, and handling. TOKYO ELECTRON ALPHA-8 SE also offers a high-level of control over the diffusion cycle. It provides precise control of temperature ramps, time-density profiles, and cycle end-point detection. For high-load applications, it is equipped with a rapid recovery model that provides on/off modulation of the heaters to limit cycle-to-cycle variations. ALPHA 8S-E's automation feature provides an easy-to-use graphical user interface, with a suite of process monitoring tools. The equipment also monitors up to 1200 process parameters, enabling advanced process control and complete traceability of the fabrication process. TEL / TOKYO ELECTRON ALPHA 8 SE also offers several advanced accessories, such as a motorized shutter for nitrogen purging and a dry gas filter for inert gas scrubbing/separation. ALPHA 8 SE diffusion system also offers an advanced effluent abatement unit that complies with SEMI S8 and ISO14644-1 standards. This ensures the emitted air is maintained at safe and environmentally compliant levels. The furnace is also designed to be robust, reliable, and efficient, with a range of options to meet customer requirements.

There are no reviews yet